1200 aluminum foil for roofing has excellent corrosion resistance and high reflectivity, effectively blocking ultraviolet rays and radiant heat, significantly improving building comfort.

Its lightweight, easy-to-install, and tear-resistant features ensure long-lasting durability in various harsh environments. Additionally, its eco-friendly and recyclable nature meets the requirements of green building standards.

Specifications for 1200 aluminum foil for roofing

Standards: ASTM D828, ASTM D774, ASTM F1249, ASTM C1263, ASTM E408

Certifications: ISO, CE, TUV

Popular products of 1200 aluminum foil for roofing

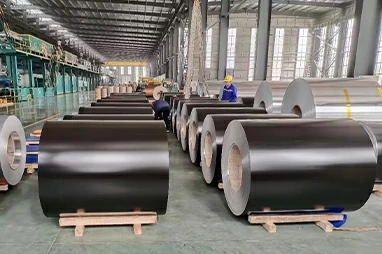

1200 color coated aluminum foil

1200 color-coated aluminum foil for roofing offers excellent durability, corrosion resistance, and thermal reflectivity.

Contact us now

- Common Thickness: 0.05mm, 0.06mm, 0.07mm, 0.08mm, 0.1mm, 0.11mm, 0.12mm, 0.15mm

- Common Width: 914mm, 912mm (customizable width available)

- Coating Thickness: 7-10μm

- Inner Diameter: 152mm, 76.2mm

- Surface Wetting Tension: ≥32 dynes

- Reflectivity: Target emissivity below 0.05

- Standard Colors: Earth red, white, black, blue, green, gray, copper (RAL colors or custom colors available upon request)

Polyester coating (PE coating)

Coating thickness: ≥18 microns

Service life: Over 10 years

Contact us now

Fluorocarbon coating (PVDF coating)

Coating thickness: ≥25 microns

Service life: Over 20 years

Surface types: Fluorocarbon/nano fluorocarbon coating

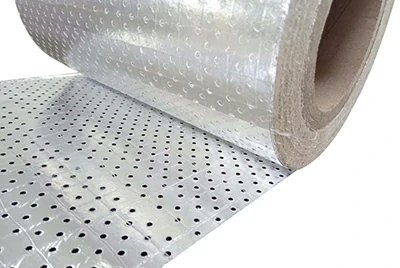

Contact us now1200 insulating aluminum for roofing

Sound and heat insulating aluminum foil helps reflect radiant heat, while the bubble layer aids in heat dissipation and sound wave prevention.

Contact us now

- Common Width: 48 inches

- Common Lengths: 3000 inches, 5000 inches, 6000 inches, 9000 inches, 12000 inches

- Multilayer Structure: Typically laminated with an aluminum foil reflective layer and a substrate (such as kraft paper, plastic film, or polyethylene bubble film).

- Air Gap: Maintaining an air gap of a certain thickness (e.g., ½ inch or more) helps improve roof ventilation and further enhances thermal insulation performance.

- Thermal Performance: Roof insulating aluminum foil can effectively block up to 93% of radiant heat.

Commonly used roof insulation aluminum foil

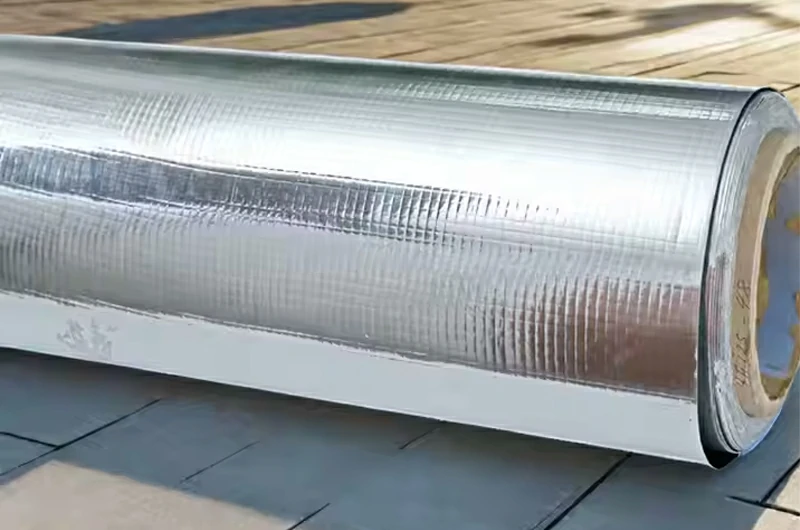

1200 extra-wide aluminum foil rolls

1200 extra-wide aluminum foil rolls for roofing feature broader dimensions, offering more efficient coverage and insulation. They are widely used in roofing for waterproofing, thermal insulation, and corrosion protection.

1200 aluminum foil for roof chemical composition

| Chemical Element | % Present |

| Si + Fe | 1.0 max |

| Cu | 0.05 max |

| Mn | 0.05 max |

| Zn | 0.10 max |

| Ti | 0.05 max |

| Other (Each) | 0.05 max |

| Others (Total) | 0.15 max |

| Aluminium (Al) | 99 min |

1200 aluminum foil for roof properties

| Physical Property | Value |

| Density | 2.70 g/cm³ |

| Melting Point | 660 °C |

| Thermal Expansion | 23 x10^-6 /K |

| Specific heat capacity | 900 J/kg-K |

| Thermal conductivity | 230 W/m-K |

| Modulus of Elasticity | 69 GPa |

| Shear Modulus | 26 GPa |

| Electrical conductivity | 58 % IACS |

Advantages of 1200 aluminum foil for roofing

- 1200 aluminum foil can reflect up to 97% of radiant heat, effectively blocking summer heat and reducing air conditioning energy consumption.

- 1200 aluminum foil coating offers excellent weather resistance and UV protection.

- 1200 high-purity aluminum has strong corrosion resistance.

- 1200 aluminum foil has good flame retardant and fire-resistant properties, enhancing building safety.

- 1200 aluminum foil is lightweight, easy to install, and highly durable, reducing long-term maintenance costs.

- 1200 aluminum foil is available in various colors and coating qualities to meet different aesthetic and functional needs.

- Aluminum foil is recyclable, aligning with green building principles and meeting high environmental standards.

Applications of 1200 aluminum foil for roofing

- Roof Cooling: Effectively reduces roof temperature, improving indoor comfort.

- Warehouse Environment Optimization: Provides thermal insulation and moisture protection for stored items, ensuring a stable environment.

- Residential Market Application: More effective than traditional concrete walls in maintaining indoor coolness, enhancing living comfort.

- Building Insulation and Sealing: Available in rolls and tapes, widely used for roof insulation, chimney insulation, and ridge and eaves insulation materials.

Strict quality control

Dimensional accuracy

Thickness tolerance: Controlled within ±3% to ensure consistent insulation and waterproofing performance.

Width tolerance: Controlled within ±1mm to avoid waste and difficulties in joining.

Length precision: Customized according to customer requirements to ensure high-precision cutting, with seamless product connections.

Surface quality

Flatness: The surface is smooth without waves, dents, or other deformations, ensuring smooth installation.

Cleanliness: Free from oil stains, oxide scales, or corrosion spots, guaranteeing proper post-processing or direct installation results.

No defects: The aluminum foil surface is free from scratches, cracks, pinholes, or bubbles, ensuring that waterproof and insulation performance is not affected.

Coating or composite layer quality

Uniformity: The coating is uniform, with no bubbling, cracking, or peeling.

Adhesion: The coating's adhesion meets international standards, ensuring long-term durability.

Color stability: The colored coating has minimal color difference and strong UV fade resistance.

Chalco's strong production capabilities

Advanced heat treatment process: 1050-O aluminum foil undergoes quenching (temperature 500-510°C, air cooling) and aging treatment (95-105°C, for 3 hours) during production, significantly enhancing hardness and strength while maintaining excellent formability and corrosion resistance.

Double-sided color-coated aluminum foil production: Using a double-roller system, we produce color-coated aluminum foil on both sides in a single pass, greatly improving production efficiency and ensuring high-quality coating results.

Powerful production lines: The company has an annual production capacity of 50, 000 tons and is equipped with the most advanced aluminum panel coating lines in China, with an annual output of up to 1 million square meters.

Complete aluminum coil equipment: We are equipped with 16 casting production lines, 3 continuous casting production lines, 1 DC production line, and multiple cutting machines, slitting machines, tensioning machines, and annealing furnaces to meet large-scale and high-standard production needs.

We offer various secondary processing services, including embossing, painting, lubrication, and slitting, to meet different customer customization requirements. Quick Quote

Packaging of 1200 aluminum foil for roofing

- Standard Wooden Box Dimensions: 1.4m × 1.3m × 0.8m, suitable for most transportation needs.

- Adjustable Size: Wooden box dimensions can be customized to meet different foil specifications according to customer requirements.

- Weight Capacity: Gross weight of 500-700 kg, net weight of 450-650 kg, suitable for large-scale logistics needs.

- Packaging Material: High-quality, durable wood to prevent vibration and impact damage.

- Safety: Sturdy structure with reinforcement to ensure the stability of aluminum foil rolls during transport.

- Environmental Friendliness: Wooden box materials are recyclable and meet environmental standards.

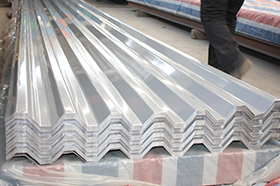

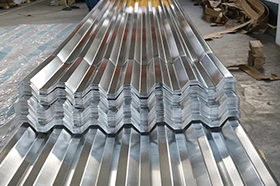

1200 aluminum foil for roofing with aluminum corrugated sheets

Paired with corrugated sheets, aluminum foil reflects up to 97% of radiant heat, using the air gap as a barrier to reduce heat transfer and keep the interior cool.

Hot-selling products related to 1200 aluminum foil for roofing

1060 aluminum foil

1100 aluminum foil

1050 aluminum foil

3003 aluminum foil

8011 aluminum foil

8079 aluminum foil