Air conditioning aluminum foil is an aluminum-based material specially used in air conditioning heat exchangers, usually in the form of thin sheets. Due to its excellent thermal conductivity, corrosion resistance and flexibility, 8011 aluminum foil provides reliable support for improving the heat exchange efficiency and service life of equipment, and it is becoming more and more popular in air conditioning heat exchange equipment.

As a professional manufacturer of air conditioning aluminum foil, Chalco is committed to providing air conditioning manufacturers with overall solutions with excellent performance and high reliability. The plain aluminum foil, hydrophilic aluminum foil, hydrophobic aluminum foil, coated aluminum foil, aluminum foil tubes for HVAC systems, and air conditioning duct insulation tape we produce are all made of high-quality 8011 aluminum. Product quality is guaranteed, welcome to inquire.Quick Quote

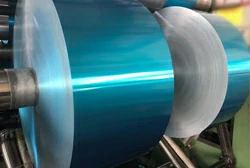

Specification of 8011 aluminum foil for air conditioning

- GB/T 3198-2010

- JIS H 4160-1994

- DIN_EN_546-2

- ROHS

8011 popular types of air conditioner aluminum foil

8011 non-coated aluminum foil for air conditioner

This type of aluminum foil refers to aluminum foil that has been rolled and annealed and has not been treated in any form on the surface.

- Temper: O

- Thickness: 0.08mm-0.2mm

- Maximum width:1800mm

- Maximum roll outer diameter:1200mm

- Application:It is mostly used in air conditioning heat exchangers in ordinary indoor environments to meet conventional cooling needs.

- Features: mature production technology, low cost, and extremely competitive price; limited anti-corrosion and moisture-proof functions.

- Limitations: The bare aluminum foil surface lacks coating treatment, and its anti-corrosion and moisture-proof capabilities are limited. Condensation water is easily accumulated, which may affect the heat exchange efficiency.

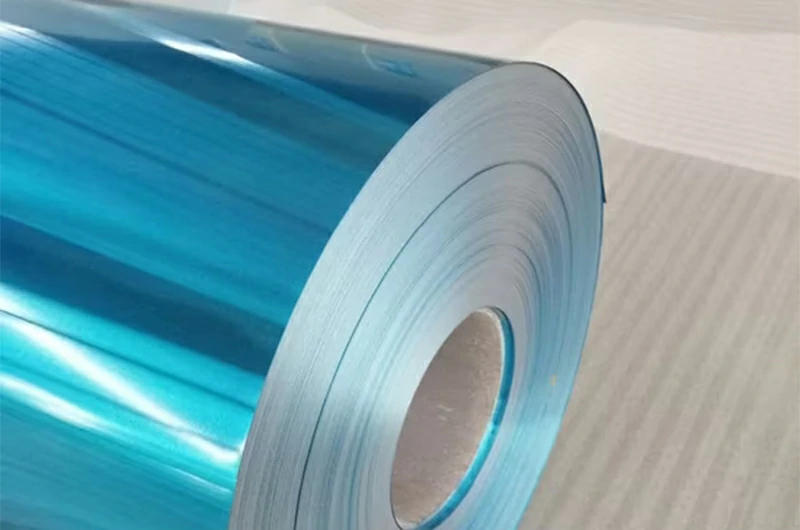

8011 hydrophilic aluminum foil for air conditioner

8011 hydrophilic aluminum foil for air conditioner is a kind of aluminum foil material with special coating treatment, which is specially designed for air conditioner heat exchanger. It uses 8011 aluminum foil as the base material, usually has excellent corrosion resistance and ductility, and the surface coating is hydrophilic.

- Temper:H22 H24 H26

- Thickness:0.08mm - 0.15mm

- Width:100mm - 1800mm

- ID:75mm, 150mm, 200mm, 300mm, 500mm.

- Application:Fins commonly used in condensers of air conditioners.

- Features: The hydrophilic coating on the surface can quickly remove condensed water, avoid the formation of water film, reduce air flow resistance, thereby improving the heat exchange efficiency of the evaporator and condenser, increasing the refrigeration efficiency by 5%, and reducing noise.

- Limitations: Compared with ordinary aluminum foil, hydrophilic aluminum foil has a higher manufacturing cost due to its special coating treatment.

8011 hydrophobic aluminum foil for air conditioner

In contrast to hydrophilic aluminum foil, its surface condensation water contact angle is larger (usually more than 75°), and the condensation water between the heat exchanger plates is removed by forming water droplets that are easy to slide off, avoiding water retention and improving heat exchange efficiency.

- Application: air conditioning condenser and evaporator

- Features: The surface contact angle is large, so that the condensation water quickly forms water droplets and slides off, avoiding water retention on the heat exchanger surface; anti-frost and corrosion resistance.

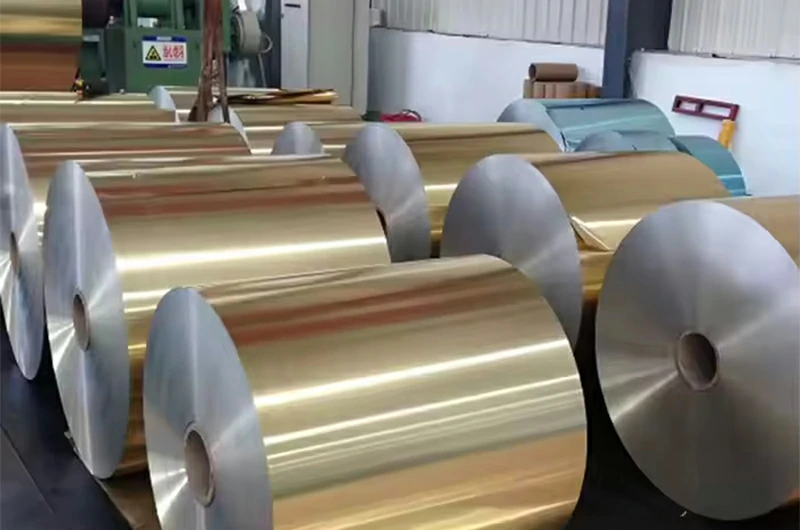

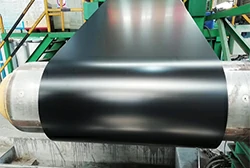

8011 coated aluminum foil for air conditioner

In addition to the hydrophilic coating and the hydrophobic coating, the surface of 8011 aluminum foil can also be coated with a special anti-corrosion coating, which makes it have excellent corrosion resistance, durability and excellent heat exchange performance, and a long service life of up to 6-10 years.

- Temper: H22, H24, H26

- Thickness:0.08mm - 0.15mm

- Width:100mm - 1800mm

- ID:75mm, 150mm, 200mm, 300mm, 500mm.

- Coating thickness:10-14μm

- Coating materials: PE, PVDF, epoxy resin

- Applications: air conditioning heat exchangers, pipes and ducts, suitable for harsh environments.

- Features: Improve the corrosion resistance, weather resistance and heat exchange efficiency of aluminum foil, ensuring that air conditioning equipment remains efficient and durable in various environments.

- Common colors: black, gold, blue.

Black coated 8011 aluminum foil

Gold coated 8011 aluminum foil

Blue coated 8011 aluminum foil

Aluminum foil tape for HVAC air conditioning

8011 aluminum foil is used as the base material and coated with a layer of pressure-sensitive adhesive on the surface, which has excellent adhesion, high temperature resistance and corrosion resistance.

Application: Sealing, insulation and protection of pipe joints and connecting parts of heating, ventilation and air conditioning (HVAC) systems.

Features: Provides long-lasting sealing performance to avoid air leakage or falling off; anti-corrosion and moisture-proof, improving the durability of air conditioning systems.

8011 aluminum foil tube for air conditioning and HVAC

Tubular components made of 8011 aluminum foil and polyester materials, they can be bent and twisted to fit into small spaces, and are very suitable for heating, cooling, ventilation and exhaust in air conditioning and HVAC systems.

Features: Easy to cut and fix, no special tools required, no toxic gas released at high temperatures, and good fire resistance.

Why use 8011 air conditioner aluminum foil?

- It has good ductility and formability and can withstand repeated bending.

- It has moderate strength and is not easy to crack or break.

- It has good thermal conductivity and high thermal conductivity, which is conducive to heat exchange.

- It has high heat dissipation efficiency, improves air conditioning performance, and helps reduce energy consumption.

- The production process is mature, the cost is relatively low, and the price is competitive.

- By attaching coating materials, the corrosion resistance is further improved and the service life is long.

- It is resistant to high temperatures and can maintain stability at higher temperatures. It is not easy to deform, ensuring the long-term and efficient operation of the air conditioning system.

How to choose the right type of 8011 air conditioning aluminum foil?

Costs

When choosing 8011 aluminum foil for air conditioning, cost is the first factor to consider. 8011 bare aluminum foil has the lowest cost and is suitable for conventional air conditioning systems, such as small air conditioners, which can significantly reduce costs. The cost of hydrophilic aluminum foil, hydrophobic aluminum foil and coated aluminum foil is usually slightly higher than that of regular aluminum foil, so you can choose it if you have enough budget.

Heat exchange efficiency

From the perspective of heat exchange efficiency, different types of 8011 air conditioning aluminum foils are suitable for different needs.

- Bare aluminum foil has strong thermal conductivity and is suitable for applications with high requirements for heat exchange efficiency and mild environment;

- Hydrophilic aluminum foil can quickly guide the flow of condensed water through its surface hydrophilicity, avoid water accumulation between fins, improve heat exchange efficiency, and is suitable for high humidity environments;

- Hydrophobic aluminum foil uses a large contact angle design to make condensed water slide off quickly, reduce the impact of water film coverage on heat exchange, further optimize heat exchange performance, and is particularly suitable for precision air conditioning equipment.

- In harsh environments, coated aluminum foil has both anti-corrosion and good thermal conductivity, ensuring long-term and efficient operation of the equipment and maintaining stable heat exchange efficiency even under corrosive conditions.

Usage environment

It is very important to choose the right 8011 air conditioning aluminum foil according to different usage environments.

- In ordinary indoor environments or when humidity is low, you can choose economical and practical bare aluminum foil or hydrophilic aluminum foil to meet basic heat exchange needs;

- In high humidity areas, hydrophilic aluminum foil can accelerate the discharge of condensed water and prevent water accumulation from affecting efficiency;

- For coastal or industrial corrosive environments, coated aluminum foil provides good anti-corrosion performance and extends equipment life;

- In extremely harsh high temperature, high humidity or strong corrosive conditions, enhanced coated aluminum foil is the best choice to ensure long-term stable operation of the system;

- If the requirements for condensed water residue are high, it is recommended to use hydrophobic aluminum foil to quickly drain water to avoid affecting operating efficiency.

Service life

Because bare aluminum foil is not covered with a coating, its waterproof and anti-corrosion properties are limited, and its service life is not as long as that of hydrophilic foil and coated aluminum foil. If a longer service life is required, coated aluminum foil is a good choice.

Why choose Chalco's 8011 air conditioner aluminum foil?

Free samples

Chalco can provide free samples according to customer requirements. After the test is passed, you can place an order and buy with confidence.

Discount surprise

For returning customers and large-volume customers, there will be surprise discounts to make your price more competitive. Contact us

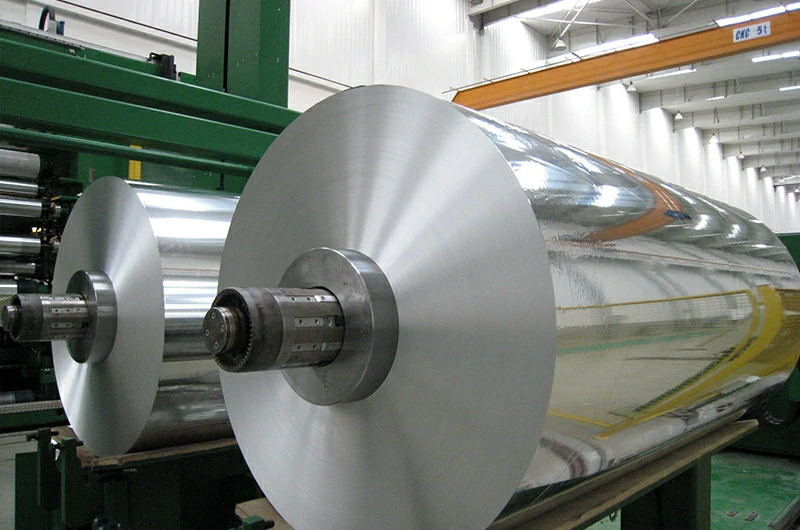

Advanced production equipment

Chalco uses German Achenbach rolling mills and KAMPF slitting machines to produce aluminum foil. The products range from ingots to coils, with a maximum width of 1800mm and a minimum thickness of 0.006mm.

Strict quality inspection

In order to ensure high-quality 8011 air-conditioning aluminum foil, Chalco will conduct the following key tests:

- Chemical composition analysis: Use a spectrometer to detect the chemical composition of the aluminum foil to ensure that the proportion of each element in the alloy meets the 8011 standard to ensure the stability and consistency of the material performance.

- Mechanical property testing: Test the tensile strength and elongation of the aluminum foil to ensure that it has sufficient strength and toughness during the molding and use process to meet the processing and application requirements.

- Surface quality inspection: Use high-definition testing equipment to check the surface of the aluminum foil to ensure that there are no defects such as scratches, pinholes, bubbles, oil stains, etc., to ensure the reliability of the product appearance and function.

- Thickness and tolerance inspection: Use a precision thickness gauge to inspect the thickness of the aluminum foil batch by batch to ensure that its thickness is uniform during the production process and meets customer specifications to avoid affecting the heat exchange performance.

- Pinhole detection: Use special testing equipment to measure the number and diameter of pinholes on the aluminum foil to ensure that its sealing and leakproofness in the air-conditioning system meet high standards.

- Coating and surface treatment testing: Test the coating thickness, adhesion and uniformity of the coated aluminum foil to ensure that the anti-corrosion performance and service life of the coating meet the requirements.

- Corrosion resistance test: Simulate the hot and humid or salt spray environment to test the corrosion resistance of the aluminum foil, especially in coastal and industrial environments, to ensure the long-term stability of the material.

- Heat exchange performance evaluation: Under simulated working conditions, evaluate the heat exchange efficiency of the aluminum foil to ensure that it meets the technical requirements of the air conditioner heat exchanger.