6061 aluminum alloy welding overview

6061 is a widely used heat-treatable aluminum alloy with good strength, corrosion resistance, machinability and moderate welding performance. It is widely used in aerospace structures, automotive parts, building profiles, industrial frames, etc. In terms of welding, 6061 has obvious advantages over some difficult-to-weld aluminum alloys (such as 2xxx or 7xxx series), but its welding performance is not "worry-free".

Especially in the commonly used T6 state, the welding of 6061 aluminum alloy will be affected by "heat affected zone (HAZ) softening". Local high temperature during welding will cause partial dissolution or coarsening of the formed strengthening precipitates (such as Mg₂Si ) , thereby significantly weakening the mechanical properties of the area near the weld - both tensile strength and fatigue properties will decrease, even approaching the annealed state (O state) level.

Therefore, although 6061 has good weldability, in order to obtain a welding effect that has both reliable structural strength and beautiful welds, it is still necessary to scientifically select welding methods and welding wire materials, and supplement them with subsequent heat treatment processes when necessary.

Complete analysis of 6061 aluminum welding methods | Various welding solutions

Different welding methods are suitable for different thickness, structural form and strength requirements of 6061 aluminum alloy. Common welding methods include TIG, MIG, high frequency welding, friction stir welding (FSW), etc. Each method has its own advantages in accuracy, efficiency and heat effect control.

| Welding method | Recommendation index | Process characteristics | Application suggestions |

| TIG welding (argon tungsten arc welding) | ⭐⭐⭐⭐⭐ | Controllable heat input and fine weld seams | Precision structural parts, small equipment, aviation parts |

| MIG welding (metal inert gas welding) | ⭐⭐⭐⭐ | Fast welding speed, suitable for welding of medium and thick plates | Industrial frames, aluminum profile splicing, engineering structural parts |

| High Frequency Welding HFW | ⭐⭐⭐⭐ | No molten pool, good welding linearity, suitable for long pipes | Heat exchange tubes, condenser tubes, headers, etc. |

| Friction stir welding FSW | ⭐⭐⭐⭐⭐ | High weld strength, low deformation, no filler metal required | High-performance panels, box structures, railcar bodies |

| Laser welding / resistance welding | ⭐⭐⭐ | The weld is very small, the heat effect is very low, and the cost is higher | Thin plate precision parts, battery pack shells, aluminum-plastic connectors |

Each welding method needs to be matched with corresponding parameter settings and welding materials to achieve the ideal welding effect.

As a professional aluminum product manufacturer, Chalco not only provides a variety of aluminum alloy profiles and components, but also provides welding processing services including TIG, MIG, high-frequency welding, friction stir welding, etc. according to customer needs. It is suitable for complex application scenarios such as structural assembly and heat exchange systems. Quick Quote

6061 welding wire selection guide | Matching welding strength and process requirements

In the welding process of 6061 aluminum alloy, the choice of filler material will directly affect the quality, strength, corrosion resistance and processing performance of the weld. Chalco provides aluminum welding wires of various specifications and models, which can cover a variety of application scenarios from structural welding to appearance precision welding.

-

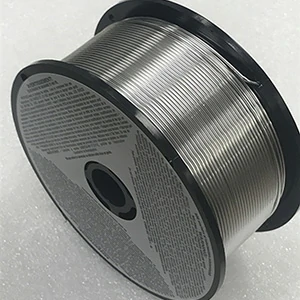

R4043 welding wire (silicon based)

R4043 welding wire (silicon based)

Features excellent crack resistance, fluidity, minimal spatter, and clean welds. Ideal for welding 6061-T6 components, thin plates, and visible seams. Easy to use with manual or automated systems, offering a cost-effective solution.

Chalco always has stock and supports customized delivery of full specifications from 0.8mm to 3.2mm.

-

ER5356 welding wire (magnesium based)

Offers higher weld strength and corrosion resistance, ideal for 6061 load-bearing structures in marine or industrial environments. Weld strength is close to the base metal, meeting demands for high mechanical performance.

Chalco supports the delivery of large-scale welding wire and is suitable for automated welding lines.

-

ER4045 welding wire (low melting point brazing wire)

ER4045 welding wire (low melting point brazing wire)

Low melting point and strong fluidity, ideal for precision brazing of heat exchangers, headers, and aluminum strip structures. Suitable for fine welding in high-end thermal systems.

Combined with Chalco composite brazing strip, a complete brazing solution can be delivered.

| Project | Applicable welding wire | Recommended instructions |

| Appearance quality first | ER4043 | Easy to use, delicate welds, suitable for non-structural parts |

| Strength First | ER5356 | High tensile strength, suitable for mechanical parts |

| No heat treatment after welding | ER5356 | No annealing required, good strength maintenance |

| Batch brazing | ER4045 / Composite Brazing Strip | Suitable for thin-walled parts and large-scale automatic welding |

Chalco not only provides high-quality welding wire materials, but also customizes alloy composition, packaging form and delivery batch according to customer project requirements, and supports various welding processes such as TIG, MIG and brazing. Please contact us to obtain welding wire selection suggestions and sample support that best matches your application scenario.Quick Quote

Hybrid brazing solutions | Low-temperature welding process for efficient connections

In addition to conventional fusion welding processes (such as TIG and MIG), **clad brazing** has become the preferred solution for connecting 6061 aluminum alloy structural parts in some applications that require higher welding deformation control, appearance consistency or batch efficiency. Its characteristics are to achieve a firm connection at a temperature lower than the melting point of the base material, avoid strength loss, and ensure dimensional stability.

Brazing is particularly suitable for:

- Integrated connection of multi-layer aluminum structures

- High-precision heat exchanger components (such as intercoolers, condensers)

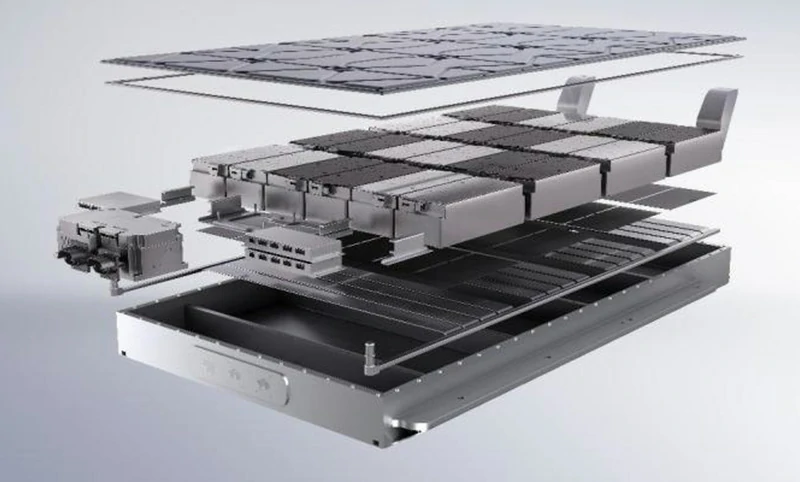

- Battery cooling module, header and internal threaded pipe system

Chalco composite brazing products (6061 aluminum base):

| Product Type | Structural form | Recommended applications | Adaptation Instructions |

| Single-sided brazing clad strip | 6061 aluminum base + one brazing layer | Heat pipe, header, heat sink connection | Suitable for symmetrical structure and simplified process flow |

| Double-sided brazing clad strip | 6061 aluminum base + upper and lower brazing layers | Shell and tube, heat exchanger core | Ensure welding symmetry and improve welding consistency |

| Three-layer composite brazing coil | Brazing layer + 6061 aluminum base + brazing layer | Flat tube, high-efficiency heat conducting parts | High-strength low-temperature connection, suitable for structural integration |

| Brazing foil and brazing sheet | Independent brazing layer, free lamination | Spot welding assistance, local reinforcement | Flexible application in welding of irregular structures |

Advantages of Chalco brazing products (6061 aluminum base):

- Integrated supply: Chalco has a complete system from brazing strip production to alloy design and strip processing;

- High matching design: the melting point, thickness and structure of the brazing layer can be customized according to 6061 welding conditions;

- Adapt to automated welding process: suitable for batch furnace brazing, roller brazing and other industrial processes;

- Can be matched with brazing wire and aluminum strip: provide overall solution to improve customer production efficiency.

Application of Chalco brazing products (6061 aluminum base):

Chalco composite brazing materials are widely used in automotive thermal management systems, HVAC air conditioning radiators, electric vehicle battery modules and other industries. We can provide matching brazing material solutions for your 6061 aluminum project, support sample development and customized mass production, and help high-performance integrated connection design.

Post-welding treatment and strength recovery solutions | Maximize the performance of 6061 welding parts

Although 6061 aluminum alloy has excellent mechanical properties in the T6 state, during the welding process, its strengthening phase (mainly Mg ₂ Si ) will be re-dissolved or coarsened due to heat input, resulting in "softening" of the weld heat affected zone (HAZ), and the local strength is even close to the O state (annealed state) level.

For welding projects with high structural strength requirements, the post-welding processing process must be reasonably designed to restore performance and ensure safety.

Common post-weld strength recovery strategies:

| Plan | Applicable situations | Advantages | Precautions |

| Overall heat treatment after welding (T6 recovery treatment) | Large structures that can be heated throughout | Good strength recovery, close to the original T6 performance | High cost, uniform heating required |

| Use T4 state before welding and ageing after welding | Controllable process projects | The overall process is consistent and easy to arrange | Material supply status needs to be customized before welding |

| Local reinforcement design | Finished structures that cannot be heat treated | Fast and controllable structure | The structure needs to reserve space and the design is complex |

| Natural Aging (T4 only) | Small or low-strength applications | No additional processing required | The strength improvement is limited and cannot replace T6 |

Chalco can provide support and cooperation services:

Although Chalco is not a full-time heat treatment processing company, we have a complete heat treatment supporting system in the manufacturing process of 6061 aluminum products. We can assist in the following according to the customer's design requirements and welding process route:

- Material pre-conditioning control (such as providing T4 state or customized annealing state feeding)

- Post-welding heat treatment process recommendations (temperature/time ratio)

- Can recommend supporting heat treatment partners (suitable for large batches/large structural parts)

Our goal is to help customers form a closed-loop solution from material selection, welding method to post-processing path , especially in industrial and engineering projects with strict requirements on post-weld strength, to provide customers with reliable technology and material support. Quick Quote

Typical application industries and welding cases | 6061 welding materials and application integrated solutions

6061 aluminum alloy has both strength, weldability and good thermal conductivity. It is widely used as a main structural material and a brazing process carrier in many industrial fields. Chalco not only supplies standard 6061 materials, but also provides integrated solutions for composite cladding, forming brazing and structural welding.

Industrial structures and equipment frames (TIG / MIG)

For example, platforms, frames, and structural joints often use 6061-T6 sheets or profiles for structural welding or component assembly. Chalco can supply 6061 extrusions, cut sheets, and welding processing services to meet rapid assembly needs.

Rail transit and aerospace structures (FSW/TIG)

In scenarios such as rail car side panels, seat supports, and connection nodes, 6061 medium and thick plates are combined with special-shaped pipes, assisted by friction stir welding (FSW) technology to achieve high-strength integrated connections.

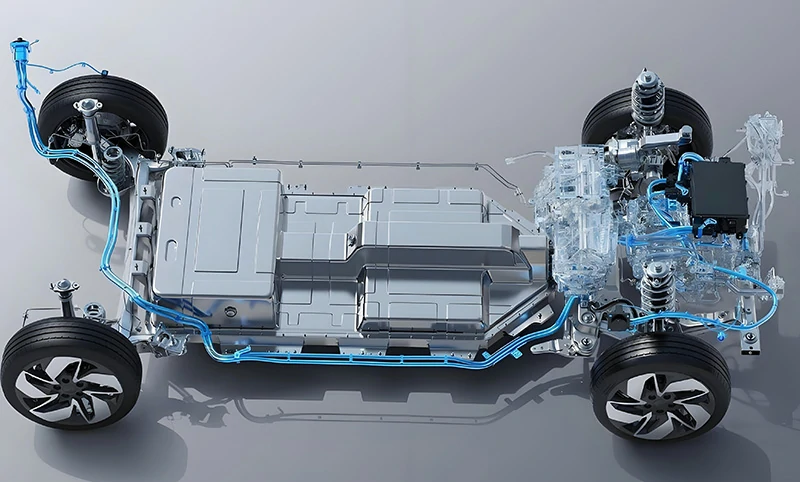

Thermal management system and brazing applications (high frequency welding/brazing)

This is a typical application area of 6061 composite brazing material. Compared with traditional high-purity aluminum, 6061 provides higher structural strength and thermal cycle stability, especially suitable for:

- Electric vehicle battery module cooling system

- Heat exchanger flat tubes, headers, high-strength fin modules

- Composite structure heat dissipation unit under high pressure

- Chalco can provide the following 6061 brazing material product portfolio

| Product type | Product form | Features |

| 6061 Composite Brazing Sheet/ Strip/ Foil/ Coil | Single-sided/double-sided/multi-layer composite | Applicable to flat tubes, cores, convection modules and other structural parts |

| 6061 composite brazing pipe | High frequency welding aluminum tube, internal thread tube | Possess excellent mechanical properties and thermal conductivity |

| 6061 Brazed Fin Stock | High strength thin strip | For heavy-duty heat exchange structures and refrigeration systems |

| 6061 composite structural parts raw material customization | Base material + cladding alloy + slitting | with automated brazing production lines |

| All products support customized thickness (0.05-5mm), width (10-1500mm) and coil/cut-to-length supply, and can be designed with cladding alloys (such as 4045, 4343, 7072, etc.) according to project conditions. | ||

As a professional aluminum product manufacturer, Chalco not only provides a variety of 6061 aluminum alloy materials, but also provides welding processing services including TIG, MIG, high-frequency welding, friction stir welding, etc. according to customer needs. It is suitable for complex application scenarios such as structural parts assembly and heat exchange systems. Quick Quote

FAQs about 6061 aluminum welding

Q1: Can 6061-T6 aluminum alloy be welded directly? Will it affect the strength?

It can be welded, but the T6 state will cause the local strength to decrease due to the softening of the heat affected zone (HAZ) during the welding process. If there are strict requirements on mechanical properties, it is recommended to perform T6 heat treatment after welding, or use T4 state welding and then artificial aging.

Q2: Which welding wire should I choose for welding 6061? ER4043 or ER5356?

If you are looking for good welding operability and crack resistance, ER4043 is recommended; if you have higher requirements for weld strength or corrosion resistance, ER5356 is recommended. Chalco can recommend a more suitable welding wire model and diameter specification based on your actual working conditions.

Q3: Can 6061 be used for brazing? Can you provide composite brazing materials?

Yes. 6061 is a high-strength, heat-treatable aluminum alloy that is widely used in brazing applications for heat exchange structures, heat pipes and other components. Chalco can supply composite brazing plates, strips, foils, tubes and fin materials based on 6061, supporting clad alloy design and batch supply.

Q4: Do you provide welding or post-processing services?

Yes. As an aluminum alloy product manufacturer, Chalco can provide welding processing services including TIG, MIG, high frequency welding, and friction stir welding according to customer needs, which are suitable for the assembly and manufacturing of various structural parts and thermal management components.

Q5: Can you provide selection suggestions for a complete set of 6061 welding projects?

Of course. We can provide customers with overall technical support from 6061 raw material selection, welding process matching, brazing solution customization to batch supply and additional processing services to help you quickly implement your project.

Get 6061 aluminum materials and welding processing services

6061 aluminum alloy is widely used in industrial structures, transportation equipment and thermal management systems due to its excellent strength, weldability and processing stability. Chalco focuses on the manufacturing and deep processing of aluminum alloy products and can provide 6061 series materials and welding processing supporting services for your project.

We can provide:

- 6061 aluminum plate, aluminum strip, aluminum foil, aluminum tube, fin and other material forms

- 6061 composite brazing materials (including brazing strips, composite welded pipes, etc.)

- Supporting welding processing services (TIG, MIG, high frequency welding, friction stir welding, etc.)

- Material customization, slitting, surface treatment and other value-added processing support

Welcome to use the form below or contact our sales engineer to obtain 6061 product specifications, sample information and welding processing cooperation details. Chalco will help you implement your project more efficiently.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote