Aluminum extrusions are widely used in various fields, mainly with 6000 series alloys. However, in aerospace and military sectors requiring higher strength, 2000 and 7000 series alloys like 2024 and 7075 are more common. They are extensively used in aircraft, naval vessels, missiles, armor, and mechanical components, significantly enhancing weight reduction and battlefield adaptability.

Chalco hot selling AMS MIL-Grade aluminum extrusion profile allloy product grade

Selecting a reliable supplier is crucial for critical components in aircraft and military applications. Trust our experienced team of technical experts to provide high-quality aluminum products that meet aerospace and military specifications, enhancing the performance and reliability of your equipment.

Chalco's aluminum extrusion profile products meet the specifications: GJB8754-2015 MIL-DTL-46147 MIL-DTL-5541 MIL-A-8625 QQ-A-200/3 ASTM B209 AMS. , and we are welcoming your inquiries at any time. Quick Quote

-

2024 aluminum extrusion profile

High strength and good fatigue performance, commonly used in high-stress aerospace and military applications.

Temper: T3 T351 T3511 T8 T851

-

2219 aluminum extrusion profile

Feature high strength and excellent corrosion resistance, suitable for demanding and military applications.

Temper: T8 T851

-

7075 aluminum extrusion profile

Renowned for the excellent high strength and outstanding corrosion resistance...

Temper: T6 T6511 T73 T73511

-

7005/7050 aluminum extrusion profile

Feature high strength and excellent corrosion resistance, suitable for demanding and military applications.

Temper: T5 T6

-

6061/6063/6082 aluminum extrusion

Feature high strength and excellent corrosion resistance, suitable for demanding and military applications.

Temper: T5 T6

-

7A04/7A09 aluminum extrusion profile

Feature high strength and excellent corrosion resistance, suitable for demanding and military applications.

Temper: T6

Chalco MIL-Grade aluminum extrusion profile hot selling products

-

Aluminum extruded tube

Offers high strength and lightweight properties, commonly used in military vehicles and aircraft structural components.

-

Aluminum extruded bar

Provides excellent strength and corrosion resistance, often used in weapon systems for frames and support parts.

-

Solid Standard Aluminum Angle Profiles: T, L, Z...

Ensures structural stability, widely applied in military equipment for support and connection structures.

-

Solid Standard Aluminum Slot Profiles: C, U, H...

Used for load-bearing and support, suitable for frameworks and support structures in military equipment.

-

Aluminum Sunflower Extrusion

Features a unique geometric shape, ideal for protective and structural optimization in specialized military devices.

-

Aluminuim Hexagonal Profile

Offers high strength and rigidity, commonly used in military robots and detection equipment frameworks.

-

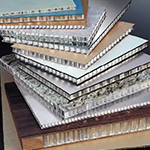

Aluminum Honeycomb Profile

Provides excellent lightweight and energy-absorbing properties, widely used in military aircraft and armored vehicle structures.

-

Aluminum Perforated Profile

Offers ventilation and weight reduction, suitable for cooling and ventilation systems in military equipment.

Chalco aluminum extrusion profile in military and defense industries

- Missile and Rocket Components: Aluminum profiles are crucial for crafting lightweight yet strong missile components, including fuselages and ducts, including for Armor Piercing Missiles, highlighting aluminum's vital military role. Our collaboration ensures top-quality profiles meeting stringent military standards, enhancing defense systems.

- Mechanical Components: Various components in military mechanical equipment, such as connectors, brackets, and frames, are also often made from aluminum alloy profiles to enhance durability and performance.

- Equipment Accessories: Accessories for various military vehicles and equipment, such as handles, grips, and support frames, are also commonly made from aluminum alloy profiles to provide lightweight and durability.

- Armor Materials: In military vehicles and equipment, aluminum alloy profiles can be used as components of armor materials, providing protection and structural support.

- Aircraft Structural Components: Aluminum alloy profiles are commonly used in the manufacture of structural components for military aircraft, such as fuselages, wings, and tail fins, due to their lightweight and high-strength characteristics, which provide sufficient structural strength while reducing overall weight.

Alu extrusion for armor-piercing-fin

Common Alloys: 2024, 7075, 7050, 2219 (for their high strength-to-weight ratio).

Common Shapes: Typically extruded into streamlined, aerodynamic profiles to reduce drag and improve performance.

Contact us now

Alu extrusion for missile tail fin

Common Alloys: 2024, 7075, 7005, 6082 (for their strength and lightweight properties).

Common Shapes: Extruded into complex, aerodynamic shapes like fins or stabilizers, including unique profiles such as the sunflower shape for specialized applications.

Contact us nowAluminum extrusion for military vehicle

Common Alloys: 6061, 6063, 7075 (for their good mechanical properties and durability).

Common Shapes: Includes various profiles such as channels, angles, and tubes to fit different structural needs.

Contact us now

Aluminum extrusion for military armor

Common Alloys: 5083, 7075 (for their excellent strength and resistance to impact and corrosion).

Common Shapes: Typically extruded into plates, panels, or custom profiles designed for specific armor configurations.

Contact us nowParameters table of Chalco MIL grade aluminum profile

| Element | Chemical composition of Chalco military grade aluminum alloy(%) | ||||

| 2024 | 2014 | 7A04 | 7A09 | 7075 | |

| Si | 0.50 | 0.50-1.20 | 0.50 | 0.50 | 0.40 |

| Fe | 0.50 | 0.70 | 0.50 | 0.50 | 0.50 |

| Cu | 3.8-4.9 | 3.9-5.0 | 1.4-2.0 | 1.2-2.0 | 1.2-2.0 |

| Mn | 0.30-0.90 | 0.40-1.20 | 0.20-0.60 | 0.15 | 0.30 |

| Mg | 1.2-1.80 | 0.20-0.80 | 1.8-2.80 | 0.20-3.0 | 2.1-2.90 |

| Cr | 0.10 | 0.10 | 0.10-0.25 | 0.16-0.30 | 0.18-0.28 |

| Zr | - | - | - | - | - |

| Zn | 0.25 | 0.25 | 5.0-7.0 | 5.1-6.1 | 5.1-6.1 |

| Ti | 0.15 | 0.15 | 0.10 | 0.10 | 0.20 |

| Al | Remainder | Remainder | Remainder | Remainder | Remainder |

| Mechanical property of Chalco armore piercing extrusion profile | |||||

| Alloy | Temper | Wall thickness/mm | Tension strength/(N/mm2) | Yield strength/(N/mm2) | Elongation/% |

| A50 mm | |||||

| Not less than | |||||

| 2024 | T4, T4511 | ≤5.0 | 390 | 295 | 10.0 |

| >5.0-10.0 | 410 | ||||

| >10.0-20.0 | 420 | 305 | |||

| >20.0-40.0 | 440 | 315 | |||

| >40.0 | 480 | 355 | |||

| 2014 | O H112 | ≤10.0 | 410 | 360 | 7.0 |

| >10.0-10.0 | 440 | 400 | |||

| >20.0 | 470 | 440 | |||

| 7A04 | ≤10.0 | 530 | 460 | 6.0 | |

| >10.0-20.0 | |||||

| >20.0-40.0 | 560 | ||||

| >40.0 | 570 | 490 | |||

| 7A09 | ≤10.0 | 530 | 460 | ||

| >10.0 | 540 | ||||

| 7075 | ≤5.0 | 540 | 480 | 7.0 | |

| Dimension tolerance of 2024 7075 aluminum profiles for armor-piercing fin | ||

| Waviness mm | Ordinary | High precision |

| ≤0.25 | Allowed | Allowed |

| >0.25-0.50 | Allowed | Every 2 meter |

| >0.50-1.00 | one per meter | Not allowed |

| >1.00 | Not allowed | Not allowed |

|

The end face of the profile should be cut flat, and the cutting slope not exceed 3mm; The longitudinal uniform bending of the profile should not be greater than 4mm/m; The plane gap on the plane of profile fins not be greater than 0.5mm; The twisting degree of the profile around the longitudinal axis not be greater than 17m; |

||

Chalco's extrusion capacity for military grade aluminum profile

| 1000 series Manufacturing Limits | Comparative Characteristics | ||

| Circle Size Range | ◆ 2” - 30” | Corrosion Resistance | ◆ Excellent |

| Weight Per Foot Range | ◆ 0.500 - 140 lbs. | Weldability (Arc) | ◆ Excellent |

| Length Range | ◆ Up to 95’ | Machinability | ◆ Poor to Fair |

| Die Availability | ◆ Custom Shapes | Workability | ◆ Good to Excellent |

| ◆ Standard Shapes | Strength | ◆ Low to Moderate | |

| 2000 series Manufacturing Limits | Comparative Characteristics | ||

| Circle Size Range | ◆3” –16” | Corrosion Resistance | ◆ Good |

| Weight Per Foot Range | ◆3.0 - 70.0 lbs. | Weldability (Arc) | ◆ Excellent |

| Length Range | ◆ Up to 65’ | Machinability Workability | ◆ Fair |

| Die Availability | ◆ Custom Shapes | Workability | ◆ Fair |

| ◆ Standard Shapes | Strength | ◆ High | |

| 5000 series Manufacturing Limits | Comparative Characteristics | ||

| Circle Size Range | ◆ 2” – 18” | Corrosion Resistance | ◆ Excellent |

| Weight Per Foot Range | ◆ 0.500 - 140 lbs. | Weldability (Arc) | ◆ Excellent |

| Length Range Die Availability | ◆ Up to 70’ | Machinability | ◆ Poor to Fair |

| Die Availability | ◆ Custom Shapes | Workability | ◆ Good to Excellent |

| ◆ Standard Shapes | Strength | ◆ Moderate | |

| 6000 series Manufacturing Limits | Comparative Characteristics | ||

| Circle Size Range | ◆ 2” - 32” | Corrosion Resistance | ◆ Good to Excellent |

| Weight Per Foot Range | ◆ 0.250 – 140 lbs. | Weldability (Arc) | ◆ Excellent |

| Length Range | ◆ Up to 95’ | Machinability | ◆ Fair |

| Die Availability | ◆ Custom Shapes | Workability | ◆ Good |

| ◆ Standard Shapes | Strength | ◆ Moderate | |

| 7000 series Manufacturing Limits | Comparative Characteristics | ||

| Circle Size Range | ◆ 2” – 16” | Corrosion Resistance | ◆ Excellent |

| Weight Per Foot Range | ◆ 3.0 – 45 lbs. | Weldability (Arc) | ◆ Excellent |

| Length Range | ◆ Up to 65’ | Machinability | ◆ Poor to Fair |

| Die Availability | ◆ Custom Shapes | Workability | ◆ Good to Excellent |

| ◆ Standard Shapes | Strength | ◆ High | |

| Extrusion presses | ||

| 8600 ton | 3000 ton | 1800 ton |

| Billet containers | Billet containers | Billet containers |

| ◆16" diameters | ◆9" diameters | ◆7" diameters |

| ◆20" diameters | ◆11" diameters | |

| ◆10"x28" rectangular | ||

| Equipment & Services | Fabrication | |

|

◆ Metallurgical Testing Laboratories ◆ Solution Heat Treat Furnace to 120’ ◆ 115’ Immersion Ultrasonic Tank ◆ Stretcher, 320-Ton Capacity ◆ Stretcher, 750-Ton Capacity with Capability of 27 Square Inch Cross Section (Aircraft Alloy) or 63 Square Inch in AA6061 |

◆ Cutoff Saws ◆Precision Saws ◆ Annealing Oven ◆ Aging Oven ◆ Knurling capability ◆ Design Assistance ◆ Nondestructive Testing ◆ Destructive Testing |

◆ Horizontal & Vertical CNC Machining ◆ 5 Axis Machining up to 10.5m long ◆ Friction Stir Welding* ◆ Punching* ◆ Painting and Anodizing* |

Chalco other hot selling military grade aluminum alloy series

7A52 armored plate

7B52 armored plate

2000 series armored plate

5000 series armored plate

Aluminum forgings for armor

Aluminum military-shelter

FAQ for purchasing Chalco military grade aluminum profiles

Q: How can I determine the appropriate specifications and dimensions for the aluminum alloy profiles I need?

A: Clearly define the required specifications and dimensions based on the design and application requirements of your missile or armor-piercing projectile. Accurate sizing and cross-sectional shape are crucial to ensure a perfect fit.

Q: How do I choose a reputable supplier for aluminum alloy profiles in the military sector?

A: Select a supplier with a strong reputation, backed by experience and positive market feedback. A supplier's reputation ensures reliable product quality and good after-sales service.

Q: When comparing suppliers, how can I balance price and quality for aluminum alloy profiles?

A: Don't base your decision solely on price. Consider the overall quality, service, and delivery times offered by different suppliers. Look for the best balance between cost and meeting your specific requirements.

Q: What should I check for in terms of appearance quality before purchasing aluminum alloy profiles?

A: Conduct a thorough visual inspection to ensure the profiles are free from visible damage, cracks, oxidation, or other surface imperfections. Opt for profiles with smooth, flawless surfaces for maximum longevity and performance.

Q: What steps should I take to address special requirements for aluminum alloy profiles, such as surface treatments or coatings?

A: Communicate your specific needs clearly with the supplier. Ensure they can accommodate your special requirements, whether it's surface treatments, anti-corrosion coatings, or customized features.

Q: How do I ensure the safe transport of aluminum alloy profiles, and what should I check upon delivery?

A: Clarify logistics arrangements and delivery times with the supplier. Proper packaging and protective measures are crucial during transportation to prevent damage. Upon delivery, inspect the profiles to confirm they are in perfect condition.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote