6063 aluminum alloy is a heat-treated, reinforced aluminum alloy with magnesium and silicon as its main alloying elements. It has excellent extrudability, good corrosion resistance, and a beautiful surface finish. With moderate strength, it is ideal for anodizing and is one of the preferred materials for architectural and industrial aluminum profiles.

Equivalent names for 6063 aluminum

| UNS | ASTM | DIN | EN | JIS | GB/T | BS | ISO |

| A96063 | AA6063 | AlMgSi0.5 / 3.3206 | EN AW-6063 | A6063 | 6063 | HE9 | AlMg0.7Si |

The properties of 6063 aluminum alloy

Strength

Corrosion Resistance

Weldability & Brazability

Workability

Machinability

The strength of 6063 aluminum alloy is considered medium, slightly lower than higher-strength alloys like 6061. Although it is not suitable for heavy-duty structures, it is sufficient for general architectural profiles and medium to light industrial applications. It provides basic structural support while maintaining good formability.

6063 has excellent corrosion resistance, especially after anodizing, which forms a dense protective layer that effectively resists oxidation and atmospheric corrosion. It is particularly suitable for outdoor use, such as doors, windows, curtain walls, and railings, which are exposed to natural environments for long periods.

6063 aluminum alloy is suitable for various common welding methods, making it easy to process. For welding, 5183 or 4043 alloy welding wires are typically used. If conductivity is more important, 4043 is recommended; if stronger welds are desired, 5346 welding wire can be used. However, due to its lower conductivity, the weld size may need to be increased to compensate.

6063 offers excellent extrudability and can be processed into various complex profiles, making it ideal for customized needs in the industrial and construction fields. It also has good bending, forming, and stamping capabilities, making it suitable for various manufacturing processes.

Although it can be machined by turning, drilling, and other methods, 6063's machinability is not as good as certain higher hardness alloys, such as 6061 or 2024. When machining, it is necessary to choose the appropriate tools and cutting parameters to achieve better surface quality.

Applications of 6063 aluminum alloy

6063 aluminum is the most popular extrusion alloy, widely used in construction applications. Therefore, it is often referred to as architectural aluminum.

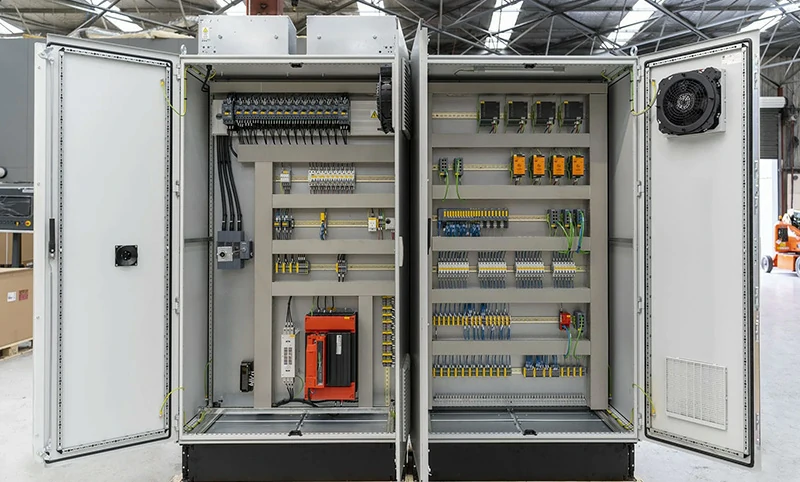

It is a medium-strength alloy used in applications such as railings, window frames, door frames, roofs, fences, sign frames, store fixtures, irrigation pipes, building products, electrical equipment, ships, piping, recreational equipment, tanks, truck frames, and trailers.

6063 aluminum chemical composition

| Element | Composition |

| Aluminium (Al) | 97.5 – 99.35% |

| Magnesium (Mg) | 0.45 – 0.90% |

| Silicon (Si) | 0.20 – 0.60% |

| Iron (Fe) | 0 – 0.35% |

| Chromium (Cr) | 0 – 0.10% |

| Copper (Cu) | 0 – 0.10% |

| Manganese (Mn) | 0 – 0.10% |

| Titanium (Ti) | 0 – 0.10% |

| Zinc (Zn) | 0 – 0.10% |

| Other(each) | ≤ 0.05% |

| Other(totalh) | ≤ 0.15% |

6063 aluminum alloy is primarily composed of aluminum, magnesium, and silicon. The high aluminum content (over 97.5%) ensures the material's lightweight and good processing properties. The combination of magnesium and silicon enhances strength and corrosion resistance while providing excellent extrudability and anodizing effects.

Other elements such as iron, copper, manganese, chromium, titanium, and zinc are present in trace amounts, further improving the alloy's structure and processing capabilities. The impurity content is strictly controlled, making 6063 aluminum highly suitable for architectural and industrial applications that require high surface quality.

What are the temper of 6063 aluminum alloy?

- O: Annealed condition, not heat-treated, the material is the softest with the best ductility and formability, lowest strength, suitable for processing where high plasticity is required.

- T1: The aluminum profile is naturally cooled and aged after extrusion, with a certain but relatively low strength, suitable for structural parts with low strength requirements.

- T4: After solution heat treatment, the material is naturally aged, offering good machinability and medium strength, suitable for applications requiring further processing or welding.

- T5: After extrusion, the material undergoes artificial aging treatment, increasing strength and hardness, commonly used for building profiles and general structural parts.

- T6: After solution heat treatment and artificial aging, the material achieves the highest strength level for 6063, suitable for industrial and engineering applications requiring high structural strength.

- T52: After extrusion, the material undergoes specific artificial aging to improve stress corrosion resistance, commonly used for complex shapes or components with uneven stress.

- T53: Similar to T52, this medium-strength aging treatment emphasizes corrosion resistance and structural stability, suitable for light-load engineering structures.

- T54: Controlled cooling and customized aging treatment provide dimensional stability and medium mechanical properties, suitable for parts with precision requirements.

- T55: Fast cooling followed by short-time artificial aging, with slightly higher strength than T5 while retaining good machinability, suitable for high-efficiency production needs.

- T832: A special treatment for stress corrosion resistance, suitable for structural applications with high reliability and service life requirements.

Mechanical properties of 6063 aluminum

| Temper | Thickness range | Ultimate tensile strength (MPa / psi) | Yield strength (MPa / psi) | Elongation (%) |

| 6063-O | All thicknesses | ≤ 130 MPa (19, 000 psi) | ≥ 49 MPa (7, 200 psi) | 18% |

| 6063-T1 | ≤ 12.7 mm (0.5 in) | ≥ 120 MPa (17, 000 psi) | ≥ 62 MPa (9, 000 psi) | 12% |

| 13 – 25 mm (0.5 – 1 in) | ≥ 110 MPa (16, 000 psi) | ≥ 55 MPa (8, 000 psi) | 12% | |

| 6063-T5 | ≤ 13 mm (0.5 in) | ≥ 140 MPa (20, 000 psi) | ≥ 97 MPa (14, 000 psi) | 8% |

| 13 – 25 mm (0.5 – 1 in) | ≥ 130 MPa (19, 000 psi) | ≥ 90 MPa (13, 000 psi) | 8% | |

| 6063-T6 | ≤ 3.15 mm (0.124 in) | ≥ 190 MPa (28, 000 psi) | ≥ 160 MPa (23, 000 psi) | ≥ 8% |

Why is 6063 aluminum alloy suitable for anodizing?

6063 belongs to the Al-Mg-Si alloy series, with moderate silicon (Si) and magnesium (Mg) content, which prevents the formation of rough, spotted, or dull surfaces that some high-silicon alloys may produce. This makes 6063 form a uniform and delicate oxide film after anodizing.

With aluminum content above 97.5% and very low impurity levels such as iron and copper, 6063 avoids color changes or instability in the oxide film due to impurity reactions during anodizing, ensuring better film formation and more stable color.

6063 alloy was originally designed for use in architectural windows, doors, curtain walls, and other decorative applications. Therefore, its formulation balances strength with appearance quality after anodizing, providing excellent results after anodizing, coloring, electrophoresis, powder coating, and other surface treatments.

After anodizing, the surface of 6063 aluminum forms a dense aluminum oxide layer, offering excellent weather resistance and corrosion resistance, making it ideal for outdoor environments (such as curtain walls, balconies, and window and door profiles).

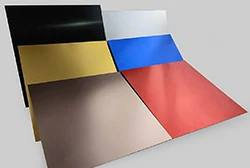

6063 aluminum alloy anodized product display examples:

Anodized 6063 aluminum sheet

Anodized 6063 aluminum round tube

Anodized 6063 aluminum square tube

Anodized 6063 aluminum angle

Anodized 6063 aluminum U-channel

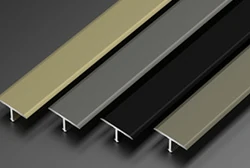

Anodized 6063 aluminum T-bar

Curious about anodizing and how to prevent color issues? Dive deeper with [All About Aluminum Anodizing]and [Anodizing Coloring Defects].

What 6063 aluminum products can Chalco provide?

6063 aluminum angle

6063 aluminum rectangular tube

6063 aluminum channel

If you have any 6063 aluminum product requirements, please click to contact us. Quick Quote

Chalco's 6063 aluminum product specifications

All Chalco 6063 aluminum alloy products adhere to the following standard specifications, covering aerospace standards, military standards, industrial and construction standards, as well as pressure vessel standards.

Aerospace/military specifications

| Specifications | Full name | Introduction |

| AMS 4156 | Aerospace Material Specification 4156 | The American Aerospace Material Specifications, applicable to 6063 aluminum alloy bars, profiles, and tubes, are primarily used for aerospace structural components. |

| MIL-P-25995 | Military Specification | The U.S. military specifications for 6063 aluminum alloy tubes (Military grade) focus primarily on corrosion resistance and structural performance. |

| QQ-A-200/9 | Federal Specification | The U.S. federal standards specifically address the technical requirements for 6063 aluminum alloy extrusions, used in industrial and military applications. |

Industrial and construction specifications

| Specifications | Full name | Introduction |

| ASTM B221 | Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes | One of the most common standards for 6063 profiles, suitable for extruded profiles. |

| ASTM B241 | Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube | Seamless and extruded aluminum tubes suitable for 6063 aluminum alloy.. |

| ASTM B491 | Aluminum-Alloy Extruded Structural Pipe and Tube | Focused on standards for structural aluminum tubing, including 6063. |

| ASTM B483 | Aluminum and Aluminum-Alloy Drawn Tube and Pipe | Standards for cold-drawn aluminum alloy tubing. |

| ASTM B210 | Aluminum and Aluminum-Alloy Drawn Seamless Tubes | Standards for cold-drawn seamless tubes made from aluminum alloys such as 6063. |

| ASTM B345 | Aluminum-Alloy Forgings | Standards applicable to aluminum alloy forgings. |

| ASTM B429 | Aluminum-Alloy Extruded Structural Pipe and Tube | Standards for extruded aluminum tubes used for structural purposes. |

Pressure vessel and boiler codes

| ASME SB221 | Similar to ASTM B221 | ASME version applicable to 6063 aluminum profiles for pressure vessels and boilers. |

| ASME SB241 | Similar to ASTM B241 | Applicable to seamless aluminum tubes that meet boiler and pressure vessel requirements. |

| ASME SB210 | Similar to ASTM B210 | Pressure equipment standards related to cold-drawn seamless aluminum tubes. |

Differences between AL 6061 and AL 6063

Although both 6061 and 6063 are common extrudable aluminum alloys in the 6 series (Al-Mg-Si series), they differ significantly in mechanical properties, corrosion resistance, surface treatment performance, and application directions, making them suitable for different project requirements.

6061 aluminum alloy – stronger structural aluminum

- Higher strength: The yield strength and fatigue strength of 6061-T6 are significantly superior to 6063, making it suitable for applications with high load-bearing or structural requirements.

- Suitable for machining: It has good machinability, making it ideal for turning, drilling, and welding.

- Slightly lower corrosion resistance: It is not as suitable for exposure to outdoor environments or damp conditions as 6063.

- Typical applications: Industrial structural parts, truck frames, bicycle components, construction machinery parts, etc.

6063 aluminum alloy – the top choice for construction and decoration

- Better surface treatment: After anodizing, it has a fine and smooth appearance, making it suitable for spraying, electrophoresis, and decorative treatments.

- Better weather resistance: More corrosion-resistant, making it suitable for long-term outdoor exposure.

- Lower strength: Yet sufficient for light-load applications such as doors, windows, and decorative parts.

- Typical applications: Window frames, door frames, curtain walls, railings, sign frames, electrical housings, furniture, irrigation pipes, boat trim, etc.

Selection advice

If you need a high-strength material with strong load-bearing capacity, choose 6061.

If you focus more on aesthetic appearance, oxidation resistance, and surface treatment performance, choose 6063.

What services can Chalco provide for you?

Free samples: Chalco can provide free 6063 aluminum profile samples to customers for testing, prototyping, or project evaluation. Orders can be placed once the tests are passed, offering more peace of mind. Quick Quote

Discounted prices: Bulk users and repeat customers can enjoy discounted prices, making them more competitive.

Aluminum profile extrusion services: With advanced extrusion production lines, Chalco can produce various types of 6063 building profiles, industrial profiles, radiator profiles, etc.

Custom cross-section design: Support customers in providing drawings or samples to develop custom cross-sections and bespoke aluminum profiles to meet personalized needs.

Surface treatment services: Various surface treatments, including anodizing, electrophoresis coating, powder coating, brushing, and polishing, are available to enhance product appearance and corrosion resistance.

Heat treatment services: Chalco offers various heat treatment states such as T1, T5, T6, etc., to meet different strength and processing requirements.

Deep processing services: Chalco provides precision processing services such as cutting aluminum, drilling, tapping, stamping, welding, and assembly, reducing customers' subsequent processing costs.

Inspection and certification support: Chalco can provide composition analysis, mechanical performance testing, anodic coating thickness testing, and collaborate with third-party organizations like SGS, TÜV to issue certification reports.