6101 aluminum alloy is a material that achieves a good balance between strength and conductivity, widely used in electrical and busbar applications. Compared to 6063 alloy, 6101 has been optimized in chemical composition to offer higher conductivity, although slightly lower than 1350 alloy, it provides higher strength, making it particularly suitable for power distribution components and equipment requiring medium strength and high conductivity.

As a heat-treatable forging alloy, 6101 aluminum exhibits excellent corrosion resistance, flexibility, and formability. It can be processed, welded, and formed using standard methods, and is easy to extrude, demonstrating outstanding processing performance that meets the industry's demand for efficient and reliable electrical solutions.

The equivalent names of 6101 aluminum alloy

| AA 6101 | EN AW-6101 | 91E | UNS A96101 |

The temper of 6101 aluminum alloy

The 6101 alloy comes in various temper conditions, eliminating the need for additional heat treatment. These temper conditions offer different levels of strength, formability, and conductivity, providing greater flexibility for design applications.

The following are the most common temper conditions for 6101 alloy:

- F temper: The F temper is the state of 6101 alloy after forming processes (such as casting, hot working, or cold working) without special heat treatment or strain hardening control. It is delivered in the as-manufactured condition and is suitable for applications that require further processing.

- T6 temper: The T6 temper is obtained through solution heat treatment and artificial aging processes. The 6101 alloy in this state has the highest mechanical strength, making it ideal for applications requiring high strength performance.

- T61 temper: The T61 temper is an over-aged state, which has higher conductivity than T6 but slightly lower mechanical properties. This state is commonly used in applications that require higher conductivity but lower strength.

- T63 temper: The T63 temper is an intermediate state between T6 and T61, with conductivity higher than T6 but lower than T61, while maintaining a balance of mechanical strength and performance. It is suitable for designs with diverse requirements.

- T64 temper: The T64 temper is a partially annealed state. It offers the highest conductivity and best formability, making it the ideal choice for applications requiring maximum formability and conductivity.

- T65 temper: The T65 temper has moderate strength and conductivity while controlling the tensile and yield strength ranges. This temper ensures repeatable bending performance and is the preferred choice for designs with high processing accuracy requirements.

- Additionally, the alloy has the following special tempers:

- T61P temper: The T61P temper has the same conductivity as the T61 temper but with optimized bending performance and consistency, offering higher yield strength. It is suitable for applications requiring high bending precision.

- T64P temper: The T64P temper has the same conductivity as the T64 temper but further enhances bending performance and consistency, making it the best choice for designs with specific high requirements.

The conductivity of 6101 aluminum alloy

| Temper | T6 | T61 | T63 | T64 | T65 |

| Conductivity | 57% IACS | 59% IACS | 58% IACS | 60% IACS | 58% IACS |

Why does 6101 aluminum alloy have a lower resistivity?

The influence of the base composition

The main component of 6101 aluminum alloy is aluminum (Al), which itself has good electrical conductivity, with a resistivity of approximately 2.8×10⁻⁸ Ω·m.

Selection of main alloying elements

- Magnesium (Mg) and silicon (Si) are the main alloying elements in 6101 alloy.

- The amounts of these elements are optimized to provide strength while minimizing their negative impact on conductivity.

- Mg and Si can form the Mg₂Si intermetallic compound, and the distribution of this precipitate phase is well-balanced, ensuring it does not significantly reduce the alloy's conductivity.

The role of heat treatment process

- Through appropriate heat treatment (solution heat treatment + aging), the alloying elements can be fully dissolved.

- The size and distribution of the precipitate phase are controlled, reducing electron scattering.

- The grain structure is optimized, and the barriers to electron conduction at grain boundaries are reduced.

Chalco 6101 aluminum hot-selling products

As a professional supplier of 6101 aluminum, Chalco mainly offers high-quality products such as 6101 aluminum busbars, 6101 aluminum sheets, and 6101 flat bars. These products are known for their excellent conductivity, high strength, and corrosion resistance, and can be widely used in power transmission, electrical equipment manufacturing, and industrial structural components.

6101 aluminum busbar is a high-performance aluminum busbar with strong conductivity, excellent mechanical properties, corrosion resistance, and lightweight, easy processing. It is widely used in the power and new energy sectors and is an ideal alternative to copper busbars.

6101 aluminum sheet is a popular alloy known for its high conductivity and good mechanical strength. It is easy to process, weld, and form, making it ideal for power distribution and equipment manufacturing, and is highly valued for its excellent performance.

6101 aluminum flat bar is an alloy with high conductivity and excellent strength, ideal for power transmission and distribution systems. It offers great corrosion resistance and processing ease, making it perfect for distribution components and equipment.

The applications of 6101 aluminum alloy in different fields

Electrical industry

6101 aluminum alloy, with its high conductivity and good mechanical properties, is widely used in the electrical industry for manufacturing busbars, conductors, and other electrical components.

Applications and features:

- Busbars: High conductivity, excellent mechanical strength.

- Conductors: Reliable conductivity, strong stability.

- Connectors: Corrosion-resistant, easy to process and manufacture.

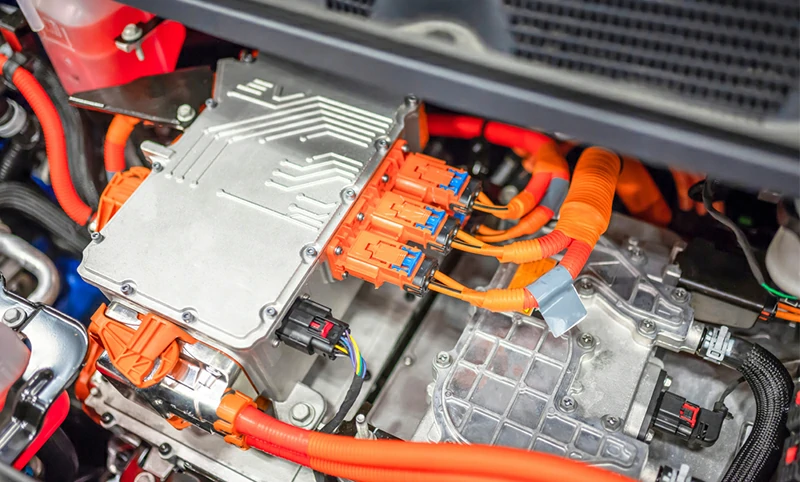

Automotive industry

In the automotive industry, 6101 aluminum alloy is commonly used to manufacture electrical components with high conductivity and reliability, such as wires and connectors.

Applications and features:

- Wiring: High conductivity, strong durability.

- Connectors: Corrosion-resistant, stable and reliable performance.

Construction industry

6101 aluminum alloy, due to its corrosion resistance and mechanical properties, is widely used in electrical and structural components in the construction industry.

Applications and features:

- Electrical components: High conductivity, excellent corrosion resistance.

- Structural components: Excellent mechanical properties, strong durability.

Consumer electronics

6101 aluminum alloy is used in consumer electronics to manufacture components that require good conductivity and heat dissipation, such as heat sinks and enclosures.

Applications and features:

- Heat sinks: High thermal conductivity, excellent heat dissipation efficiency.

- Enclosures: Corrosion-resistant, durable.

The mechanical properties of 6101 aluminum alloy

The mechanical properties of 6101 aluminum alloy vary significantly depending on its heat treatment and processing state. In the annealed state, it exhibits good ductility and workability, while after solution heat treatment and artificial aging, its strength and hardness are significantly improved.

This variation in performance allows 6101 aluminum alloy to meet a wide range of application needs, from high-strength structural components to electrical conductors, demonstrating great flexibility and versatility.

To provide a clearer understanding of these performance changes, the following detailed table compares key mechanical property parameters of 6101 aluminum alloy in different states. This table can help you comprehensively evaluate and choose the appropriate material condition for specific application requirements.

| Property | 6101-H111 | 6101-T6 | 6101-T61 | 6101-T63 | 6101-T64 |

| Tensile Strength (MPa) | 96 | 221 | 140 | 150 | 140 |

| Yield Strength (MPa) | 75 | 193 | 105 | 135 | 115 |

| Elongation at Break (%) | 25 | 15 | 10 | 8 | 12 |

| Hardness (Brinell) | 26 | 65 | 62 | 70 | 60 |

The chemical composition of 6101 aluminum alloy

6101 aluminum alloy is primarily composed of aluminum, magnesium, and silicon, with smaller amounts of other elements. The typical composition is as follows:

| Element | Composition (%) |

| Aluminum (Al) | Remainder |

| Magnesium (Mg) | 0.35 – 0.8 |

| Silicon (Si) | 0.30 – 0.7 |

| Iron (Fe) | 0.0 – 0.5 |

| Copper (Cu) | 0.0 – 0.1 |

| Chromium (Cr) | 0.0 – 0.03 |

| Zinc (Zn) | 0.0 – 0.1 |

| Titanium (Ti) | 0.0 – 0.03 |

| Manganese (Mn) | 0.0 – 0.03 |

| Other (each) | 0.05 |

| Other (total) | 0.15 |

The production and processing technology of 6101 aluminum alloy

Extrusion

Extrusion is a commonly used process for shaping 6101 aluminum alloy into various forms, such as rods, tubes, and profiles. The process involves forming long products with consistent cross-sections using molds.

The process steps are as follows:

- Preheat the aluminum billet to approximately 400-500°C.

- Place the billet into the extrusion press.

- Use a ram to force the billet through the die.

- Cool the extruded profile using air or water.

- Stretch the profile to straighten it and release internal stresses.

- Cut the profile to the desired length.

Rolling

Rolling is an important process used to shape 6101 aluminum into sheets and foils, where thickness and surface finish are controlled through rollers.

The process steps are as follows:

- Preheat the ingot to approximately 400-500°C.

- Gradually reduce the thickness through rollers.

- Anneal the sheet to eliminate internal stresses.

- Cold roll to achieve the final thickness and surface finish.

- Cut the sheet to the desired size.

Forging

Forging improves the mechanical properties of aluminum by applying high pressure to shape the material, making it suitable for the production of high-strength and durable components.

Process steps:

- Preheat the steel billet to approximately 400-500°C.

- Place the billet into the forging die.

- Apply high-pressure forming to the billet.

- Cool the forged components using air or water.

- Perform post-forging heat treatment to optimize the properties.

Casting

Although 6101 is not typically used for traditional casting, it can be used to produce components with enhanced mechanical properties through specific methods.

Common method: Centrifugal casting: Used for special applications to improve mechanical properties.

6101 aluminum alloy vs 1350 aluminum alloy

| Property | 6101 Aluminum Alloy | 1350 Aluminum Alloy |

| Conductivity | High conductivity, slightly lower than 1350 | Ultra-high conductivity (≥61% IACS) |

| Mechanical Strength | Higher strength, suitable for electrical and structural applications | Lower strength, ideal for applications requiring high conductivity |

| Corrosion Resistance | Excellent, suitable for harsh environments | Good, suitable for general environments |

| Typical Applications | Busbars, electrical conductors, connectors | Conductors, wires, cables |

| Workability | Easy to extrude and form | Good workability, slightly less than 6101 |

| Cost | Relatively higher | Generally lower |