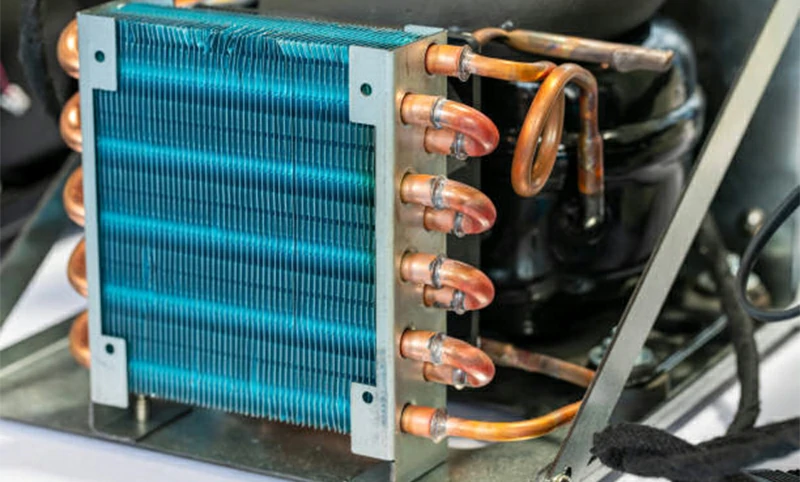

8006 aluminum foil is a high-performance aluminum material known for its high strength, excellent formability, and ductility, as well as its outstanding corrosion resistance. 8006 aluminum foil is commonly used in the production of finned materials for various heat exchangers such as radiators, evaporators, and condensers.Quick Quote

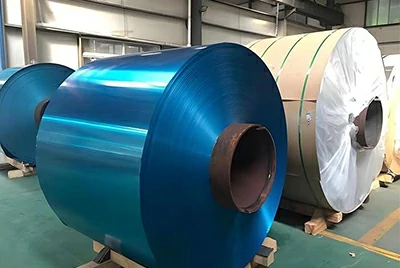

Chalco offers a range of surface treatments for 8006 aluminum foil, including hydrophilic coatings and hydrophobic coatings. Among these, hydrophilic aluminum foil comes in multiple coating options, including blue, gold, and natural colors, which can significantly enhance condensate diffusion efficiency, thus increasing the heat exchange area. On the other hand, hydrophobic coatings are ideal for anti-freezing and high-humidity environments, further expanding the range of potential applications.

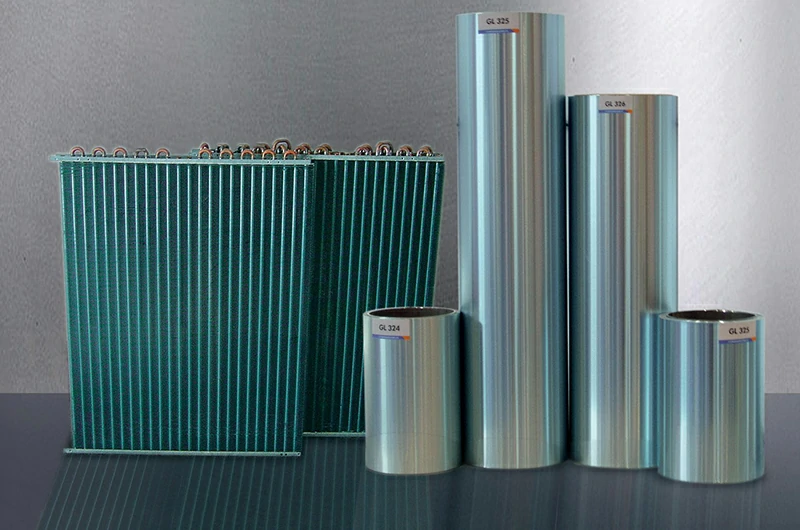

Best-selling products of 8006 aluminum fin stock

8006 Bare Aluminum Fins

Bare aluminum fins, with excellent thermal conductivity, are used in radiators, insulation panels, and HVAC equipment. While prone to oxidation and corrosion, their low cost and efficiency make them suitable for specific applications.

8006 Hydrophilic Aluminum Foil

Hydrophilic aluminum fins feature a coating that spreads condensate water, preventing droplets and increasing the heat exchange area. This boosts heat transfer efficiency by 5%, reduces noise, and provides corrosion and mold resistance, ideal for air conditioners, evaporators, and condensers.

Features of 8006 Hydrophilic Aluminum Foil

- Corrosion-resistant, mold-resistant, and odor-free: The hydrophilic coating provides high corrosion resistance, effectively preventing mold growth and ensuring odor-free operation.

- Uniform condensate distribution: The hydrophilic layer ensures that the condensate water evenly spreads across the fin surface, preventing water droplet formation and improving heat exchange rate by about 5%.

- Noise reduction: Because condensate water doesn’t form droplets, the noise caused by vibration is significantly reduced.

- Eco-friendly properties: It prevents dust from entering air conditioning systems, meeting environmental protection requirements.

8006 Hydrophobic Aluminum Foil

Hydrophobic aluminum fins feature a special coating for water resistance and anti-contamination, ideal for freezing environments in air conditioners and heat pumps. The coating increases condensate drainage, prevents water buildup, enhances heating efficiency, reduces freezing, and ensures energy-efficient operation.

Featured products of 8006 aluminum fin stock

8006 Blue Aluminum Fins

-

8006 Blue Aluminum Fins

8006 Blue Aluminum Fins8006 blue hydrophilic aluminum fins, coated for excellent hydrophilicity and corrosion resistance, are ideal for air conditioning evaporators. The coating spreads condensate water, preventing droplets, improving ventilation, and enhancing heat exchange efficiency to reduce energy consumption.

| Coil side | Inside | Outside |

| Chemical compound | Polyurethane | Polyurethane |

| Color | Blue | Blue |

| Lacquer surface properDes | Hydrophobic | Hydrophobic |

| CoaDng masses, per side g/m2 | 3-4 | 3-4 |

| CoaDng thickness, single spot µm | 2-3 | 2-3 |

8006 Golden Aluminum Fins

-

8006 Blue Aluminum Fins

8006 Blue Aluminum Fins8006 golden hydrophilic aluminum fins offer outstanding hydrophilicity and corrosion resistance. The golden coating provides an aesthetically pleasing appearance while also increasing the speed at which condensate water diffuses, preventing droplets from hindering heat exchange and further improving energy efficiency.

Coating of 8006 gold aluminum fin stock

| Coil side | Inside | Outside |

| Chemical compound | Polyurethane | Polyurethane |

| Color | Gold | Gold |

| Lacquer surface properDes | Hydrophobic | Hydrophobic |

| CoaDng masses, per side g/m2 | 5-6 | 5-6 |

| CoaDng thickness, single spot µm | 4-5 | 4-5 |

-

8006 Corrosion-Resistant Aluminum Fins

8006 Corrosion-Resistant Aluminum Fins8006 corrosion-resistant aluminum fins feature a special corrosion-resistant coating that helps prevent corrosion, extending the service life of the equipment and improving ventilation quality. These fins are perfect for use in harsh environments.

-

8006 Self-Lubricating Aluminum Fins

8006 Self-Lubricating Aluminum Fins8006 self-lubricating aluminum fins are coated with a special self-lubricating layer that eliminates the need for additional lubricants during the stamping process. This simplifies the subsequent processing steps, enhances production efficiency, and reduces costs.

-

8006 Anti-Mold Aluminum Fins

8006 Anti-Mold Aluminum Fins8006 anti-mold aluminum fins are treated with a special anti-mold coating, effectively preventing the growth of mold and improving ventilation quality. These fins are especially suitable for the dehumidifying sections of indoor air conditioning systems, ensuring good air quality during long-term use.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Basic parameters of 8006 aluminum fin stock

| Alloy | 8006 |

| Temper | O, H22, H24, H26 |

| Thickness | 0.08-0.2mm |

| Width | 100-1400mm |

| Color | Bare, Blue, Golden, light blue, light gold |

| Surface | Bare, Hydrophilic, Hydrophobic, Epoxy |

| Core Inner Diameter | 76mm, 150mm, 200mm, 300mm |

| Sleeve Material | Aluminum, Carbon, Steel |

| Outer Diameter | Customized according to customer needs |

| Packaging | Click to view specific packaging standards |

| Inspection | Click to view specific testing standards |

Characteristics of 8006 aluminum fin stock

High strength and good ductility

8006 aluminum foil possesses high strength and excellent ductility, making it ideal for forming complex-shaped fins that meet the high-performance demands of heat exchangers. Its strength ensures long-lasting reliability, especially in industrial environments, where it performs exceptionally well.

Superior corrosion resistance

The hydrophilic and hydrophobic coatings on 8006 aluminum foil provide exceptional corrosion resistance, ensuring the long-term reliability of heat exchangers even in harsh environments. Notably, the hydrophilic coating significantly extends the service life of the equipment.

Excellent thermal conductivity

8006 aluminum foil exhibits high thermal conductivity, with the hydrophilic coating ensuring that condensate water is evenly distributed, enhancing heat transfer efficiency by approximately 5%. The hydrophobic coating is ideal for freeze prevention, helping to avoid frosting and ice formation.

Reduced air resistance

The hydrophilic coating reduces airside resistance and lowers pressure drop, improving the system's energy efficiency. Tests show that reducing airflow resistance can improve the heat exchange rate by about 10-15%, significantly enhancing overall performance.

Anti-contamination properties

The anti-contamination properties of the hydrophilic coating prevent dust, dirt, and oil from accumulating on the surface of the fins. This ensures the efficient and stable operation of the equipment over time. Its anti-contamination characteristics not only reduce the frequency of cleaning and maintenance but also lower operating costs.

Fields of cooperation for 8006 aluminum fin stock

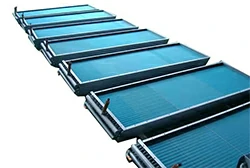

Air Conditioning Equipment:Ideal for use in home air conditioners, refrigerators, and automobile air conditioning systems for evaporators, condensers, and other heat exchanger components, enhancing the cooling efficiency of the equipment.

Refrigeration Equipment:Widely used in freezers, cold storage units, and other cooling systems, ensuring efficient cooling performance.

Automotive Radiators:Used in engine cooling systems, 8006 aluminum fins improve heat dissipation efficiency, extending the service life of the engine.

Industrial Heat Exchangers:Applied in multiple industries such as chemical, energy, electronics, nuclear, and shipbuilding for efficient thermal management.

Wind Energy and Electronic Equipment:Utilized in wind power generation systems and electronic devices for efficient heat dissipation, ensuring system stability and reliability.

Specific applications

8006 Aluminum Fins for Heat Exchangers

8006 Aluminum Fin Stock for Condensers

8006 Aluminum Fin Stock for Air Conditioning Systems

8006 Aluminum Fin Stock for Refrigerators

8006 Aluminum Fin Stock for Evaporators

8006 Aluminum Fin Stock for Radiators

You can also choose other Chalco fin stock materials

Why choose Chalco?

Leading product technology

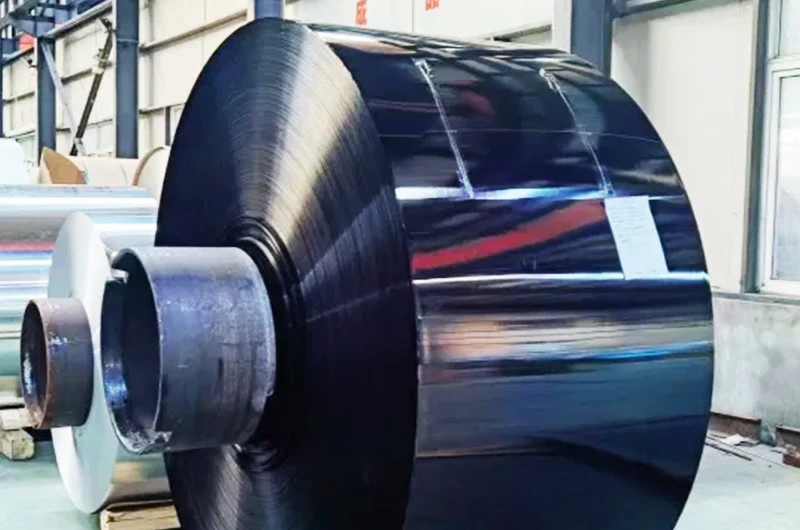

We utilize German machinery to produce Fin Stock aluminum foil, ensuring that 8006 aluminum fin stock outperforms similar market products in heat transfer efficiency and corrosion resistance. With a complete production line from aluminum ingot to coil, we offer a production width of up to 1800mm and thicknesses as thin as 0.006mm.

Long-term partnerships

We have established long-term partnerships with renowned air conditioning manufacturers, holding a significant share in the air conditioning market. Our deep understanding of customer needs allows us to provide customized solutions.Quick Quote

Comprehensive technical support

Our technical team employs advanced processes and strictly controls production steps to ensure that our products meet EN standards. With traceable raw materials, we provide reliable solutions.

Comprehensive certifications & standards

Our products are certified with SGS-ROHS, SGS-REACH, MSDS, FDA, TDS, ISO9001, and ISO14001, meeting global quality and environmental standards.

Customization services

We offer customized products in different thicknesses, widths, and coatings based on customer requirements. We also adopt standard export packaging to ensure safe transport.

Quality customer experience

We are dedicated to delivering high-quality products while providing value-added services through efficient after-sales support and technical assistance. From order placement to delivery, every step is designed to offer a worry-free service experience, ensuring the successful implementation of your project.

Standard specifications of 8006 aluminum fin stock

- EN 573-3 - 2009 Aluminium and aluminium alloys. Chemical composition and form of wrought products. Chemical composition and form of products

- EN 546-2 - 1997 Aluminium and aluminium alloys. Foil. Mechanical properties

- EN 683-2 - 2006 Aluminium and aluminium alloys. Finstock. Mechanical properties

- BS EN 10204 - Metallic Products: Types of Inspection Documents

Chemical composition of 8006 aluminum fin stock (EN 573-2)

| Element | EN-AW 8006 |

| Si | 0.40 |

| Fe | 1.2-2.0 |

| Cu | 0.30 |

| Mn | 0.30-1.0 |

| Mg | 0.10 |

| Cr | - |

| Ni | - |

| Zn | 0.10 |

| Ti | - |

| Remarks | - |

| Others (Each) | 0.05 |

| Others (Total) | 0.15 |

| Al | Rem |

Mechanical properties of 8006 aluminum fin stock (EN 683-2)

| Properties | Value |

| Tensile strength Rm/Mpa | 50 |

| Yield strength Rp0.2/Mpa | 75-110 |

| Elongation A100/% | 18% |

| Erichsen without lube /mm | 6.5 |

8006 Aluminum fin material purchasing guide

Dimensions of 8006 aluminum fin stock (EN 683-3)

1.Thickness and Tolerance

Thickness Range: 0.12 mm to 0.25 mm.

Tolerance:

- For 0.12 mm thickness, tolerance is ±0.01 mm.

- For 0.25 mm thickness, tolerance is ±0.02 mm.

2.Width and Tolerance

Width Range: 270 mm to 575 mm.

Tolerance: All width tolerances are ±0.30 mm.

All dimensional deviations (tolerances) must comply with the latest version of EN 683-3, applicable to specifications not specifically mentioned.

Surface quality of 8006 aluminum fin stock

- The surface of the aluminum foil should be uniform in color, free from defects that may affect performance, such as coating voids, wrinkles, stripes, color differences, scratches, inclusions, or corrosion.

- Edge Quality: The edge of the aluminum foil should be tightly rolled and uniform, with no cracks or burrs. Overlap should be ≤2 mm and taper should be ≤5 mm.

- Joints: The joint rate should not exceed 20%, and the joints should be clearly marked.

Inspections of 8006 aluminum fin stock (EN 10204)

1. Adhesion Test: Perform Erichsen tear test on both internal and external surfaces in accordance with EN 13523 to ensure no peeling occurs.

2. M.E.K. Solvent Resistance (Polymerization Evaluation): Both internal and external surfaces must meet the >20 double rubs solvent resistance standard (compliant with EN 13523).Quick Quote

3. Corrosion Resistance: Both internal and external surfaces must pass a 1000-hour salt spray test (ASTM B117, 5% NaCl, 35°C, pH 6.5-7.2). The edges of the sample must be protected to ensure no corrosion.

4. UV Resistance: Conduct a 1000-hour UV test under UVA340 0.89 W/m² conditions, including thermal cycling and condensation, with the gloss retention rate at 60° to be less than 30%.

5. Alkaline Resistance Test: Soak the fin stock in 20% NaOH solution for 3 minutes, then check for any bubbling. This test ensures that the coating can withstand alkaline cleaners.

6. Humidity and Heat Test: Test the fins for corrosion resistance under specific temperature and humidity conditions. Fins are exposed to high temperature and humidity to assess their weathering and corrosion resistance.

7. Oil Resistance: Soak for 48 hours without blistering or peeling, with hydrophilicity θ ≤ 10°.

8. Odor: No abnormal odor after 10 minutes at 140°C baking and room temperature immersion test.

Labelling of 8006 aluminum fin stock

- Coil Labels: Each coil should be labeled with product name, alloy state, specifications, weight, batch number, joint quantity and location, inspector's stamp, and company name.

- Pallet Labels: Each pallet should be labeled with supplier's name, delivery address, purchase order number, product name, alloy state, specifications, and total gross/net weight.

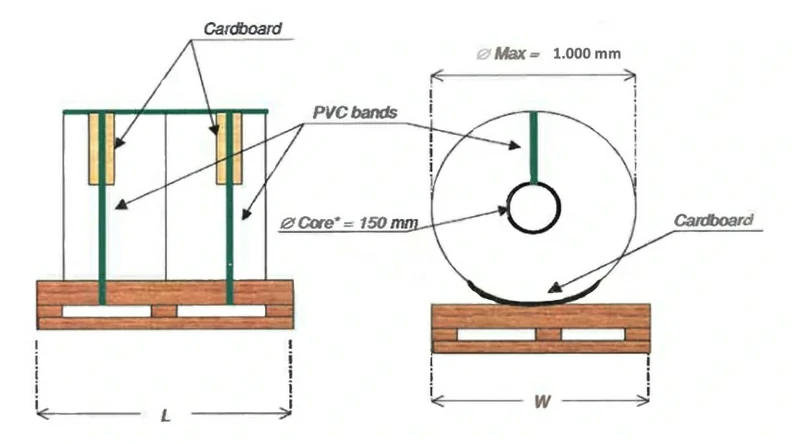

1. Core and Coil Diameter

- Core inner diameter: 150 mm.

- Coil outer diameter: Not exceeding 1000 mm.

- Coil weight: Not exceeding 840 kg.

2. Pallet Specifications

- Pallet size (European standard): 1200 mm x 800 mm.

- Packaging height: Not exceeding 1200 mm.

- Packaging weight: Not exceeding 1100 kg.

3. Packaging Method

- Coils are placed with the core facing out (E2W) on the pallet.

- Use cardboard dividers between coils and pallets for protection.

- Coils are secured with nylon and polyester straps, with protective coverings before packing.

- Use PE film for waterproof wrapping, avoiding polystyrene (foam plastic) and only using eco-friendly cardboard for packaging protection.

- Each pallet contains only one annealing batch of material to ensure consistency.

FAQ

What are the characteristics of different types of fin stock materials?

| Fin Stock Type | Key Characteristics | Applications |

| Bare Aluminum | High thermal conductivity, cost-effective, corrosion-prone | Indoor HVAC systems |

| Hydrophilic Aluminum Foil | Water-repellent, corrosion protection, improved heat transfer | Air conditioners, evaporators |

| Hydrophobic Aluminum Foil | Water-beading, frost prevention, corrosion resistance | Refrigeration units, dehumidifiers |

| Anti-corrosion Aluminum | Coated for corrosion resistance, durability, long lifespan | Marine HVAC, industrial heat exchangers |

| Epoxy-coated Aluminum | Strong protection against chemicals, pollutants, and corrosion | Industrial cooling, outdoor HVAC systems |

| Pre-coated Aluminum | Factory-applied coatings, consistent performance, ready-to-use | High-volume HVAC, automotive radiators |

| Perforated Aluminum | Perforations for better airflow and reduced pressure drop | High-efficiency air conditioning systems |

How is fin stock material produced?

1. Cleaning Process: After rolling and annealing the aluminum foil, a comprehensive cleaning process is carried out to remove all impurities and oil, ensuring that the aluminum foil substrate remains clean and uncontaminated. This step is crucial for providing a good surface condition for the subsequent coating application.

2. Pre-treatment Process: The surface of the cleaned aluminum foil undergoes a pre-treatment process to ensure that the coating adheres evenly to the substrate. This step improves the bonding strength between the aluminum foil and the coating, reducing the risk of coating peeling.

3. Coating Application: Special processes are used to apply hydrophilic or hydrophobic coatings evenly onto the surface of the aluminum foil. These coatings enhance the product's performance in heat exchangers. The uniformity of the coating directly impacts the performance of the fin stock, so this process is strictly controlled to ensure even coverage and the appropriate thickness of the coating.

4. Drying and Curing: After coating, the aluminum foil undergoes drying and curing to ensure strong adhesion and durability of the coating. The drying process is typically carried out under controlled temperature and humidity conditions to achieve the best coating effect, while curing enhances the mechanical properties of the coating, ensuring the fin stock material operates efficiently over the long term.

5. Quality Inspection: Finally, rigorous quality inspections are conducted, including tests for coating adhesion, corrosion resistance, and thickness. These checks include wiping tests, salt spray tests, etc., to verify the integrity and performance of the coating, ensuring that every batch of fin stock material meets high-quality standards.

Why use aluminum as fin stock material?

- High Thermal Conductivity: Aluminum offers excellent thermal conductivity, significantly improving the overall efficiency of heat exchangers.

- Lightweight: Aluminum is much lighter than many other metals, making it easier to handle and contributing to a reduction in the overall weight of the equipment.

- Corrosion Resistance: Aluminum naturally forms an oxide layer on its surface, providing excellent corrosion resistance, which is ideal for humid or corrosive environments.

- Ease of Fabrication: Aluminum has excellent formability, making it easy to manufacture complex-shaped fins through stamping, rolling, welding, and other processes.

- Cost-Effectiveness: Aluminum is more affordable than materials like copper and stainless steel, making it a cost-efficient choice for many applications.

- High Recyclability: Aluminum is highly recyclable, offering significant environmental benefits by reducing its impact on the environment.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote