Chalco can produce AMS 4152 UNS A92024 QQA 200/3 copper aluminum alloy grade extrusions 2024 for Aerospace, has AS9100 Collin Aviation Certification.

Specification: ASTM B221, ASTM B316, EN 12020, EN 13249, EN754, EN 755, JIS H4005,

Hot selling products of 2024 aluminum extrusion profiles

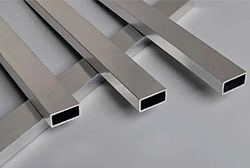

2024 Aluminum Square Tube

2024 Aluminum rectangular tube

2024 aluminum oval tube

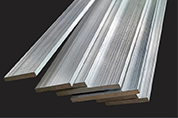

2024 aluminum flat bar

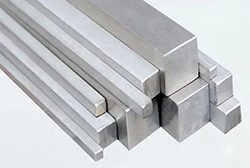

2024 aluminum square bar

2024 aluminum hexagonal bar

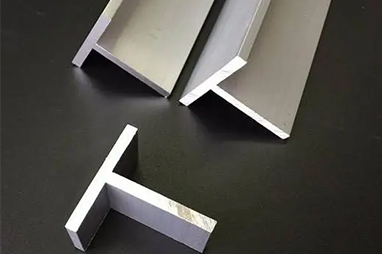

2024 aluminum angle

2024 aluminum T bar

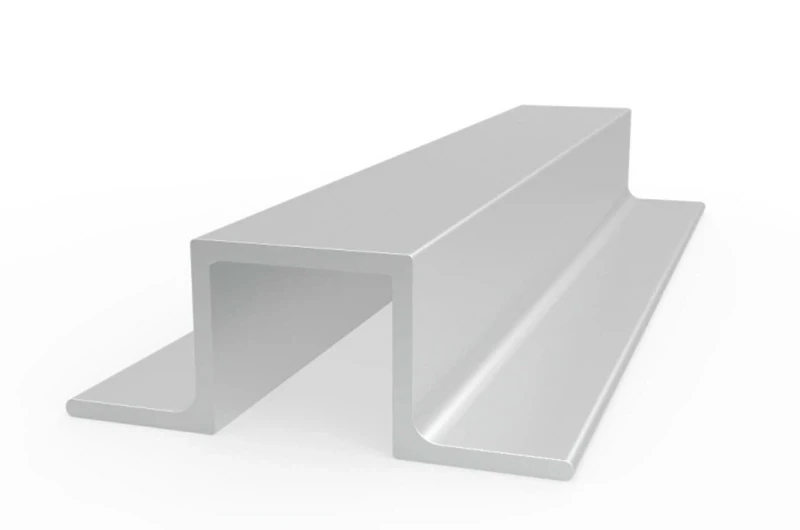

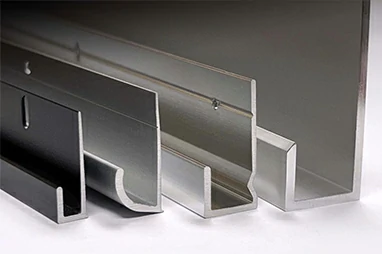

2024 Aluminum U Channel

2024 Aluminium Z Section

2024 Aluminium Hat Channel

2024 Aluminum J Channel

There are more sizes and shapes of 2024 aluminum profiles in practical applications. It is necessary to select the appropriate profile size and shape according to the specific application requirements.Welcome contact

| Name | 2024 aluminum Extrusions |

| Hot selling Temper | O, T3, T8, T351, T3511, T8511 |

| Equivalent name | 2024, AW-AlCu4Mg1, AU4G1, 3.1355, A92024, AlCu4Mg1, AlCuMg2 |

| 2024-T3 Aluminum Extrusions AMS 4152 | Thickness:0.125"-10"(3-250mm) |

| Width:0.5"-20"(12-500mm) | |

| 2024-T6 Aluminum Rings AMS 4152 | OD Range:1"-10"(25-250mm) |

| Thickness:0.125"-2"(25-50mm) | |

| 2024-O Aluminum Extrusion AMS4152 | Thickness:0.03"-4"(0.8-100mm) |

| Width:0.5"-16"(12-400mm) | |

| 2024-T4511 Extrusion AMS 4152 | Thickness:0.25"-4"(6-100mm) |

| Width:0.5"-12"(12-300mm) | |

| 2024-T6511 Extrusion AMS 4152 | Thickness:0.125"-20"(3-500mm) |

| Width:0.5"-24"(12-600mm) | |

| Length | Max 30m, Fix & Cut Length or Customized |

| Color | Silver, gold, natural color, silver, bronze, champagne, red, gray black, customized |

| Surface treatment | Anodizing, powder coating, electroplating, etc. |

| Processing services | CNC cutting, drilling, etching, etc. |

| Production Process | Extrusion, cold drawing, forging, etc. |

| Package | Refer to detailed packaging requirements |

| Standard | AMS-4152, AMS-4164, AMS-4165, ASTM-B221, AMS-QQ-A-200/3 |

Chemical composition of Chalco 2024A aerospace aluminum alloy

| 2024 alloy chemical | |

| Chemical element | % Present |

| Si | 0.5 |

| Fe | 0.5 |

| Cu | 3.8-4.9 |

| Mn | 0.3-0.9 |

| Mg | 1.20-1.8 |

| Ti | 0.15 |

| Cr | 0.10 |

| Zn | 0.25 |

| Other (Each) | 0.0-0.05 |

| Aluminium (Al) | Balance |

Mechanical properties of Chalco 2024 aerospace high quality extrusion

| Temper | Tensile strength | Yeild strength | Elongation |

| T4 | 460 MPa | 220 MPa | 19 % |

| T351 | 460 MPa | 260 MPa | 19 % |

| T851 | 480 MPa | 450 MPa | 20 % |

Product features of Chalco 2024 aviation aluminum alloy extrusion

High strength: aviation aluminum profiles have high strength and can withstand the weight and various external forces on various parts such as the fuselage and wing surfaces.

Lightweight: aviation aluminum profiles are lighter than traditional steel, which can reduce the overall weight of the aircraft and improve its load capacity and flight performance.

Good corrosion resistance: aviation aluminum profiles have good corrosion resistance, can resist various harsh environments and climatic conditions, and ensure the long-term stability and safety of aircraft structures.

Easy to process: aviation aluminum profiles can be processed and formed through various processing techniques, which can meet the needs of different shapes and sizes, and also have high plasticity and weldability.

Recyclability: aviation aluminum profile is a recyclable material, which can reduce environmental pollution and waste of resources, and is in line with the concept of sustainable development.Quick Quote

Application of Chalco 2024A industrial aerospace grade aluminium extrusion

Fuselage structure: aviation aluminum profiles can be used for the keel, beam and rib structure of the fuselage, which bear the weight of the fuselage and various external forces to ensure the stability and safety of the fuselage.

Wing surface structure: aviation aluminum profiles can be used for the main beam and sub-beam of the wing surface, which can support the load of the wing surface and distribute the weight of the aircraft to various parts of the wing surface.

Landing gear: aviation aluminum profiles can be used for structures such as brackets and bases of the landing gear. They can withstand the weight of the landing gear and various external forces to ensure the firmness and stability of the landing gear.

Engine bracket: aviation aluminum profiles can be used for engine hangers and brackets, which can support the weight of the engine and disperse the vibration and impact of the engine to other parts of the aircraft.

Chalco 2024 aerospace grade aluminum related products

2024 Aerospace Aluminum Rod Bar

2024 aerospace aluminum tube

2024 aerospace aluminum wire

2024 aerospace aluminum foil

2024 aerospace aluminum plate

2024 aluminum military profiles

Production process of Chalco aluminum alloy 2024 (UNS A92024) Extrusion

At present, the production process of aviation aluminum profiles mainly includes casting, extrusion and rolling.

Melting and casting is the method of heating the aluminum material to a liquid state and cooling it through a mold;

Extrusion is to extrude the aluminum material into profiles of various cross-sectional shapes;

Rolling is to pass the aluminum material through multiple passes of pressure. It is tapered and formed into profiles of the desired shape.

Why choose Chalco Aluminium as alloy 2024 aerospace extrusion materials manufacturer?

Chalco provides excellent quality aerospace materials, as well as the best technical services in the market, and has a deep knowledge base on how to support customers in meeting future challenges.

We have a complete set of domestic advanced aerospace materials research and development, testing and analysis instruments, which guarantee the efficiency of new product research and development and accelerate the transformation of scientific and technological achievements.

In addition, our R&D & innovation and verification capabilities can help enhance customers' competitiveness by saving time and cost in new product development and marketing.

We have passed the AS9100 certification required by the aviation industry and the Colin Aviation certification, and produce according to the AMS 4152 UNS A92024 QQA 200/3 standard required by customers, providing a strong guarantee for the quality of aerospace materials produced by our company.

The Chalco brand stands for quality, delivery and a solid reputation. With leading technology and globally competitive products, we can continue to develop together with our customers in the future.