Aluminum window profiles have become the preferred choice in modern construction due to their light weight, high strength, excellent corrosion resistance, and diverse design options. Whether you are looking for energy-efficient thermal aluminum window profiles or high-end, aesthetically pleasing wood grain transfer aluminum window profiles, our aluminum window profiles meet both performance and aesthetic requirements.

After reading this article, you will understand:

Chalco boasts an extensive aluminum supply chain system, offering custom aluminum window profiles and OEM/ODM services for finished aluminum doors and windows. If you prefer to purchase finished aluminum doors and windows, our professional design team can provide you with a one-stop aluminum door and window solution.

What are the types of aluminum alloy window frames?

Based on structure and performance, aluminum window profiles can be categorized as follows:

Standard Aluminum Window Profiles

Standard aluminum window profiles are formed by high-temperature extrusion of aluminum billets that are suitable for extrusion, followed by various surface treatments. Their structure is relatively simple, and the window frame cross-section is thin. They are primarily used for indoor areas or regions where additional thermal insulation is not required. These profiles are suitable for general residential and commercial buildings.

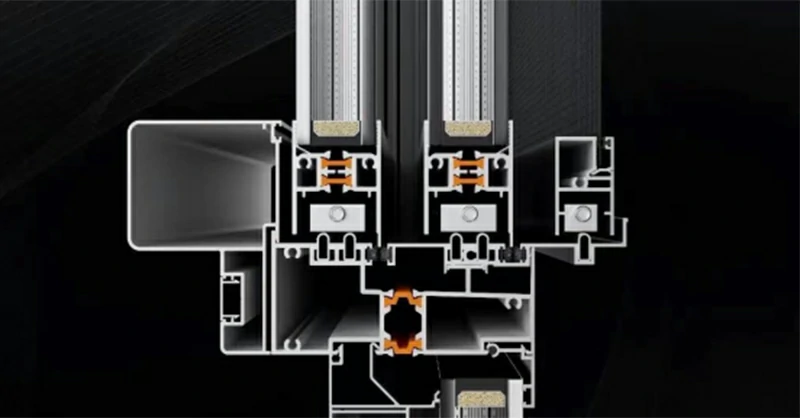

Thermal Break Aluminum Window Profiles

Thermal break aluminum window profiles, also known as thermal bridge aluminum, consist of ordinary aluminum profiles for both the inner and outer layers, with a middle layer of polyamide thermal insulation material. This "thermal break” structure significantly reduces heat conduction, making it an ideal choice for energy-efficient buildings, especially in cold or hot climates. These profiles effectively improve a building's energy efficiency rating.

Aluminum-Wood Composite Window Profiles

Aluminum-wood composite profiles are made primarily of aluminum with an inner layer of composite wood. The wood serves as an interior decorative element and enhances insulation properties. The aluminum-wood composite structure combines the natural beauty of wood with the high durability of aluminum, making it a high-end window profile. These profiles are often used in projects that demand an elegant appearance and require adaptability to different climates.

Aluminum Window Frame Profiles

Aluminum window frame profiles are used to create aluminum window frames, which form the structural foundation of windows. With high strength and corrosion resistance, these profiles effectively support glass and ensure the stability of the window. Aluminum window frame profiles are suitable for various architectural styles and offer good thermal and acoustic insulation. They are widely used in both residential and commercial buildings.

Aluminum Sill Profiles

Aluminum sill profiles are used to support the bottom of the window, serving both aesthetic and waterproof functions by preventing moisture from penetrating indoors. They have excellent weather resistance and corrosion properties, making them suitable for various climates. Aluminum sill profiles are designed with strength and protective capabilities, perfectly complementing the window frame and enhancing the overall performance of the window.

Aluminum Glazing Bead Profiles

Aluminum glazing bead profiles are used to secure window glass in place. They work with the window frame to ensure that the glass is firmly fixed. These profiles not only provide support but also effectively prevent air and moisture infiltration. Aluminum glazing bead profiles are highly durable, corrosion-resistant, and can be enhanced with surface treatments to improve aesthetic appeal, making them ideal for modern aluminum window systems.

Aluminum Window Trim Profiles

Aluminum window trim profiles are used for the decorative edging of windows, enhancing the window's appearance and overall aesthetics. These profiles cover the gap between the window frame and wall, while also offering waterproof and dustproof functions. Aluminum window trim profiles have excellent wind pressure resistance and corrosion resistance, making them suitable for various architectural styles and increasing the visual appeal of windows.

Common alloy grades of aluminum window profiles

Aluminum door frames are typically made from 6000 series aluminum alloys, with the most common and suitable grades including 6060-T6/T66, 6061-T6, 6063-T5, and 6005-T6. These alloys are widely used in door and window manufacturing due to their excellent performance and processability.

6060 Aluminum offers high corrosion resistance and can be heat-treated to increase strength. In T6 and T66 states, 6060 alloy provides good mechanical properties, making it ideal for architectural door and window frames that require a good appearance and medium strength.

6061 Aluminum is one of the most popular and preferred aluminum alloys for door and window profiles due to its excellent corrosion resistance and mechanical properties. While it has slightly lower strength compared to other 6000 series alloys, it offers good formability, high machinability, weldability, and cold-workability. Heat treatment can further enhance its strength, making it outstanding for door and window applications.

6063 Aluminum is considered the best alloy in the 6000 series for extrusion, especially suitable for door and window profile production. Its excellent corrosion resistance and smooth surface make it an ideal choice for doors and windows. 6063 aluminum also has excellent anodizing properties and other surface treatments, making it suitable for products requiring finer appearances and durability.

6005 Aluminum has high strength and excellent fatigue resistance, making it perfect for large structural door and window frames. Its good extrusion performance makes manufacturing complex profiles easier, and it is suitable for door and window projects that require higher strength and fatigue resistance.

Surface treatments for aluminum window profiles

Chalco offers a variety of surface treatments for aluminum window profiles. Below are some common surface treatments. For more information on PVDF, electrophoretic coating, and other surface finishes, please check our aluminum material surface treatments.

Anodized Aluminum Window Profiles

Anodizing creates a hard, corrosion-resistant oxide layer on the surface of aluminum window profiles, which not only enhances corrosion resistance but also gives the profile a metallic, aesthetic finish. Common colors include black, white, brown, silver, and more. Anodized film thickness: 7-23μm

Spray Coated Aluminum Window Profiles

Chalco’s aluminum window profiles feature powder or fluorocarbon coatings in over 200 colors, offering excellent weather resistance and UV protection for diverse architectural styles. Powder coating thickness: 60-80μm

Wood Grain Transfer Aluminum Window Profiles

Wood grain transfer technology gives aluminum window profiles a realistic wood texture, combining aluminum's durability with wood's aesthetic appeal. Ideal for high-end decorative projects, it offers a perfect alternative to aluminum-wood composite windows.

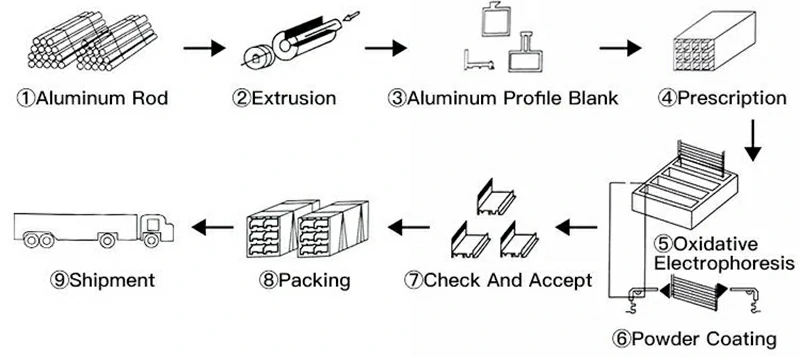

Production process of aluminum window profiles

Our aluminum door frame production process strictly adheres to the ISO 9001 Quality Management System, encompassing the following steps:

- Extrusion Billets: All aluminum billets used for door and window frame extrusion strictly comply with EN 573 chemical composition requirements to ensure the basic quality of the products. Each batch undergoes chemical composition analysis and physical performance testing to ensure conformity.

- Extrusion Molding: Aluminum profiles are extruded using high-precision equipment to ensure size tolerance within ±0.05 mm. Advanced molds and extrusion techniques are used to ensure uniform profile dimensions and smooth, defect-free surfaces.

- Heat Treatment: The extruded aluminum profiles undergo heat treatment to improve mechanical properties, increasing their strength and toughness.

- Surface Treatment: Aluminum profiles undergo anodizing, powder coating, and wood grain transfer surface treatments to enhance their corrosion resistance and aesthetic appeal. Anodizing gives the profiles a long-lasting color, powder coating provides a range of color options, and wood grain transfer creates a wood-like decorative effect.

- Final Inspection: Aluminum profiles undergo rigorous checks for mechanical properties, surface finish, and dimensional accuracy to ensure the quality meets customer requirements. This includes tensile strength testing, bending tests, and surface defect detection to ensure every profile meets quality standards.

Secondary processing services for aluminum window profiles

- Drilling: Drilling is the process of creating round cross-sectional holes in aluminum window profiles using a drill bit, typically used for installing bolts or other fasteners. This process is precise and efficient, ideal for profiles requiring high accuracy.

- Milling: Milling is a machining process where a rotating cutter removes material from the aluminum window profile to form specific shapes or create holes, typically used for complex connection parts.

- Cutting to Size: We offer cutting, sawing, and precise 45-degree cutting, accurately reducing the length of aluminum window profiles. This service is suitable for custom applications to ensure the profiles meet project requirements.

- Stamping: Stamping is the process of placing aluminum profiles into a stamping press, where tools and molds shape the material into the desired net shape. This process is ideal for mass production of identical parts, suitable for large-scale door and window manufacturing.

- Welding: Welding is a manufacturing method that uses high temperatures to fuse different materials together. Once cooled, the parts form a complete assembly. Welding is common in the manufacturing of aluminum window frames, particularly in areas requiring high-strength connections.

- Bending: Bending involves creating U-shaped, V-shaped, or other desired forms along a straight axis of the aluminum profile. This process is commonly used for custom curved designs in windows and doors to meet specific building requirements.

- Assembly: Assembly refers to combining various aluminum window profiles and other components to form a complete window frame or assembly. This process emphasizes precision fitting to ensure the stability and functionality of the final product.

- CNC Machining: CNC (Computer Numerical Control) machining involves precise cutting, drilling, or milling of aluminum window profiles controlled by a computer. CNC machining ensures each part meets highly consistent specifications and is ideal for complex structures and projects requiring high precision.

Quality assurance for chalco aluminum window profiles

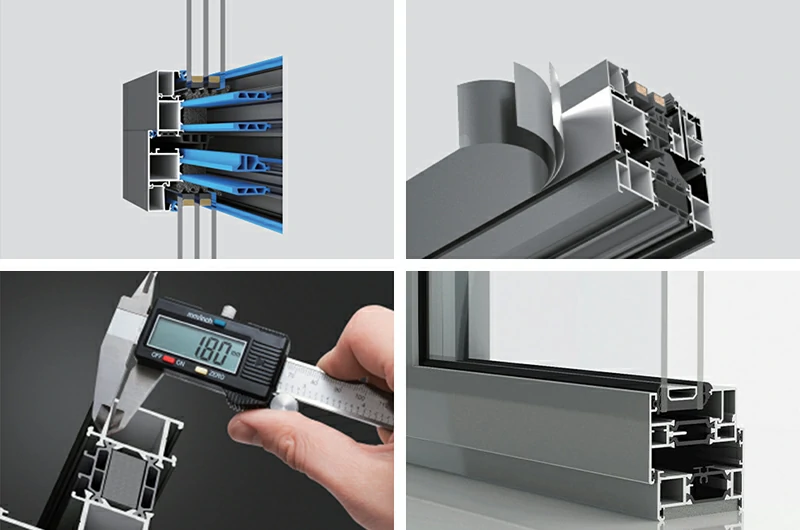

Chalco's aluminum window profiles strictly follow the ISO 9001 quality management system standards to ensure that products meet industry regulations in terms of raw materials, dimensional accuracy, surface quality, mechanical properties, and thermal performance.

Through comprehensive quality control processes, Chalco is committed to providing high-performance, durable, and energy-efficient aluminum window profiles.

- Raw Material Inspection: All extrusion billets used must meet the EN 573 standard to ensure their composition and purity meet the required specifications, avoiding material instability or non-compliance during the extrusion process.

- Dimensional Accuracy Control: During the extrusion of aluminum window profiles, continuous monitoring of dimensional accuracy is essential. Even slight deviations can affect the structural strength and performance of the profiles, so each batch undergoes stringent dimensional checks to ensure compliance with design specifications.

- Surface Quality Inspection: The surface of aluminum window profiles must be free of visible scratches, dents, or other visual defects. Through surface smoothness inspection, we ensure that the coating is uniform and reaches the required thickness, enhancing corrosion resistance and weather resistance to meet long-term usage demands.

- Mechanical Performance Testing: Aluminum window profiles undergo mechanical performance tests, including stress and elasticity tests, to verify their strength under various load conditions. This ensures that the profiles can withstand the intended loads and maintain safety and stability in actual applications.

- Thermal Performance Testing: Especially for thermal break aluminum window profiles, thermal performance testing is essential. The profiles must undergo thermal isolation tests to ensure they offer excellent thermal insulation properties, meeting energy-saving and environmental standards, and effectively improving building energy efficiency.

Applications of aluminum window profiles

Residential Buildings: Aluminum window profiles provide strong yet aesthetically pleasing solutions for window frames, ensuring home safety. With diverse designs, aluminum window profiles can meet the needs of various residential styles, from traditional casement windows to modern sliding windows.

Commercial Buildings: Sliding window profiles are perfect for modern office buildings and shopping malls, providing ample natural light. Aluminum window profiles can be combined with large glass panels to create a high-end, sophisticated visual effect, enhancing the commercial value of the building.

Public Facilities: Skylights and canopy windows are widely used in public places like libraries and museums to increase natural light, while reducing dependence on electric lighting, contributing to energy conservation and environmental protection.

Advantages of aluminum as a window frame material

Lightweight and High Strength: Aluminum is renowned for its high strength-to-weight ratio, making it resistant to deformation and ensuring the long-term durability of windows. The lightweight nature of aluminum profiles reduces the load on building structures and makes installation easier.

Corrosion Resistance: Aluminum is naturally corrosion-resistant. After anodizing and powder coating, its corrosion resistance is further enhanced, making it suitable for humid and rainy environments. Anodizing forms a hard protective layer on the aluminum surface, boosting its resistance to corrosion and extending its lifespan.

Thermal Insulation: Thermal break aluminum profiles reduce heat transfer, helping maintain stable indoor temperatures and lowering energy costs. By adding thermal insulation materials within the aluminum profiles, they effectively separate internal and external temperature differences, making them an ideal choice for energy-efficient buildings.

High Malleability: Aluminum alloy materials are easy to process, allowing custom designs based on specific customer needs. A wide variety of shapes and surface treatment options are available.

