At Chalco, we understand that windows and doors are not just simple openings in a building; they serve the multiple purposes of connecting the interior and exterior, ensuring security, and enhancing aesthetics. In modern architecture, windows and doors must not only fulfill basic opening and closing functions, but they also need to offer outstanding beauty, comfort, and high performance, meeting people's demand for quality of life and environmental sustainability.

For this reason, aluminum windows and doors have become the preferred choice for more and more architects and property owners. With their excellent strength, durability, and energy efficiency, aluminum windows and doors have seen wide application in various building projects. As a leading brand in the aluminum processing industry, Chalco continuously innovates, leveraging exceptional design and manufacturing capabilities to provide efficient, eco-friendly, and aesthetically pleasing window and door solutions that meet diverse building needs, enhancing both the comfort and security of living and working environments.

From Design to Assembly: The Full-Process Advantage of Chalco Aluminum Windows and Doors

At Chalco, we focus not only on the high performance of aluminum windows and doors, but also on every step of the process from design to assembly, ensuring that each window and door perfectly meets the customer's needs. Here are the advantages of our full-process approach:

Precision Design and Custom Solutions

Our design team works closely with customers to customize the style, size, and functionality of the windows and doors according to specific requirements. Whether it is a modern minimalist style or a traditional classic design, we offer personalized solutions to ensure that each window and door seamlessly blends architectural aesthetics and functional needs, increasing the building’s value. Through advanced design software and simulation technology, we can foresee and resolve potential issues at the design stage, shortening communication cycles and improving design efficiency.

Efficient Production and Precision Processing

Once the design solution is finalized, Chalco uses advanced production equipment and high-precision technology to ensure that aluminum windows and doors meet industry-leading standards during manufacturing. We strictly control every step of the process to ensure the strength and durability of the aluminum profiles. By optimizing production workflows, we improve production efficiency, reduce manufacturing costs, and provide high-quality and cost-effective products for our customers.

Assembly Precision and Convenience

In the assembly process, Chalco uses high-precision CNC machining to achieve micron-level precision, ensuring that every window and door fits perfectly in size and structure. This not only guarantees the stability and durability of the products but also enhances the ease of installation, saving customers time and labor costs. Before shipping, all finished windows and doors undergo rigorous inspection and are carefully packaged with shockproof materials, ensuring they remain in excellent condition during transportation and providing a high-quality foundation for installation.

Durability and Environmental Performance of Windows and Doors

Our aluminum windows and doors are not only highly corrosion-resistant and oxidation-resistant, but they also offer excellent soundproof and thermal insulation properties, creating a comfortable and energy-efficient living environment for your building. With high-quality materials and craftsmanship, Chalco's windows and doors maintain their beauty over the long term, reducing future maintenance costs and embodying the principles of environmental sustainability.

In addition to performance, the appearance of windows and doors is also crucial. Below are our innovations and considerations in appearance design.

Appearance Design of Aluminum Windows and Doors: Enhancing Architectural Charm

As the "eyes" of a building, the appearance of windows and doors directly impacts the overall aesthetic and atmosphere of the structure. Chalco's design team customizes the appearance of each window and door based on the architectural style and environmental context, ensuring perfect integration with the building.

1. Design Considerations Balancing Aesthetics and Functionality

At Chalco, our design team not only focuses on the aesthetic beauty of the windows and doors, but also fully considers the functional requirements and the usage environment of the building. We offer customized solutions to ensure that the windows and doors not only complement the architectural style but also provide exceptional durability and energy efficiency.

- Architectural Style and Environmental Adaptability: We design windows and doors that harmonize with the overall architectural style (such as modern minimalist, European classical, etc.) and the surrounding environment.

- Energy Efficiency and Physical Performance: Aluminum windows and doors offer excellent thermal insulation and soundproofing, effectively enhancing the energy efficiency of buildings and meeting environmental requirements.

- Durability and Cost-Effectiveness: We carefully select materials and processing techniques to ensure the windows and doors are long-lasting, while also providing cost-effective solutions.

2. Size and Proportions of Windows and Doors: Balancing Aesthetics and Functionality

Modern architecture often seeks large windows for optimal natural light. However, achieving a balance between beauty, energy efficiency, and performance during the design process is key.

- Large vs. Small Windows: In our design, we consider the lighting needs, energy standards, and the window-to-wall ratio to determine the ideal size and design, ensuring large windows do not lead to excessive heat loss.

- Balancing Architectural Harmony: We focus on ensuring the windows blend seamlessly with the building's facade, maintaining both a stylish appearance and high functionality.

3. Different Types of Aluminum Windows: Perfect Solutions for Every Need

Chalco offers a wide variety of aluminum window types, each with unique design and functional advantages to meet different architectural styles, space requirements, and usage environments. Whether you need large windows, compact designs, or solutions that prioritize ventilation or space-saving, our aluminum windows deliver optimal results.

Aluminum Casement Windows

A classic design, ideal for various types of buildings. Typically available in single or double sash configurations, casement windows open inwards or outwards. They provide excellent sealing, making them perfect for residential and commercial buildings requiring soundproofing, insulation, or high security.

Aluminum Sliding Windows

Widely used due to their space-saving design, especially in modern apartments or commercial buildings. The smooth sliding experience on the bottom rail makes them ideal for large windows, enhancing indoor ventilation and natural light.

Aluminum Tilt and Turn Windows

These windows can tilt inwards or rotate 90 degrees, combining ventilation and security advantages. They are especially suitable for high-rise buildings or places requiring easy cleaning. This design provides flexible ventilation while minimizing external space occupation.

Aluminum Folding Windows

With excellent flexibility and space utilization, folding windows are ideal for areas that require large openings, such as balconies, terraces, or courtyards. The top and bottom rails allow the window to fold fully to one side, maximizing the opening space and enhancing lighting and ventilation.

Aluminum Lift Windows

Lift windows are commonly used for taller, narrower window areas. They slide along an aluminum rail system, providing ample ventilation without occupying additional indoor space. They are especially suited for kitchens, stairwells, or other confined spaces.

Aluminum Drift Windows

Drift windows slide along the track to one side when opened, without occupying any additional space inside or outside. They are ideal for locations requiring large openings and excellent ventilation, such as living rooms or public spaces.

Aluminum Fixed Windows

Fixed windows are generally used in areas that do not require opening. They provide ample natural light through large glass panels while ensuring the building maintains a modern appearance and high transparency.

Aluminum Skylights

Installed on the roof, skylights provide natural light and ventilation, especially for attics, kitchens, or commercial spaces requiring additional light. Aluminum skylights offer excellent weather resistance, waterproofing, and can withstand harsh weather conditions.

4. Window and Door Colors and Shapes: The Magic of Design

The appearance design of aluminum windows and doors cannot be separated from the clever use of color and shape. The right color and shape not only enhance the building's modernity, but also complement the surrounding environment.

- Color Matching: Dark tones bring a sense of stability to the building, while lighter shades offer a fresher look. Matching colors with the building's base tone and surrounding environment ensures the windows and doors blend seamlessly into the overall design.

- Shape Design: Aluminum windows and doors can be designed in various shapes, such as flat, angular, or curved. However, design choices need to balance budget and production difficulty, ensuring both aesthetic appeal and cost efficiency.

5. Facade Grid Design: The Aesthetics of the Golden Ratio

Grid design on the facade not only affects the visual effect but also directly influences functionality. We pay close attention to the coordination of horizontal and vertical grid lines, using the golden ratio to ensure the visual effect of the windows and doors is both unified and natural.

Structural Design of Aluminum Windows and Doors: Balancing Stiffness, Strength, and Load-Bearing Capacity

We understand that the structural design of aluminum windows and doors must not only provide high strength but also balance stiffness and stability to ensure the product’s long-term reliability in various complex environments. Below are the key advantages of Chalco in the structural design of aluminum windows and doors:

1. Wind Load and Temperature Stress: Ensuring Wind Pressure Resistance and Thermal Expansion Adaptability

The structural design of aluminum windows and doors must first consider wind load. Wind load is determined by factors such as wind speed, building height, and geographic location, typically ranging from 0.04-0.4 kN/m².

Chalco’s design team simulates wind pressure under various climate conditions to ensure that windows and doors can function stably in high wind environments. Additionally, the thermal expansion coefficient of aluminum may cause dimensional changes in windows and doors due to temperature fluctuations. Therefore, temperature stress must be considered in the design to ensure that windows and doors do not deform or get damaged due to thermal expansion.

2. Load-Bearing Member Design: Multi-Directional Stress and Stable Load-Bearing

Each component in the aluminum window and door structure must withstand forces from different directions, including tension, compression, bending, shear, and torsion.

Chalco uses high-strength aluminum alloy profiles and employs advanced Computer-Aided Design (CAD) tools to conduct Finite Element Analysis (FEA), ensuring that each load-bearing member achieves the highest industry standards for strength, stiffness, and stability under external forces.

In particular, we ensure that the stiffness of the window and door structures remains adequate to avoid deformation or instability when subjected to wind pressure, temperature fluctuations, and other environmental stresses.

3. Glass Design: Dual Protection Against Compression and Safety

To ensure the long-term safety of aluminum windows and doors, glass design plays a critical role. Depending on the building’s requirements, Chalco offers various glass materials, including tempered glass and insulated glass.

For residential windows, we typically use 5mm thick tempered glass, while public buildings use glass with thicknesses of 8mm or more to ensure wind pressure resistance and impact resistance.

By optimizing the fit between the glass and the window frame, we ensure that the glass does not crack or detach during long-term use, preventing safety hazards.

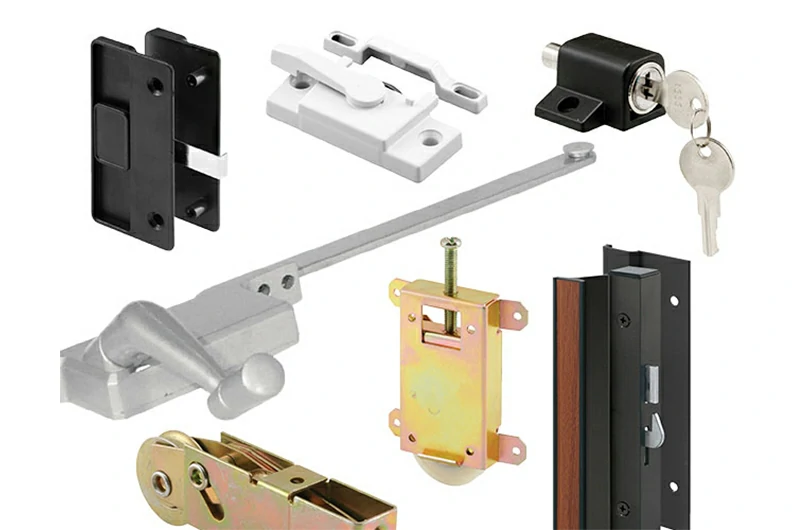

4. Connection Design: Details Determine Window and Door Stability

The components of aluminum windows and doors are connected by precisely designed hardware connectors to ensure they do not loosen or detach over time.

Chalco selects high-strength, stainless steel, or galvanized steel hardware to ensure corrosion resistance and durability.

Each connection point is meticulously designed and calculated to ensure that even under extreme conditions, such as high winds or earthquakes, the window and door structure remains stable.

Energy-Efficient Design of Aluminum Windows and Doors: Enhancing Insulation and Energy Performance

As the demand for energy conservation and environmental protection continues to grow, Chalco’s aluminum windows and doors stand out due to their innovative design and advanced technology, significantly improving the energy performance of buildings. By optimizing insulation and heat retention design, our window systems effectively reduce energy consumption, ensuring a comfortable indoor environment while decreasing the burden on air conditioning and heating systems.

1. Core of Energy-Efficient Design: Optimizing Three Modes of Heat Transfer to Minimize Heat Loss

The key to energy-efficient window design lies in controlling heat loss effectively. Chalco utilizes a series of innovative designs to optimize three major modes of heat transfer, ensuring stable indoor temperatures and reducing energy consumption:

- Convective Heat Transfer: By improving seals and frame designs, we reduce air movement through window gaps, preventing the exchange of cold and hot air, and improving heat retention.

- Conductive Heat Transfer: Low thermal conductivity materials, such as insulating aluminum alloy profiles, are used to reduce heat transfer between the indoor and outdoor environments.

- Radiative Heat Transfer: Low-E coatings and films are employed to effectively reflect thermal radiation, reducing heat loss through the glass surface.

2. Glass Energy-Efficient Design: A Highly Effective Thermal Shield

Glass plays a crucial role in energy-efficient design. Chalco employs various glass technologies to enhance the thermal performance of our windows and doors:

Glass Films

Specially designed films reflect thermal radiation, reducing heat loss. These films not only enhance the aesthetic appeal but also significantly reduce the load on air conditioning and heating systems.

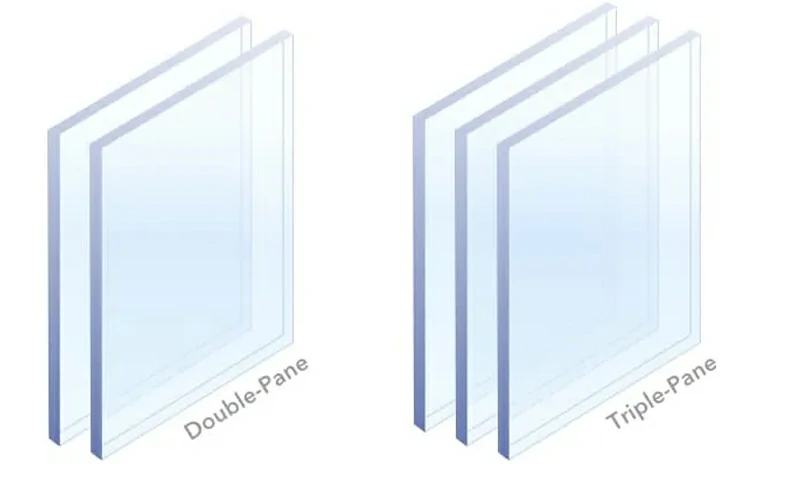

Glass Structures: We offer insulated glass and low-emissivity (Low-E) coated glass to improve thermal performance:

- Single-Glazed Glass (K≈6W/m²·K) offers poor energy performance.

- Insulated Glass (K≈2.3-3.2W/m²·K) adds an air layer to provide better insulation.

- Low-E Coated Insulated Glass (K≈1.4-1.8W/m²·K) incorporates inert gas fillings, significantly improving energy efficiency and reducing energy consumption.

3. Aluminum Thermal Break Profiles: Efficient Insulation

These profiles help windows and doors effectively isolate external cold and heat, maintaining a stable indoor temperature.

- Injection Thermal Break Profiles: These profiles are filled with low thermal conductivity materials, providing excellent thermal insulation and effectively reducing energy loss.

- Strut Thermal Break Profiles: Non-conductive materials are inserted into the aluminum profiles to form a strong insulation barrier, significantly increasing the thermal resistance of windows and doors, ensuring stable indoor temperatures.

4. Double (Multi)-Layer Structural System: The "Magic" of Air Layer Insulation

By designing double-glazed or multi-layered glass, Chalco greatly enhances the insulating effect of windows and doors:

- Gas Filling Technology: Inert gases (such as argon and krypton) are filled between glass layers, providing extremely low thermal conductivity, greatly improving insulation performance.

- Multi-Layer Air Cavities: Multi-layer air cavities form a stronger insulation barrier, further reducing heat loss and ensuring stable indoor temperatures.

- This design increases initial investment, but its long-term energy savings provide significant returns.

5. Sunshade Technology: Keeping Heat "Outside the Door"

Chalco uses innovative sunshade designs to effectively reduce the thermal impact of solar radiation, enhancing indoor comfort:

- Sunshade Louvers: These can be adjusted to control the amount of sunlight entering the room, preventing excessive heat.

- External Sunshades: These reduce direct solar heat gain, increasing the efficiency of air conditioning systems and lowering energy consumption.

These sunshade technologies help buildings stay cool during the summer, reducing air conditioning use and effectively saving energy.

Aluminum Alloy Windows and Doors Customization Service: Personalized Design and Precise Solutions

Every construction project has its unique design requirements, and Chalco understands the importance of custom aluminum alloy windows and doors. Whether for residential, commercial buildings, or specialized structures, Chalco offers flexible custom solutions to ensure each window and door perfectly matches the architectural style and functional requirements, enhancing the overall quality and energy efficiency of the building.

Exclusive Design Team for Tailored Solutions

Chalco has an experienced design team dedicated to working closely with clients to understand the unique needs of each project. Based on the client’s style, functionality, and size requirements, we provide fully customized aluminum alloy windows and doors solutions. This personalized design not only ensures that the windows and doors seamlessly integrate with the architectural style but also meets special functional needs, such as energy efficiency, sound insulation, and privacy protection, thereby improving the building's usability and comfort.

Advanced Technology Supporting Efficient Production

Chalco uses advanced manufacturing processes and high-precision production equipment to ensure that each custom aluminum alloy window and door meets strict international quality standards. Whether it is for large-scale mass production or highly personalized customization, we can deliver efficiently, meeting various building project timelines and quality requirements to ensure smooth project implementation.

Chalco’s exclusive design team will collaborate closely with clients throughout the process to understand each project’s unique requirements and provide tailor-made solutions. This ensures that each door and window perfectly aligns with the building’s style and functional use, enhancing the overall quality of the architecture. Contact us now to co-create the perfect window and door system that meets your specific needs.

Aluminum Window and Door Profile Frame Assembly: Precision Craftsmanship and Secure Connections

The assembly of aluminum window and door profile frames is a crucial step in ensuring the quality and durability of the products. Chalco maintains strict control over every step— from profile cutting, drilling to precise assembly— using advanced equipment and meticulous craftsmanship to guarantee that each window and door structure is aesthetically pleasing, stable, and meets high durability standards. Our efficient processes and innovative designs not only ensure product quality but also enhance the building's lifespan and safety.

1. Precision Profile Cutting: Ensuring Perfect Size and Seamless Fit

First, the aluminum window profiles need to be cut precisely according to the design requirements. Cutting is typically done using a saw machine or CNC cutting machines, which ensure the cut surface is straight and angles are accurate.

- Cutting Precision: Especially when a 45° or 90° angle connection is needed, precise cutting ensures that the assembled window frame fits seamlessly, improving the sealing of the window.

- Cutting Size: Each profile is cut based on the actual size of the window frame to ensure smooth subsequent assembly.

2. Precision Drilling: Providing Secure Installation Positions for Hardware

Next, drilling holes in the profiles for hardware and frame connectors is necessary. Though seemingly simple, drilling is crucial as it directly impacts the secure installation of hardware and smooth operation during use.

- Equipment Choice: Drill machines or CNC drill machines are used for precise drilling to ensure hole positions meet design specifications.

- Hole Accuracy: Any deviation can affect the installation of hardware components (e.g., hinges, handles), leading to potential issues, so the drilling must follow the blueprint requirements strictly.

3. Frame Assembly: Multiple Joining Methods to Ensure Stability and Aesthetic Appeal

The assembly of the aluminum window frame is a key step, generally involving three main joining methods: 45° angle, right-angle, and vertical joints. Based on the window type and design requirements, the most suitable joining method is selected to ensure the frame’s stability and visual appeal.

- 45° Angle Joint: Primarily used for connecting window frames to sashes. This method is not only aesthetically pleasing but also effectively enhances the sealing of the frame.

- Right-angle Joint and Vertical Joint: Used for connecting vertical and horizontal components of the window frame, providing stronger structural support and stability.

4. Connection Methods and Fixing: Ensuring Firm and Long-term Stability

The assembly of aluminum window profiles not only relies on precise cutting and drilling but also involves various connection methods and fasteners to ensure the stability and safety of each connection point. Common joining methods include:

Mechanical Fasteners: Strong connections

- Screws, bolts, or aluminum studs: Used for 45° or 90° angle joints, combined with aluminum angle steel or aluminum brackets to ensure a secure connection between profiles.

- Screw-motherboard connection: Uses stainless steel screws for connection, typically used in horizontal or vertical grooves, providing corrosion resistance and easy on-site adjustment or disassembly.

Folding Joints (Folded Edges): Reinforcing connection points

Folded edge connections are used to enhance the stability and load-bearing capacity of connection points. The width of the fold should be moderate, balancing material usage and connection strength.

Rivet Connections: Stable and durable, long-lasting

- Self-piercing rivets: Used for high-stress connections, ensuring long-term stability without loosening.

- Threaded rivets and blind rivets: Threaded rivets are suitable for areas that can be operated on both sides, while blind rivets are ideal for single-sided operation. Riveting is typically used for non-removable and stable connections, providing higher strength and safety.

5. Final Inspection and Precision Control: Ensuring Perfect Detail

The final assembly of the frame requires careful inspection of every detail to ensure the firmness and accuracy of each connection point. Typically, assembly is carried out on a dedicated assembly table.

- Assembly Process: Use of clamps to secure profiles ensures that each joint fits tightly with no gaps.

- Quality Inspection: After assembly, the entire frame undergoes strict quality checks, including checking the diagonal accuracy, tightness of connectors, and overall flatness. Only when all standards are met will the frame move on to packaging and transportation.

Chalco Aluminum Windows and Doors: The Choice for Quality and Trust

Whether for enhancing the aesthetic of a building, increasing security, or improving energy efficiency, Chalco aluminum windows and doors are always the ideal choice. With advanced design concepts, innovative technological support, and rigorous production processes, we provide high-quality aluminum alloy windows and doors products for every customer. Chalco is committed to advancing green building development, creating sustainable architectural solutions with excellence and innovation.

Choosing Chalco means not only selecting a window and door but also choosing a future of quality, innovation, and environmental sustainability.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote