5083 aluminum plate primarily contains magnesium, offering good weldability, corrosion resistance, and fabrication properties. Its moderate strength makes it very suitable for manufacturing tank trucks for liquids. These characteristics position the 5083 aluminum plate as one of the preferred materials for aluminum tankers.Welcome to Contact

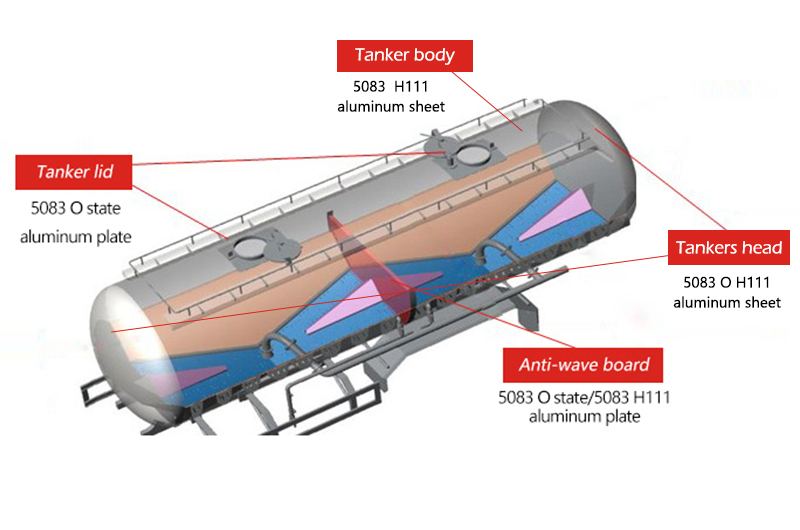

The body of a tank truck consists of components such as side panels, wave breakers, and tank openings. The tank body typically uses 5083 H111 aluminum plate, while the tank lid and internal partitions use the softer 5083-O aluminum plate for easier bending.

The width of aluminum plates for tank trucks is less than 2.2 meters, with common thicknesses of 5, 6, 7, and 8 mm. A complete tank body usually requires 4 to 6 aluminum plates welded together. Therefore, welding performance is crucial for ensuring the structural integrity and seal of the tank body.

Reasons to Select Chalco as Your Trusted 5083 Aluminum Plate Supplier

As we all know, oil tank trucks are dangerous goods on the road, and the requirements for safety are very strict. In order to ensure that our products meet the safety requirements of the tank truck industry, we have passed the certification of the EN14286 standard (European standard for the safety of liquid transport tank trucks) and the ASTM B209 standard (the American aluminum plate industry standard).

Chalco cooperates with many well-known tank car manufacturers, including CIMC Lingyu, pt.geluran adikarya, almutlak, etc.Quick Quote

Chalco has a complete set of advanced material research and development, testing, and analysis instruments, which can provide high-quality aluminum plates that meet safety standards for the tank truck industry to ensure safety and reliability during transportation.

Specifications of 5083 aluminum sheet plate for oil tanker

| Alloy | 5083 |

| Temper | O, H111 |

| Thickness | 3.00-12.00mm |

| Width | 1000-2600mm |

| Length | 2000-12000mm |

| Surface grade | Click to view detailed surface treatment |

| Permissible deviation | Click to view detailed Permissible deviation |

| Standard | EN14286, ASTM B209 |

Features of 5083 aluminum sheet plate for oil tanker

High strength: 5083 aluminum plate has been heat-treated, has good strength and stability, and can withstand mechanical stress and impact load.

High safety: the 5083 aluminum plate meets the safety requirements of the oil tanker industry, is corrosion resistant, and reduces the risk of leakage and pollution.

Excellent corrosion resistance: 5083 aluminum plate can resist the corrosion of fuel and oil, and prolong the service life of the tanker.

Good welding performance: 5083 aluminum plate can be reliably welded with other materials, which is convenient for manufacturing and assembling tank trucks.

Lightweight design: Compared with traditional steel, 5083 aluminum plate has a lower density, which realizes the lightweight of tank trucks and improves fuel economy and transportation efficiency.

Recyclability: as an aluminum alloy material, 5083 aluminum sheet can be recycled, which saves energy and has better competitiveness and higher economic benefits.

Exceptional Quality 5083 Aluminum Plate for Oil Tanker Applications and Structural Solutions

5083-O tanker aluminum plate

5083-O aluminum plate belongs to the annealed state, has good plasticity and processability and has good welding performance, and can be reliably double-sidedly welded with the tank body to ensure the tightness and safety of the tanker Structural strength. Therefore, it is often used in oil tanker heads and anti-wave plates.

5083-H111 tanker aluminum plate

5083-H111 has high strength and good plasticity, can withstand certain impact and vibration, making it an ideal material for tank truck body production. Generally, 6mm thick aluminum plates are used, and multiple aluminum plates can be effectively connected together by a can rolling machine to ensure the integrity and strength of the tanker body.

5083-H321 tanker aluminum plate

The 5083-H321 aluminum plate is stabilized for excellent resistance to stress corrosion cracking. It is suitable for use in high-intensity and high-stress environments. Therefore, it is often used in liquid level gauges, air inlets and other parts of tank trucks. Its resistance to stress corrosion cracking enables it to withstand the stress and corrosion of liquid petroleum products.

Durability and Low Maintenance Costs: The Economic Benefits of Aluminum Tankers

First, aluminum alloy tank trucks excel in safety, boasting a solid accident record. Their low center of gravity enhances braking stability, and the use of non-combustible materials reduces the risks of sparks and static electricity buildup. Additionally, the lighter weight of aluminum alloy bodies allows for higher effective payloads, which can decrease the number of transport trips and improve return on investment.

In terms of fuel efficiency, aluminum alloy tank trucks help lower carbon dioxide emissions, making them more environmentally friendly. Their strong corrosion resistance ensures a lifespan of 15 to 20 years, while maintenance costs remain low, as they do not require painting and have a durable appearance that is easy to clean. Finally, the high recyclability of aluminum provides additional revenue after the truck is decommissioned.Click to order

5083 H111 aluminum sheet plate stock list

| Description | Thickness(mm) | size/mm | Spec |

| 5083 H111 aluminum sheet | 1 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 1 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 1.5 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 1.5 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 2 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 2 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 2.5 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 2.95 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 3 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 3 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 4 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 4 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 5 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 5 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 6 | 1250x2500 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 6 | 1500x3000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 16 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 18 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 30 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 35 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 40 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 45 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 55 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 65 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 70 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 80 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 90 | 2000x4000 | EN 485, ASTM B209 |

| 5083 H111 aluminum sheet | 110 | 2000x4000 | EN 485, ASTM B209 |

Chemical composition of 5083 aluminum sheet plate for oil tanker

| Element | Composition % |

| Si | 0.40 |

| Fe | 0.40 |

| Cu | 0.10 |

| Mn | 0.40-1.0 |

| Mg | 4.0-4.9 |

| Cr | 0.05-0.25 |

| Ni | - |

| Zn | 0.25 |

| Ti | 0.15 |

| Al | Remainder |

Mechanical properties of 5083 aluminum sheet plate for oil tanker

| Temper | Thickness/mm | Tensile Strength /MPa | Specified non-proportional Tensile Strength/MPa | Elongation After Break/% | A50 mm | Bending Radius |

| O, H111 | 3.00-6.00 | 290-370 | ≥145 | ≥17 | ≥4930 | 1.5t |

| >6.00-12.00 | 290-370 | ≥145 | ≥17 | ≥4930 | 4.0t | |

| H116 | 3.00-6.00 | 305-370 | ≥220 | ≥12 | - | 3.0t |

| >6.00-12.00 | 305-370 | 220 | ≥12 | - | 6.0t | |

| H321 | 3.00-6.00 | 305-370 | ≥220 | ≥l2 | - | 3.0t |

| >6.00-12.00 | 305-370 | ≥220 | ≥12 | - | 6.0t |

Surface grade of 5083 aluminum sheet plate for oil tanker

| Type | Standard Plate | High Class Plate | Bright Plate | Mirror Plate |

| Surface | ★★★☆☆ | ★★★★☆ | ★★★★☆ | ★★★★★ |

| Roughness Ra/μm | 0.5-0.8 | 0.3-0.5 | 0.1-0.3 | ≤0.04 |

| Product Description | Smooth surface Defect deepness <Minus Tolerances Of Thickness | Fine and smooth surface No or only very little colour aberration and chatters | Bright, fine and Smooth surface No colour aberration and chatters | Mirror reflective Surface Reflectance ≥86% |

| Applicable Standards | GB/T 3880 | EN14286 ASTM B209 EN485 Customer special requirements | EN14286 ASTM B209 Customer special requirements | EN14286 ASTM B209 Customer special requirements |

| Application | Use directly or After brashing Tanker Body, Tanker Head Wall Partition, Resistance Plate | Use directly Tanker Body, Tanker Head Wall Partition, Resistance Plate | Use directly Tanker Body, Tanker Head | Use directly Tanker Body, Tanker Head |

Permissible deviation of 5083 aluminum sheet plate for oil tanker

| Thickness tolerances within the following width ranges | ||||

| Thickness | ≤1250 | >1250-1600 | >1600-2000 | >2000-2600 |

| 3.00-3.50 | +0.28 | +0.28 | +0.30 | +0.40 |

| >3.50-6.00 | +0.32 | +0.32 | +0.40 | +0.45 |

| >6.00-8.00 | +0.38 | +0.45 | +0.50 | +0.60 |

| >8.00-12.00 | +0.45 | +0.55 | +0.65 | +0.80 |

Aluminum Sheet Plate Procurement Guide

1. 5083 Aluminum Sheet Plate Weight

The weight of an aluminum sheet is calculated based on its length, width, and density. For instance, the density of 5083 aluminum alloy is 2.8g/cm³. The formula to calculate weight is:

Weight = Length (mm) × Width (mm) × Thickness (mm) × Density (2.8g/cm³)

This formula allows for accurate estimation of the aluminum sheet's weight, helping customers determine logistics costs and container space requirements.

2. 5083 Aluminum Sheet Plate Price

The FOB price of an aluminum sheet is typically based on the daily LME aluminum ingot price plus processing fees, adjusted according to exchange rates. We offer pricing in USD, EUR, or CNY as per the customer's preference. Customers can choose to customize aluminum sheets based on their specific needs or make quick purchases from our available inventory.

3.Complete Documentation Reports

Ensuring the completeness of documentation is essential for quality tracking and assurance during the procurement process. We provide a full set of detailed quality reports, including raw material certificates, lab test reports, fumigation certificates, specification guides, commercial invoices, and warranties, ensuring transparency and traceability of the product's quality.

4. Detailed Export Packaging

To ensure the integrity of aluminum sheets during international shipping, we use high-standard export packaging such as fumigation wooden crates and wooden pallets to prevent issues like rust, corrosion, scratches, deformation, or other damage during transit. Our packaging undergoes rigorous testing, with a damage rate of only one-third of the industry average, guaranteeing the product's safe arrival at its destination.

5. Professional Container Loading Solutions

Our experienced team offers flexible container loading solutions based on customer requirements. Whether opting for a 20ft, 40ft container or bulk cargo shipment, we provide optimized loading plans. Our professional loading design can save up to 15% of container space, significantly reducing logistics costs.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote