The foil serves as a barrier to prevent air leakage and isolate the ducts, contributing to temperature maintenance and reducing energy loss. Additionally, aluminum foil is often employed to wrap air conditioning coils, aiding in enhancing their efficiency and lifespan.

As a professional manufacturer of aluminum foil for air conditioning, Chalco offers a range of high-quality products including hydrophilic aluminum foil, hydrophobic aluminum foil, coated aluminum foil, fin materials, aluminum foil pipes for HVAC (Heating, Ventilation, and Air Conditioning) systems, and insulation tape for air conditioning ducts. Our aim is to provide air conditioning manufacturers with solutions that deliver outstanding performance and reliability.Welcome contact

Chalco air conditioner aluminum foil parameters

| Alloy | 1100, 1200 3102, 8011 etc. |

| Temper | H22, H24, H26 etc. |

| Thickness | 0.07-0.2mm (The minimum thickness is lower than the prevailing market standard 0.09mm) |

| Width | 200-1650mm |

| Inner diameter of foil coil | 75mm, 150mm, 200mm etc. |

| Specification | GBT 3198-2010 JIS H 4160-1994 DIN_EN_546-2 |

Aluminum alloy series of Chalco hot selling air conditioner foil

-

1030B H26 air conditioner aluminum foil

Mainly used for fins on air conditioner radiators and evaporators, providing good thermal conductivity and corrosion resistance.

-

3102 H26 air conditioner aluminum foil

Commonly used on the condenser and evaporator fins of air conditioners, it helps enhance heat dissipation efficiency.

-

8011 O H22 H24 air conditioner foil

Soft and easy to mold, mainly used for AC refrigerant pipes and outdoor unit casing, typically 0.08-0.2mm thick.

-

1100/1200 H22 air conditioner aluminum foil

Good processability and corrosion resistance. Commonly used in AC systems for heat exchangers and evaporators, typically 0.1-0.3mm thick.

-

1300 H22 air conditioner aluminum foil

Used for thermal conduits in air conditioning systems or for crafting fins on condensers and evaporators.

-

8006 O H22 air conditioner foil

Typically used in air conditioning systems for crafting pipes, connectors, etc., with good malleability and bendability.

-

7072 O air conditioner aluminum foil

Frequently used for AC system connectors and insulation pads, its flexibility suits diverse processing requirements.

-

4343/3003/4343 composite aluminum foil

Strong corrosion resistance, excellent weldability, easy to shape into radiator fins. Suitable for general-purpose AC radiators and coolers.

-

4343/3003/4045 composite aluminum foil

High corrosion resistance, excellent welding, ideal for high-performance cooling systems and radiators.

Chalco hot selling air conditioner foil products

Bare aluminum foil for air conditioningQuick Quote

Plain and economical, this uncoated aluminum foil, typically made from 1100 or 1200 O-temper alloys, is commonly used in budget split air conditioners. It wraps coils or insulation but has limited corrosion and moisture protection, often needing additional processing.

Hydrophilic aluminum foil for air conditioningQuick Quote

Crafted from alloys like 8011 H24, hydrophilic aluminum foil, with a special water-absorbing coating, enhances heat transfer, prevents corrosion, and makes up over 80% of AC aluminum foil. Boosting cooling efficiency by around 5%, it's an ideal choice for air conditioner cooling.

Hydrophobic aluminum foil for air conditioningQuick Quote

Also termed water-repellent foil, it contrasts with hydrophilic foil, featuring a larger contact angle (around 75°) for effective water resistance. This treatment prevents water accumulation on air conditioning components by causing droplets to bead up and roll off.

Coated aluminum foil for air conditioningQuick Quote

Air conditioning aluminum foil, in addition to hydrophilic and hydrophobic coatings, may have epoxy resin coatings for durability and corrosion prevention. Applied outside the hydrophilic layer, common colors include blue, gold, green, etc.

Aluminum foil and sheet for fin materialQuick Quote

Common alloy grades include 1100, 1200, 8011, 8021, 8079, etc. In air conditioning, the choice of alloy depends on the desired mechanical properties. Aluminum fins provide significant surface area in contact with air to facilitate efficient heat transfer.

HAVC aluminum tape and foil tubeQuick Quote

Single-layer aluminum AC pipes, made of aluminum and polyester, are easy to connect and install. Highly flexible and corrosion-resistant, they offer effective protection for metal components. Fire-certified, durable, and can be cut without special tools.

Air conditioning aluminum foil tapeQuick Quote

A single-sided tape for HVAC systems, with an 18μm aluminum foil and high-performance acrylic adhesive, offers strong sealing and bonding. Ideal for central air conditioning ducts and pipeline joints, it exhibits excellent weather and humidity resistance.

Aluminum foil insulation tape for air conditioner duct refrigeratorQuick Quote

Designed for insulating air conditioning refrigerant ducts, this tape has excellent insulation and corrosion resistance. Used to reinforce and insulate ducts, it prevents heat loss and maintains system stability.

The color selection of air conditioning aluminum foil: It's Not Just for Aesthetics!

-

Silver

Uncoated aluminum foil usually retains its natural metallic silver color. Silver foil is widely used in various air conditioning systems, especially in the manufacturing of components like evaporators, condensers, and fins.

-

Blue

Hydrophilic aluminum foil, typically blue, features a special coating that enhances heat exchange efficiency and prevents water droplet buildup, ideal for air conditioning evaporators and condensers.

-

Gold

Gold aluminum foil, with special coatings for corrosion resistance, is often used in high-end air conditioning condensers and heat exchangers, as well as for decorative purposes.

-

Black

Some air conditioning aluminum foils are black coated, mainly for UV resistance and corrosion protection. This is especially used in high-temperature environments or outdoor air conditioning equipment.

Functional analysis of color selection

The color of air conditioning aluminum foil is not merely for aesthetic purposes; it is closely related to the functionality of the coatings applied:

- Hydrophilic Coating (Blue): The blue aluminum foil features a hydrophilic coating that absorbs moisture, improving heat exchange efficiency. In high-humidity environments, the hydrophilic coating effectively prevents water droplet accumulation, reducing scale buildup on the heat exchange surface and enhancing the cooling performance of the air conditioning system.

- Corrosion-Resistant Coating (Gold): Gold aluminum foil is used to enhance the corrosion resistance of the foil, particularly in high-temperature or humid environments. The gold coating effectively resists corrosive substances such as moisture and salt in the air, extending the lifespan of the air conditioning system.

- Thermal Conductivity: While the color itself does not directly affect the thermal conductivity of aluminum foil, the choice of coating can influence heat exchange efficiency. Hydrophilic coatings can improve thermal conductivity, while corrosion-resistant coatings help maintain the cleanliness of the heat exchanger surface.

Why are Blue and Gold the most common?

Blue and gold aluminum foils are the most commonly found in the market due to their distinct functional advantages:

- Blue Aluminum Foil (Hydrophilic Coating): Due to the special properties of its hydrophilic coating, blue aluminum foil excels in improving heat exchange efficiency, making it particularly suitable for air conditioning systems that require frequent cooling. It effectively reduces moisture accumulation, keeping the heat exchanger clean and enhancing the overall efficiency of the air conditioning system.

| Coil side | Inside | Outside |

| Chemical compound | Polyurethane | Polyurethane |

| Color | Blue | Blue |

| Lacquer surface properDes | Hydrophobic | Hydrophobic |

| CoaDng masses, per side g/m2 | 3-4 | 3-4 |

| CoaDng thickness, single spot µm | 2-3 | 2-3 |

- Gold Aluminum Foil (Corrosion-Resistant Coating): The corrosion-resistant coating of gold aluminum foil allows it to maintain excellent performance even in high-temperature and humid environments, making it ideal for use in components such as condensers. Its durability and resistance to corrosion make gold aluminum foil highly favored in the market, especially for air conditioning systems that require long-term, efficient operation.

| Coil side | Inside | Outside |

| Chemical compound | Polyurethane | Polyurethane |

| Color | Gold | Gold |

| Lacquer surface properDes | Hydrophobic | Hydrophobic |

| CoaDng masses, per side g/m2 | 5-6 | 5-6 |

| CoaDng thickness, single spot µm | 4-5 | 4-5 |

The color selection of air conditioning aluminum foil is not just for aesthetic purposes; it directly impacts the performance and durability of the air conditioning system. Blue and gold aluminum foils have become the mainstream choices in the market due to their superior performance in heat exchange efficiency and corrosion resistance.

Advantage of Chalco air conditioner aluminum foil

- The aluminum foil has a good shape, with no pinholes, scratches, dents, oil stains, dust, or other impurities on the surface, and a uniform thickness.

- It exhibits high strength, good ductility, and excellent corrosion resistance, including resistance to alkali, salt spray corrosion, and resistance to humid and hot conditions.

- The hydrophilic aluminum foil shows good hydrophilic performance, with an initial hydrophilicity of a < 100, and after environmental testing, the hydrophilicity is a < 250.

- Coated aluminum foil has strong adhesion, uniform thickness, and high corrosion resistance.

Application of Chalco aluminum foil in air conditioner system

-

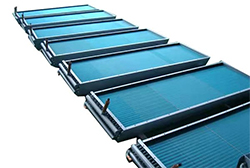

Air Conditioner Evaporator and CondenserQuick Quote

Air Conditioner Evaporator and CondenserQuick QuoteThe evaporator and condenser are core heat exchange components in an air conditioning system. Aluminum foil, as a heat exchange material, can effectively improve thermal conductivity and ensure the cooling and heating performance of the air conditioning system.

- Improved Heat Exchange Efficiency: Aluminum foil increases the surface area, promoting heat exchange between air and refrigerant, thus enhancing cooling and heating performance.

- Stable System Operation: The high thermal conductivity of aluminum foil helps maintain a stable operating temperature in the air conditioning system under high loads, preventing overheating that could affect system performance.

- Corrosion Resistance: The corrosion-resistant properties of aluminum foil ensure that the evaporator and condenser can be used in humid environments without rusting or failing, extending the lifespan of the air conditioning system.

-

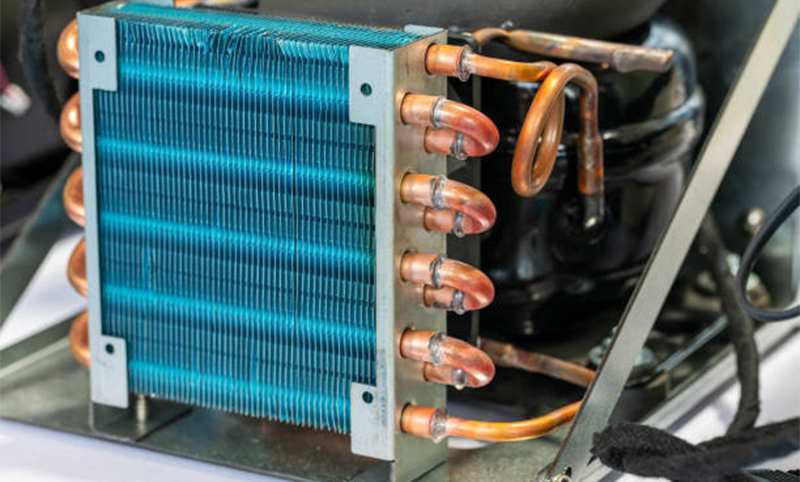

Air Conditioner FinsQuick Quote

Air Conditioner FinsQuick QuoteAir conditioner fins are used to enhance heat exchange efficiency and are typically found in the evaporator and condenser of air conditioners. Aluminum foil is commonly used to manufacture fin materials due to its excellent thermal conductivity and lightweight properties.

- Increased Surface Area: By forming aluminum foil into fins, the surface area in contact with air is increased, improving thermal conductivity.

- Improved Heat Exchange: Aluminum foil fins accelerate air flow, enhancing heat exchange efficiency and reducing energy consumption in the air conditioning system.

- Lightweight and Durable: The lightweight nature of aluminum foil ensures that the fins do not add extra weight to the system while maintaining excellent performance in various climate conditions.

-

Air Conditioner Ducts and Refrigerant Pipe ProtectionQuick Quote

Air conditioner ducts are used to transport refrigerants or air. Aluminum foil is commonly used as an outer protective layer or inner wrapping layer for the ducts to improve system efficiency and durability.

- Improved System Efficiency: Wrapping air conditioner ducts with aluminum foil reduces heat loss, maintaining the temperature stability of the refrigerant inside the ducts, thus improving the overall efficiency of the air conditioning system.

- Prevention of Condensation and Corrosion: The moisture-resistant properties of aluminum foil effectively prevent condensation on the surface of the ducts, avoiding corrosion from moisture and ensuring the system operates stably over the long term.

- Enhanced Durability: The corrosion-resistant properties of aluminum foil make it an ideal protective material for air conditioner ducts, especially in high-humidity or corrosive environments, extending the lifespan of the ducts.

- Prevention of External Contamination: Aluminum foil effectively blocks dust, moisture, and other contaminants from the air, protecting the ducts from external damage.

-

Air Conditioner Filters and Air Purification SystemsQuick Quote

The filters and air purifiers in air conditioning systems are used to clean the air and ensure indoor air quality. Aluminum foil, as a core material in filters, has strong antibacterial and anti-pollution properties.

- Enhanced Filtration Efficiency: Aluminum foil can be used to make highly efficient air filtration materials that help remove dust, bacteria, and other pollutants from the air.

- Prevention of Bacterial Growth: The antibacterial properties of aluminum foil effectively prevent the growth of bacteria on filters, maintaining the hygiene and air quality of the air conditioning system.

- Improved Airflow: The lightweight and high thermal conductivity of aluminum foil help improve airflow, enhancing the efficiency of the filter.

-

Air Conditioner Outdoor Unit Shell and Connection ComponentsQuick Quote

The shell and connection components of an air conditioner outdoor unit need to have good weather resistance and corrosion resistance to withstand harsh external environments. Aluminum foil is commonly used for the protective layer of the outdoor unit shell and the sealing components of connecting pipes.

- Corrosion Resistance: The oxidation and corrosion-resistant properties of aluminum foil ensure that the outdoor unit shell can be used in high-temperature, humid, and salt-laden environments over the long term.

- Improved Aesthetics: The glossy surface and treatment of aluminum foil enhance the aesthetic appeal of the air conditioner shell, adapting to various design styles.

- Noise Reduction: The lightweight and flexible nature of aluminum foil effectively reduces noise during the operation of the air conditioning system, improving user comfort.

Choose Chalco aluminum foil for your air conditioner project

Chalco has established long-term cooperative relationships with numerous well-known air conditioning manufacturers, holding a significant market share in the air conditioning industry.

- Chalco uses German Achenbach mills and KAMPF slitters for Fin Stock aluminum foil, ranging from ingots to coils. Max width: 1800mm, min thickness: 0.006mm.

- With advanced tech, Chalco produces various aluminum foils (EN standards), overseeing production steps and tracing raw material origins.

- Certificates available: SGS-ROHS, SGS-REACH, MSDS, FDA, TDS, ISO9001 & ISO14001.

- Product packaging meets regulations and customer needs, using standard export methods, including plastic film or kraft paper cover, wooden boxes or pallets for protection, and clear labels for safe transportation.