6061 and 6063 extruded profiles: analysis of the "twin stars" in the aluminum profile industry!

Among aluminum alloy extrusion profiles, 6061 and 6063 are the two most common choices. They both belong to the 6000 series aluminum alloy, with magnesium (Mg) and silicon (Si) as the main alloying elements. They have good strength, corrosion resistance and machinability, and are therefore widely used in construction, rail transportation, industrial manufacturing, automobiles, aerospace and other fields.

Although they both belong to the 6000 series, they are different in mechanical properties, processing characteristics and application directions, so they are often compared together when selecting materials:

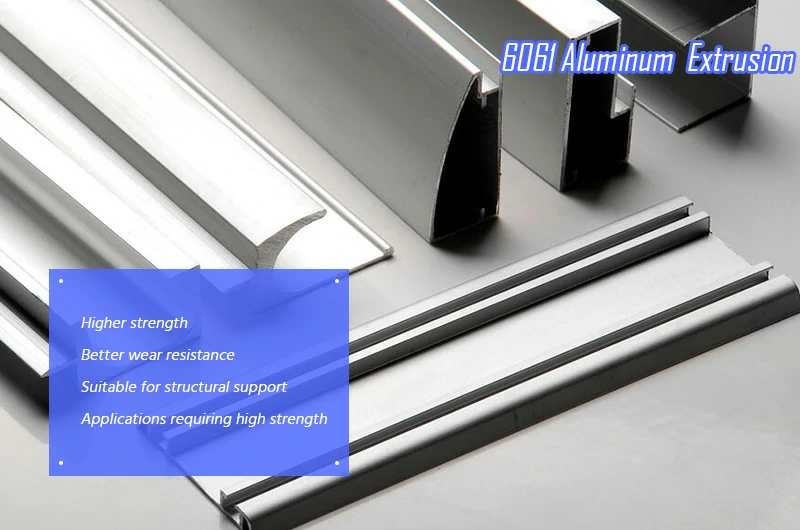

6061 Aluminum

6061 has higher strength and better wear resistance, and is suitable for applications requiring high strength such as structural support, heavy-duty machinery, and aerospace components.

Contact us now

6063 Aluminum

6063 has better extrusion performance and surface treatment effect, and is suitable for scenes with high requirements on appearance, such as building decoration, rail transportation, door and window frames, etc.

Contact us nowBecause they each have their own advantages and can complement and overlap in some applications, 6061 and 6063 are often compared together. How to make the most appropriate choice between the two? Next, we will analyze in depth from the aspects of composition, performance, processing characteristics, application fields, etc., and recommend Chalco's high-quality 6061 & 6063 aluminum extrusion profiles to help you find the product that best meets your needs.

6061 vs. 6063 chemical composition comparison

| element(%) | 6061 | 6063 |

| Si (Silicon) | 0.4 - 0.8 | 0.2 - 0.6 |

| Fe (Iron) | 0 - 0.7 | 0 - 0.35 |

| Cu (Copper) | 0.15 - 0.40 | 0 - 0.10 |

| Mn (Manganese) | 0 - 0.15 | 0 - 0.10 |

| Mg (Magnesium) | 0.8 - 1.2 | 0.45 - 0.9 |

| Cr (Chromium) | 0.04 - 0.35 | 0 - 0.10 |

| Zn (Zinc) | 0 - 0.25 | 0 - 0.10 |

| Ti (Titanium) | 0 - 0.15 | 0 - 0.10 |

- 6061 has higher copper (Cu) and magnesium (Mg) contents, which increases strength but sacrifices some extrusion properties.

- 6063 has a higher silicon (Si) content and better extrusion fluidity, making the profile surface smoother and suitable for architectural decoration purposes.

6061 vs. 6063 mechanical properties comparison

| Performance parameters | 6061-T6 | 6063-T6 |

| Tensile strength(MPa) | 290 - 310 | 205 - 245 |

| Yield strength(MPa) | 240 - 276 | 170 - 200 |

| Elongation(%) | 8 - 12 | 10 - 16 |

| Hardness (HB, Brinell hardness) | 95 | 73 |

| Density(g/cm³) | 2.70 | 2.70 |

- 6061 has higher strength and is suitable for high-load structures such as aviation and automobile chassis

- 6063 has higher elongation and lower surface hardness, which is suitable for decorative structures that require high finish; 6063-T6 can replace 6061 in some cases, providing better extrusion performance and certain strength

Recommended products:

- Chalco 6061-T6 profile → suitable for machining, load-bearing structures

- Chalco 6063-T5 profile → suitable for window frames, curtain walls, radiators

6061 vs. 6063 extrusion performance & processing comparison

The performance of aluminum alloy extrusion profiles depends not only on the material itself, but also on the extrusion process and processing methods. 6061 and 6063 are the most common extrusion alloys, and they have their own advantages and disadvantages in terms of extrusion speed, processability, surface treatment, etc.

| Alloy | Extrusion speed | Solderability | Machinability | Surface finish |

| 6061 | Slow | excellent | good | generally |

| 6063 | Faster | excellent | Easier | Excellent |

- 6061 has a slower extrusion speed, but its high strength and excellent machinability make it more suitable for structural applications such as mechanical equipment, aerospace frames, etc.

- 6063 is more smoothly extruded, suitable for complex cross-section profiles, and has excellent surface finish. After anodizing, it has a more beautiful appearance and is particularly suitable for the field of architectural decoration, such as curtain walls, window frames, door frames, etc.

Recommended products

- Chalco 6061 structural profiles → suitable for mechanical and aerospace fields , providing higher strength and durability

- Chalco 6063 architectural decoration profile → Suitable for scenes with high appearance requirements such as curtain walls, window frames , door frames , etc.

6061 vs. 6063 machining & surface treatment comparison

In addition to extrusion performance, 6061 and 6063 also differ significantly in the way they can be subsequently processed. 6061 is suitable for high-precision processing due to its excellent mechanical properties, while 6063 has more advantages in bending and surface treatment.

| Processing method | 6061 Extrusion Profile | 6063 Extruded Profile |

| Extrusion performance | Moderate, difficult for complex profiles | Excellent, suitable for complex sections |

| CNC Machining | Excellent, can be used for high-precision processing | Good, but lower hardness, slightly higher processing efficiency |

| Welding performance | Good weldability, but heat treatment is required after welding | Better weldability, suitable for welding structural parts |

| Bending & Forming | High hardness, average bending performance | Better softness, suitable for cold bending |

| Anodizing & Surface Treatment | The surface finish after treatment is average, and the color difference is large | The surface is uniform after treatment and the appearance is better |

If CNC precision machining and high-strength structural parts are required, 6061 profiles are recommended.

If bending or high-quality surface treatment is required, 6063 profiles are recommended.

Recommended products

- Chalco 6061 CNC machined profiles → suitable for machining & high strength structural applications

- Chalco 6063 anodized profile → suitable for architectural decoration & lightweight requirements

6061 vs. 6063 application scenario comparison

| Application Areas | 6061 Applicable products | 6063 Applicable products |

| Aerospace | Aircraft frame, fuselage reinforcement | - |

| Automobile & Rail Transit | Chassis, bumper, battery bracket | Window frames, lightweight roof racks |

| Architecture & Structure | Bridge supports, curtain wall frames, C-shaped, H-shaped, T-shaped profiles | Doors, windows, curtain walls, decorative profiles |

| Industrial Equipment & Machinery | Robot frame, machine tool base, assembly line bracket | Lightweight equipment frame |

| Radiators & Power Electronics | High power radiator, industrial heat sink | Electronic heat sink, small radiator |

| Marine & Ship | Ship structures, offshore platform supports | Door frame, railing |

6061 and 6063 aluminum alloy extrusion profiles have their own advantages in different application fields, which mainly depend on the strength requirements, corrosion resistance, machinability and appearance processing requirements.

6061 is suitable for high-strength and high-load-bearing structural parts

6063 is more suitable for building decoration, lightweight frames and complex cross-section profiles due to its excellent extrusion performance and surface treatment effect.

Why recommend Chalco as your 6061 & 6063 aluminum extrusion profiles supplier?

When choosing 6061 and 6063 aluminum extrusion profiles, in addition to considering material properties, you also need a reliable supplier to ensure product quality, processing accuracy and a stable supply chain. Chalco provides high-quality aluminum profile solutions for various industries with its rich industry experience, advanced production technology and global services.

Global certification, quality assurance

- Comply with international standards - ASTM B221, EN 755, GB/T 5237, AMS 4150 and many other industry standards

- Aviation & Rail Transit & Automobile—— Supplying Boeing, Airbus, Tesla, Ford, BYD, CRRC and other well-known companies

- Marine & Industrial—— DNV, ABS, CCS maritime certifications ensure corrosion resistance and reliability

Advanced productivity to meet diverse needs

- Powerful extrusion capability—— Equipped with 600T-12500T extruders, capable of producing super-large size and complex cross-section profiles

- Precision CNC processing——provides cutting, drilling, tapping, welding, bending and other precision deep processing

- Diverse surface treatments - anodizing, powder coating, electrophoresis, wood grain transfer, to meet aesthetic and corrosion resistance requirements

Efficient supply chain, customized services on demand

- OEM & ODM supply——Specific cross-sections and processing technology can be customized according to customer needs

- Global supply & fast delivery - Flexible production to ensure fast delivery of bulk & small batch orders

- One-stop solution - from alloy selection → extrusion production → precision machining → surface treatment → logistics distribution, fully meeting project needs

Looking for the best 6061 & 6063 aluminum extrusion profiles? Chalco provides you with high-quality customized solutions, welcome to consult!