6061 T6 aluminum alloy is widely used in aerospace, automobile manufacturing, construction, electronic equipment, sports equipment, shipbuilding industry and tooling manufacturing due to its high strength, corrosion resistance, excellent machinability and lightweight properties, and the market demand continues to grow. With its good weldability and heat treatment strengthening ability, this aluminum alloy plays an important role in many structural parts and mechanical parts.

Chalco provides a rich inventory of 6061 T6 aluminum alloy, covering various specifications such as aluminum plates, aluminum bars, aluminum tubes, aluminum profiles, forgings, aluminum billets, etc., and supports customized processing to meet the needs of different industries. Welcome to cooperate and share high-quality aluminum solutions!

What is 6061 aluminum T6 temper

6061: Indicates that the alloy belongs to the 6XXX series aluminum alloy. Its main alloying elements are magnesium (Mg) and silicon (Si). It has good mechanical properties and corrosion resistance.

T6: Indicates that the aluminum alloy has undergone a solution heat treatment + artificial aging strengthening process to achieve optimal strength.

- Solution Heat Treatment: The aluminum alloy is heated to about 530°C (985°F) to fully dissolve the alloying elements, and then quickly quenched to room temperature.

- Artificial aging: The quenched aluminum alloy is heated to 160°C (320°F) and maintained for 8 hours to promote the precipitation of alloying elements and form a strengthening phase, thereby increasing hardness and strength.

Click to jump to view detailed [Performance Parameters Table]

Why is T6 the most popular temper for 6061 alloy?

Among the various 6061 aluminum alloy tempers, T6 temper has become the first choice in the market due to its excellent comprehensive performance. Whether in terms of strength, processing performance, or fatigue resistance, T6 has shown outstanding advantages. The table below provides a detailed performance comparison to help you better understand the temper advantages of 6061 T6 temper.

| Advantages | General performance of 6061 | Is the 6061-T6 temper optimal? | Explain |

| Strength to Weight Ratio | 6061 has a good strength-to-weight ratio, being stronger than pure aluminum while remaining lightweight. | Best | The maximum strength (tensile strength 310-330 MPa) was achieved after T6 treatment, which was much higher than that of O and T4 tempers. |

| Machinability | 6061 is suitable for CNC machining, turning, drilling, milling and other processes, and has good processing performance. | Best | T6 has moderate hardness and better cutting performance, and is suitable for CNC precision machining. T4 is slightly inferior. |

| Anti-fatigue performance | 6061 has good fatigue resistance and is suitable for situations where long-term load bearing is required. | Best | After T6 treatment, the internal structure of the material is more uniform and its fatigue resistance is better than that of the annealed temper (O temper). |

| Surface treatment compatibility | 6061 can be subjected to surface treatments such as anodizing, electroplating, and spraying to improve aesthetics and durability. | Best | The hardness and structure of T6 temper are suitable for surface treatment such as anodizing, electroplating, and spraying, and the surface wear resistance is better. |

| Corrosion resistance | 6061 has excellent resistance to oxidation and corrosion, making it suitable for marine, outdoor and wet environments. | Best | T6 still maintains the good corrosion resistance of 6061 and is particularly suitable for outdoor or humid environments. |

| High temperature resistance | The performance of 6061 is stable at room temperature and medium temperature, but its strength will decrease at high temperature. | Not optimal | T6 will lose strength in high temperature environments, and T651 or other heat treatments may be more suitable for extreme temperature environments. |

| Weldability | 6061 can be MIG and TIG welded, but the strength after welding will be affected in some heat treatment tempers. | Not optimal | 6061-T6 can be welded, but the strength of the heat affected zone will be reduced after welding, and the welding performance of T4 temper is better. |

- Reasonable production cost: Compared with 7XXX high-strength aluminum alloy, 6061-T6 has lower raw material and processing costs. At the same time, the heat treatment process is mature, suitable for large-scale manufacturing, and cost-effective.

- Adequate supply and high market recognition: Due to the wide application of 6061-T6 and the mature global supply chain, almost all aluminum alloy manufacturers can provide stable supply, convenient procurement, and small price fluctuations, making it the preferred aluminum alloy in the market

Therefore, 6061-T6 is not only the alloy of choice in many industries, but also an indispensable and important material in modern industrial manufacturing.

6061 T6 aluminum sheet plate

6061 T6 sheet thickness range: 0.032 inches (about 0.81 mm) - 0.375 inches (about 9.53 mm)

6061 T6 plate thickness range: 0.6-200mm,

Dimensions: The common size is 48 inches x 144 inches (about 1219 mm x 3658 mm), and it can also be customized in 12-inch (about 305 mm) increments according to needs, such as 12 inches x 48 inches, 24 inches x 48 inches, etc.

Surface treatment: Color-coated, anodized, punched, some sheets are coated with PVC on one side to protect the surface finish.

Implementation standards: ASTM.B209, AMS.4027, AMS-QQ-A-250/11, AMS.4025, ASTM B209, DIN EN 485-2, GB/T 3190

Products display:

6061 T6 aluminum bare sheet

No additional coating, suitable for applications where subsequent machining, welding or anodizing is required.

6061 T6 clad sheet plate

The outer layer is coated with high-purity aluminum to improve corrosion resistance, especially suitable for aerospace and highly corrosive environments.

6061 T6 precision milled plate

After precision machining, the surface is highly flat and the tolerances are strictly controlled.

6061 T6 diamond plate

6061 T6 checkered plate

6061 T6 anodized aluminum plate

6061 T6 aluminum bar

Diameter range: φ5mm~φ500mm

Length: Regular length is 1000mm~6000mm, can be customized according to customer needs

Surface treatment: Various surface treatments such as bright surface, brushed surface, oxidation treatment, etc. can be provided

Processing services: turning, milling, drilling, tapping, anodizing, bending, stamping

Implementation standards: ASTM B221, EN 573-3, GB/T 3191, etc.

Products display:

6061 T6 cold drawn bar

6061 T6 round bar

6061 T6 square bar

6061 T6 aluminum flat bar

Thickness: 0.08"-9.8"(2-250mm)

Width: 0.2"-11.8"(5-300mm)

Length: 3m/6m/12m, customizable for cutting

Surface treatment: tin plating, copper-aluminum composite, anodizing

Edge processing: Right angle, rounded corner, R rounded corner

Specification: ASTM B221, AMS-QQ-A-200/8

Products display:

6061 T6 tinned aluminum busbar

6061 T6 bent aluminum bar

6061 T6 busbar

6061 T6 extruded aluminum

Tubes: Diameters range from 6mm to 450mm, wall thickness range from 0.5mm to 12mm.

Bars: Diameter range from 6 mm to 350 mm.

Structural shape: Thickness ranges from 0.5mm to 100mm, width ranges from 10mm to 1200mm.

Implementation standard: BS EN 755-2:2008

Product display:

6061 T6 aluminum angle

6061 T6 aluminum T-bar

6061 T6 aluminum I-beam

6061 T6 aluminum H-beam

6061 T6 aluminum channel

6061 T6 aluminum Z-bar

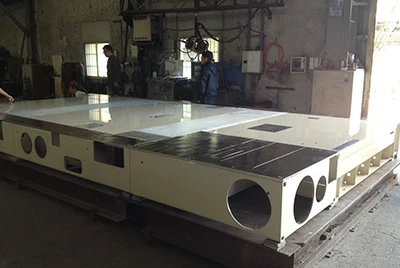

6061 T6 forged aluminum

Free forging block: maximum weight ≤5T, length ≤7000mm, width ≤2000mm, height ≤500mm.

Free forging disc: maximum weight ≤5T, diameter ≤2500mm.

Free forging ring: maximum weight ≤5T, outer diameter of quenched parts ≤2500mm, outer diameter of non-quenched parts ≤4000mm.

Free forging shaft: maximum weight ≤8T, length ≤7000mm, diameter ≤800mm.

General closed die forgings: PVA ≤ 3.0, diameter ≤ 1950mm.

Complex closed die forgings: PVA ≤ 1.5㎡, diameter ≤ 1400mm.

Products display:

6061 T6 forging ring

6061 T6 forging block

6061 T6 forged disc

6061 T6 aluminum tube

6061 T6 aluminum tube is a high-strength, corrosion-resistant and easy-to-process aluminum alloy tube, which is widely used in aerospace, automobile manufacturing, shipbuilding, rail transportation, mechanical equipment and other industries. Its T6 heat treatment temper enables it to have excellent mechanical properties while maintaining a light weight.

Products display:

6061 t6 seamless pipe

6061 t6 round tube

6061 t6 square tube/rectangular tube

6061 t6 thin wall tube

6061 t6 extruded tube

6061 t6 forged pipe

6061 T6 aluminum block

6061 T6 aluminum cube is a high-strength, corrosion-resistant, easy-to-process aluminum alloy material suitable for mold manufacturing, mechanical parts, aerospace, automotive industry and other fields. The T6 temper is solution treated and artificially aged to give it excellent mechanical properties.

Products display:

6061 T6 precision machined aluminum blocks

6061 T6 aluminum block for mold processing

6061 T6 milled aluminum block

6061 T6 billet aluminum

6061 T6 aluminum billet is a high-strength, corrosion-resistant, easy-to-process aluminum alloy billet, widely used in secondary processing such as extrusion, forging, machining, casting, etc. It is the basic material for the production of high-performance aluminum materials such as aerospace, automobiles, ships, rail transportation, and mechanical equipment. The 6061 aluminum ingot in T6 temper undergoes solution heat treatment and artificial aging, giving it excellent mechanical properties and dimensional stability.

Produts display:

6061 extrusion billet

6061 forging billet

6061 CNC machining billet

Why Choose Chalco as your supplier of 6061 T6 products

Among many 6061 T6 aluminum alloy manufacturers and suppliers, Chalco stands out with its excellent production capacity, rich inventory, professional deep processing services and industry-leading quality standards. Whether you are purchasing standard 6061 T6 aluminum in bulk or customizing a product that requires precision machining, Chalco can provide you with a cost-effective solution.

Production advantages: high-quality aluminum manufacturer

Chalco is not only a supplier of 6061 T6 aluminum, but also a high-standard manufacturer. We have significant advantages in the following aspects:

- Control of the entire industry chain: From aluminum ingot smelting, alloy proportioning, extrusion molding to heat treatment, integrated production ensures the traceability and stability of product quality.

- High-standard production system: Strictly implement international standards such as ASTM B221, EN 573-3, GB/T 3191, etc. to ensure that materials meet the strict requirements of various industries.

- Precise alloy composition control: Advanced smelting and refining technology is used to ensure that 6061 T6 aluminum alloy has excellent mechanical properties and corrosion resistance.

- Advanced heat treatment process: The strength and hardness of T6 temper have been fully optimized to ensure the stability of the mechanical properties of the material.

- Large-scale production capabilities: Chalco has multiple production lines for aluminum bars, sheets, tubes and profiles to meet large volume orders with guaranteed lead times.

- Ample inventory and fast delivery: Chalco stocks 6061-T6 aluminum bars, plates, tubes, and profiles across multiple warehouses. We support both bulk and small-batch orders, ensuring quick response and reduced lead times for faster production.

- Global logistics system: strong warehousing and distribution capabilities, able to quickly respond to customer needs, reduce inventory pressure, and shorten procurement cycles.

Processing advantages: Not just aluminum, we provide complete processing solutions

Chalco not only provides T6 basic products, but also can carry out deep processing to save time and cost for customers.

- CNC precision machining: Provide high-precision machining services such as turning, milling, and drilling, so that aluminum can be directly applied to the final product, reducing the customer's secondary processing costs.

- Cutting and cut-to-length processing: Providing customized sized aluminum bars, aluminum plates, and aluminum tubes to reduce material waste and optimize customers' production efficiency.

- Bending, welding and assembly: With professional welding and forming capabilities, we provide customers with one-stop structural parts processing services.

- Anodizing and surface treatment: Different levels of anodizing can be provided according to customer needs to improve the corrosion resistance, aesthetics and service life of aluminum.

- Extrusion molding and customized profiles: With a variety of extrusion dies, we can produce aluminum profiles with complex cross-sections to meet the needs of industries such as aviation, rail transportation, and construction.

If you are looking for high-quality, cost-effective, high-precision processed 6061 T6 aluminum alloy products, Chalco is undoubtedly your best choice. We can not only provide standardized aluminum materials, but also carry out deep processing according to your needs, helping you shorten production cycles, improve efficiency, reduce costs, and make your business more competitive!

Chalco 6061 T6 product 7 major cooperation areas

Chalco is committed to providing high-quality 6061 T6 aluminum alloy products to customers around the world. With excellent material properties, precision processing capabilities and high-quality services, we have maintained close cooperation with many industries such as aerospace, automotive manufacturing, construction industry, electronic equipment, sports equipment, shipbuilding industry and tooling manufacturing, and enjoy a good reputation in the industry.

Our 6061 T6 aluminum alloy products have become the first choice for many companies in need of high-performance aluminum materials due to their high strength, corrosion resistance, excellent machinability and lightweight properties.

1. 6061 T6 products for aerospace

6061 T6 aluminum alloy is widely used in the aerospace field for key components such as aircraft structures, brackets, cockpit components, etc. due to its light weight, high strength and corrosion resistance.

Product form and application area:

- 6061 T6 Aluminum Plate: Cabin frame, aviation skin, bulkhead support

- 6061 T6 Aluminum Bar: Connectors, Fixing Brackets, Fasteners

- 6061 T6 Aluminum Tube: Hydraulic pipeline, fuel delivery pipeline

- 6061 T6 Aluminum Extrusion Profiles: Cabin structural parts, seat rails

2. 6061 T6 products for automobile manufacturing

6061 T6 aluminum alloy is widely used in components such as automobile body, chassis structure, power system and battery tray of new energy vehicles due to its high strength, low density, excellent corrosion resistance and good machinability.

Product form and application area:

- 6061 T6 Aluminum Plate: body guard plate, battery tray, engine compartment heat shield

- 6061 T6 Aluminum Bar: Suspension support rods, steering components, axles

- 6061 T6 Aluminum Tube: Frame structure, exhaust pipe, cooling system pipe

- 6061 T6 Aluminum Profiles (Extrusion Profiles): Door reinforcement beams, anti-collision beams, roof brackets

3. 6061 T6 products in the construction industry

6061 T6 aluminum alloy is used in the construction industry for structural frames, door and window systems, curtain wall supports and other fields due to its high strength, corrosion resistance and good machinability.

Supply product form and application parts:

- 6061 T6 angle bar: building frame support, structural beam

- 6061 T6 C-Channel: curtain wall support, bridge structure

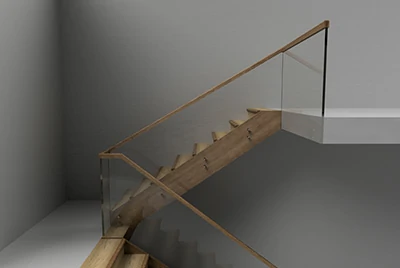

- 6061 T6 T-bar: stair handrails, railing supports

- 6061 T6 aluminum plate: Exterior wall decorative panels, building curtain wall systems

- 6061 T6 aluminum profiles: Door and window frames, building rails, ceiling keels

4. 6061 T6 products for electronic equipment

6061 T6 aluminum alloy is widely used in electronic equipment casings, radiators, power supply casings, etc. due to its good thermal conductivity, heat dissipation capacity and high mechanical strength.

Supply product form and application parts:

- 6061 T6 aluminum plate: Laptop shell, server chassis, electronic product panel

- 6061 T6 aluminum tube: Battery cooling system, electronic cooling system pipes

- 6061 T6 heat sink profiles: LED heat sink, power cooling system, chip cooling module

- 6061 T6 aluminum bar: electronic equipment structural support, battery module bracket

5. 6061 T6 products for sports equipment

6061 T6 aluminum alloy is widely used in the sports equipment industry for bicycle frames, scooters, trekking poles, golf clubs, etc. due to its light weight, high strength and impact resistance.

Supply product form and application parts:

- 6061 T6 Aluminum Tube: Bicycle frames, scooter stands, trekking poles

- 6061 T6 Aluminum Bar: Golf clubs, badminton racket shafts, fitness equipment support rods

- 6061 T6 Aluminum Plate: Sports equipment pedals, ski support structures

- 6061 T6 Aluminum Extrusion Profiles: Ski equipment frames, surfboard supports

6. 6061 T6 products for marine industry

The high corrosion resistance and seawater resistance of 6061 T6 aluminum alloy make it widely used in ship structures, deck components, bulkheads, offshore equipment and other fields.

Supply product form and application parts:

- 6061 T6 Aluminum Plate: Hull structure, deck anti-skid plate, bulkhead reinforcement plate

- 6061 T6 Aluminum Bar: Ship support beams, marine equipment connectors

- 6061 T6 Aluminum Tube: Ship railings, lifeboat frames, cooling system pipes

- 6061 T6 Aluminum Extrusion Profiles: Ship cabin frames, deck rails, ship ladders

7. 6061 T6 products for Tooling & Molding

6061 T6 aluminum alloy is widely used in mold manufacturing, tooling, precision processing equipment and other fields due to its high hardness, stability and good processing performance.

Supply product form and application parts:

- 6061 T6 Mold Aluminum Block: Plastic Mold, Die Casting Mold, Injection Mold

- 6061 T6 Aluminum Plate: mold substrate, mechanical equipment base, pressure vessel panel

- 6061 T6 Aluminum Bar: Fixtures, Positioning Fixtures, Precision Machining Parts

- 6061 T6 Aluminum Profiles (Extrusion Profiles): CNC machine tool support parts, automation equipment guide rails

6061 T6 detailed parameters

| Physical Properties | Metric | English | Comments |

| Density | 2.7 g/cc | 0.0975 lb /in³ | AA; Typical |

| Mechanical Properties | Metric | English | Comments |

| Hardness, Brinell | 95 | 95 | AA; Typical; 500 g load; 10 mm ball |

| Hardness, Knoop | 120 | 120 | Converted from Brinell Hardness Value |

| Hardness, Rockwell A | 40 | 40 | Converted from Brinell Hardness Value |

| Hardness, Rockwell B | 60 | 60 | Converted from Brinell Hardness Value |

| Hardness, Vickers | 107 | 107 | Converted from Brinell Hardness Value |

| Ultimate Tensile Strength | 310 MPa | 45000 psi | AA; Typical |

| Tensile Yield Strength | 276 MPa | 40000 psi | AA; Typical |

| Elongation at Break | 12 % | 12 % | AA; Typical; 1/16 in. (1.6 mm) Thickness |

| Elongation at Break | 17 % | 17 % | AA; Typical; 1/2 in. (12.7 mm) Diameter |

| Modulus of Elasticity | 68.9 GPa | 10000 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Notched Tensile Strength | 324 MPa | 47000 psi | 2.5 cm width x 0.16 cm thick side-notched specimen, Kt = 17. |

| Ultimate Bearing Strength | 607 MPa | 88000 psi | Edge distance/pin diameter = 2.0 |

| Bearing Yield Strength | 386 MPa | 56000 psi | Edge distance/pin diameter = 2.0 |

| Poisson's Ratio | 0.33 | 0.33 | Estimated from trends in similar Al alloys. |

| Fatigue Strength | 96.5 MPa | 14000 psi | AA; 500, 000, 000 cycles completely reversed stress; RR Moore machine/specimen |

| Fracture Toughness | 29 MPa-m½ | 26.4 ksi-in½ | KIC; TL orientation. |

| Machinability | 50 % | 50 % | 0-100 Scale of Aluminum Alloys |

| Shear Modulus | 26 GPa | 3770 ksi | Estimated from similar Al alloys. |

| Shear Strength | 207 MPa | 30000 psi | AA; Typical |

| Thermal Properties | Metric | English | Comments |

| CTE, linear 68°F | 23.6 µm/m-°C | 13.1 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 25.2 µm/m-°C | 14 µin/in-°F | Estimated from trends in similar Al alloys. 20-300°C. |

| Specific Heat Capacity | 0.896 J/g-°C | 0.214 BTU/lb-°F | |

| Thermal Conductivity | 167 W/m-K | 1160 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

| Melting Point | 582 - 652 °C | 1080 - 1205 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater; Eutectic melting can be completely eliminated by homogenization. |

| Solidus | 582 °C | 1080 °F | AA; Typical |

| Liquidus | 652 °C | 1205 °F | AA; Typical |

| Processing Properties | Metric | English | Comments |

| Solution Temperature | 529 °C | 985 °F | |

| Aging Temperature | 160 °C | 320 °F | Rolled or drawn products; hold at temperature for 18 hr |

| Aging Temperature | 177 °C | 350 °F | Extrusions or forgings; hold at temperature for 8 hr |

More 6061 aluminum temper selection tips

When choosing 6061 products, T6 temper is the most common strengthening temper, but it is not the only choice. Different tempers are suitable for different processing needs, so understanding the difference between T6 and other tempers, as well as the processing methods suitable for T6 temper, can help you choose the right aluminum bar products more accurately.

| temper | Features | Strength (MPa) | Application Scenario |

| 6061-O | Annealed temper, very soft | 124 MPa | Deep drawing, bending, applications requiring high ductility |

| 6061-T4 | Solution treated but not fully aged, lower strength | 207 MPa | Applications requiring subsequent processing or forming |

| 6061-T6 | Solution treatment + artificial aging, highest strength | 310-330 MPa | Structural parts, mechanical parts, large projects |

| 6061-T651 | Tensile stress relieved version in T6 temper | 310-330 MPa | High-precision machining to reduce internal stress and deformation |

Selection suggestion:

- If high-strength and good rigidity materials are required, T6 is the first choice, especially for structural parts that bear heavy loads.

- If the material requires better plasticity, such as bending, stamping or stretching, it is recommended to choose O temper or T4 temper.

- If used for CNC precision machining, T651 is better because it is stress-relieved and less likely to deform.