Aluminum door profiles are structural components made from high-strength aluminum alloys, primarily used in door frames. They provide stability, durability, and aesthetic appeal in buildings. Whether in residential or commercial buildings, aluminum door profiles have become the preferred material for modern doors and windows due to their lightweight nature, corrosion resistance, and design flexibility.

Chalco boasts a large and efficient aluminum supply chain system, offering custom aluminum door profile services, as well as OEM/ODM services for finished aluminum doors and windows. If you wish to directly purchase finished aluminum doors and windows, we have a professional design team that can provide you with a one-stop aluminum door and window solutions.

After reading this article, you will understand:

To learn more about aluminum window frames, please check out the Ultimate Guide to Aluminum Door Profiles.

What aluminum profiles are included in an aluminum door system?

According to structure and performance, aluminum window profiles can be categorized into the following types:

Standard Aluminum Door Profiles

Standard aluminum door profiles are formed by extruding aluminum billets at high temperatures, followed by various surface treatments. These profiles have a simple structure and a thinner frame cross-section, making them suitable for commercial spaces like offices and shops with low thermal insulation requirements, or for residential projects where cost control is crucial.

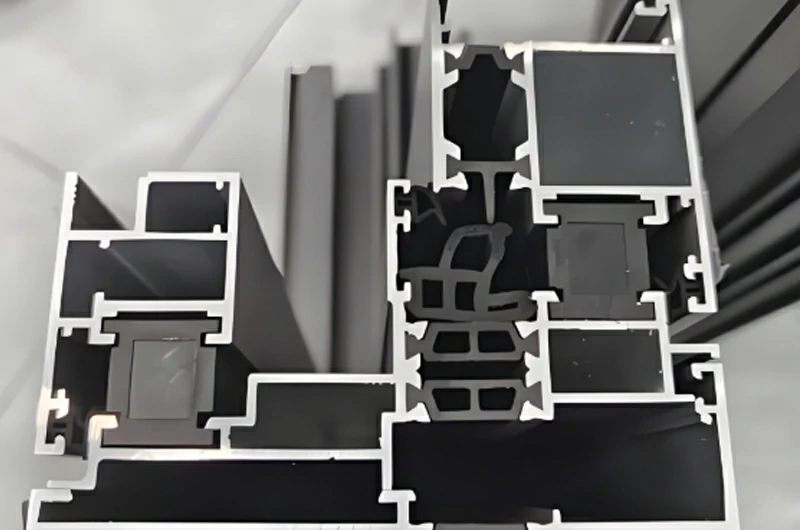

Thermal Break Aluminum Door Profiles

Thermal break aluminum door profiles, also known as broken bridge aluminum, utilize an innovative "thermal break" structure, combining inner and outer layers of aluminum profiles with polyamide thermal insulation material. This effectively reduces heat transfer and significantly improves the energy efficiency of buildings. Especially suitable for cold regions and high-end residential buildings, these profiles can greatly reduce energy consumption and enhance indoor comfort. Compared to standard aluminum door profiles, thermal break aluminum provides better insulation performance and a longer service life, making it an ideal choice for high-end construction projects.

Aluminum-Wood Composite Door Profiles

Aluminum-wood composite profiles feature aluminum profiles as the main material, with a composite wood core inside. The wood serves primarily for interior decoration and enhancing insulation. Combining the natural beauty of wood with the high weather resistance of aluminum, these profiles are considered high-end door and window materials, suitable for projects that seek both aesthetic appeal and adaptability to various climates.

Aluminum Door Frame Profiles

Aluminum door frame profiles are the primary materials used to construct the framework of doors, providing support and stability. Typically made from high-strength aluminum through an extrusion process, they are treated to enhance corrosion resistance and aesthetic appeal. These profiles must be tightly integrated with other components, such as door panels and hardware, to ensure the overall structural stability of the door.

Aluminum Door Track Profiles

Aluminum door track profiles are used for the guide rail system of sliding doors (sliding aluminum profiles), ensuring smooth opening and closing. Made from high-strength aluminum, they are precisely processed to ensure the tracks are straight and smooth. Sliding aluminum profiles include top tracks, bottom guides, and auxiliary components (such as rollers, guide devices, etc.).

Aluminum Threshold Profiles

Aluminum threshold profiles, also known as aluminum door sill profiles, are installed at the bottom of the door, serving functions such as sealing, waterproofing, and enhancing aesthetics. Aluminum threshold profiles need to be tightly integrated with flooring materials (like tiles, wooden floors, etc.), as well as the door frame and door panel, to ensure the overall waterproofing and sealing properties of the door.

Frameless Aluminum Profiles

Frameless aluminum profiles refer to aluminum profiles designed to fix glass without the traditional framework structure. Using high-strength aluminum alloys and advanced connection technologies, these profiles allow for a solid attachment of glass to the door and window system without requiring the heavy traditional frame. This design offers larger glass areas and a minimalist aesthetic. They are commonly used in high-end villas, luxury hotels, and exhibition halls.

Comprehensive analysis of different types of aluminum door profiles

Aluminium sliding door profiles

Aluminum sliding door profiles, made from high-strength alloys, are used for door frames, tracks, rollers, and accessories. They are precisely processed and surface-treated for smooth operation, excellent sealing, and an attractive appearance.

Contact us now

Features

- Smoothness and Durability: Sliding doors need to remain smooth under frequent use, requiring profiles and accessories with high durability.

- Sealing Performance: Good sealing performance prevents air, water, and noise penetration, improving the user experience.

- Ease of Installation: The sliding door system should be designed to minimize installation time and cost.

- Space Utilization: Sliding doors should effectively save space and adapt to various spatial layouts.

- Aesthetic Appeal: The profile design should harmonize with the overall décor style and offer diverse surface finishing options.

Typical Applications

- Residential: Used for balcony doors, internal partition doors, wardrobe doors, etc.

- Commercial Buildings: Such as offices, shops, and hotel rooms, where space-saving solutions are needed.

- Public Buildings: Hospitals, schools, exhibition halls, etc., where high traffic is expected, and efficient door usage is required.

Folding door aluminum profiles

Folding door aluminum profiles, made from high-strength alloys, are used for frames, leaves, hinges, and other components. They are precisely processed and surface-treated to ensure stability, durability, and aesthetic appeal.

Contact us now

Features

- Smoothness and Durability: Folding doors must remain smooth with frequent use, requiring profiles and components to be highly durable.

- Space Utilization: Folding doors should effectively save space and adapt to different spatial requirements.

- Sealing Performance: Excellent sealing performance enhances the door's soundproofing, heat insulation, and waterproof abilities.

- Ease of Installation: Folding door systems should be easy to install to reduce installation time and costs.

- Aesthetic Appeal: The profile design should align with the overall decoration style and offer various surface treatment options.

Application Scenarios

- Residential: Used for wardrobe doors, storage room doors, kitchen doors, etc., where folding functionality is needed.

- Commercial Buildings: Such as conference rooms, office partitions, exhibition doors, etc.

- Public Buildings: Libraries, schools, hospitals, etc., where folding doors are frequently used.

Aluminum swing door profiles

Aluminum swing doors, or vertical hinged doors, are built using high-strength aluminum profiles for frames, leaves, hinges, and accessories. Precisely processed and surface-treated, they ensure stability, durability, and aesthetics.

Contact us now

Features

- Structural Stability: Swing doors need sufficient load-bearing capacity and stability to avoid deformation or looseness.

- Durability: The door profiles must be highly corrosion-resistant and wear-resistant to adapt to different environmental conditions.

- Sealing Performance: Good sealing properties improve the door's soundproofing, heat insulation, and waterproof performance.

- Ease of Installation: The design of the profiles should facilitate easy installation, minimizing time and costs.

- Aesthetic Appeal: The profile design should match the overall décor style and offer multiple surface treatment options.

Application Scenarios

- Residential: Used for main entrance doors, internal partition doors, bathroom doors, etc.

- Commercial Buildings: Offices, shops, restaurants, etc., where reliable opening and closing of doors is essential.

- Public Buildings: Hospitals, schools, government agencies, etc., where high-frequency door usage is required.

Aluminum profiles for wardrobe doors

Aluminum profiles for wardrobe doors are designed for secure connections and smooth operation. Made from high-strength alloys, they undergo precise processing and surface treatment to enhance durability and aesthetics.

Contact us now

Features

- Smoothness and Durability: Wardrobe doors must operate smoothly under frequent use, and the profiles and accessories need to be highly durable.

- Space Utilization: Sliding wardrobe doors, for example, should effectively save space and meet various spatial layout needs.

- Aesthetic Appeal: The profile design must match the overall furniture style and offer diverse surface treatment options.

- Ease of Installation: The wardrobe door system must be designed for easy installation to reduce time and costs.

- Sealing Performance: Good sealing performance enhances soundproofing and dust-proofing for wardrobe doors.

Application Scenarios

- Residential: Used for various wardrobe doors, such as sliding wardrobe doors and hinged wardrobe doors.

- Commercial Spaces: Hotel room wardrobe doors, mall display cabinet doors, etc.

- Office Spaces: Office storage cabinet doors, conference room storage doors, etc.

Aluminum profiles for glass doors

Aluminum profiles for glass doors are designed to securely support and fix glass doors, ensuring a strong connection between the glass and the door frame or leaf. Made from high-strength aluminum alloys, these profiles are precisely processed and surface-treated to improve durability and aesthetics.

Contact us now

Features

- Stability and Safety: Glass door profiles must ensure the secure attachment of glass to prevent loosening or detachment, ensuring safety.

- Aesthetic Design: The profile design should harmonize with the door's overall aesthetic, enhancing the door's visual appeal.

- Ease of Installation: The profile design should allow for easy installation, reducing installation time and costs.

- Compatibility: The glass door profile must be compatible with different glass thicknesses and types to ensure structural coordination.

- Durability and Maintenance: The profile should be durable, easy to clean, and maintain, preventing loosening or damage over time.

Application Scenarios

- Residential: Used for glass sliding doors, glass swing doors, and balcony doors.

- Commercial Buildings: Display windows, office partition doors, conference room doors, etc.

- Public Buildings: Exhibition halls, libraries, hospitals, etc., where large glass doors are required.

Slim profile aluminum doors

Slim profile aluminum doors, also known as thin profile aluminum doors, are designed using thin aluminum alloy profiles to provide lightweight, modern, and efficient door solutions. Despite the thin profile, the high-strength materials and advanced design processes ensure the door's stability and durability.

Contact us now

Features

- Structural Stability: Slim profile aluminum doors must retain sufficient strength to ensure door stability despite the lightweight design.

- Aesthetic Appeal and Design: The slim design emphasizes minimalist and modern aesthetics, with the profile seamlessly fitting into the overall architectural style.

- Ease of Installation: The slim profile aluminum door system must be easy to install, minimizing installation time and cost.

- Durability: The profile should be highly corrosion-resistant and wear-resistant to withstand various environmental conditions.

- Sealing Performance: Good sealing performance enhances soundproofing, heat insulation, and waterproofing for an optimal user experience.

Application Scenarios

- High-End Residential: Used for luxury residences requiring minimalist aesthetics and lightweight doors.

- Commercial Buildings: Offices, exhibition halls, hotels, etc., where a light, modern door system is required.

- Public Buildings: Libraries, museums, conference centers, etc., where the visual effect and functionality of doors are emphasized.

- Interior Decoration: Used for interior partition doors and glass doors, enhancing the open and aesthetic feel of a space.

Aluminum french door profiles

Aluminum French door profiles are designed for double swing doors with a wide frame to support two panels. They offer an elegant appearance and excellent soundproofing, heat insulation, and waterproofing, enhancing the beauty of any home or building.

Contact us now

Features

- Structural Stability: French doors require sufficient load-bearing capacity and stability to avoid deformation or loosening.

- Aesthetic Design: The profile design should seamlessly integrate with the overall décor style, offering multiple surface finishing options.

- Sealing Performance: Good soundproofing, heat insulation, and waterproofing properties prevent external noise and weather from affecting the indoor environment.

- Ease of Installation: The French door system must be easy to install, minimizing installation time and cost.

- Durability: The door profiles need to be highly corrosion-resistant and wear-resistant to adapt to different environmental conditions.

Application Scenarios

- Terraces and Balconies: Provide ample natural light and ventilation while maintaining excellent sealing performance.

- Main Home Entry: Enhance the overall beauty and security of the home’s entrance.

- Commercial Buildings: Offices, conference rooms, etc., requiring an elegant appearance and good soundproofing.

- Public Buildings: Hotels, restaurants, etc., emphasizing high-end and elegant door systems.

Aluminum pocket door profiles

Aluminum pocket door profiles are used for doors that slide into the wall cavity, making them "disappear" into the wall when opened. This design greatly saves space, making it ideal for small rooms or areas with limited floor space. Typically used in small rooms, bathrooms, wardrobes, etc., where space efficiency is a priority.

Contact us now

Features

- Installation Difficulty: Pocket doors require sufficient wall cavity space, which may cause concerns for customers about the complexity of the installation process and the additional time and costs involved.

- Space Utilization: Customers seek pocket doors that maximize space efficiency and adapt to various spatial layout needs.

- Smooth Sliding: The door should slide smoothly, with an efficient and durable track and roller system to reduce maintenance frequency.

- Aesthetic Appeal: The profile design must align with the overall interior style, offering a variety of surface treatment options to enhance the visual impact of the door.

- Sealing Performance: Excellent soundproofing, heat insulation, and waterproof performance to improve comfort and privacy.

Applications

- Bathroom Doors: Save space while providing good privacy and sealing performance.

- Wardrobe Doors: Used in small wardrobes or closets to save space for opening the door.

- Office Partition Doors: Facilitate flexible partitioning in office spaces, enhancing space utilization.

- Small Commercial Stores: Ideal for commercial spaces where both space-saving and aesthetic design are needed.

- Small Home Rooms: Such as study rooms, storage rooms, etc., to enhance space efficiency.

Surface treatment of aluminum door frames

-

Anodized Aluminum Door Profiles

Anodized Aluminum Door ProfilesAnodizing is an electrochemical treatment process that generates a hard, corrosion-resistant oxide film (8-25μm) on the surface of aluminum door frames. This oxide film not only enhances the corrosion resistance of aluminum profiles but also provides a unique metallic feel and aesthetic appeal.

-

Powder Coated Aluminum Door Profiles

Powder Coated Aluminum Door ProfilesPowder coating is a dry spraying technique that uses electrostatic forces to evenly adhere powdered paint to aluminum profiles. The coated surface is then cured at high temperatures to form a strong, durable layer (60-80μm). Chalco’s aluminum door frames can be powder coated or fluorocarbon sprayed, with more than 200 color options available.

-

Electrophoretic Coated Aluminum Door Profiles

Electrophoretic Coated Aluminum Door ProfilesElectrophoretic coating is an electrochemical coating process in which a uniform layer is deposited on the surface of the aluminum profile to enhance its corrosion resistance and aesthetics. Under the influence of voltage, ions of the coating material move and deposit onto the aluminum profile’s cathodic surface, forming a solid, durable layer.

-

Fluorocarbon Coated Aluminum Door Profiles

Fluorocarbon Coated Aluminum Door ProfilesFluorocarbon spraying is a high-performance coating process in which fluorocarbon paint is applied to the surface of aluminum profiles, creating a weather-resistant, corrosion-resistant, and long-lasting color finish. The fluorocarbon spraying process includes strict pre-treatment and multi-layer spraying steps to ensure high coating quality and performance.

-

Wood Grain Transfer Aluminum Door Profiles

Wood Grain Transfer Aluminum Door ProfilesWood grain transfer is a surface treatment technology that reproduces realistic wood grain patterns on aluminum profiles. Through a special printing process, natural wood textures are transferred onto the aluminum surface, combining the durability of aluminum with the aesthetic appeal of wood, making it an excellent alternative for aluminum-wood composite doors and windows.

For more information on aluminum surface treatments, please visit our Ultimate Guide to Aluminum Surface Treatments.

Common alloy grades of aluminum door profiles

Aluminum door frames are typically made from 6000 series aluminum alloys, with the most common and suitable grades including 6060-T6/T66, 6061-T6, 6063-T5, and 6005-T6. These alloys are widely used in door and window manufacturing due to their excellent performance and processability.

6060 Aluminum offers high corrosion resistance and can be heat-treated to increase strength. In T6 and T66 states, 6060 alloy provides good mechanical properties, making it ideal for architectural door and window frames that require a good appearance and medium strength.

6061 Aluminum is one of the most popular and preferred aluminum alloys for door and window profiles due to its excellent corrosion resistance and mechanical properties. While it has slightly lower strength compared to other 6000 series alloys, it offers good formability, high machinability, weldability, and cold-workability. Heat treatment can further enhance its strength, making it outstanding for door and window applications.

6063 Aluminum is considered the best alloy in the 6000 series for extrusion, especially suitable for door and window profile production. Its excellent corrosion resistance and smooth surface make it an ideal choice for doors and windows. 6063 aluminum also has excellent anodizing properties and other surface treatments, making it suitable for products requiring finer appearances and durability.

6005 Aluminum has high strength and excellent fatigue resistance, making it perfect for large structural door and window frames. Its good extrusion performance makes manufacturing complex profiles easier, and it is suitable for door and window projects that require higher strength and fatigue resistance.

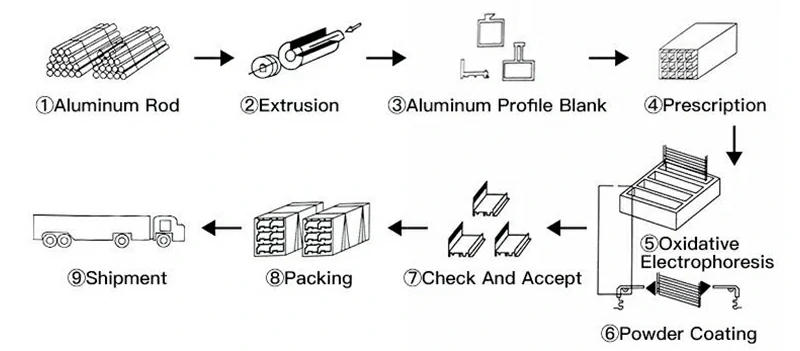

Production process of aluminum door profiles

Our aluminum door frame production process strictly adheres to the ISO 9001 Quality Management System, encompassing the following steps:

- Extrusion Billets: All aluminum billets used for door and window frame extrusion strictly comply with EN 573 chemical composition requirements to ensure the basic quality of the products. Each batch undergoes chemical composition analysis and physical performance testing to ensure conformity.

- Extrusion Molding: Aluminum profiles are extruded using high-precision equipment to ensure size tolerance within ±0.05 mm. Advanced molds and extrusion techniques are used to ensure uniform profile dimensions and smooth, defect-free surfaces.

- Heat Treatment: The extruded aluminum profiles undergo heat treatment to improve mechanical properties, increasing their strength and toughness.

- Surface Treatment: Aluminum profiles undergo anodizing, powder coating, and wood grain transfer surface treatments to enhance their corrosion resistance and aesthetic appeal. Anodizing gives the profiles a long-lasting color, powder coating provides a range of color options, and wood grain transfer creates a wood-like decorative effect.

- Final Inspection: Aluminum profiles undergo rigorous checks for mechanical properties, surface finish, and dimensional accuracy to ensure the quality meets customer requirements. This includes tensile strength testing, bending tests, and surface defect detection to ensure every profile meets quality standards.

Advantages of aluminum as a door frame material

- Outstanding Durability: Aluminum is corrosion-resistant, rust-resistant, and warp-resistant, ensuring that the door frame maintains good condition in various environments without fading or decaying over time.

- Energy Efficiency: Aluminum door frames can be equipped with thermal break technology, helping buildings stay warm in winter and cool in summer, improving overall energy efficiency and reducing energy consumption.

- Lightweight Design: Aluminum is lightweight but strong, making it easy to install and reducing the load on building structures, which enhances construction efficiency and convenience.

- Design Versatility: Aluminum can be treated with various surface treatments (such as anodizing, powder coating, wood grain transfer, etc.) to achieve a wide range of colors and finishes, meeting different architectural styles and design requirements.

- Low Maintenance Cost: Aluminum door frames have smooth surfaces, are easy to clean, and require minimal maintenance, saving time and costs over the long term.

Why choose chalco's aluminum door profiles?

Choosing Chalco aluminum door profiles ensures you receive high-precision, high-quality, environmentally-friendly, and market-competitive aluminum door solutions.

1. Certified Quality Assurance

Chalco's aluminum door profiles are ISO 9001 and ISO 14001 certified, ensuring that our products meet international standards for quality and environmental management. We guarantee that every aluminum door profile adheres to strict quality requirements, helping customers enhance their brand image and product competitiveness.

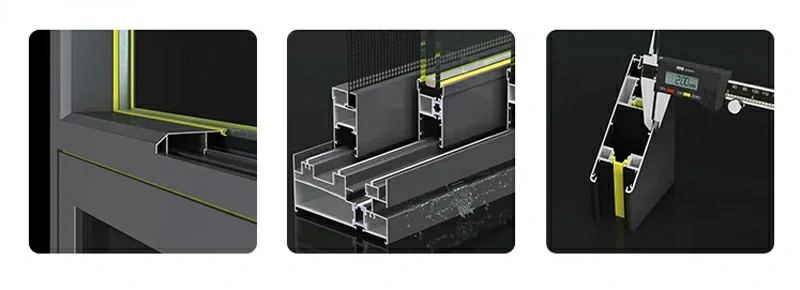

2. Precise Manufacturing Process

We employ advanced production technology, with over 10 extrusion production lines, 2 powder coating lines, and 1 wood transfer line. Our highly automated equipment ensures an efficient and precise manufacturing process. We follow an "ultra-high precision" standard, controlling dimensional tolerances to within ±0.05mm, ensuring each product meets perfect specifications.

3. Zero Waste, Zero Defects Quality Control

Chalco implements a strict "8S" management method during production and quality control to minimize waste and eliminate defects. We strive for every aluminum door profile to be flawless, ensuring customer satisfaction and zero complaints globally.

4. Technologically Advanced, Meeting Diverse Needs

We apply international advanced technologies in profile design, mold development, extrusion, powder coating, and wood transfer. Our strong R&D and technical support capabilities allow us to meet the personalized needs of different customers. Additionally, our production lines can handle large-scale orders, with an annual production capacity of up to 30, 000 tons.

5. Eco-friendly and Sustainable

Chalco is committed to producing environmentally friendly aluminum door profiles using green manufacturing processes. We focus not only on the functionality and aesthetics of our products but also on their environmental impact, ensuring that every step meets sustainable development standards.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Aluminum Door Profiles - The Ultimate Guide

- What are the standard requirements for aluminum door profiles?

- What are the common specifications of aluminum door profiles?

- Can aluminum door profiles support the weight of large glass doors?

- How to choose the surface treatment for aluminum door profiles?

- How to select the color of aluminum door frames?

- What are the application fields of aluminum door profiles?

- How to improve the energy efficiency of aluminum door profiles?

- Are aluminum door profiles compatible with other building materials?

- What are the connection methods for aluminum door profiles?

- Are aluminum door profiles environmentally friendly?

- How do aluminum door profiles perform in extreme weather conditions?

- What is the durability of aluminum door profiles?

- How to ensure the quality of aluminum door profiles?

- What is the minimum order quantity for aluminum door profiles?

- What factors affect the price of aluminum door profiles?

- What is the typical delivery time for aluminum door profiles?

- How to order and install aluminum door frames?

What are the standard requirements for aluminum door profiles?

Aluminum door frames need to meet the standards of both aluminum alloys and door/window performance to ensure high-quality and long-term reliability in terms of dimensional accuracy, mechanical performance, corrosion resistance, and door/window functionality.

Aluminum Alloy Standards

- EN 755-1: 2016 "Aluminum alloy extruded profiles - Part 1: Manufacturing methods and inspection requirements"

- EN 12020-2: 2001 "Aluminum alloy extruded profiles - Part 2: Corrosion resistance"

- EN 13115: 2001 "Aluminum alloy window and door frames - Structural requirements"

Door/Window Performance Standards

- EN 13126-8: 2011 "Mechanical durability requirements for windows and doors"

- EN 16034: 2014 "Thermal insulation performance of external windows and doors"

- EN 12210: 2000 "Wind pressure performance test for external windows"

- EN 12207: 2000 "Air permeability test for external windows"

- EN 12208: 2000 "Water tightness test for external windows"

These standards ensure that aluminum door profiles provide excellent mechanical properties, weather resistance, and meet the modern architectural demands for safety, energy efficiency, and environmental sustainability.

What are the common specifications for aluminum door profiles?

Aluminum door profiles are generally specified by the cross-sectional height of the profile, forming different size series. Common specifications include:

- Section Dimensions: 70 series, 80 series, 90 series, 100 series, etc., with a wall thickness generally not less than 1.6mm.

- Structural Components: Door frame profiles, door threshold profiles, door track profiles, etc.

- Special Profiles: Such as thermal break aluminum profiles, airtight sealing profiles, sliding door profiles, casement door profiles, folding door profiles, frameless door profiles, conservatory profiles, etc. The model depends on the specific design.

Choosing the right profile specification requires considering the size of the doors/windows, opening mechanism, performance requirements, and aesthetics.

Can aluminum door profiles support the weight of large glass doors?

Yes, Chalco’s aluminum door frames are made from high-strength, high-quality 6000 series primary aluminum, offering excellent strength and stability. These profiles can support large glass panels and heavy-duty doors, ensuring structural integrity and safety. They are ideal for projects requiring wide openings and high stability, such as frameless glass doors and ultra-narrow sliding doors, which are some of our specialty products.

How to choose the surface treatment for aluminum door frames?

The choice of surface treatment depends on your design requirements and the environment in which the aluminum door frames will be used.

- Anodizing is suitable for applications requiring a metallic feel and high corrosion resistance.

- Powder coating offers a wide range of color options and excellent weather resistance.

- Electrophoretic coating is ideal for complex profiles requiring uniform, durable coatings.

- Fluorocarbon spraying is perfect for high-end and harsh environments.

- Wood grain transfer satisfies the need for a natural, high-end decorative effect.

How to select the color of aluminum door frames?

The color of aluminum door extrusions can be chosen according to the overall architectural style of the building.

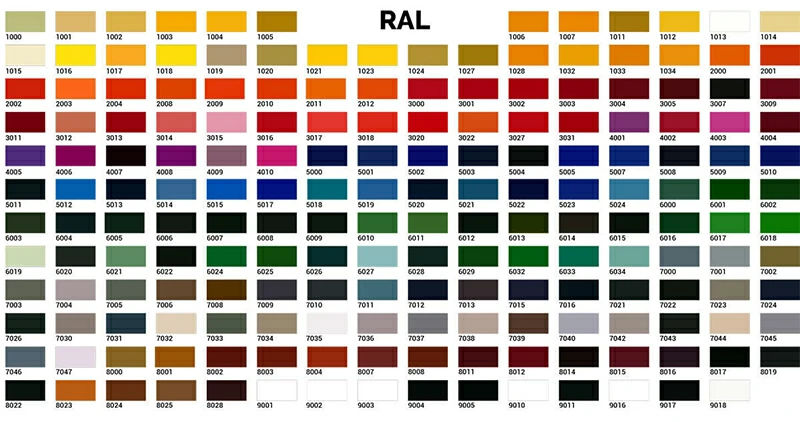

We offer more than 200 colors in powder coating, including common colors like standard white, graphite black, anthracite grey, dove grey, ivory cream, van dyke brown, silver, bronze, and champagne.

If these standard colors do not meet your needs, we can also customize any color from the RAL color chart to match your project's design.

What are the application fields of aluminum door and window profiles?

Aluminum door and window profiles have a wide range of applications, including:

- Residential Buildings: Used to manufacture various types of doors, windows, conservatories, curtain walls, railings, etc., enhancing the comfort and aesthetic appeal of living spaces.

- Commercial Buildings: Applied in office buildings, shopping malls, hotels, and other commercial spaces for doors, windows, partitions, curtain walls, etc., meeting the demands for high strength and durability.

- Industrial Buildings: Used in factories and warehouses for doors, windows, ventilation openings, etc., offering excellent corrosion resistance and weathering performance.

- Furniture Manufacturing: Used to make wardrobe doors, cabinet doors, office partitions, etc., combining both functionality and aesthetics.

How to improve the energy efficiency of aluminum door and window profiles?

To enhance the energy efficiency of aluminum door and window profiles, the following measures can be taken:

- Adopt Thermal Break Technology: Chalco inserts thermal break strips in the middle of aluminum door profiles, reducing the U-value and blocking the transfer of heat and cold, thus improving insulation performance.

- Use Energy-Efficient Glass: Employ Low-E glass, double-glazed glass, and other high-performance glass to reduce heat loss.

- Strengthen Sealing: Use high-quality PA66 sealing materials to prevent air leakage and improve airtightness.

- Optimize Design: Based on the climate conditions of the building's location, choose suitable profile structures and glass configurations.

- Professional Installation: Ensure quality installation to avoid energy loss caused by improper installation.

Can aluminum door frames be compatible with other building materials?

Yes, Chalco’s aluminum door frames can seamlessly integrate with glass, wood, various hardware fittings, and other building materials, ensuring structural coordination and aesthetic appeal. The flexible design and high compatibility make them suitable for various complex architectural and renovation projects.

What are the connection methods for aluminum door and window profiles?

There are three main methods for connecting aluminum door and window profiles:

Mechanical Connection: Using screws, corner braces, expansion bolts, and other fasteners to connect profiles and accessories. This method is simple, reliable, and easy to install and maintain.

Welded Connection: Using arc welding, TIG welding, and other welding techniques to melt the aluminum profiles into one solid unit, forming a high-strength, seamless connection. However, welding requires specialized skills and may affect the surface treatment of the profiles.

Adhesive Connection: Using structural adhesives or bonding agents to glue the profile components together. This method is suitable for applications requiring high aesthetic standards, but the bonding strength is dependent on the adhesive’s performance and strict construction conditions.

Are aluminum door profiles environmentally friendly?

Yes, aluminum profiles have excellent recyclability and meet modern environmental requirements. Our production processes focus on reducing energy consumption and waste emissions to ensure products meet environmental standards.

- Recyclability: Aluminum profiles are 100% recyclable, and their performance remains unchanged after recycling, reducing resource waste.

- Reduced Energy Consumption: High-performance aluminum alloy doors and windows provide excellent thermal insulation and sealing, reducing energy consumption and carbon emissions in buildings.

- Eco-Friendly Production Processes: Modern aluminum production processes emphasize environmental protection, reducing emissions of waste gases, wastewater, and solid waste.

As a leading aluminum supplier in China, Chalco maintains high environmental standards to further ensure the eco-friendliness of its products.

How do aluminum door frames perform in extreme weather conditions?

Chalco's aluminum door frames are made from high-strength 6000 series aluminum. According to your project needs, we can customize aluminum door frames up to 2.0mm thick, ensuring outstanding performance in extreme weather conditions, with excellent wind pressure resistance and waterproof performance.

Whether in high-wind environments in high-rise buildings or in humid, high-temperature conditions, Chalco’s aluminum door frames maintain structural stability and aesthetic appeal, ensuring long-term reliability of the door and window system.

What is the durability of aluminum door profiles?

Chalco's aluminum door frames are highly durable, offering corrosion resistance, rust prevention, and warp resistance. They are not prone to rotting or fading, ensuring they maintain excellent condition over the long term in various climate conditions. This makes them particularly well-suited for high-rise buildings and extreme weather environments.

How to ensure the quality of aluminum door profiles?

To ensure the quality of aluminum door profiles, consider the following key factors:

- Choose a Reliable Supplier: Suppliers with professional qualifications and good reputation are more likely to provide high-quality products.

- Check Certifications and Test Reports: Ensure that the products meet international and industry standards, such as ISO certification, CE certification, etc.

- Material Inspection: Pay attention to the chemical composition, mechanical performance, and dimensional accuracy of the profiles, and conduct third-party testing if necessary.

- Surface Treatment Quality: Inspect the surface for smoothness, absence of scratches, bubbles, color discrepancies, and other defects.

- Batch Consistency: Ensure consistent product quality across different batches to avoid quality variation that could impact construction and usage.

What is the Minimum Order Quantity (MOQ) for aluminum door profiles?

Generally, the Minimum Order Quantity (MOQ) for aluminum door profiles is 500 kg per model. However, the MOQ may vary depending on the supplier and customization requirements. It is recommended to contact us directly for accurate MOQ and pricing information. Quick Quote

What factors affect the price of aluminum door profiles?

The price of aluminum door frames is mainly influenced by the following factors:

1. Raw Material Costs: Fluctuations in the price of aluminum ingots directly affect the base cost of the profiles.

2. Profile Specifications and Complexity: The more complex the profile cross-section and the larger the size, the higher the production difficulty and material consumption, which leads to higher costs.

3. Surface Treatment Processes: Different surface treatment methods (such as anodizing, powder coating, fluorocarbon coating, etc.) come with varying costs. The more complex the treatment process, the higher the price.

4. Order Quantity: Bulk orders typically offer more competitive pricing. The larger the order, the lower the unit cost.

5. Transportation and Logistics Costs: Shipping distance and method can affect the final delivery price.

What is the typical delivery time for aluminum door profiles?

The delivery time for aluminum door profiles depends on the following factors:

- Product Type: Standard profiles have a shorter production cycle, typically between 15 to 25 days. Custom profiles may require a longer production time.

- Order Quantity: Large orders may require more time for production and delivery.

- Production Scheduling: The supplier's production schedule and current order volume will impact delivery time.

- Logistics and Shipping: Shipping distance and methods will also influence the delivery cycle.

It is recommended to confirm the delivery date with the supplier before placing the order and allow sufficient time to meet project deadlines.

How to order and install aluminum door frames?

To order aluminum door frames, you will need to provide the door frame dimensions and design requirements.

We offer detailed technical support and installation guides to ensure smooth installation of aluminum door frames.

Once your order is confirmed, we will produce and arrange logistics on time to ensure timely delivery.

During installation, we recommend that a professional craftsman handle the installation to ensure secure connections and optimal performance of the door frame.

Contact us now for customized aluminum door profile solutions

Contact us now to learn more about the applications, customization options, and pricing of aluminum door profiles. You can also visit our product page for more details. Let our expert team help you find the best aluminum door profile solutions for your project!

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote