An aluminum casement window is a traditional window type where the window frame is made of aluminum and opens outward or inward with a side hinge design. It is one of the most widely used window types. This design allows the window to open completely, offering excellent ventilation. The high strength and durability of aluminum allow for thinner frames and larger glass areas, providing maximum visibility.

As a leading aluminum processing manufacturer, Chalco can design and produce aluminum casement windows that meet the requirements of standards such as EN 13115, EN 13126, EN ISO 12567, EN 12210, and more. With the full industry chain advantage from raw material sourcing to production and assembly, Chalco offers high production efficiency, fast delivery, and prices 20% lower than other professional door and window companies of the same quality. Save cost

Read this article to learn about:

- Advantages of aluminum casement windows

- Types of aluminum casement windows

- Opening mechanisms of aluminum casement windows

- Safety features of aluminum casement windows

- Energy-efficient design of aluminum casement windows

- Surface finishes for aluminum casement windows

- Glass configurations for aluminum casement windows

- FAQ

Chalco's best-selling aluminum casement windows

HC-61 aluminum casement window

The HC-61 aluminum casement window is a relatively economical product, particularly suitable for small apartments, standard residential buildings, and users with moderate soundproofing and heat insulation requirements.

Contact us now

The HC-61 is a casement window with basic thermal insulation performance. It uses extruded 6063-T5 aluminum alloy, features a double-glazed structure with a single cavity, and adopts a three-seal design for excellent sealing performance. It supports multiple opening methods, including inward and outward opening.

Basic information of HC-61 casement window

| Cavity structure | Double-glazed, single cavity |

| Alloy | 6063-T5 |

| Profile wall thickness | 1.4mm |

| Window frame thickness | 61mm |

| Window frame thermal break width | 24mm |

| Window sash thickness | 70mm |

| Window sash thermal break width | 24mm |

Product performance of HC-61 casement window

| Performance | Grade | Reference Standards |

| Thermal insulation, Uw | Class C | EN ISO 12567-1:2011 |

| Air permeability | Class 8 | EN 1026:2000, EN12207:1999 |

| Water tightness | 7A | EN 1027:2000, EN 12208:1999 |

| Wind load resistance | Class C5 | EN 12211:2000, EN 12210:1999 |

| Acoustic insulation | Class 4 [up to 33dB] | EN ISO 10140-2:2011, EN ISO 10140-4:2011 |

HC-65 aluminum casement window

The HC-65 aluminum casement window offers excellent cost-performance and is highly suitable for standard residential buildings, educational institutions, and light commercial projects. It is ideal for both new constructions and renovation projects.

Contact us now

The HC-65 is a casement window with medium thermal insulation performance. It uses extruded 6063-T5 aluminum alloy, features a double-glazed structure with a single cavity, and adopts a design based on water vapor separation and equal pressure principles. The window frame also follows European standard groove design. You can pair it with our hardware accessories or consult us for purchase options, as our hardware is highly compatible.

Basic information of HC-65 aluminum casement window

| Cavity structure | Double-glazed, single cavity |

| Alloy | 6063-T5 |

| Profile wall thickness | 1.4mm |

| Window frame thickness | 65mm |

| Window frame thermal break width | 24mm |

| Window sash thickness | 70mm |

| Window sash thermal break width | 24mm |

Product performance of HC-65 aluminum casement window

| Performance | Grade | Reference Standards |

| Thermal insulation, Uw | Class C | EN ISO 12567-1:2011 |

| Air permeability | Class 8 | EN 1026:2000, EN12207:1999 |

| Water tightness | 7A | EN 1027:2000, EN 12208:1999 |

| Wind load resistance | Class C5 | EN 12211:2000, EN 12210:1999 |

| Acoustic insulation | Class 4 [up to 33dB] | EN ISO 10140-2:2011, EN ISO 10140-4:2011 |

HC-70 aluminum insulated casement window

The HC-70 aluminum insulated casement window has excellent thermal insulation performance, which helps reduce energy costs. It is suitable for commercial and residential projects requiring high thermal insulation.

Contact us now

The HC-70 features medium thermal insulation performance and uses high-quality 6060-T6 alloy aluminum profiles with a 1.6mm profile wall thickness for increased strength. It is equipped with co-extruded soft and hard composite sealing strips, which offer excellent compression deformation resistance. The window has a lower thermal transmission coefficient, and overall air-tightness and water-tightness are improved.

Basic information of HC-70 aluminum insulated casement window

| Cavity structure | Double-glazed, single cavity |

| Alloy | 6060-T6 |

| Profile wall thickness | 1.6mm |

| Window frame thickness | 70mm |

| Window frame thermal break width | 33mm |

| Window sash thickness | 79mm |

| Window sash thermal break width | 33mm |

Product performance of HC-70 aluminum insulated casement window

| Performance | Grade | Reference Standards |

| Thermal insulation, Uw | Class C [1.5W/(m2.k)] | EN ISO 12567-1:2011 |

| Air permeability | Class 8 | EN 1026:2000, EN12207:1999 |

| Water tightness | 8A | EN 1027:2000, EN 12208:1999 |

| Wind load resistance | Class C5 | EN 12211:2000, EN 12210:1999 |

| Acoustic insulation | Class 5 [up to 36dB] | EN ISO 10140-2:2011, EN ISO 10140-4:2011 |

HC-76 aluminum insulated casement window

The HC-76 aluminum insulated casement window is a triple-glazed window with a U-value as low as 1.2 W/(m²·K), providing excellent insulation. It is perfect for cold climates or buildings requiring high thermal isolation.

Contact us now

The HC-76 is a medium-high thermal insulation performance casement window. It uses the stronger 6060-series aluminum frame, which provides better durability. The window incorporates refrigerator-grade insulation cotton to enhance the overall insulation performance. The 39mm custom thermal break strips efficiently block heat transfer. Additionally, it features a step drainage design, ensuring smoother water drainage and a more aesthetically pleasing look.

Basic information of HC-76 aluminum insulated casement window

| Cavity structure | Triple-glazed, Double-cavity |

| Alloy | 6060-T6 |

| Profile wall thickness | 1.6mm |

| Window frame thickness | 76mm |

| Window frame thermal break width | 39mm |

| Window sash thickness | 85mm |

| Window sash thermal break width | 39mm |

Product performance of HC-76 aluminum insulated casement window

| Performance | Grade | Reference Standards |

| Thermal insulation, Uw | Class B [1.2W/(m2.k)] | EN ISO 12567-1:2011 |

| Air permeability | Class 8 | EN 1026:2000, EN12207:1999 |

| Water tightness | 9A | EN 1027:2000, EN 12208:1999 |

| Wind load resistance | Class C5 | EN 12211:2000, EN 12210:1999 |

| Acoustic insulation | Class 5 [up to 36dB] | EN ISO 10140-2:2011, EN ISO 10140-4:2011 |

HC-81 aluminum insulated casement window

The HC-81 aluminum insulated casement window has a 44mm thick PA66 custom thermal break strip and also provides certain fire-resistant properties, making it very suitable for public buildings and commercial towers.

Contact us now

The HC-81 is a high-performance thermal insulated casement window, featuring a stronger 6005-series aluminum frame, commonly used for rail transportation and bridge extrusion, with improved fatigue resistance. It uses 44mm custom thermal break strips and a multi-chamber design to block heat transfer efficiently. The insulation cotton is closed-cell foam, which effectively improves the window's performance.

Basic information of HC-81 aluminum insulated casement window

| Cavity structure | Triple-glazed, Double-cavity |

| Alloy | 6060-T66 |

| Profile wall thickness | 1.8mm |

| Window frame thickness | 81mm |

| Window frame thermal break width | 44mm |

| Window sash thickness | 90mm |

| Window sash thermal break width | 44mm |

| Fire resistance integrity | 30-60min |

Product performance of HC-81 aluminum insulated casement window

| Performance | Grade | Reference Standards |

| Thermal insulation, Uw | Class A [1.0W/(m2.k)] | EN ISO 12567-1:2011 |

| Air permeability | Class 8 | EN 1026:2000, EN12207:1999 |

| Water tightness | 9A | EN 1027:2000, EN 12208:1999 |

| Wind load resistance | Class C5 | EN 12211:2000, EN 12210:1999 |

| Acoustic insulation | Class 5 [up to 36dB] | EN ISO 10140-2:2011, EN ISO 10140-4:2011 |

HC-85 double-inward casement window

The HC-85 double inward casement window features a dual-opening design, suitable for medium to large window sizes. It uses a triple-glazed design for better thermal and sound insulation performance.

Contact us now

The HC-85 inward-opening window uses a high-precision 6060-T66 aluminum frame with a wall thickness of up to 1.8mm, ensuring high strength and good weather resistance. The window is paired with CNC-machined hidden drainage outlets, providing smooth and visually appealing drainage.

Basic information of HC-85 double-inward casement window

| Cavity Structure | Triple-glazed, Double-cavity |

| Alloy | 6060-T66 |

| Profile Wall Thickness | 1.8mm |

| Window Frame Thickness | 85mm |

| Frame Internal Viewing Width | 27mm |

| Sash Internal Viewing Width | 78mm |

| Glass Configuration | 5mm+12A+5mm+12A+5mm |

Product performance of HC-85 double-inward casement window

| Performance | Grade | Reference Standards |

| Thermal insulation, Uw | Class C [1.4-2.0W/(m2.k)] | EN ISO 12567-1:2011 |

| Air permeability | Class 8 | EN 1026:2000, EN12207:1999 |

| Water tightness | 9A | EN 1027:2000, EN 12208:1999 |

| Wind load resistance | Class C5 | EN 12211:2000, EN 12210:1999 |

| Acoustic insulation | Class 5 [up to 38dB] | EN ISO 10140-2:2011, EN ISO 10140-4:2011 |

HC-90 aluminum inward casement window

The HC-90 aluminum inward casement window features an inward-opening design that allows for tilting and rotation. It uses a multi-point locking system and surface-mounted bolts, offering enhanced security.

Contact us now

Basic information of HC-90 aluminum inward casement window

| Cavity Structure | Triple-glazed, Double-cavity |

| Alloy | 6060-T66 |

| Profile Wall Thickness | 1.8mm |

| Window Frame Thickness | 90mm |

| Frame Internal Viewing Width | 40mm |

| Sash Internal Viewing Width | 81mm |

| Glass Configuration | 5mm+16A+5mm+16A+5mm |

Product performance of HC-90 aluminum inward casement window

| Performance | Grade | Reference Standards |

| Thermal insulation, Uw | Class B [1.2W/(m2.k)] | EN ISO 12567-1:2011 |

| Air permeability | Class 4 | EN 1026:2000, EN12207:1999 |

| Water tightness | 8A | EN 1027:2000, EN 12208:1999 |

| Wind load resistance | Class C4 | EN 12211:2000, EN 12210:1999 |

| Acoustic insulation | Class 5 [up to 38dB] | EN ISO 10140-2:2011, EN ISO 10140-4:2011 |

HC-99 aluminum inward casement window

The HC-99 aluminum inward casement window complies with the latest energy-saving standards for buildings, with a U-value of 1.0 W/(m²·K). It effectively reduces energy consumption and helps create a green, sustainable living environment.

Contact us now

Basic information of HC-99 aluminum inward casement window

| Cavity Structure | Triple-glazed, Double-cavity / Quadruple-glazed, Triple-cavity |

| Alloy | 6060-T66 |

| Profile Wall Thickness | 1.8mm |

| Window Frame Thickness | 90mm |

| Frame Internal Viewing Width | 27mm |

| Sash Internal Viewing Width | 81mm |

| Glass Configuration | 5mm+16A+5mm+16A+5mm/ 5mm+12A+5mm+12A+5mm+12A+5mm |

Product performance of HC-90 aluminum inward casement window

| Performance | Grade | Reference Standards |

| Thermal insulation, Uw | Class A [1.0W/(m2.k)] | EN ISO 12567-1:2011 |

| Air permeability | Class 4 | EN 1026:2000, EN12207:1999 |

| Water tightness | 9A | EN 1027:2000, EN 12208:1999 |

| Wind load resistance | Class C5 | EN 12211:2000, EN 12210:1999 |

| Acoustic insulation | Class 6 [up to 41dB] | EN ISO 10140-2:2011, EN ISO 10140-4:2011 |

Aluminum casement window gallery

Other aluminum window types available from Chalco

- Aluminum Sliding Windows

- Aluminum Tilt and Turn Windows

- Aluminum Folding Windows

- Aluminum Fixed Windows

- Aluminum Skylights

- Aluminum Special Shape Windows

Benefits of Chalco aluminum casement windows

- Easy Maintenance: Aluminum casement windows require no special materials for maintenance, and can be cleaned easily with just a wipe.

- Excellent Thermal Performance: With double-glazed or triple-glazed designs, these windows effectively insulate, lowering the U-value and reducing energy consumption.

- Safety: Reinforced aluminum alloy frames are equipped with multi-point locking systems and anti-pry features to enhance window security.

- Environmentally Friendly: Aluminum is recyclable, has a low carbon footprint, and meets sustainable development standards.

- Excellent Daylighting: The strong properties of aluminum allow for slimmer frames, providing larger glass areas and exceptional views.

- Good Ventilation: With the ability to fully open, these windows offer excellent ventilation, ideal for enjoying natural breezes.

Types of Chalco aluminum casement windows

Outward Opening Casement Windows

Opens outward from the side, saving interior space. Available in single or double-opening styles.

Single Frame Casement Windows

Composed of one window pane, suitable for smaller rooms or bathrooms.

Double Frame Casement Windows

Also known as French casement windows, these consist of two window panes with hinges on both sides.

Triple Frame Casement Windows

Composed of three window panes, ideal for larger rooms like bedrooms or living rooms.

Top-Hung Casement Windows

Opens from the side with a fixed top, offering weatherproofing from the bottom.

Slimline Casement Windows

Features a very narrow frame design for a sleek look, allowing for larger glass areas.

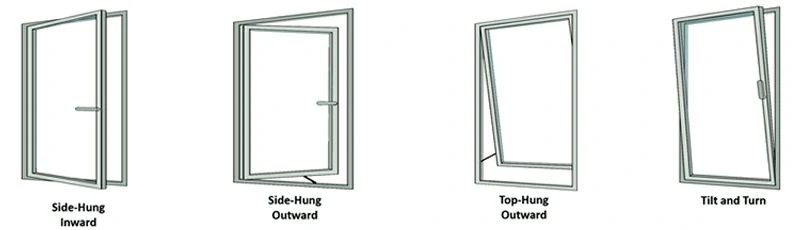

Opening mechanisms of Chalco aluminum casement windows

Safety features of Chalco aluminum casement windows

1. High-Strength Aluminum Window Frames

Chalco uses high-strength aluminum alloy frames with reinforced designs to provide superior impact resistance. These frames effectively prevent forced entry and vandalism while offering excellent corrosion and weather resistance for long-lasting durability and high security.

2. Safety Glass

Aluminum casement windows are equipped with laminated or tempered safety glass. Even if the glass breaks, the shards stay in place, significantly enhancing shatter resistance and preventing break-ins. This provides extra anti-theft protection.

3. Multi-Point Locking System

Chalco’s aluminum casement windows are equipped with a high-security multi-point locking system, which locks the window at several points. Simply turn the key to lock all points, providing superior resistance to forced entry.

4. Standard Key Locking Handles

To further enhance security, windows come with standard key locking handles, preventing unauthorized opening and tampering, thus improving anti-theft performance.

Energy-saving design of Chalco aluminum casement windows

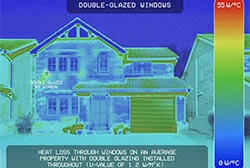

Low U-value Enhances Insulation

Chalco's aluminum casement windows feature a double-glazed design, achieving a U-value as low as 1.4 W/m²K. A lower U-value means better insulation, effectively reducing heat loss and improving overall energy efficiency.

For higher thermal insulation, triple-glazed versions can achieve a U-value as low as 1.0 W/m²K. In cold regions, such low U-values significantly reduce energy costs and save on heating during long winters.

" High-performance aluminum sliding windows optimize the U-value to prevent external heat from entering or escaping, reducing the need for air conditioning and heating, thus cutting energy consumption. ”

Efficient Sealing Design

Our casement window frames feature three sealing strips: exterior, interior, and an insulation strip in the middle. This design effectively prevents air leakage and heat dissipation. The combined action of these strips reduces heat transfer through the window frame, enhancing thermal insulation performance.

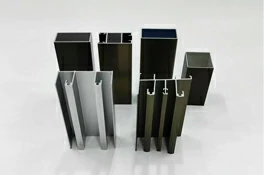

Polyamide Insulation Materials

The aluminum window frames use polyamide insulation strips, effectively blocking heat transfer and enhancing the thermal performance of the frame, making it comparable to other materials used in energy-efficient windows.

Chalco Aluminum casement windows finishing options

Anodizing

Anodizing is an electrochemical process that forms a hard oxide layer on the surface of aluminum. This layer offers exceptional corrosion resistance and abrasion resistance. Additionally, the oxide layer can be colored as per requirements, with common colors including silver, rose gold, black, white, and bronze.

Application Scenario: Ideal for high-end residential and commercial buildings, especially in outdoor environments, providing long-term durability.

Powder Coating

Powder coating involves evenly spraying powder coating material onto the surface of the aluminum window, followed by high-temperature curing to form a dense, durable coating. This process offers a wide range of color choices, with classic colors such as black, white, and grey, and over 200 other RAL colors to meet different customer needs.

Application Scenario: Widely used in commercial buildings, residential windows, and architectural projects requiring personalized colors.

Wood Grain Transfer Printing

Wood grain transfer printing uses heat transfer technology to imprint wood grain patterns onto the aluminum surface, simulating the appearance of natural wood. This finish combines the aesthetic appeal of wood with the durability and easy maintenance of aluminum.

Application Scenario: Suitable for architectural projects that require the look of wood but want to avoid the maintenance and lifespan issues associated with real wood, such as in villas and luxury residences.

Glass options for Chalco aluminum casement windows

The glass used in aluminum windows is a key component that affects performance, appearance, and safety. Different types of glass not only impact the thermal insulation and soundproofing effects of the window, but also its strength, safety, and visual appeal.

Flat glass

Flat glass is the most common type of glass, with uniform thickness, typically manufactured using the float glass process. It includes various types of glass with different properties and applications, such as clear glass, tempered glass, colored glass, patterned glass, and more. Depending on thermal and acoustic needs, the glass can be configured as double-glazed or triple-glazed.

Single-Glazed Glass

Single-glazed glass loses the most heat and is prone to condensation and dampness.

Double-Glazed Glass

Double-glazed glass reduces heat loss to a quarter of that of single-glazed glass.

Triple-Glazed Glass

Triple-glazed glass reduces heat loss by an additional 35% compared to double-glazed glass, offering superior energy efficiency and economy.

Low-E glass (coated glass)

Low-E glass (also known as low emissivity glass) is coated with a thin layer of metal oxide that effectively reflects heat while allowing visible light to pass through. This type of glass has outstanding thermal insulation and energy-saving properties, increasing the energy efficiency of the window and extending its lifespan. It is ideal for windows requiring high energy efficiency, as well as UV and infrared control, making it especially suitable for modern green buildings.

" Using Low-E glass effectively blocks UV rays, reducing fading of furniture, carpets, and curtains, thereby prolonging the lifespan of interior furnishings. ”

Insulated glass

Insulated glass consists of two or more panes of glass with a dry gas (such as air or argon) in between. The panes are sealed with adhesive around the edges to enhance thermal insulation and soundproofing. This makes it an ideal choice for improving energy efficiency and comfort in both residential and commercial buildings.

However, compared to ordinary glass, insulated glass is more costly to produce and may require special design considerations in extreme climates to avoid condensation or breakage between the glass panes.

FAQ

To help our customers better understand our products and services, we provide a comprehensive FAQ section to address common questions about our supplied products, maintenance advice, customization options, and more.

Can you provide OEM/ODM services?

Yes, we can provide both OEM and ODM services. We have previously provided customized doors and windows for many internationally renowned door and window companies.

- OEM (Original Equipment Manufacturer): We can manufacture doors and windows according to your specifications, design, and branding. We take responsibility for production and processing, ensuring the product quality meets your standards.

- ODM (Original Design Manufacturer): In addition to manufacturing according to your requirements, we also offer complete product design and development services. From design to production, we can provide innovative solutions tailored to your needs, helping you create unique products.

Whether OEM or ODM, Chalco has the technical strength and production capacity to ensure your specific needs are met, helping you lower costs and improve market competitiveness.

Can you supply doors and windows for homeowners?

Yes, Chalco can provide door and window solutions for homeowners. Whether you're renovating a new house or refurbishing an old one, we offer high-quality, stylish, and reliable doors and windows. We provide a full range of styles, and you can choose based on your needs, including design, performance, and budget, to help you create a fresh new look for your home.

Installation Service:

While we can provide high-quality doors and windows, you will need to hire local professional installers. We offer installation guidance and support to ensure the products are installed accurately and professionally, adding beauty and comfort to your home.

Can you supply doors and windows to door and window companies?

Yes, Chalco can supply aluminum profiles for doors and windows or process doors and windows according to your drawings.

As a leading aluminum processing enterprise in China, we have strong production capabilities that can significantly reduce your product costs. Our range of aluminum profiles is diverse and of superior quality, meeting different design and functional requirements. Additionally, we can provide customized processing to ensure that every batch of products meets high-quality standards.

You can trust us with your door and window manufacturing needs, and we will provide efficient, reliable supply chain support.

Can you supply doors and windows to construction contractors?

Yes, Chalco can provide finished doors and windows to construction contractors or offer OEM/ODM services. By processing doors and windows through our facilities, we can help you save on construction costs while ensuring quality. Our door and window products include aluminum doors and windows, commercial doors, storefront doors, curtain walls, and more, widely used in residential, commercial, hotel, education, retail, and office projects.

We collaborate with many internationally recognized brands, and our products undergo rigorous testing to ensure reliability and compliance with high standards. Whether for large-scale construction projects or customized requirements, we offer fast manufacturing, on-time delivery, and precise installation support to help you complete your projects on budget and schedule.

Are the aluminum doors and windows you provide glass windows or non-glass windows?

We can provide a full system of aluminum doors and windows as well as non-glass aluminum windows. If you prefer to purchase the glass locally, all our windows are designed to make glass installation easy on-site. When confirming your order, we will provide complete glass dimensions and details to ensure smooth installation. If needed, we can also provide the glass products along with complete glass installation instructions.

Whether you choose a full system window or a non-glass aluminum window, we can offer customized solutions to meet your requirements and budget.

What is your typical delivery time?

Delivery time depends on the specific project requirements and the products ordered. Typically, from manufacturing completion to shipment to your destination port, the total time is approximately 20-30 days, with the exact time depending on the destination port and delivery method.

- Production Time: From order confirmation to product completion, it generally takes 15-30 days. If you provide drawings and only need processing for door and window profiles, the production cycle may be shorter.

- Complete Door and Window Processing: If you request complete door and window processing, the production cycle may be slightly longer.

- Design and Processing: If you entrust us with the full design and manufacturing of doors and windows, the entire cycle may be longer due to the additional time needed for design, sample creation, and production.

We will provide a specific delivery time based on your project needs and ensure on-time delivery.