1050 aluminum foil for roof is a high-purity aluminum material (99.5% content) known for its excellent corrosion resistance, weatherability, and formability.

It enhances roof aesthetics and reduces heat transfer and cooling costs, offering a practical and valuable solution for your building.

Specifications of 1050 aluminum foil for roof

Alloy Material Standards: EN 573-3, EN 485-2, EN 546-2, ASTM B209

Performance and Durability Test Standards: ASTM B117, ASTM G154, ASTM C1371, ASTM C1549

Building Material Standards: AS 4200.1, SANS 1381-4 Class D, EN 13501-1

Certifications: ROHS, CE, SGS

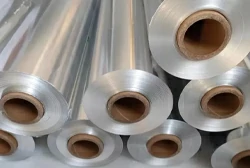

Popular products of 1050 aluminum foil for roof

1050 aluminum foil for roof includes color-coated foil, insulation foil, extra-wide rolls, and corrugated sheets, offering flexible solutions for various buildings.

We provide standard and custom sizes to meet diverse needs, ensuring a perfect fit and efficient installation.

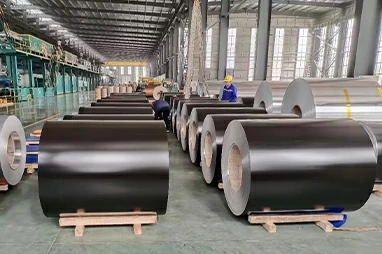

1050 color coated aluminum foil

1050 color-coated aluminum foil is a high-performance material treated with varnishing, color coating, anodizing, and mirror polishing.

Contact us now

- Common thicknesses: 0.05mm, 0.06mm, 0.07mm, 0.08mm, 0.1mm, 0.11mm, 0.12mm, 0.15mm

- Common widths: 912mm, 914mm (custom widths available)

- Coating thickness: 7-10μm

- Inner diameter: 76.2mm, 152mm

- Surface wettability: ≥32 Dynes

- Reflectivity: Target emissivity below 0.05

- Standard colors: Earth red, white, black, blue, green, gray, copper (RAL colors or custom colors available upon request)

- Coating type: Single-side or double-side coating

Polyester coating (PE coating)

Coating thickness: ≥18 microns

Service life: Over 10 years

Contact us now

Fluorocarbon coating (PVDF coating)

Coating thickness: ≥25 microns

Service life: Over 20 years

Surface types: Fluorocarbon/nano fluorocarbon coating

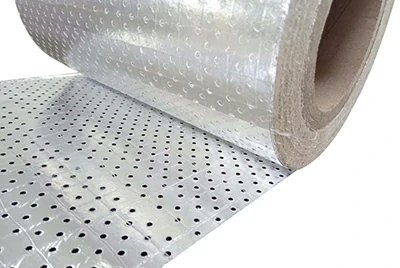

Contact us now1050 roof insulation aluminum

1050 roof insulation aluminum foil reduces external heat entering the building by reflecting radiant heat.

Contact us now

- Common width: 48 inches

- Common lengths: 3000 inches, 5000 inches, 6000 inches, 9000 inches, 12000 inches

- Multi-layer structure: Typically laminated with a reflective aluminum foil layer and a substrate (such as kraft paper, plastic film, or polyethylene bubble film).

- Air gap: Maintaining a certain thickness of air gap (e.g., ½ inch or larger) helps improve roof ventilation and further enhances insulation performance.

- Roof insulation aluminum foil effectively blocks up to 93% of radiant heat.

Commonly used roof insulation aluminum foil

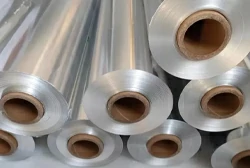

1050 extra wide aluminum foil rolls

Aluminum alloy extra-wide foil rolls are commonly used in roofing systems. They offer excellent corrosion resistance, weatherability, and lightweight properties, making them suitable for various types of roof structures.Quick Quote

1050 aluminum foil for roof chemical elements

| Chemical Element | % Present |

| Si | 0.25 max |

| Fe | 0.40 max |

| Cu | 0.05 max |

| Mn | 0.05 max |

| Mg | 0.05 max |

| Zn | 0.07 max |

| Ti | 0.05 max |

| Other (Each) | 0.03 max |

| Others (Total) | - |

| Aluminium (Al) | 99.5 min |

Performance of 1050 aluminum foil for roof

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 650 °C |

| Thermal Expansion | 24 x10^-6 /K |

| Specific heat capacity | 900 J/kg-K |

| Thermal conductivity | 230 W/m-K |

| Modulus of Elasticity | 68 GPa |

| Shear Modulus | 26 GPa |

| Electrical conductivity | 61 % IACS |

Advantages of 1050 aluminum foil for roof

- Up to 96% radiant heat reflectivity: Reduces heat absorption on the roof surface, lowering internal building temperatures.

- Coatings of polyester, polyvinylidene fluoride (PVDF), nano-ceramic, and acrylic enhance UV resistance and maintain long-term durability.

- 1050 aluminum alloy, made from pure aluminum, offers excellent corrosion resistance.

- The low density of aluminum foil makes it lighter than traditional roofing materials.

- Superior moisture barrier with extremely low water vapor transmission rate (WVTR), preventing mold growth on the roof.

- Enhanced tear and puncture resistance, ensuring roof sealing and durability.

- 1050 aluminum alloy has high weldability, suitable for traditional welding methods.

- Environmentally friendly coatings free from lead, chromium, and isophorone, compliant with EU REACH and RoHS regulations.

- Extra-wide design reduces seams, enhancing the overall integrity of the roof structure, ideal for large-area building coverage.

Applications of 1050 aluminum foil for roof

- Roof insulation: With up to 96% reflectivity, it blocks external heat, reduces air conditioning load, and saves energy.

- Roof waterproofing: Effectively prevents moisture penetration, providing moisture resistance and mold prevention, extending roof lifespan.

- Roof decoration: Offers a wide range of color choices, enhances weather resistance, and improves aesthetics.

- Green energy-efficient buildings: Lightweight, recyclable, and compliant with green building standards, reducing the carbon footprint.

- Exterior walls and ceilings: Highly weather-resistant, suitable for building exterior walls and ceilings, combining durability and aesthetics.

- Sound absorption and noise reduction: Enhances soundproofing, ideal for areas where noise control is needed.

- Honeycomb composite panels: Excellent formability and strength, suitable for high-strength roof and wall applications.

Strict quality control

Dimensional accuracy

Thickness tolerance: Controlled within ±3% to ensure consistent insulation and waterproofing performance.

Width tolerance: Controlled within ±1mm to avoid waste and difficulties in joining.

Length precision: Customized according to customer requirements to ensure high-precision cutting, with seamless product connections.

Surface quality

Flatness: The surface is smooth without waves, dents, or other deformations, ensuring smooth installation.

Cleanliness: Free from oil stains, oxide scales, or corrosion spots, guaranteeing proper post-processing or direct installation results.

No defects: The aluminum foil surface is free from scratches, cracks, pinholes, or bubbles, ensuring that waterproof and insulation performance is not affected.

Coating or composite layer quality

Uniformity: The coating is uniform, with no bubbling, cracking, or peeling.

Adhesion: The coating's adhesion meets international standards, ensuring long-term durability.

Color stability: The colored coating has minimal color difference and strong UV fade resistance.

Chalco's strong production capabilities

Advanced heat treatment process: 1050-O aluminum foil undergoes quenching (temperature 500-510°C, air cooling) and aging treatment (95-105°C, for 3 hours) during production, significantly enhancing hardness and strength while maintaining excellent formability and corrosion resistance.

Double-sided color-coated aluminum foil production: Using a double-roller system, we produce color-coated aluminum foil on both sides in a single pass, greatly improving production efficiency and ensuring high-quality coating results.

Powerful production lines: The company has an annual production capacity of 50, 000 tons and is equipped with the most advanced aluminum panel coating lines in China, with an annual output of up to 1 million square meters.

Complete aluminum coil equipment: We are equipped with 16 casting production lines, 3 continuous casting production lines, 1 DC production line, and multiple cutting machines, slitting machines, tensioning machines, and annealing furnaces to meet large-scale and high-standard production needs.

We offer various secondary processing services, including embossing, painting, lubrication, and slitting, to meet different customer customization requirements.Quick Quote

1050 aluminum foil for roof packaging

- Roll packaging: Aluminum foil rolls are placed in paper tubes and wrapped with moisture-proof film.

- Pallet/box packaging: Aluminum foil rolls are secured in wooden pallets or wooden boxes to ensure stable transportation.

- Strapping: Straps are used to prevent aluminum foil rolls from shifting.

- Damage protection design: Filling materials are used to protect the aluminum foil from damage.

- Labeling: Detailed labels are attached, including specifications, quantity, production information, etc.

- Compliance: Packaging meets international shipping and customs requirements.

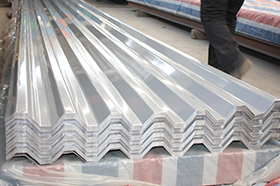

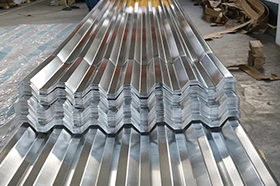

1050 aluminum foil for roof paired with aluminum corrugated sheets

Paired with corrugated sheets, aluminum foil reflects up to 97% of radiant heat, using the air gap as a barrier to reduce heat transfer and keep the interior cool.

Hot-selling products related to 1050 aluminum foil for roof

1060 aluminum foil

1100 aluminum foil

1200 aluminum foil

3003 aluminum foil

8011 aluminum foil

8079 aluminum foil