Low Maintenance: The non-porous surface of aluminum window profiles makes them easy to clean, requiring only a simple wipe. Aluminum does not rust or warp, and its low maintenance cost makes it perfect for long-term use in building projects.

Why choose Chalco's aluminum window profiles?

Choosing Chalco Aluminum Window Profiles ensures you receive high-precision, high-quality, environmentally-friendly, and market-competitive aluminum door solutions.

1. Certified Quality Assurance

Chalco's Aluminum Window Profiles are ISO 9001 and ISO 14001 certified, ensuring that our products meet international standards for quality and environmental management. We guarantee that every aluminum door profile adheres to strict quality requirements, helping customers enhance their brand image and product competitiveness.

2. Precise Manufacturing Process

We employ advanced production technology, with over 10 extrusion production lines, 2 powder coating lines, and 1 wood transfer line. Our highly automated equipment ensures an efficient and precise manufacturing process. We follow an "ultra-high precision" standard, controlling dimensional tolerances to within ±0.05mm, ensuring each product meets perfect specifications.

3. Zero Waste, Zero Defects Quality Control

Chalco implements a strict "8S" management method during production and quality control to minimize waste and eliminate defects. We strive for every aluminum door profile to be flawless, ensuring customer satisfaction and zero complaints globally.

4. Technologically Advanced, Meeting Diverse Needs

We apply international advanced technologies in profile design, mold development, extrusion, powder coating, and wood transfer. Our strong R&D and technical support capabilities allow us to meet the personalized needs of different customers. Additionally, our production lines can handle large-scale orders, with an annual production capacity of up to 30, 000 tons.

5. Eco-friendly and Sustainable

Chalco is committed to producing environmentally friendly Aluminum Window Profiles using green manufacturing processes. We focus not only on the functionality and aesthetics of our products but also on their environmental impact, ensuring that every step meets sustainable development standards.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Aluminum Window Profiles - The Ultimate Guide

- What is the wall thickness standard for aluminum alloy window profiles?

- How important is the thickness of aluminum window extrusions?

- What standards should aluminum window profiles generally meet?

- Are aluminum window profiles suitable for large-sized windows?

- What grade of aluminum alloy is typically used for window frames?

- How are aluminum window profile frames assembled?

- How to choose the color for aluminum window extrusions?

- What advantages do aluminum window frames have over uPVC window frames?

- What advantages do aluminum window frames have over wooden window frames?

- Is your window losing heat... and increasing your electricity bills?

- What is a thermal break? What are the common types of thermal breaks?

- How is the thermal performance of Chalco aluminum window profiles?

- What is LOW-E glass? What are its benefits?

- What standards does aluminum window profile insulation meet?

- Are aluminum window profiles suitable for coastal projects?

- How to maintain aluminum window profiles?

What is the wall thickness standard for aluminum alloy window profiles?

The wall thickness of aluminum alloy window profiles for outward-opening windows should not be less than 1.8mm, while inward-opening windows should have a minimum thickness of 1.4mm. For high-rise buildings, it is recommended to increase the thickness of the profiles. Typically, if the window or door exceeds 3-4 square meters, the profile thickness can be increased, or additional posts can be added to enhance physical strength.

How important is the thickness of aluminum window extrusions?

The thickness of aluminum window extrusions directly affects the window's thermal insulation properties, strength, and durability. Thicker aluminum extrusions provide better thermal resistance, enhancing overall insulation and reducing energy consumption. Moreover, thicker profiles increase the structural strength of the window, ensuring its stability under harsh weather conditions, making them particularly suitable for large window structures.

What standards should aluminum window profiles generally meet?

Aluminum window profiles need to meet two major categories of standards: aluminum alloy and window and door standards.

Firstly, aluminum profiles must comply with standards like EN 755, EN 12020, EN 13988, and EN 1396, ensuring precision, mechanical properties, and corrosion resistance.

Secondly, aluminum window profiles must adhere to window performance standards, such as EN 13115, EN 12210, EN 13126, and EN 12567, to ensure wind pressure resistance, air tightness, and thermal insulation performance, meeting safety and energy efficiency requirements.

These standards guarantee high-quality and reliable aluminum window profiles.

Are aluminum window profiles suitable for large-sized windows?

Yes, aluminum window profiles are highly suitable for large-sized windows.

Aluminum alloys in the 6000 series are commonly used for window frames due to their high strength and excellent extrusion properties, which can bear larger loads and offer excellent weather resistance. Aluminum material can typically be customized for window frames up to 4 meters in length without worrying about deformation, whereas PVC frames may only support up to 2.5-3 meters.

Compared to uPVC windows, aluminum windows have stronger rigidity and can support larger panes of glass, making them ideal for buildings that require large views, such as commercial buildings and exhibition halls.

What grade of aluminum alloy is typically used for window frames?

Chalco primarily uses 6000 series aluminum alloys for manufacturing window frames, including 6063, 6060, 6061, and 6005 alloys. The most popular alloys for window frame extrusions are 6063 and 6061.

Generally, 6063 aluminum is widely used for window and door profiles due to its good corrosion resistance and formability. On the other hand, 6061 aluminum alloy, known for its higher strength, is used in applications that require greater mechanical performance. These alloys offer good weldability and machinability, making them ideal for window and door manufacturing.

How are aluminum window profile frames assembled?

The assembly of aluminum window profile frames mainly involves cutting, drilling, connecting, and final assembly. The precision of each step is crucial to ensure the structural strength and long-term durability of the window. For a detailed step-by-step guide on assembling aluminum window frames, please refer to our Aluminum Window Frame Assembly Step-by-Step Guide.

How to choose the color for aluminum window extrusions?

The color selection for aluminum window extrusions can be made according to the overall design style of the building.

We offer over 200 powder coating colors, with common options including standard white, graphite black, anthracite grey, dove grey, ivory cream, van dyke brown, silver, bronze, champagne, etc. You can also opt for a dual-color finish, where the exterior and interior can have different colors, for example, dark grey outside and white inside.

If these standard colors do not meet your requirements, we can also customize the color based on your project’s style, offering any RAL powder-coated finish, whether single or dual-tone.

Our powder coatings are durable, with high-quality finishes that require minimal maintenance – just occasional cleaning with a sponge.

White(9910 Gloss)

Black (9005 Matt)

Dark Grey(7016 Matt)

Dove Grey (7035 Semi Gloss)

Ivory Cream(1015 Semi-Gloss)

Brown(8017 Matt)

What advantages do aluminum window frames have over uPVC window frames?

Aluminum windows and uPVC windows each have their own unique features in terms of aesthetics, pricing, durability, and energy efficiency.

Aluminum windows are more suitable for modern architecture, providing a sleek and stylish appearance while performing excellently in large-scale applications and over long-term use.

uPVC windows, on the other hand, have a lower initial cost and are ideal for budget-conscious customers focused on sound insulation.

For a detailed comparison of aluminum windows and uPVC windows, check out our Top 10 Differences Between Aluminum and uPVC Windows.

What advantages do aluminum window frames have over wooden window frames?

Aluminum window profiles offer greater durability compared to wooden window frames, with minimal maintenance required. Aluminum is highly corrosion-resistant and has excellent formability, making it suitable for both modern and traditional architectural styles. Furthermore, through wood grain transfer technology, aluminum profiles can mimic the natural appearance of wood but with better weather resistance and stability, making them ideal for various climates.

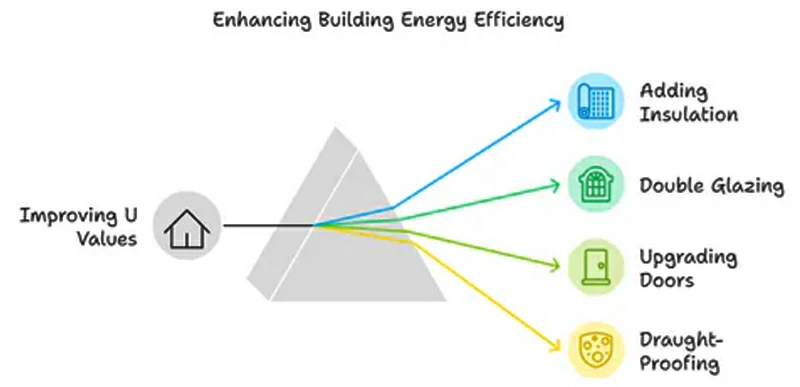

Is your window losing heat... and increasing your electricity bills?

Winter means poor ventilation, heat loss, and a cold season, not cozy evenings. The cold weather leads to higher heating bills that strain household budgets.

On average, homes in Europe lose up to 18% of their heat through windows! This means that windows account for nearly one-fifth of our heating expenses.

Chalco’s insulated aluminum windows, designed scientifically, use PA66 thermal breaks combined with double or triple-glazed glass to reduce heat loss, ensuring that cold nights become comfortable again while significantly lowering your heating costs!

What is a thermal break? What are the common types of thermal breaks?

A thermal break is a crucial component that enhances the performance of system doors and windows. It not only impacts the profile quality but also affects various performance characteristics, including wind resistance, water tightness, air tightness, thermal insulation, and heat resistance, playing a critical role in the overall quality of the system.

- PVC: Made from PVC resin powder mixed with 25% calcium carbonate, this material is lightweight and cost-effective, but it tends to age easily. Its thermal stability is poor, and it can release toxic gases when exposed to high temperatures or burned.

- PA66: This is a plastic alloy with excellent anti-aging properties, a high melting point, low thermal expansion, and outstanding heat resistance.

How is the thermal performance of Chalco aluminum window profiles?

Chalco's aluminum window profiles use a thermal break design, incorporating PA66 nylon thermal breaks inside the profiles, connecting both ends to form an insulated layer between the inner and outer profiles. This design effectively blocks heat transfer between the interior and exterior, enhancing the window’s thermal performance and reducing energy consumption. The design ensures windows have a low U-value, making them ideal for energy-efficient buildings.

What is LOW-E glass? What are its benefits?

LOW-E glass (Low Emissivity Glass) is coated with a layer that reflects ultraviolet (UV) rays, blocking outdoor heat in summer and maintaining indoor temperature in winter, offering protection for the human body. This technology helps reduce energy consumption by enhancing the thermal insulation properties of the window.

How is the insulation performance of aluminum window profiles?

One of the most important performance indicators when evaluating the energy efficiency of aluminum windows is the U-value. The U-value indicates the insulating effect of a glazing unit in both heating and cooling conditions. The lower the U-value, the better the insulation performance.

For double-glazed aluminum window profiles, the U-value typically reaches 1.4 W/m²K or lower, ensuring optimal energy efficiency for buildings. All our profiles are rigorously tested to meet the highest industry standards for thermal insulation.

Are aluminum window profiles suitable for coastal projects?

Yes, aluminum window profiles are highly suitable for coastal projects. Chalco’s aluminum profiles are treated with ultra-durable coatings or anodized to provide excellent corrosion resistance, making them capable of withstanding the high humidity and salt environments of coastal regions, ensuring that the windows maintain excellent performance and longevity even in harsh coastal conditions.

How to maintain aluminum window profiles?

Maintaining aluminum window profiles is straightforward.

Simply wipe them down with a soft cloth and a neutral cleaner, avoiding harsh acidic or alkaline chemicals.

Additionally, periodically check moving parts such as sliding devices and hinges, applying lubricant as necessary to keep them functioning smoothly.

These simple maintenance steps will effectively extend the life of your aluminum windows and ensure they maintain excellent performance over time.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote