Why choose Chalco 5052 industrial ceiling fan blade aluminum plate?

Aluminum plate stock

Chalco has its own factory and has a large inventory of 5052 aluminum sheets for customers to purchase directly, which greatly shortens the lead time.

Quality assurance

Chalco industrial ceiling fan blades use 5052 aluminum sheets, which belong to aviation-grade aluminum sheets, and the quality of the aluminum sheets meets the ASTM B209 standard.

Specification of Chalco 5052 aluminum sheet for industrial ceiling fan blades

| Alloy | 5052 |

| Temper | H12, H22, H32, H38, H112 |

| Thickness | 1.5-3mm |

| Width | 1000-2000mm |

| Length | 3000-6000mm |

| Surface Treatment | Double-sided polished or Single-sided polished |

| Color | Silver or Customized |

| Packaging | Strapped packaging or Customized |

Chemical composition of Chalco 5052 industrial ceiling fan blade aluminum sheet

| Element | Composition (%) |

| Al | Remainder |

| Mg | 2.2-2.8 |

| Si | 0-0.25 |

| Fe | 0-0.40 |

| Cu | 0-0.10 |

| Cr | 0.15-0.35 |

| Zn | 0-0.10 |

| Mn | 0-0.10 |

| Other(total) | 0-0.15 |

| Other(each) | 0-0.05 |

Mechanical properties of Chalco 5052 industrial ceiling fan blade aluminum plate

| Temper | Thickness/mm | Tensile strength /Mpa | non-proportional tensile strength /Mpa | Elongation /% |

| H12 | >0.20-0.50 | 210-280 | 180 | 4 |

| >0.50-1.50 | 5 | |||

| >1.50-3.00 | 5 | |||

| >3.00-6.00 | 8 | |||

| H22, H32 | >0.20-0.50 | 210-260 | 130 | 5 |

| >0.50-1.50 | 5 | |||

| >1.50-3.00 | 7 | |||

| >3.00-6.00 | 10 | |||

| H38 | >0.20-0.50 | 270 | 210 | 3 |

| >0.50-1.50 | 3 | |||

| >1.50-3.00 | 4 | |||

| H112 | >6.00-12.50 | 190 | 80 | 7 |

| >12.50-40.00 | 170 | 70 | - | |

| >40.00-80.00 | 170 | 70 | - |

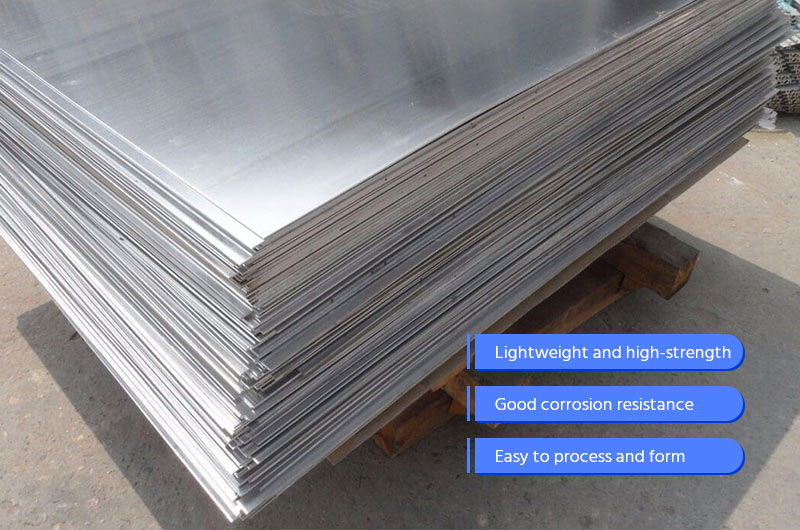

Advantages of using Chalco 5052 aluminum sheet for industrial ceiling fan blades

Lightweight and high-strength: Chalco 5052 aluminum plate is a lightweight magnesium-aluminum alloy material with low density, which reduces the weight of the fan blade and reduces the load on the suspension device. At the same time, it has high strength to keep the industrial ceiling fan blade stable under high-speed operation.

Good corrosion resistance: Chalco 5052 aluminum alloy has excellent corrosion resistance and can maintain stability in wet, corrosive gas or chemical environments.

Easy to process and form: Chalco 5052 aluminum sheet is easy to process and form, which helps to manufacture various customized shapes and sizes of industrial ceiling fan blades to meet the ventilation needs of different places.

Good thermal conductivity: Chalco 5052 aluminum plywood has good thermal conductivity, and the industrial ceiling fan blades can dissipate heat more effectively during use, prolonging the service life.

Production methods of industrial ceiling fan aluminum blades

At present, there are two mainstream production methods of industrial ceiling fan blades in the market, one is pure aluminum plate bending forming, and the other is aluminum extrusion forming.

Aluminum plate bending fan blade

Aluminum plate bending fan blades are generally made of 5052 aviation-grade aluminum alloy plates, which are light and strong fan blades formed under advanced bending technology. Through the process of cutting, bending and surface treatment, the aluminum plate is made into blades of various sizes and shapes according to the design requirements of ceiling fans. Its excellent corrosion resistance, thermal conductivity and recyclability make it an ideal choice for the manufacture of industrial ceiling fans, providing efficient ventilation and cooling effects, and suitable for various industrial environment needs.

Aluminum extruded fan blade

The aluminum extrusion process fan blade is to use raw materials such as aluminum liquid or aluminum ingot to melt in the furnace, and then extruded through the extruder until it flows out of the mold to form an industrial fan blade with the required cross-sectional shape, size and certain mechanical properties.

Advantages and disadvantages of aluminum plate bending fan blades vs aluminum extruded fan blades

There are two production processes for the blades of industrial ceiling fans. The advantage of aluminum plate bending is that the material is pure and there is no risk (under the premise of ensuring the purity of the aluminum plate), but the production cost is relatively high, so this fan is also slightly more expensive than ordinary fans; aluminum extrusion The production cost of pressed fan blades is relatively low, and the fan blades can have different colors, but it has high requirements on the production process, and it is easy to cause the quality of the fan blades to be substandard. Therefore, when choosing this type of product, it is necessary to strictly inspect the production process and Strength, in order to avoid the risk of use.

Effect of industrial ceiling fan blades on ceiling fan performance

Material selection: the material of the ceiling fan blades is critical to performance. Using lightweight but strong aluminum alloy materials, such as 5052 aluminum plate, can provide high strength, good corrosion resistance and thermal conductivity, reduce motor load and save energy.

Blade shape and number: the shape and number of blades affect the fan's airflow generation and delivery. Generally, the more blades, the stronger the wind, but too many blades may increase wind resistance and affect efficiency.

Blade inclination: the inclination of the blade has an important influence on the wind force and direction of the fan. A reasonable blade inclination can make the wind force more concentrated and the wind direction more stable.

Blade weight and balance: the weight of the blade should be balanced to avoid vibration and noise problems.

Surface treatment: the surface treatment of the blade, such as spraying or anodizing, can increase its corrosion resistance, wear resistance and aesthetics.

Blade diameter and speed: the blade diameter and speed directly determine the air volume and speed of the fan.

Fan structure and motor performance: the matching between blades and fan structure and motor performance also affects the overall performance and efficiency of the fan

FAQ

Q: Are you a manufacturer? Do you have your own factory?

A: We are a manufacturer with our own factory with many years of production experience and established a good reputation.

Q: What colors can powder coatings be made of?

A: We have several advanced powder coating production lines, and can customize any color you need according to your requirements.

Q: Can you send me samples?

A: We can send samples, and the specific cost needs to be negotiated according to the actual situation.

Q: Do you have after-sales service for your products?

A: Our products have after-sales service. If there is any problem with the product you ordered, please contact us, and we will give you a satisfactory solution as soon as possible.