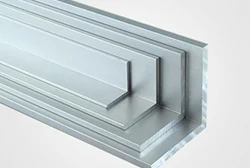

Among high-performance aluminum materials, the 7075 Aluminum Angle stands out as a top choice for advanced engineering projects due to its exceptional strength, fatigue resistance, and lightweight characteristics. After T6 heat treatment, its tensile strength reaches up to 560 MPa, nearly twice that of 6061 Aluminum Angle, while maintaining a remarkably low density—making it ideal for extreme load applications.

Compared with conventional aluminum alloys, the 7075 Aluminum Angle offers an outstanding strength-to-weight ratio, along with excellent corrosion resistance and machinability. It is widely used in aerospace, automotive manufacturing, defense equipment, and precision machinery.

If you're seeking a material that delivers both maximum strength and lightweight performance, the 7075 Aluminum Angle is undoubtedly the perfect solution.

Specifications of 7075 Aluminum Angle

Alloy: 7075

Temper: O, T6, T6511

Wall Thickness: 1/16”, 1/8”, 3/16”, 1/4”, 3/8”, 1/2”

Leg Height: 1/2”, 3/4”, 7/8”, 1”, 1 1/4”, 1 1/2”, 2”, 2 1/2”, 3”, 4”, 6”

Length: 1–6 m, custom lengths available (±0.5 mm tolerance)

Manufacturing Process: Extruded

Standards: ASTM B221, AMS-QQ-A-200/11

Surface Finishes: Mill finish, Polished, Anodized, Powder Coated, Electrophoresis Coated, Brushed. Click to view available surface treatments

Further Processing: Cutting, Drilling, Welding, Bending, CNC Machining. Click to view available processing options

Hot-Selling Sizes of 7075 Aluminum Angle

| Details (Size x Thickness) | Length | Standard |

| 1/2" X 1/2" X 1/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 3/4" X 3/4" X 1/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 3/4" X 3/4" X 3/16" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 1" X 1" X 1/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 1" X 1" X 3/16" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 1" X 1" X 1/4" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 1-1/4" X 1-1/4" X 1/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 1-1/4" X 1-1/4" X 3/16" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 1-1/4" X 1-1/4" X 1/4" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 1-1/2" X 1-1/2" X 1/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 1-1/2" X 1-1/2" X 3/16" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 1-1/2" X 1-1/2" X 1/4" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 2" X 2" X 1/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 2" X 2" X 3/16" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 2" X 2" X 1/4" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 2" X 2" X 3/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 2-1/2" X 2-1/2" X 1/4" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 2-1/2" X 2-1/2" X 3/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 3" X 3" X 1/4" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 3" X 3" X 3/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 3" X 3" X 1/2" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 4" X 4" X 1/4" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 4" X 4" X 3/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 4" X 4" X 1/2" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 5" X 5" X 3/8" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 5" X 5" X 1/2" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 6" X 6" X 1/2" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

| 6" X 6" X 3/4" 7075-T6/T6511 Aluminum Angle | Customizable | AMS-QQ-A-200/11 |

Whether you're focused on precise designs or large-scale production, these best-selling sizes of 7075 Aluminum Angle can optimize your project's performance.

Contact us today to request free samples and customized solutions—boost your engineering competitiveness now! Quick Quote

Types of 7075 Aluminum Angle Offered by Chalco

Chalco provides a wide range of 7075 Aluminum Angle products to meet the diverse needs of various industries. Below is an overview of our available types:

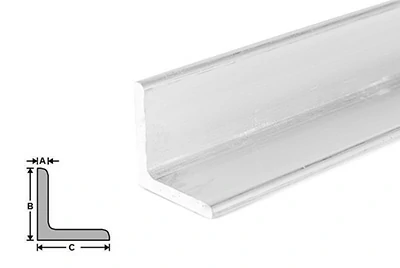

7075 Radius Corner Structural Aluminum Angle

Features rounded inner and outer corners to reduce stress concentration and improve structural integrity. Commonly used in aerospace and high-stress structural components.

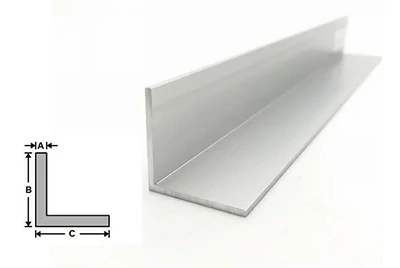

7075 Sharp Corner Aluminum Angle

Machined with precise 90° corners for applications requiring accurate connections and support, such as frames and machine brackets.

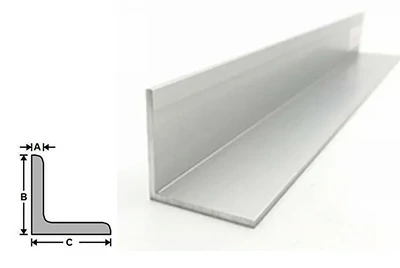

Contact us now7075 Equal Leg L-Shaped Aluminum Angle

Both legs are equal in length, offering balanced support and stability. Ideal for use in construction, machinery manufacturing, and general structural applications.

Contact us now

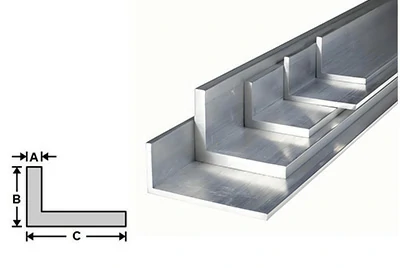

7075 Unequal Leg L-Shaped Aluminum Angle

Legs of different lengths provide specific support configurations for custom frames and specialized bracket designs.

Contact us nowOther Available Types of 7075 Aluminum Angle

7075 Equal Thickness L Angle

Uniform thickness across the entire cross-section, ensuring consistent strength and stability.

7075 Unequal Thickness L Angle

Varying thickness along the cross-section to meet specific strength and weight distribution needs.

7075 Heavy-Duty Aluminum Angle

Thick-walled and built for high-load applications in heavy machinery and structural engineering.

7075 Aerospace-Grade Aluminum Angle

Complies with AMS standards, featuring high strength and low weight, ideal for aircraft structures.

7075 Extruded Aluminum Angle

Produced via extrusion, offering high dimensional accuracy and excellent surface quality.

7075 Polished Aluminum Angle

Polished surface for enhanced gloss and appearance, perfect for decorative or high-finish applications.

7075 Anodized Aluminum Angle

Anodized for superior corrosion resistance and wear protection, suitable for outdoor and harsh environments.

Custom 7075 Aluminum Angle

Tailored solutions to meet unique design and performance requirements across various industries.

If you're interested in our 7075 Aluminum Angle products or have any questions, feel free to reach out to our expert team.

We're committed to delivering the highest quality materials and services—and we look forward to collaborating with you.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Gallery of 7075 Aluminum Angle

Applications of 7075 Aluminum Angle

Aerospace Industry

Standard: AMS-QQ-A-200/11

With its high tensile strength (up to 560 MPa) and lightweight properties, 7075 Aluminum Angle is widely used in aircraft fuselage frames, wing support structures, and rocket booster components. It reduces weight under extreme loads while meeting demanding fatigue resistance standards.

Military Industry

Used in armored vehicle frames, missile launcher structures, and other key components. Its excellent impact resistance enhances mobility and battlefield survivability. Surface coating technologies are often applied to improve corrosion resistance in humid or marine environments.

Industrial Machinery

Applied in robot joints, stamping press supports, and similar mechanical structures, 7075 angles offer structural stability under repeated stress. Their excellent machinability makes them suitable for complex parts, although due to poor weldability, mechanical fastening (e.g., riveting or bolting) is preferred.

Sports Equipment

Used in high-performance bicycle frames, racing chassis, and climbing gear, 7075 Aluminum Angle provides near-steel strength while reducing weight. For example, key bike joints can be 30% lighter. Mechanical joints are preferred over welding to avoid weld defects.

Transportation Sector

Standard: AMS-QQ-A-200/11

Ideal for modified car chassis, lightweight rail car bodies, and marine reinforcements, 7075 Aluminum Angle replaces steel to reduce energy consumption. In marine environments, anodizing is essential to prevent salt spray corrosion.

Electronics & Drones

Commonly used in drone arms and optical equipment mounts, the low density and high rigidity of 7075 Aluminum Angle balance strength with endurance. For example, drone arms for racing applications can withstand high-speed impact while minimizing battery load.

Chalco's 7075 Aluminum Angle Surface Treatments & Precision Machining

As a global leader in aluminum solutions, Chalco is committed to quality-first, customer-centric service. We offer high-end custom 7075 Aluminum Angle solutions with world-class surface treatment and fabrication capabilities—ensuring every product meets the most rigorous standards.

Surface Treatment Options

We employ state-of-the-art rolling and surface finishing lines to provide tailored surface effects that meet the highest industry requirements for appearance, corrosion resistance, and durability.

-

Anodizing

Anodizing

Advanced anodizing processes with thickness control from 10–30μm. Options include matte, sandblasted, and natural finishes. Maximum length up to 12 meters. Widely used in architecture and decorative applications.

-

Powder Coating

Powder Coating

Coating thickness between 60–100μm. Uniform finish with excellent abrasion and corrosion resistance. Ideal for outdoor and heavy-duty environments.

-

Electrophoretic Coating (E-coating)

Electrophoretic Coating (E-coating)

Provides uniform color and high adhesion for applications demanding both aesthetic value and chemical resistance.

-

PVDF & Special Coatings

PVDF & Special Coatings

Options include PVDF, wood grain, matte, and other functional & decorative finishes tailored for premium applications.

-

Other Surface Treatments

Other Surface Treatments

Includes brushing, polishing, plating, sandblasting, silvering, and painting. Chalco offers the optimal finish for every application using its extensive equipment and process expertise.

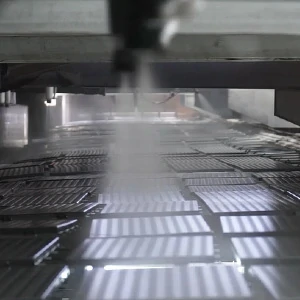

Advanced Fabrication Capabilities

Cutting & Drilling

Laser and mechanical cutting for complex shapes; precision drilling and punching for assemblies.

CNC Milling & Machining

High-precision machining ensures every detail meets design specs for demanding applications.

Welding, Bending & Assembly

Automated welding, precise bending, and efficient assembly ensure structural integrity and finish.

Why Choose Chalco as Your 7075 Aluminum Angle Supplier?

Choosing Chalco means choosing performance, precision, and partnership.

Advanced Technology & Equipment

Industry-leading aluminum smelting and extrusion lines deliver high-strength, lightweight, fatigue-resistant 7075 Aluminum Angles in various custom specifications.

Strict Quality Control & Certifications

All products are rigorously tested and certified to international standards, ensuring reliability in critical industries.

Extensive Industry Experience & Customization

Decades of experience in aerospace, automotive, and rail transit enable us to provide full customization in size, finish, and processing.

Fast Supply & Flexible Delivery

With large stock availability and agile manufacturing, standard products ship in as fast as 7 days. Custom orders benefit from our extensive die library for quick turnaround and cost control.

Full-Service Professional Support

From design consultation to online quoting and after-sales service, our experts support you every step of the way—so you can focus on project success.

Partner with Chalco for your 7075 Aluminum Angle needs—where quality meets efficiency.

Contact us today for more product details or tailored solutions.

FAQ

1. Do you offer cutting and CNC machining services?

Yes, we provide full CNC machining services including cutting, drilling, milling, welding, and assembly for 7075 aluminum angles. Custom secondary processing is available based on project requirements.

2. What factors affect the price of 7075 aluminum angle?

The price depends on multiple variables such as:

- Raw material costs

- Product dimensions and tolerances

- Heat treatment process

- Extrusion die cost

Due to the high strength and complex alloy composition, 7075 aluminum tends to be priced higher than standard aluminum grades.

3. Can I customize 7075 aluminum angle?

Absolutely. We support customization for dimensions, surface treatments, and machining options. While custom production may incur higher initial costs, it ensures perfect fit and performance for specialized applications.

4. What are the advantages of 7075 aluminum angle over steel angles?

7075 aluminum angle offers:

- Much lighter weight

- Excellent corrosion resistance

- Higher strength-to-weight ratio

It is ideal for aerospace and high-performance applications, although it is generally more expensive than steel.

5. How do I calculate the weight of 7075 aluminum angle?

To estimate weight:

a. Use density = 2.81 g/cm³

b. Measure the width of both legs (a, b) and thickness (t)

c. Calculate area: A = (a × t) + (b × t) – t²

d. Multiply by extrusion length to get volume

e. Volume × density = weight (convert to kg if needed)

This ensures accuracy for design and shipping.

6. How is 7075 aluminum angle connected in assemblies?

Common methods include:

- Welding (requires specialized techniques)

- Brazing

- Mechanical fastening (bolts, rivets)

Due to lower weldability, mechanical joining is often preferred for structural reliability.

7. What is the best way to cut and bend 7075 aluminum angle?

For cutting, use band saws or miter saws with suitable blades to achieve clean cuts.

For bending, a precision press brake is recommended. Avoid bending after surface treatments like anodizing, as it may cause micro-cracks.

8. What causes cracking in 7075 aluminum angle?

7075 contains copper, which boosts strength but reduces corrosion resistance. In humid or marine environments, stress corrosion cracking may occur along grain boundaries. Proper coatings or anodizing are recommended to prevent this.