When aluminum foil is mentioned, people usually think of its lightweight and flexible characteristics, rarely connecting it to the high strength and performance required in the aerospace industry. However, 5052 aluminum foil is one of the few types widely used in aviation. It not only offers excellent corrosion resistance and formability but also maintains outstanding mechanical properties under stringent aerospace standards.

Chalco has the capability to produce high-quality 5052 aluminum foil, providing the aerospace industry with 5052 aluminum foil that meets the necessary standards, fulfilling customers' high demands for performance and quality.Welcome contact

Chalco's capacity to produce aerospace grade aluminum:

AS9100, OHSAS 18001, ISO14001, ISO 9001, NADCAP HT, NADCAP NDT, IATP16949

Chalco 5052 aluminum foil specifications:

AMS: AMS 4015, AMS 4016, AMS 4018, AMS 4019, AMS 4022, AMS 4348

MIL: MIL-DTL-46027, MIL-DTL-46063, MIL-DTL-46192, MIL-DTL-5052

QQ: QQ-A-250/8, QQ-A-250/12, QQ-A-250/10

Specification of Chalco 5052 aerospace aluminum foil

| Temper | O, H12, H16, H19, H18, H32, H34 |

| Thickness | 0.018-0.20mm |

| Width | 100-1600mm |

| Typical product |

Honeycomb aluminum material |

| Packing | The packaging materials shall be free of foreign matter, damage, pollution, moisture, shock and static electricity. At the same time, the packaging should be marked with the quality standard, batch number, production date and other information of the product for tracking management. |

Honeycomb slice —— 5052 aluminum foil customized products

5052 aluminum Honeycomb slice has the characteristics of light weight, high strength, excellent corrosion resistance and sound insulation, and are often used in the aerospace field to manufacture components such as bulkheads, sound insulation panels, heat insulation panels and aircraft shells.

Contact us now

The 5052 aerospace-grade aluminum honeycomb core is a lightweight, high-strength structural material made from 5052 aluminum alloy foil. It is ideal for demanding applications that require superior strength, corrosion resistance, and high-temperature performance. This core meets the performance needs of industries such as aerospace, defense, and marine engineering and complies with AMS C7438 Rev A standards. It offers broad adaptability and can be tailored in various forms and sizes according to customer specifications.

Typical 5052 aluminum honeycomb core product display

-

High density 5052 corrugated aluminum honeycomb core material

Cell Sizes: 1/8″ – 3/16″

Densities: 14.5 pcf – 55.0 pcf

Sheet "Ribbon” (L): 36″ typical – 96″ max

Sheet "Transverse” (W): 30″ typical

-

Lightweight 5052 aluminum honeycomb core material

Cell Sizes: 1/8″ – 3/8″

Densities: 1.0 pcf – 8.1 pcf

Sheet "Ribbon” (L): 48″ typical – 72″ max

Sheet Thickness (T): 20″/34″ max

Product availability of Chalco honeycomb core material

- Panel Forms: Includes untrimmed panels, cut panels, and machined parts.

- Expanded and Unexpanded Forms: Available in unexpanded blocks, unexpanded sheets, and expanded sheets for various processing needs.

- Perforation Options: Available with or without perforations for ventilation in specific applications.

- Customization: Special sizes, tolerances, CNC machining, and die-cut sizes are available upon request.Customization: Special sizes, tolerances, CNC machining, and die-cut sizes are available upon request.

5052 aluminum honeycomb core material product features

- High Operating Temperature: Suitable for high-temperature environments.

- Excellent Thermal Conductivity: Offers outstanding heat conduction.

- Flame Retardant: Complies with strict fire safety standards.

- Moisture and Corrosion Resistant: Ideally suited for humid and corrosive environments.

- Fungus Resistant: Maintains stability in a wide range of harsh conditions.

- Lightweight, High Strength: Combines low weight with structural strength, making it suitable for high-performance applications.

- Machinable and Roll-Formable: Easy to process and shape to meet complex structural requirements.

- Long-Term Reliability: Maintains mechanical properties for at least 15 years under standard storage conditions.

Application field of Chalco 5052 aluminum honeycomb core material

- Aerospace: Aircraft flooring, leading and trailing edges of wings, fuel cells, fuselage components, and helicopter rotor blades.

- Defense and Marine: Military bulkheads and marine cabin joiner panels.

- Other High-Performance Fields: Engine compartments, roll-formed applications, energy absorption, anchor points, reinforcement, EMI/RFI shielding, and air and light directional panels.

- General Structural Applications: Suitable for structural components requiring high compression and shear strength.

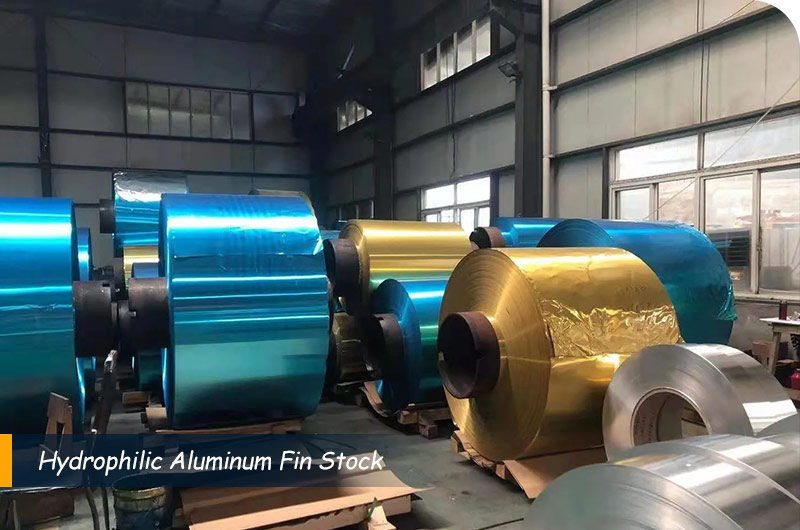

Color coated aluminum foil —— 5052 aluminum foil hot selling products

5052 aluminum color coated foil provides excellent corrosion resistance and an attractive appearance, widely used in packaging and decorative applications, offering a variety of color options to meet different customer needs.

Contact us now

Fin stock —— 5052 aluminum foil for enhanced heat exchange efficiency

5052 aluminum fin stock foil is used for manufacturing heat exchanger fins, featuring outstanding thermal conductivity and lightweight characteristics, significantly enhancing heat exchange efficiency, making it ideal for use in air conditioning, automotive, and electronic devices.

Contact us now

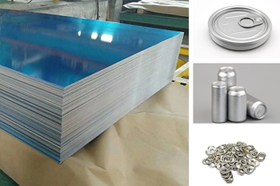

Packaging solutions —— 5052 aluminum foil for durable and fresh food storage

5052 aluminum foil is widely used in packaging due to its excellent barrier properties and corrosion resistance. Key applications include aluminum container foil, can body ends, and ring pulls, ensuring food safety and freshness. Its lightweight nature and aesthetic options also make it ideal for various packaging needs. Quick Quote

5052 aluminum container foil

5052 aluminum container foil offeres excellent barrier properties and strength to ensure food safety and freshness in packaging.

Contact us now

5052 aluminum foil for can body end and ring pull

5052 aluminum foil for ring pull, can body and can ends, provides good formability and corrosion resistance for secure sealing of canned foods.

Contact us nowHigh reflectivity solutions - 5052 mirror aluminum foil

5052 mirror aluminum foil provides excellent reflectivity and durability, making it ideal for lighting and reflective insulation. Its polished surface enhances light reflection, while the 5052 alloy offers strength and corrosion resistance for diverse applications.

Contact us now

Chalco 5052 aluminum foil hot selling alloy temper and mechanical properties

-

5052-O aluminum foil

Offers excellent ductility, suitable for complex-shaped packaging applications.

-

5052-H32 aluminum foil

Moderate strength, suitable for lightweight packaging and heat exchanger fins.

-

5052-H34 aluminum foil

Higher strength, suitable for lightweight packaging and shape-critical fin designs.

| Alloy | 5052-O aluminum foil | 5052-H32 aluminum foil | 5052-H34 aluminum foil |

| Yield strength | ≥68 MPa | 172 MPa | ≥241 |

| Yield strength UTS | ≥136 MPa | 228 MPa | ≥290 |

| Elongation | ≥18% | 6% | ≥6 |

| Thermal conductivity (W/m · K) | 138 W/m-K | 138 W/(m·K) | 138 W/(m·K) |

Chalco 5052 aerospace aluminum foil chemical composition

| Element | % |

| Al | 95.6-97.7 |

| Mg | 2.2-2.8 |

| Mn | 0.1-0.4 |

| Cr | 0.15-0.35 |

| Cu | 0.1-0.4 |

| Fe | ≤0.4 |

| Si | ≤0.25 |

| Sn | ≤0.05 |

| Zr | ≤0.05 |

| Other | ≤0.15 |

Chalco 5052 aluminum foil performance advantages

- 5052 aluminum foil has excellent corrosion resistance and can resist the corrosion of atmospheric, acidic and alkaline environment, which makes it one of the preferred materials for important components such as aircraft structure and spacecraft shell.

- 5052 aluminum foil has high strength and toughness, can withstand most mechanical and impact loads, and has good vibration resistance and reliability.

- 5052 aluminum foil is easy to process and form, and can be manufactured into parts of various shapes and sizes to meet the complex design requirements in the aerospace field.

- 5052 aluminum foil has relatively light weight compared with other materials, which can realize lightweight design of aircraft and improve aircraft performance and fuel economy.

Chalco 5052 aluminum foil in aviation application

- Aircraft Structures

- Fuel Tanks

- Heat Shields

- Interior Decoration

- Bolts and Fasteners

- In other fields, 5052 aerospace aluminum foil finds applications in automotive manufacturing, shipbuilding, and electronics, providing excellent lightweight and corrosion-resistant properties.

Chalco 5052 aerospace aluminum foil related products

FAQ for purchasing Chalco 5052 aluminum foil

Q: What is Chalco's production capacity for 5052 aluminum foil?

A: Chalco boasts a well-equipped production line, ensuring on-time delivery of products that meet international certification standards. Our production process maintains the stability and consistency of the products.

Q: Can I expect stable pricing for 5052 aluminum foil from Chalco?

A: Yes, Chalco offers first-hand supply of 5052 aerospace aluminum foil with a stable price. For specific pricing, please contact our customer service team for quotations and free samples. We're eager to collaborate with you.

Q: How does Chalco ensure the quality of its 5052 aluminum foil?

A: Chalco strictly maintains the quality of its aluminum foil slices, ensuring precise end face alignment with no burrs or damage. Additionally, we guarantee that the adhesive tape at the joint does not stick to one layer, and the layout is clean and flat. The foil's surface is free from corrosion, cavities, folds, browning, grooving, and other defects.

Q: What quality tests are conducted on Chalco's 5052 aluminum foil?

A: Chalco employs a range of testing methods, including ultrasonic flaw detection, X-ray flaw detection, and X-ray diffraction, to ensure that our products meet the required performance and quality standards.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote