5052 color-coated aluminum foil is used for fin material, has good corrosion resistance and formability, and is widely used in heat exchangers and air-conditioning equipment.

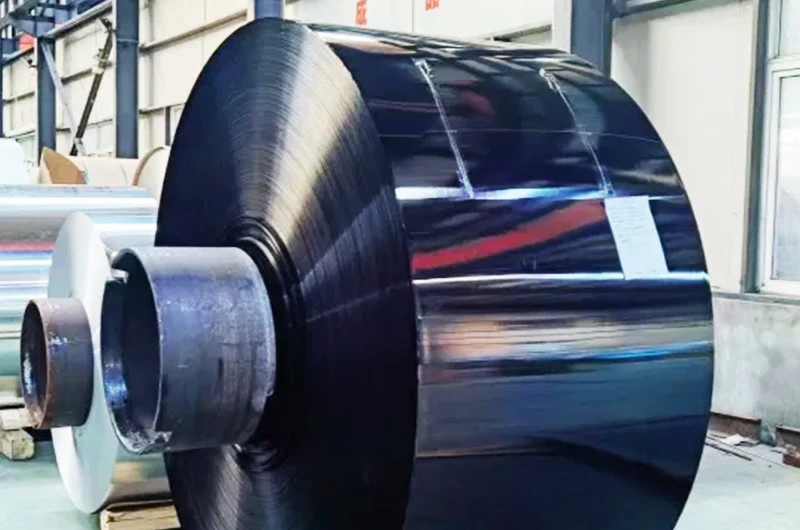

Specification for 5052 color coated aluminum foil for fin material

- Alloy non-coated:EN 573-3 Grade AW-5052 (AlMg2, 5)

- Technical delivery:EN 683-1

- Quality certificate:DIN EN 10204

Coating information of 5052 color coated aluminum foil for fin material

| Coil side | Inside | Outside |

| Chemical compound | Polyester or customized | Polyester or customized |

| Color | Black or customized | Black or customized |

| Number of layers | Double | Double |

| Lacquer surface properties | Hydrophobic | Hydrophobic |

| Coating masses, per side, double layer | 11 – 15g/cm3 | 11 – 15g/cm3 |

| Coating thickness, single spot, double layer | 10-14μm | 10-14μm |

Mechanical properties of 5052 color coated aluminum foil for fin material

| Tensile strength | 175MPa - 225MPa |

| Yield strength | >65MPa |

| Elongation | >20% |

| Erichsen without lube | >6.5mm |

EN 683-2, applies to all mechanical properties not expressly mentioned in these specifications.

Characteristics of 5052 color-coated aluminum foil for fin stock

Corrosion resistance: 5052 aluminum has good corrosion resistance, enhanced by the black polyester coating, which protects against humidity, acidic gases, and salt spray.

Heat dissipation: 5052 aluminum fins offer excellent thermal conductivity and efficiency in cooling systems. The black coating also improves heat dissipation.

Aesthetic appearance: The black polyester coating provides a sleek and modern look, suitable for products like home appliances and vehicles.

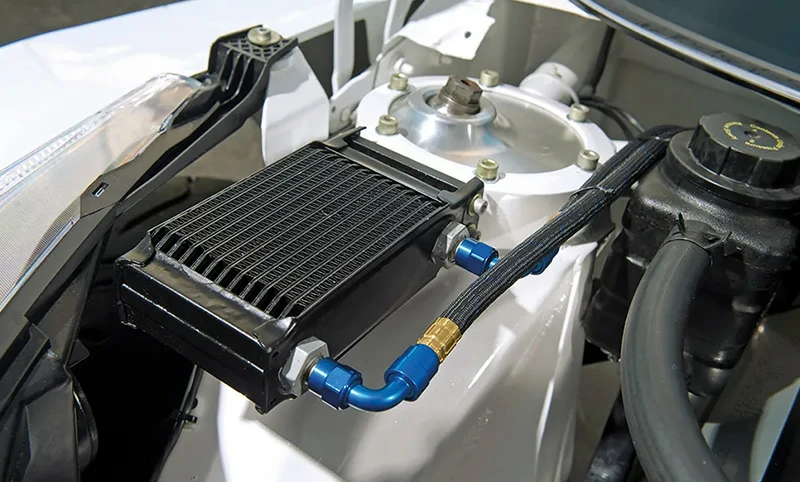

Application of 5052 color coated aluminum foil for fin stocks

Air conditioning systems: used in heat exchangers for central and residential air conditioners to enhance heat transfer efficiency and prevent corrosion.

Condensers and evaporators: employed in refrigeration and freezing equipment to ensure stable operation in high humidity and corrosive environments.

Power electronics heat sinks: used in inverters, converters, and high-power LED fixtures to help maintain low operating temperatures.

Automotive cooling systems: utilized in engine coolers and oil coolers to improve heat dissipation in high-temperature conditions.

Home appliances: such as evaporators or condensers in refrigerators and freezers, ensuring efficient and stable operation.

Dimensional tolerance of 5052 color coated aluminum foil for fin material

Thickness (nominal size ) Tolerance (at any point) Width (nominal size) Tolerance 0.2mm ±0.02mm 345mm ±0.3mm 0.2mm ±0.02mm 427mm ±0.3mm 0.2mm ±0.02mm 455mm ±0.3mmEN 683-3, current version, applies to all dimensional deviations (tolerances) not expressly mentioned in these specifications.

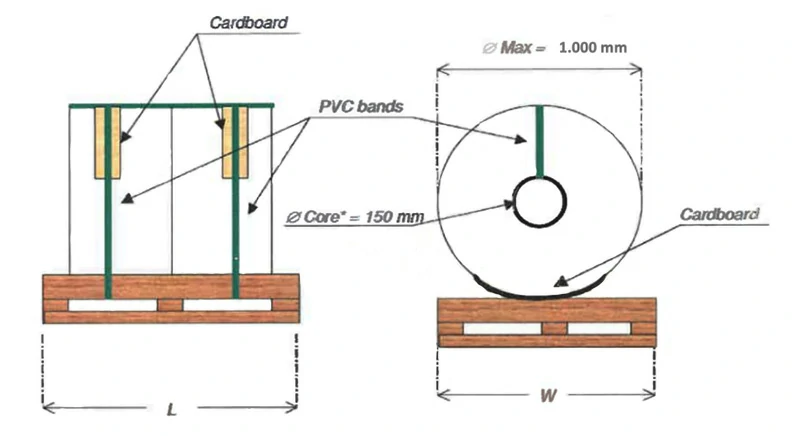

Packaging

| Coil core ID | 150mm |

| Coil OD | ≤1.000mm |

| Coil weight | ≤840kg |

| Pallet (euro pallet) | 1200 x 800mm |

| Package height | ≤1200mm |

| Package weight | ≤1.100kg |

- Coils placed on pallet: E2W (eye to the wall)

- Cardboard interlayer protection between pallet and coils

- Coils wrapped with nylon and fixed polyester ring, protection below strapping

- Coils stretch wrapped rainproof in PE foil

- No polystyrene (Styrofoam) to be used for packing/protection, but environment friendly alternatives (i.e. cardboard) only

- Coils on one pallet containing material from one specific annealing batch only

Inspection items

| Coil side | Inside | Outside |

| Adhesion | Erichsen + tear with adhesive tape – no delamination (in accordance with EN 13523) | Erichsen + tear with adhesive tape – no delamination (in accordance with EN 13523) |

| M.E.K. resistance (polymerization evaluation) | >20 double rubs (in accordance with EN 13523) | >20 double rubs (in accordance with EN 13523) |

| Corrosion resistance | 1500h in salt spray fog, ASTM B117 5% NaCl at 35°C, pH 6, 5- 7, 2. Sample without cross and with protected edges | 1500h in salt spray fog, ASTM B117 5% NaCl at 35°C, pH 6, 5- 7, 2. Sample without cross and with protected edges |

| UV resistance | 1500h UVA340 0, 89 W/m2 EN 13523-10; cycle 8 h light at 60o + 4 h condensation at 50o – gloss at 60℃ ritention < 30%. | 1500h UVA340 0, 89 W/m2 EN 13523-10; cycle 8 h light at 60o + 4 h condensation at 50o – gloss at 60℃ ritention < 30%. |