1100 aluminum foil for roofing is a high-quality material made of high-purity aluminum with an aluminum content of up to 99%. It has excellent corrosion resistance, excellent heat reflection performance and ductility. It can effectively cope with harsh climatic conditions while providing excellent waterproof and heat insulation effects. It is a commonly used lightweight and energy-saving option in building roof systems and is widely used in industrial and civil buildings.

The specifications of Chalco's 1100 aluminum foil for roofing

- EN 546

- EN 573

- ASTM B209

- ASTM E2148

- GB-T3880-2012

- RoHS

Product introduction of 1100 aluminum foil for roof

- Temper: O

- Thickness:0.014-0.03mm

- Width:20-1600mm

- Coating thickness:7-10μm

- Roll inner diameter: 76mm, 152mm

- Coating layer: single side, double side

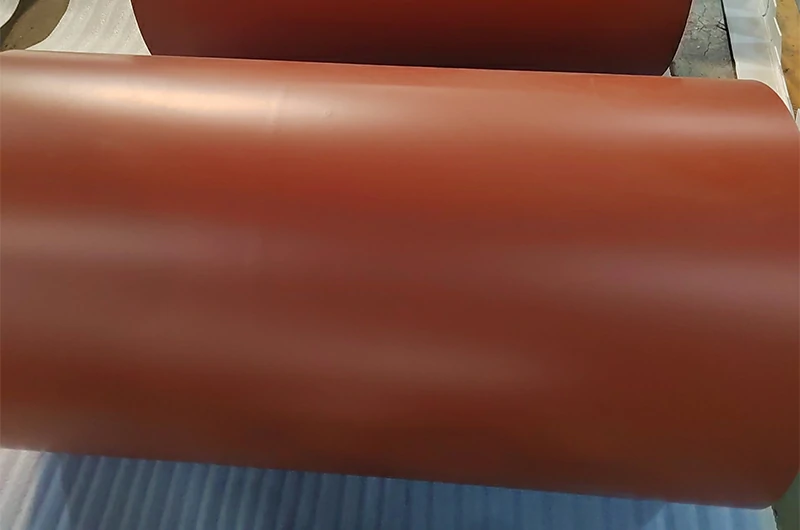

- Color:gold, silver, red, blue, black, gray, white, green, copper, brown, wood, etc.

What are the characteristics of Chalco's 1100 aluminum foil for roofing?

Up to 96% radiant heat reflectivity

1100 aluminum foil has excellent reflective properties and can reflect 96% of solar radiation, significantly reducing the heat absorption rate of the roof surface. This feature is particularly important in high-temperature areas. By reducing the heat transferred into the building, it effectively reduces the air-conditioning load, thereby saving energy costs.

UV resistance and thermal stability

Chalco 1100 roofing aluminum foil uses polyester coating, polyvinylidene fluoride coating, nano ceramic coating and acrylic coating to not only significantly enhance UV resistance, but also maintain long-lasting durability in extreme climate conditions through excellent thermal stability .

Lightweight design

The low density of aluminum foil material makes it lighter than traditional roofing materials without sacrificing strength. The lightweight properties reduce the burden on the building structure, reduce construction costs, and facilitate installation and transportation.

Moisture barrier

Chalco 1100 aluminum foil has excellent moisture-proof performance and extremely low water vapor transmission rate (WVTR), which can effectively prevent moisture penetration and protect building materials from moisture damage. It is especially suitable for humid or rainy areas to prevent roof corrosion or mold growth and extend the service life of the building.

Tear and puncture resistant

1100 aluminum foil has enhanced tear and puncture resistance during design and manufacturing. Even during installation or transportation, the aluminum foil maintains its integrity and is not easily torn by external forces or punctured by sharp objects, ensuring the sealing and durability of the roof.

Energy saving

With its excellent heat reflection performance, 1100 roof aluminum foil can effectively block external heat from entering the room, significantly reducing indoor temperature fluctuations, thereby reducing the running time and energy consumption of the air conditioning system. Especially in areas with high temperatures and strong sunlight, this insulation effect not only improves energy efficiency, but also provides a more comfortable indoor environment, making it an ideal choice for energy saving and consumption reduction..

The main purpose of 1100 aluminum foil for roof

1100 roof aluminum foil is widely used in roof insulation, and common uses include:

- Waterproof layer material: used in the waterproof system of building roofs to prevent rain and moisture penetration and protect the building structure.

- Insulation reflective layer: as a roof insulation material, it efficiently reflects solar heat, reduces indoor temperature, and saves air conditioning energy consumption.

- Anti-corrosion protective layer: provides anti-oxidation and anti-corrosion protection for the roof surface, prolongs the service life of the roof, and is particularly suitable for high humidity or salt spray environments.

- Insulation system auxiliary: used in conjunction with insulation materials to improve the overall insulation performance, and is widely used in energy-saving buildings and environmental protection projects.

- Architectural decoration: used to enhance the aesthetics of the roof appearance, while adding an additional protective layer to the building.

Application case of 1100 aluminum foil for roof

1100 Mechanical properties of roofing aluminum foil

| Alloy | Temper | Tensile Strength | Yield Strength | Elongation |

| 1100 | O | 88MPa | 29MPa | 32% |

| 1100 | H24 | 130MPa | 110MPa | 3.9% |

| 1100 | H26 | 150MPa | 130MPa | 2.8% |

Delivery quality standards for Chalco 1100 roofing foil

In order to ensure the high performance and reliability of 1100 roofing aluminum foil in construction projects, Chalco has formulated a series of strict delivery standards for its product quality, as follows:

Chemical composition

Aluminum content: The aluminum content is not less than 99.0%, ensuring its pure aluminum characteristics, in line with international and national standards such as GB/T 3190 or ASTM B209.

Impurity control: Strictly limit the content of impurities such as silicon (Si), iron (Fe), copper (Cu) to ensure the ductility, anti-corrosion and heat reflection effect of the product.

Dimensional accuracy

Thickness deviation: The thickness of the aluminum foil is strictly controlled within ±3% to ensure consistent insulation and waterproofing effects.

Width deviation: Controlled within ±1 mm to avoid material waste or difficulty in splicing during construction.

Length accuracy: Customized length according to customer needs, high cutting accuracy to ensure complete and seamless product docking.

Surface quality

Flatness: The surface is smooth and flat, without ripples, bumps or other deformations that affect construction.

Cleanliness: No oil, oxide scale, corrosion spots or pollutants to ensure the effect of subsequent processing or direct installation.

No defects: There should be no scratches, cracks, pinholes or bubbles on the surface of the aluminum foil, which may affect its waterproof and heat-insulating properties.

Quality of coating or composite layer

Uniformity: If the aluminum foil has an anti-corrosion coating or a composite waterproof layer, the coating must be uniform without blistering, cracking or falling off.

Adhesion: The coating adhesion meets international standards to ensure that it does not fall off even after long-term exposure to harsh environments.

Color stability: If there is a colored coating, the color must be consistent, without color difference, and it must be resistant to UV fading.

Packaging requirements

Protective packaging: Use sturdy wooden boxes or waterproof paper packaging, and add anti-collision cushions inside to avoid mechanical damage during transportation.

Moisture-proof and anti-oxidation: The inner packaging is sealed with moisture-proof materials, and the outer packaging is coated with an anti-rust coating to ensure stability during transportation.

Clear labeling: Each packaging box must be clearly marked with product specifications, batch numbers, production dates and manufacturer information for easy traceability and management.

Environmental protection

Non-toxicity: Comply with the RoHS directive and ISO 14000 series environmental standards to ensure that the product does not contain harmful substances such as lead and cadmium.

Recyclability: 100% recyclable, in line with the requirements of green building materials.

Testing and certification

Factory inspection: Each batch of products must undergo strict factory inspection, including chemical composition analysis, tensile test, dimensional measurement and surface quality inspection.

Third-party certification: SGS, TÜV and other third-party quality certification reports can be provided according to customer needs to ensure that the product meets the project requirements.

Why choose Chalco?

- Free sample provision: Chalco provides free samples of 1100 roofing aluminum foil according to customer needs, helping customers to conduct performance testing and quality assessment before purchasing, reducing procurement risks.

- Multiple specifications selection: The sample specifications are complete, and different thicknesses, widths and coating types can be selected, which is convenient for customers to simulate actual application scenarios and verify the suitability of materials.

- On-demand production: Customize the size, surface treatment (such as coating, anti-corrosion treatment) and packaging form of 1100 aluminum foil according to project requirements, and provide flexible customized solutions.

- Small batch trial service: In addition to samples, Chalco can provide customers with small batch trial orders, which is convenient for customers to conduct comprehensive testing at the beginning of the project and reduce the risk of large-scale procurement.

- Quality inspection: Provide various quality inspection books to ensure that the quality of 1100 roofing aluminum foil meets the technical standards required by the project.