Aluminum profiles for missile tail fins offer excellent properties such as high strength, lightweight, high temperature resistance, and corrosion resistance, meeting the stringent requirements for precision, durability, and stability during missile flight.

Chalco's 2024, 6082, and 7005 aluminum profiles feature no eccentricity, no burrs, no crystallization, smooth surfaces, tight tolerances, and precise dimensions. Original quality certificates can be provided, and custom military-grade extrusions in special sizes are available upon request.

Specifications for aluminum profiles used in missile tail fins

Standards: EN 573-3, EN 755, ASTM B221/B221M, MIL-SPEC

Certifications: NADCAP HT, NADCAP NDT, AS9100D, ISO9001, HSE, AS9100C, GJB9001B, PED

Popular products of aluminum profiles for missile tail fins

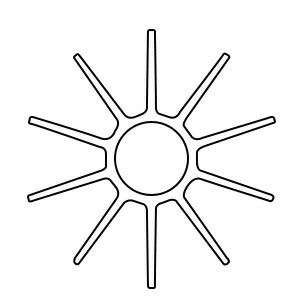

7005 aluminum profiles for missile tail fins (1915 GOST T4784-74)

Russian Grade: 1915

7005 aluminum alloy is an ideal choice for missile tail fins due to its exceptional high strength, corrosion resistance, and stress corrosion cracking resistance. It can withstand the intense airflow and mechanical stress caused by high-speed flight.

- Outer Diameter: 120mm - 150mm

- Inner Diameter: 30mm - 50mm

- Number of Fins: 10

- Fin Thickness: 2-5mm

- Length: 2800mm (Customizable)

- Vickers Hardness: ≥17.5HW

- Tensile Strength: ≥ 350 MPa

- Yield Strength: ≥ 290 MPa

- Elongation: ≥ 15%

- Surface: No peeling, bubbles, scratches, etc.

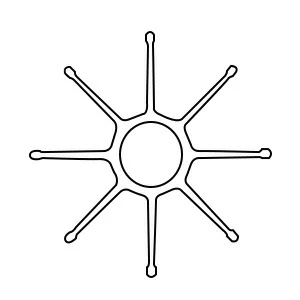

2024-T351 Aluminum Profiles for Missile Tail Fins

Temper: T351

2024-T351 offers high strength and good machinability, with excellent fatigue strength that ensures the material does not experience fatigue failure under long-term high-frequency vibrations and stress cycles. It is commonly used for structural components requiring high strength and good fatigue performance.

- Outer Diameter: 120mm - 150mm

- Inner Diameter: 30mm - 50mm

- Number of Fins: 8 or 10

- Fin Thickness: 2-5mm

- Length: Customizable

- Surface: No peeling, bubbles, scratches, etc.

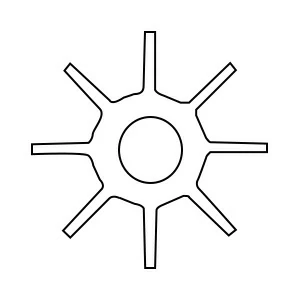

6082-T6 aluminum profiles for missile tail fins

Temter: T6

6082-T6 aluminum profiles are ideal materials for missile tail fin manufacturing due to their high strength, good corrosion resistance, and excellent cost-effectiveness, offering significant cost advantages in large-scale production.

- Outer Diameter: 40mm - 80mm

- Inner Diameter: 15mm - 50mm

- Number of Fins: 8

- Fin Thickness: 2-3mm

- Length: Customizable

- Yield Strength: ≥ 245 MPa

- Tensile Strength: ≥ 314 MPa

- Elongation: ≥ 8%

- Surface: No peeling, bubbles, scratches, etc.

Seamless tubes for missile tail fins

Hot-extruded seamless aluminum tubes are processed to form the main structure of missile tail fins, which can be installed later through welding, riveting, or other methods.

With no welds or joints, they perform well in high-pressure, high-temperature, and high-precision applications.

- Alloys: 7075, 2024, 2011

- Diameter of Drawn Seamless Tubes: 6 - 130mm

- Wall Thickness of Drawn Seamless Tubes: 1 - 2mm

- Diameter of Extruded Seamless Tubes: 25 - 420mm

- Wall Thickness of Extruded Seamless Tubes: 5 - 10mm

- Mechanical Properties: Customizable according to customer requirements

- Advantages: High strength, high precision, strict tolerances, better surface finish, and higher mechanical performance

Chemical elements of aluminum profiles for missile tail fins

Increased levels of zinc, silicon, and copper significantly enhance strength, while the addition of zirconium helps improve the alloy's operating temperature.Quick Quote

| Element | 6082 (%) | 7005 (%) | 2024 (%) |

| Aluminum (Al) | 95.2 - 98.3 | 91 - 94.7 | 90.7 - 94.7 |

| Silicon (Si) | 0.7 - 1.3 | 0 - 0.35 | 0 - 0.5 |

| Magnesium (Mg) | 0.6 - 1.2 | 1.0 - 1.8 | 1.2 - 1.8 |

| Manganese (Mn) | 0.4 - 1.0 | 0.2 - 0.7 | 0.3 - 0.9 |

| Iron (Fe) | 0 - 0.5 | 0 - 0.4 | 0 - 0.5 |

| Chromium (Cr) | 0 - 0.25 | 0.060 - 0 .2 | 0 - 0.1 |

| Zinc (Zn) | 0 - 0.2 | 4.0 - 5.0 | 0 - 0.25 |

| Titanium (Ti) | 0 - 0.1 | 0.010 - 0.060 | 0 - 0.15 |

| Copper (Cu) | 0 - 0.1 | 0 - 0.1 | 3.8 - 4.9 |

| Zirconium (Zr) | - | 0.080 - 0.2 | 0 - 0.2 |

| Residuals | 0 - 0.15 | 0 - 0.15 | 0 - 0.15 |

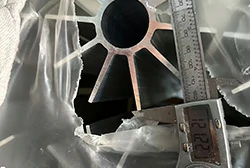

Customer case studies for aluminum profiles used in missile tail fins

Aluminum alloys are widely used in missile structures such as wings and tail fins. For example, the tail fins of the former Soviet SA-2 missile, the wings and tail fins of the British "Bloodhound" missile, and the wings of the American "Hawk" missile are all made from aluminum alloys.

We use high-strength, high-temperature resistant, corrosion-resistant, and lightweight aluminum profiles to effectively address challenges related to missile precision, durability, and stability. We have successfully provided customized aluminum profile solutions to numerous clients.Quick Quote

Quality assurance for aluminum profiles used in missile tail fins

Customized solutions

We offer customized solutions tailored to specific customer requirements. Whether it's alloy selection, mold design, or process adjustments, we can flexibly adapt to meet special needs.

Extrusion capability

Our company possesses world-class aluminum profile extrusion equipment, capable of handling various complex shapes of aluminum alloy products.

Our company has robust production capabilities, capable of handling multiple production lines simultaneously to meet large-volume orders and ensure rapid delivery within a short timeframe.

Precision mold design

Our company employs advanced mold design technology to ensure that profile shapes and dimensions meet stringent customer requirements. This approach helps avoid profile deformation and dimensional deviations, ensuring product quality and consistency.

Strict process control

In the extrusion process of aluminum finned tubes, our company strictly controls extrusion temperature, pressure, and speed. Precise temperature control prevents defects such as profile tearing or grain coarsening caused by overheating or overcooling of the material.

Original quality certificate

We provide a complete set of quality inspection reports, including composition analysis, mechanical performance testing, and traceability records.

Advantages of aluminum profiles for missile tail fins

- High Strength: Aluminum profiles offer superior strength, capable of withstanding the immense impact forces during missile launch, ensuring structural stability and reliability.

- Lightweight: The lightweight nature helps reduce the overall missile weight, enhancing flight performance and range.

- Heat Resistance: Aluminum maintains stable performance under high-temperature conditions.

- Corrosion Resistance: Aluminum has excellent corrosion resistance, adapting to various harsh environmental conditions.

- Excellent Machinability: Easy to process into various shapes and sizes, meeting the precise manufacturing needs of missile tail fins.

- Electromagnetic Shielding: Protects internal electronic equipment from external electromagnetic interference, ensuring the stability and reliability of the missile system.

Packaging for aluminum profiles used in missile tail fins

- Each profile is individually wrapped with protective materials such as plastic film, bubble wrap, or shock-resistant paper.

- Multiple profiles are bundled together into small packages, typically secured with plastic or metal straps and covered with protective material.

- Profiles are placed in custom wooden crates or frames, separated by dividers, with cushioning material added inside the crates.

- Alternatively, profiles can be neatly arranged on pallets and secured with strapping or shrink wrap.