Lightweight, weather-resistant, beautiful, and easy to process - ACP boards are widely used in building curtain walls, interior decoration, advertising signs, etc. due to their excellent performance and cost advantages. Chalco provides ACP board solutions with various thicknesses, core materials, fire ratings, and surface finishes, supporting flexible customization and fast delivery to meet the needs of multiple industries and scenarios.

Directory Navigation:

- Product type overview: ordinary, fireproof, high-strength and other types of ACP

- Finish and coating options: PE, PVDF, wood grain, mirror, etc.

- Structure and performance analysis: layered analysis and performance advantages

- Processing and customization capabilities: flexible customization of size, pattern and color

- Typical application scenarios: building curtain walls, all-aluminum cabinets, advertising signs, etc.

- Price influencing factors and selection suggestions

- Technical Parameters

- FAQ and purchasing process

Chalco ACP board product types and purchasing guide

-

Ordinary ACP board

Ordinary ACP boardFeaturing an LDPE core, it offers light weight, strength, rich colors, and easy processing—ideal for signs, displays, and interior decoration in non-fireproof settings. Core material type: low density polyethylene core (LDPE Core)

GB/T 17748.2-2021 ASTM E84 Class C (combustion grade) -

Flame Retardant ACP Board (FR ACP / Fire Retardant Core)

Flame Retardant ACP Board (FR ACP / Fire Retardant Core)Made with a modified mineral core, it combines flame retardance and workability—ideal for fire-safe public spaces like subways, airports, and hospitals. Core material type: flame retardant mineral composite core (Modified Mineral Core)

GB/T 17748.2-2021; Class B1 (GB 8624-2012) ASTM E84 Class B EN 13501-1 Bs 1, d 0 -

High flame retardant ACP board (A2 ACP / A2 Core ACP)

High flame retardant ACP board (A2 ACP / A2 Core ACP)Using an A2-grade inorganic core with minimal combustibles, it's ideal for high fire-safety areas like high-rises, rail transit, hospitals, and data centers. Core material type: High mineral / inorganic core

GB/T 17748.2-2021 Class A2 (GB 8624-2012) EN 13501-1 A2-s1, d0; ASTM E84 Class A -

High Strength ACP

High Strength ACPReinforced aluminum and core materials enhance impact resistance and stability, ideal for heavy-load uses like industrial housings, structural parts, and equipment surfaces. Core material type: reinforced polyethylene core material / special composite core material (customizable)

GB/T 17748.2-2021 ASTM E331 (structural sealing) -

Flexible ACP

Flexible ACPWith bendable cores and soft aluminum, it offers great flexibility for curved facades, sculptures, and arched ceilings. Core material type: Flexible composite polymer core

GB/T 17748.2-2021 ASTM D790 (flexural modulus) -

Bendable ACP

Bendable ACPDesigned for bending and rounding, it resists cracking and suits light boxes, column wraps, curved facades, and signage. Core material type: low density polyethylene core / customized flexible core material

GB/T 17748.2-2021 ISO 178 (bending performance) Can be used with CNC bending performance testing

Chalco ACP panel finishes – matches all styles

We provide a variety of coating systems such as PE, PVDF, Nano, FEVE, etc. as the basic protection and functional layer of ACP panels, fully meeting the diverse requirements for weather resistance, decorative properties and service life in different indoor and outdoor environments. Quick Quote

| Coating Type | Full name | Features | Application Scenario |

| PE coating | Polyester | Bright colors, low cost, average weather resistance | Indoor decoration, signage, short-term outdoor |

| PVDF coating | Polyvinylidene Fluoride | Excellent weather resistance, strong corrosion resistance, long-lasting color | Exterior walls, curtain walls, high-end building exterior finishes |

| Nano coating | Nanometer Coating | Self-cleaning function, anti-fouling, oil-resistant and pollution-resistant, suitable for exterior surfaces with high cleanliness requirements | Hospital exterior walls, high-end commercial buildings, landmark projects |

| FEVE coating | Fluoro Ethylene Vinyl Ether | Excellent overall performance, longer color retention, suitable for building exteriors with extremely high requirements for color stability | High-end building curtain walls, urban complexes, long-term exposed building facades |

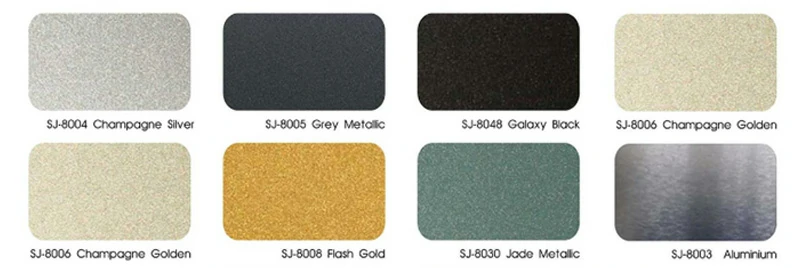

Based on various coating systems such as PE, PVDF, Nano and FEVE, Chalco provides a variety of finishing options such as mirror, brushed, wood grain, marble, etc., to meet the multi-level aesthetic and performance needs from basic decoration to high-end architecture, helping customers achieve an ideal balance between function, protection and visual expression.

- Color customization: support Pantone color card matching, customize exclusive colors according to samples

- Gloss control: Matte / Semi-matt / High gloss / Mirror free choice

- Texture customization: pattern depth, texture direction, and three-dimensional sense can be customized according to the design

- Sample proofing service: submit design drawings/physical samples, and quickly evaluate the proofing

Welcome to provide your design requirements, we will provide 1V1 customized suggestions and quotation services. [Quick Mailbox]

Color solid color/high gloss color

The basic and universal ACP surface form provides a wide range of color options to meet different brightness requirements (matte/semi-gloss/high-gloss). It has good outdoor weather resistance and decorative properties, is easy to construct, and is cost-effective.

Typical applications: store exterior walls, billboards, interior partitions, public space walls, industrial plant facades

Wood & Stone Look

Through thermal transfer or lamination, the natural texture of wood or stone is reproduced on the surface of ACP board, achieving both visual simulation and actual lightness. It is an environmentally friendly alternative to traditional wood and stone decoration.

Typical applications: high-end residential decoration, commercial chain storefronts, hotel lobbies, interior background walls, cultural exhibition halls

Mirror Finish

Mirror ACP uses a high-gloss coating or reflective film, which has a strong reflective effect and a modern feel, and is often used to create a space extension and technological atmosphere.

Typical applications: shopping mall atriums, brand windows, modern exhibition halls, fashion flagship stores, lighting guide reflective structures

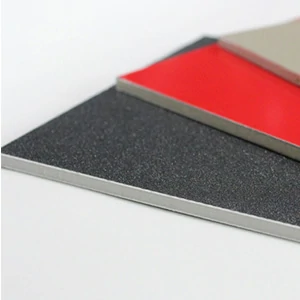

Brushed & Metallic Texture

The surface is mechanically brushed to show a delicate metal texture, and then protected with an anti-corrosion coating. It has a sense of technology and luxury, and looks calm and elegant.

Typical applications: elevator cars, electrical panels, office building entrances, hotel elevator halls, office space background walls

Creative & Textured Finishes

Using special coating or embossing technology to create 3D textures or textures to enhance tactile and visual changes is a common decorative solution for high-end customized projects.

Typical applications: exhibition centers, brand stores, cultural theme buildings, personalized office spaces, high-end residential decorative panels

Chalco ACP panel performance advantages - give you a comprehensive understanding of ACP board

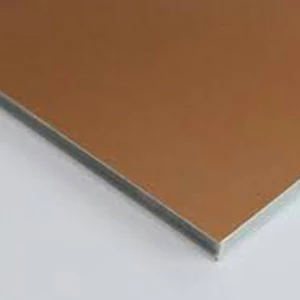

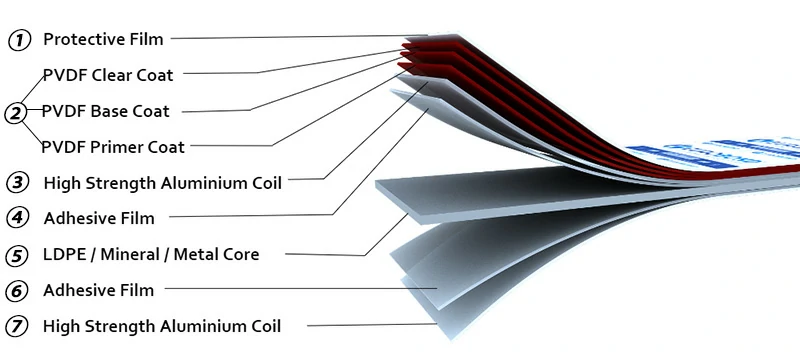

| Layer | name | Material Description | Functional Description |

| ① | Protective film | Peelable plastic film | Prevent surface scratches during transportation/processing, and remove after installation |

| ② | Coating system | PE or PVDF coating | Providing decorative colors and surface weathering resistance, it is the core of beauty and performance |

| ③ | Upper aluminum plate | High-strength aluminum alloy (usually 3003/5005/1100) | Provide structural strength and support the rigidity of the overall board |

| ④ | Adhesive layer | High performance hot melt adhesive film | Firmly combine the aluminum plate and the core material to ensure the overall peel strength |

| ⑤ | Core layer | LDPE / FR Core / A2 Mineral Core, etc. | Determining fire rating, weight, and strength is the core of classification |

| ⑥ | Lower aluminum plate | High-strength aluminum alloy | Enhance overall rigidity and maintain symmetrical structural stability |

| ⑦ | Adhesive layer | High performance hot melt adhesive film | Corresponding to the upper layer, two-way bonding |

| ⑧ | Bottom coating (optional) | Anti-corrosion coating/Primer | Improve the corrosion resistance and adhesion of the back of the sheet (if re-lamination is required) |

- Lightweight and high strength: The density is only about 1/2 of that of solid aluminum plate, which is convenient for transportation and construction.

- Good flatness: multi-layer composite structure ensures excellent surface flatness and is not easy to deform

- Excellent processability: can be cut, bent, punched, and engraved, suitable for a variety of structural shapes

- Flexible fire protection performance: optional FR / A2 core material to meet different levels of building fire protection requirements

- Strong weather resistance: using high-quality PE, PVDF coating, PVDF outdoor service life can reach more than 15-20 years

- Decorative diversity: supports a variety of surface effects such as mirror, wood grain, marble, brushed, etc.

Chalco ACP board processing and customization capabilities

Chalco has mature aluminum-plastic panel production lines and precision processing equipment, with one-stop manufacturing capabilities from material compounding, surface treatment to finished product processing. We can flexibly customize the size, thickness, core material and finish according to customer needs to meet personalized applications in multiple industries and scenarios.

Flexible customization service

Chalco ACP sheets can provide standard sheets, and are more adept at responding to customized requirements such as multiple specifications, multiple core materials, and large and small batches, helping customers quickly implement engineering projects:

- Sample customization (fastest delivery within 3~5 days)

- Engineering supporting solution suggestions

- OEM / ODM pattern, packaging, logo customization

- Small batch proofing/fast delivery mechanism

| Plate thickness | Conventional 3/4mm, customizable 2~6mm thickness |

| Aluminum skin thickness | 0.18mm/0.21mm/0.3mm/0.4mm |

| Sheet size | Width 1220 / 1250 / 1500mm, maximum length 6000mm+ |

| Core material selection | LDPE (ordinary) / FR (flame retardant) / A2 (high flame retardant) |

| Adhesive system | The high-performance adhesive layer is used to ensure a firm bond between the aluminum plate and the core material to prevent peeling and bulging, and is suitable for high temperature and humid environments. |

Core processing capabilities

Chalco has a complete aluminum-plastic panel precision processing production line, supporting high-precision cutting, bending, punching, compounding and other deep processing services:

| Cutting capacity | ±0.5mm accuracy, supports cut-to-length cutting and ultra-wide sheet material processing |

| Slotting bending | CNC automation equipment, capable of designing structures such as column wrapping and special-shaped curtain walls |

| Drilling and Punching | A variety of apertures and patterns can be customized to suit ventilation panels, advertising boards, etc. |

| Hot pressing composite | High lamination efficiency, suitable for mass production and large-scale surface treatment |

Various surface treatment capabilities

Chalco is equipped with an advanced aluminum coil coating production line that can support coating operations with a maximum aluminum skin thickness of 0.7mm and a plate width of 1550mm. It has high-precision color matching, high adhesion pretreatment and fast delivery capabilities, fully ensuring the stable output of different coating systems (PE/PVDF/Nano/FEVE) and decorative surface treatment effects.

We support the full-link decorative processing capabilities from basic coating systems to diverse visual textures to meet customers' differentiated needs in terms of brand expression, aesthetics, anti-corrosion and anti-fouling, etc.:

- PE / PVDF / Nano / FEVE coating systems

- Wood grain/marble/mirror/brushed/3D relief and other visual styles

| Surface type | Style Category | Implementation Description | Involved processing instructions |

| Color solid color/high gloss color | Solid color/ Glossy effect | Base color coat + clear coat (optional) | Optional gloss level (gloss, matte, semi-gloss, etc.) |

| Wood grain/ Marble grain | Wood grain/stone grain simulation series | Thermal transfer, color transfer or lamination | The surface is covered with a decorative pattern film layer, and then sprayed with a transparent PE layer or varnish |

| Mirror | High gloss mirror series | Aluminum film coating or high gloss varnish coating | High gloss paint or mirror film is required, and the surface should be extremely smooth |

| Brushed/Metallic Texture | Modern metal texture series | Aluminum plate mechanical brushed texture + surface clear coating | The brushed texture is completed during the aluminum coil processing stage and requires protective varnish packaging |

| Creative Texture Texture | Personalized pattern embossed series | Embossing, relief, partial printing and other processes are carried out on the basis of coating | Produces a three-dimensional texture or tactile feel, can be combined with a local varnish effect |

Chalco ACP board industry cooperation 5 major sectors

Chalco aluminum-plastic composite panels are widely used in many core industries such as construction, transportation, home furnishing, advertising, etc. due to their excellent weather resistance, fire rating, finishing diversity and processing flexibility. We not only provide materials, but also provide one-stop solutions from selection to supporting processing for customer projects.

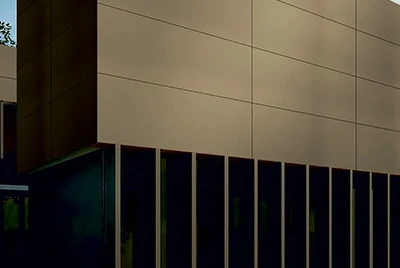

ACP board for building curtain wall system

Typical applications: Commercial complex facades, high-rise building curtain walls, special-shaped edging structures

Advantages of cooperation:

- PVDF coating + A2/B1 fireproof core material, meeting the requirements of high fire resistance and long weather resistance

- Supports 3~6mm various thicknesses and large size customization

- Can be matched with brushed, stone-grained and other decorative surfaces to enhance the building facade effect

>

>

ACP board for interior decoration system

Typical applications: office partitions, elevator edging, commercial space ceilings, background walls

Advantages of cooperation:

- PE coating has rich colors and is easy to apply

- The board surface is flat and lightweight, supporting CNC slotting and bending

- Formaldehyde-free and environmentally friendly core materials are optional, meeting green building interior standards

>

>

ACP board for all-aluminum home/cabinet system

Typical applications: cabinet door panels, bathroom cabinet back panels, furniture facings, sliding door panels

Advantages of cooperation:

- Moisture-proof and fire-proof, stain-resistant and easy to clean, suitable for wet areas such as kitchens/bathrooms

- Mirror, wood grain, 3D and other finishes are available, supporting OEM pattern development

- Compatible with all-aluminum structural parts, meeting the trend of lightweight and durable home furnishings

>

>

ACP board for transportation hubs/public facilities

Typical applications: Airports, subways, station walls/ceilings, traffic guidance systems

Advantages of cooperation:

- Supports A2 fireproof and impact-resistant design, meeting public space safety requirements

- Easy-to-clean surface for high-touch areas

- Provide customized opening, punching and bending services to adapt to special-shaped structures

>

>

ACP board for advertising and signage systems

Typical applications: outdoor billboards, shop fronts, light boxes, exhibition display boards

Advantages of cooperation:

- High-gloss pure color, mirror, and brushed surfaces are all available, with outstanding visual effects

- Smooth surface, easy to engrave and print, supports UV inkjet and silk screen printing

- Support small batch customization, fast delivery, and adapt to changing advertising scenarios

>

>

ACP sheet price guide: influencing factors and selection suggestions

When purchasing aluminum composite panels, price is usually one of the important factors. Different material configurations, finishing processes and project requirements will affect the cost of ACP panels.

Chalco provides diversified product selection and flexible quotation mechanism. The following content will help you quickly understand the price structure of ACP panels and reasonable selection suggestions.

| Core material type | Ordinary LDPE core material has the lowest price; FR (flame retardant) core material has a moderate price; A2 (high flame retardant mineral core) has a relatively high price |

| Aluminum skin thickness | The thicker the aluminum sheet, the higher the strength and the higher the price. Common thicknesses are 0.18mm / 0.21mm / 0.30mm / 0.40mm |

| Coating type | PE coating is low-cost and suitable for indoor use; PVDF/Nano/FEVE coating has stronger weather resistance and corrosion resistance and is more expensive |

| Finishing effects | Standard solid colors have the lowest cost; special finishes such as wood grain, marble, mirror, etc. have a slightly higher price due to the complex process. |

| Degree of customization | Demands for special sizes, non-standard colors, small batch customization, etc. will affect the unit price and minimum order quantity |

| Order quantity | bulk orders can be diluted, and the price is more advantageous |

| Transportation mode and distance | Long-distance transportation or the need for reinforced packaging will increase the overall cost |

Practical selection suggestions

- Limited budget, suitable for interior decoration : ACP with PE coating + LDPE core can be selected to meet the needs of aesthetics and basic strength.

- For public areas or commercial building facades : It is recommended to choose PVDF coating + FR or A2 core material to ensure weather resistance and fire resistance.

- Customized engineering projects : Clarifying parameters such as size, color, and surface effects in advance will help to provide accurate quotes and shorten delivery cycles.

- Brand logo and advertising applications : Mirror, high-gloss solid color or brushed panels are recommended, which have a strong visual impact and are easy to construct.

To obtain a project-specific quotation or sample evaluation, please contact Chalco Customer Support Team [Quick Mailbox/Button].

Chalco ACP board technical parameter reference table

| Panel Composition Overview | ||||

| Specification | Unit | Standard | B-51 d0 (4mm) | A2-S1 d0 (4mm) |

| Alloy | — | EN 485-2 | AA 3105 / AA5005 | AA 3105 / AA5005 |

| Temper | — | EN 485-2 | H-14 / 16 | H-14 / 16 |

| Skin Thickness | mm | — | 0.5 | 0.5 |

| Core Material | — | EN 13501-1 | Fire retardant mineral thermoplastic core | Non-combustible core |

| Panel Weight | kg/m² | — | 7.5 | 8.2 |

| Product Tolerances | ||

| Specification | Unit | Tolerance |

| Panel Weight | % | ±5% |

| Panel Thickness | mm | ±0.2 |

| Skin Thickness | mm | ±0.03 |

| Panel Width (1250, 1500mm) | mm | ±2 |

| Panel Length (up to 6000mm) | mm | ±4 |

| Bow (Length or Width) | % | Max 0.5 |

| Squareness | mm | Max 5 |

| Mechanical Characteristics | |||

| Specification | Unit | Standard | Value |

| Tensile Strength | MPa | — | 45 (B-51) / 43 (A2-S1) |

| 0.2% Proof Stress | MPa | ASTM E8 | 42 (B-51) / 41 (A2-S1) |

| Elongation | % | — | ≥ 5 (B-51) / ≥ 2 (A2-S1) |

| Modulus of Elasticity | MPa | — | 70000 |

| Thermal Characteristics | |||

| Specification | Unit | Standard | Value |

| Linear Thermal Expansion | mm/m/100°C | EN 1999-1-1 | 2.4 |

| Deflection Temperature | °C | ASTM D648 | ≥110 (B-51) / ≥116 (A2-S1) |

| Temperature Resistance | °C | ASTM C518 | -50 to +80 |

| Specification | Unit | Standard | Value |

| Acoustic & Fire Characteristics | |||

| Specification | Unit | Standard | Value |

| Sound Transmission Loss (Rw) | dB | ASTM E90-09 | 27 |

| Reaction to Fire | — | NFPA 285 | PASS |

| Reaction to Fire | — | EN 13501-1 | B, s1, d0 / A2, s1, d0 |

| Reaction to Fire | — | DIN 4102-1 / TBW 0300734 | Class B / Class A2 |

| Self-Ignition Temperature (>343°C) | — | ASTM D1929 | PASS |

| Fire Retardant Performance | — | TBW E119-20 | 120 min / 180 min |

| Surface Finish Characteristics | |||

| Specification | Unit | Standard | Value |

| Paint Finishes | — | — | PVDF / FEVE |

| Gloss @60°C | % | JIS / AAMA 2605-13 | 20–35% |

| Pencil Hardness | — | — | HB–F |

| Backside Service Coating | — | — | PE |

FAQs on purchasing ACP boards

Q: In what environments can ACP boards be used? Is it waterproof and fireproof?

A: Chalco provides common (LDPE), flame retardant (FR) and high flame retardant (A2) core materials, suitable for indoor and outdoor, dry and wet environments and various fire rating requirements. The products have excellent moisture resistance, corrosion resistance and weather resistance.

Q: Can you provide customized colors and sizes? What is the minimum order quantity?

A: Support RAL / Pantone color card customization, thickness, width and length can be customized as needed. MOQ is as low as small batch order, and samples can be delivered in 3-5 days at the fastest.

Q: What certifications or test reports can you provide?

A: We can provide ISO, RoHS, REACH, ASTM E84, EN13501, GB/T17748 and other certification reports according to customer requirements to meet the needs of export or engineering bidding.

Q: Is the transportation safe? Do you provide packaging solutions?

A: All boards are packaged with customized wooden pallets + protective film to meet the requirements of export container transportation and ensure safe and damage-free transportation throughout the entire process.

Order process & service

Procurement process:

- 1Submit requirements → Provide specifications/quantity/application information

- 2Confirm the plan → Exclusive customer service provides samples and drawings for confirmation

- 3Sign the contract → clearly define the delivery date, price, and warranty terms

- 4Production and delivery → Factory efficient production scheduling and fast delivery

- 5After-sales service → Provide technical support and problem response

- Samples delivered in 3 days

- Support custom length/multi-size/multi-color

- Global delivery & engineering support

- Dedicated engineering team assists in model selection and structural solution matching

Service commitment:

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote