Why choose Chalco aluminum supplier?

As we all know, oil tank trucks are dangerous goods on the road, and the requirements for safety are very strict. In order to ensure that our products meet the safety requirements of the tank truck industry, we have passed the certification of the EN14286 standard (European standard for the safety of liquid transport tank trucks) and the ASTM B209 standard (the American aluminum plate industry standard).

Chalco cooperates with many well-known tank car manufacturers, including CIMC Lingyu, pt.geluran adikarya, almutlak, etc.

Chalco has a complete set of advanced material research and development, testing, and analysis instruments, which can provide high-quality aluminum plates that meet safety standards for the tank truck industry to ensure safety and reliability during transportation.

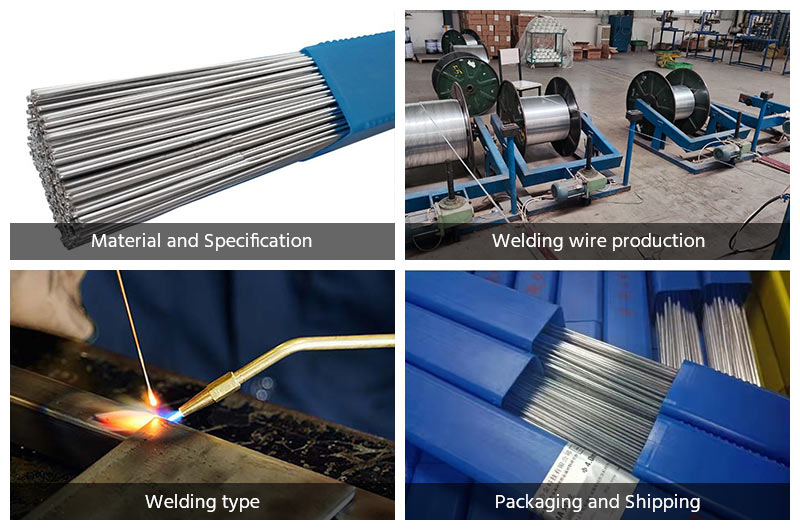

Specification parameters of ER5183 ER5356 aluminum welding wire for oil tanker

| Alloy | Category | Dimensions mm | Net weight (per box or roll) kg | ||

| Diameter | Length | Coil Diameter | |||

| 5183, ER5183 5356, ER5356 | Straight wire | 1.60, 2.00, 2.40, 3.00, 3.20, 4.00, 5.00 | 1000 | - | 2.5, 5, 10, 20 |

| Reel-mounted wire | 0.80, 1.00, 1.20, 1.60 | - | 100 | 0.45 | |

| 200 | 2.0, 2.5 | ||||

| 270, 300 | 5, 6, 7 | ||||

| Hollow coil wire | 2.40, 3.00, 3.20, 4.00 | - | - | 5, 8, 10, 12, 15 | |

Chemical composition of ER5183 ER5356 aluminum welding wire for oil tanker

| Element | Composition % | |

| 5183 | 5356 | |

| Si | 0.40 | 0.25 |

| Fe | 0.40 | 0.40 |

| Cu | 0.10 | 0.10 |

| Mn | 0.50-1.00 | 0.05-0.20 |

| Mg | 4.3-5.2 | 4.5-5.5 |

| Cr | 0.05-0.25 | 0.05-0.20 |

| Ni | - | - |

| Zn | 0.25 | 0.10 |

| Ti | 0.15 | 0.06-0.20 |

| Be | 0.0005 | 0.00 |

| Al | Remainder | |

Physical properties of ER5183 ER5356 aluminum welding wire for oil tanker

| Physical property | ER5183 | ER5356 |

| Tension strength (MPa) | 275-300 | 250-300 |

| Yield strength (MPa) | 125-140 | 110-140 |

| Elongation (%) | 15-20 | 15-25 |

| Melting temperature℃ | 574-638 | 575-633 |

| Thermal conductivity w/m•K | 120 | 120 |

| Linear expansion coefficient 10-6/K(20-100℃) | 24.2 | 24.1 |

| Electric conductivity % IACS | 29 | 29 |

Allowable deviation of ER5183 ER5356 aluminum welding wire for oil tanker

| Wire Category | Diameter allowable deviation/mm | Diameter allowable deviation/mm |

| Reel-mounted wire | -0.02 | - |

| Hollow coil wire | -0.02 | - |

| Straight wire | ±0.10 | ±2 |

Features of ER5183 ER5356 aluminum welding wire for oil tanker

Features of ER5183 welding wire

Chemical composition: ER5183 welding wire contains elements such as magnesium and manganese, making it suitable for welding materials with high magnesium content in aluminum alloys.

Corrosion resistance: ER5183 welding wire has good corrosion resistance and can maintain the stability of the weld in harsh environments.

High strength: after welding, the aluminum alloy weld seam has high strength, which is suitable for oil tanker parts that require high welding strength.

Welding performance: ER5183 welding wire has good welding performance, which can provide good fluidity and weld appearance quality.

Features of ER5356 welding wire

Chemical composition: ER5356 welding wire contains elements such as magnesium and manganese, and is suitable for welding most aluminum alloy materials, including common aluminum alloys and magnesium alloys.

Anti-corrosion performance: ER5356 welding wire has good anti-corrosion performance and is suitable for tank truck parts working in harsh environments.

High fluidity: ER5356 welding wire has high fluidity, which makes the welding operation more convenient and easier to control.

Welding performance: ER5356 welding wire can provide high-quality welds with good welding performance and appearance quality.

Application of Chalco ER5183 ER5356 aluminum welding wire for oil tanker

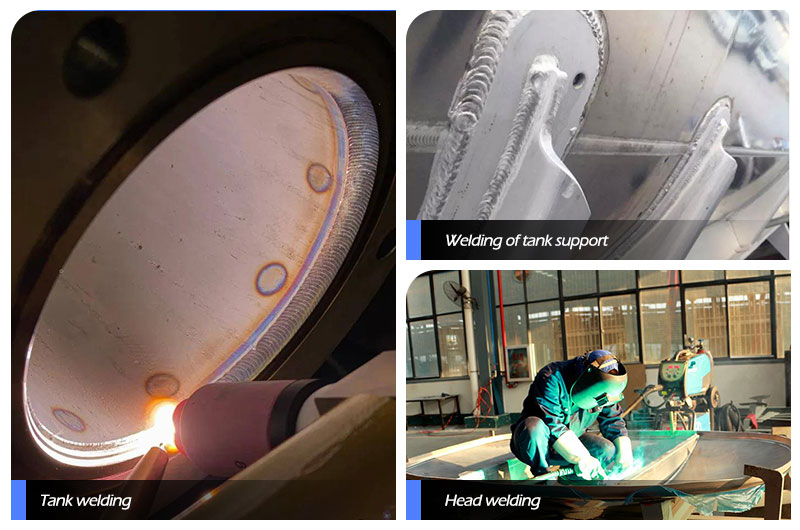

In the manufacturing process of tank trucks, ER5183 ER5356 aluminum alloy welding wires are usually used for welding. ER5183 ER5356 welding wire is a commonly used aluminum alloy welding wire, which has good welding performance and corrosion resistance, and is suitable for welding aluminum alloy materials.

The application of ER5183 ER5356 aluminum welding wire in the manufacture of tank trucks includes the following aspects:

Tank truck body welding: ER5183 ER5356 welding wire is often used for welding the body parts of tank trucks, including welding tank wall panels, welding tank body structures and connectors, etc. It can provide good weld strength and corrosion resistance, ensuring the stability and safety of the tank truck during use.

Welding of valves and joints: components such as valves and joints in tank trucks also need to be welded. Welding with ER5183 ER5356 welding wire can ensure the reliability and tightness of the connection to meet the operation requirements of the tanker.

Pipe welding: piping systems in tank trucks require welded connections. ER5183 ER5356 welding wire can be used to weld aluminum alloy pipes to ensure the firmness and sealing of pipe connections.

Precautions for purchasing ER5183 ER5356 tanker aluminum welding wire

Gauge and size: determine the required wire gauge and size, such as diameter, wire length, etc. Make sure the welding wire you purchase meets tank truck welding requirements and specifications.

Quality certification: choose welding wire products with qualified certification. Check whether there are relevant quality certification marks on the product packaging, such as the AWS logo, to ensure reliable product quality.

Supplier reputation: choose a reputable supplier or distributor. Chalco Aluminum has a good reputation and ability to supply quality products.

Packaging and storage: check that the wire packaging is intact and that it has not been affected by moisture, corrosion, or other adverse effects. Also, care should be taken when storing welding wire to avoid exposure to moisture, moisture, or other harmful environments.

Selection of welding wire type: according to the specific requirements and welding specifications of the tanker, determine whether to choose ER5183 or ER5356 welding wire. Selection can be made by consulting a professional welding engineer or following code recommendations.

Follow code: always follow applicable welding codes and standards when purchasing and using welding wire. Make sure that the selected welding wire meets the specification requirements, and that the welding wire is handled and stored correctly according to the specification.