8011 aluminum foil has excellent corrosion resistance, light weight and thermal insulation properties, making it a popular choice for roofing materials. Whether used for moisture barriers, reflecting thermal radiation, or composite roof structures, this material can provide excellent thermal insulation performance.

Chalco's 8011 roof aluminum foil insulation material can reflect up to 96% of heat and maintain a stable reflection effect after long-term use. This not only effectively blocks external heat from entering the room, but also greatly improves the energy efficiency of the house.

Specifications for Chalco 8011 roofing aluminum foil

- EN 546

- ASTM B479

- RoHS

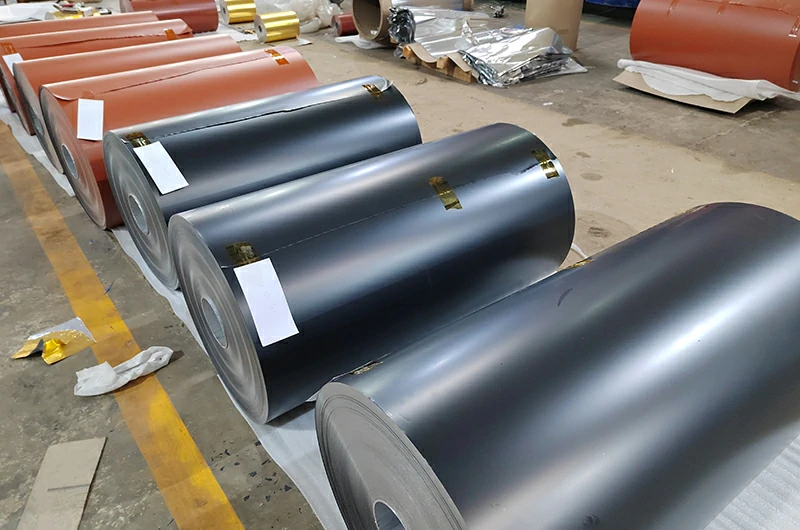

Common 8011 roofing aluminum foil

Bare 8011 aluminum foil for roof

Roof bare 8011 aluminum foil is an aluminum foil material without coating or surface treatment. It is lightweight, high-strength and has good corrosion resistance. It is often used for heat insulation, moisture-proof and protective layer of building roofs.

Contact us now

- Temper: O

- Thickness: 0.014mm – 0.03mm

- Width: 20mm - 1600mm

- Features: Lightweight, corrosion-resistant, heat-insulating, moisture-proof, surface uncoated, heat reflectivity up to 96%.

- Limitations: No coating protection, limited corrosion and moisture-proof performance.

- Application: Commonly used in roof insulation, moisture-proof layer and simple protective environment, suitable for projects with low decorative requirements.

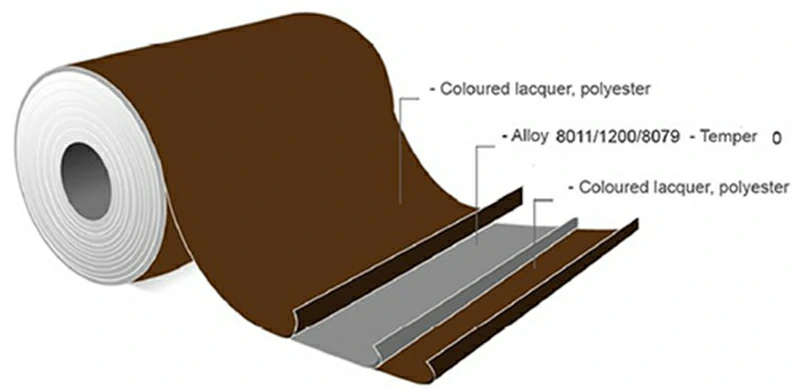

8011 coated aluminum foil for roof

8011 roof coated aluminum foil is a lightweight and durable aluminum material that has been specially coated to increase resistance to corrosion, UV rays and adverse weather conditions while also providing enhanced thermal insulation and aesthetic qualities.

Contact us now

- Thickness:0.015mm - 0.2mm

- Width:20mm - 1600mm

- Coating thickness:7 – 10μm

- Top layer: Colored lacquer, polyester, PE

- Bottom layer: Colored lacquer, polyester, PE

- Coating surface:double side

- Color: gold, silver, red, blue, black, gray, white, green, copper, brown, wood, or customized.

- Features: Adding a coating on the surface of aluminum foil enhances thermal insulation, weather resistance, oxidation resistance and decorative properties, while providing a longer service life.

- Application: Used in rooftop buildings with higher requirements for aesthetics and durability, such as high-end residential or public facility roofs.

How to choose the right 8011 roofing aluminum foil?

When choosing 8011 roofing foil for roof insulation, the following factors should be considered:

- Thickness: Choose 0.00093-inch thick foil for durability and ideal reflective performance.

- Width: Common specifications are 48, 60, and 96 inches, which fit standard roof panels and reduce seams.

- Texture: Wrinkled or pleated textures are better for uneven surfaces, while smooth surfaces may corrugate easily.

- Packaging: It is recommended to use tear-resistant bags or boxes for packaging to avoid shipping and installation damage.

- Reflectivity: The target emissivity is less than 0.05 to ensure the highest heat reflection effect.

The main purpose of 8011 roof aluminum foil

8011 roofing foil is widely used for roof insulation. Common uses include:

- Underlayment: used under roof tiles, wood or metal panels to act as a waterproof barrier and thermal insulation layer.

- Cavity liner: installed on the attic or roof deck to reflect radiant heat and improve thermal insulation.

- Single-ply roofing: used under membrane systems such as TPO and PVC to provide moisture resistance and thermal insulation.

- Metal buildings: cost-effective insulation solution for corrugated steel, aluminum or copper roof panels.

- Renovation projects: upgrade old insulation materials to improve thermal insulation performance.

8011 installation of aluminum foil roof insulation

Installation techniques directly affect the insulation effect, and key steps include:

- Preparation: Make sure the roof deck is dry and flat, and repair any defects.

- Unroll and secure: Lay the foil, use foil-specific tape to seal the seams, and secure the edges to prevent wind.

- Prevent convection: If necessary, install fabric under the foil to block air flow and ensure the insulation is airtight.

Delivery quality standards of Chalco 8011 roofing aluminum foil

Chalco ensures that 8011 roofing aluminum foil meets customer needs with high-standard production and quality management systems. The following are the main standards for its delivery quality:

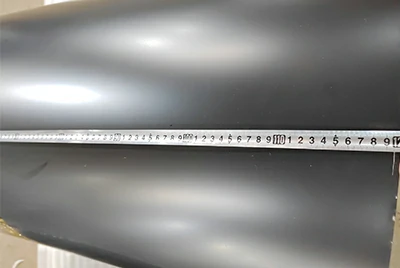

Dimensional tolerance

Thickness: Tolerance is controlled within ±0.005mm to ensure uniformity and durability of aluminum foil.

Width: Customized according to customer requirements, standard width range is 48 inches to 96 inches, width tolerance is ±1mm.

Coil weight: The weight of each roll is precisely controlled for easy transportation and use.

Surface quality

Flatness: There are no obvious wrinkles, ripples, pinholes or cracks on the surface of the aluminum foil.

Cleanliness: No oil stains, spots or impurities, ensuring smooth brightness to improve reflective performance.

Texture consistency: Wrinkles or smooth textures are evenly distributed to meet the needs of heat insulation and aesthetics.

Mechanical properties

Tensile strength: meets national and international standards to ensure the strength requirements of aluminum foil during roof construction.

Elongation: ensures that the aluminum foil has good toughness and is suitable for different roof shapes and bending requirements.

Packaging and shipping

Protective packaging: Use tear-resistant plastic bags, composite cartons or wooden boxes to prevent scratches or deformation during transportation.

Moisture-proof measures: Add a moisture-proof layer to ensure that the aluminum foil is not affected by moisture during transportation and storage.

Clear labeling: Each roll of aluminum foil is marked with specifications, weight, production batch and testing certification for easy customer verification.

Environmental protection and compliance

Environmental requirements: The product complies with RoHS standards, contains no harmful substances, and is suitable for environmentally friendly construction projects.

Certification support: Provide ISO 9001 quality management system certification and other necessary material performance test reports.