Ventilation aluminum profiles are a type of aluminum profile specifically designed for air vents, ventilation openings, or exhaust ports. They are commonly used in air conditioning, ventilation systems, or ventilation devices in buildings.

Chalco can produce aluminum profiles for vents in various shapes for the frames and blades of aluminum alloy vents, with reliable quality, outstanding performance, and competitive pricing.

Specifications for air vent aluminum profiles

Specifications: ASTM B221

Certification: ROHS, ISO

Classification of air vent aluminum profiles

Air vent aluminum profiles are usually divided into profiles for vent frames and profiles for vent blades, which are assembled into a complete aluminum alloy air vent using connectors.

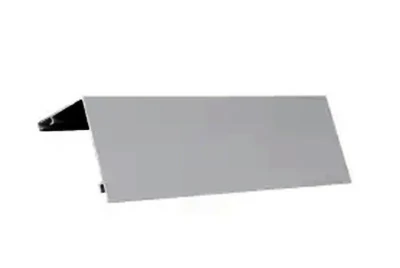

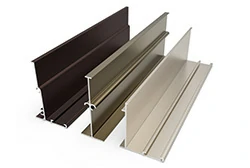

Air vent frame aluminum profiles

Mainly used for making aluminum alloy air vent frames, usually requiring cutting to meet the size and angle assembly requirements.

Common alloys: 6063, 6061

Width: 0.5mm-12mm.

Length: Custom.

Precision: ±0.15mm.

Contact us now

Surface treatment: Polishing, powder coating, anodizing, electrophoresis, and buffing.

Further processing: Precision cutting, drilling, milling, manufacturing.

Features: High quality, scratch-resistant, deformation-resistant.

Our air vent aluminum profiles come in a variety of colors and shapes, all of which can be customized.

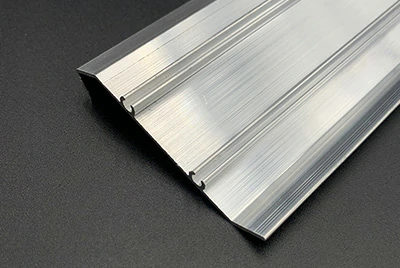

Aluminum alloy air guiding blades

Air guiding blades are key components in air vents used to direct airflow. Aluminum alloy blades can be adjusted both vertically and horizontally to control air movement and enhance the even distribution of indoor air.

Common alloys: 3003, 6061, 6063.

Contact us now

Thickness: 0.5mm - 1.5mm.

Width: 10mm - 50mm.

Length: Customized as needed.

Popular applications of air vent aluminum profiles

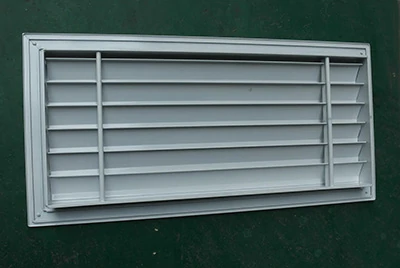

Aluminum alloy single-layer louvered air vents

Single-layer adjustable louvers are used for air intake or delivery in ducts. They can be fitted with a louver damper to adjust airflow and can be paired with aluminum alloy filters. Blades can be horizontal or vertical, allowing flexible control of airflow direction.

Aluminum alloy double-layer louvered air grille

The double-layer louvered air grille features two sets of blades that can be adjusted vertically and horizontally, allowing for more precise control of air flow and direction. It is widely used in air conditioning systems where flexible air flow adjustment is needed.

Aluminum alloy gravity louver air vents

These vents feature an automatic opening and closing function. When the system stops running, the louvers automatically fall to prevent backdraft. This type of vent is commonly used in fresh air systems and exhaust systems.

Aluminum alloy diffusers

Diffusers come in square, round, and other shapes, dispersing air flow in multiple directions. They are typically installed on the ceiling and are suitable for large spaces such as offices, shopping malls, and theaters.

Continuous aluminum soffit vent

A continuous aluminum soffit vent is a ventilation device installed under the eaves of a building, primarily used to promote air circulation in the attic or space below the roof.

Aluminum gable vent

An aluminum gable vent is a ventilation device installed on the gable of a roof, used to promote air circulation within the building by expelling heat and moisture. It is commonly used in residential, commercial, and industrial buildings' attics or roof areas to improve air quality and temperature control.

Chalco other aluminum alloy air vents

Aluminum alloy spherical air vents

Aluminum alloy swirl air vents

Aluminum alloy curved air vents

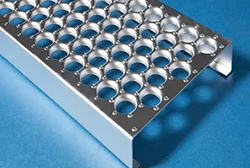

Aluminum alloy perforated air vents

Aluminum alloy concealed frame air vents

Aluminum alloy decorative louvered air vents

Reliable quality

- Our products meet industry and safety standards, giving you confidence in their quality.

- Chalco uses advanced production equipment and technology to ensure the dimensional accuracy of air vent aluminum profiles, reducing installation errors.

- Anodizing or coating provides strong corrosion protection.

- Finished products are supplied with quality certificates or test reports as per customer requirements.

How to address condensation issues with aluminum alloy air vents?

- The temperature difference between the surface of the air vent and the indoor environment (or the temperature around the vent) can be significant, causing the surface temperature of the vent to be lower. Combined with high indoor humidity, this can lead to condensation on the indoor unit's air vent. This may result in wall dampness, mold growth, and even peeling of wall paint, affecting the aesthetic appeal of the home.

- Chalco's newly produced aluminum alloy composite air vents feature insulation material on the frame and eco-friendly plastic-coated aluminum alloy blades. This design ensures that the aluminum alloy vent does not deform under heat and effectively prevents condensation.

How to choose the right aluminum alloy air vent?

Choose the type of air vent: Select the appropriate type based on project features, airflow organization, adjustment performance, and air delivery method.

Determine the vent size: Based on the required airflow (supply or exhaust), choose a vent size within the allowable airflow range at the vent's neck or inlet/outlet cross-section. Typically, the airflow speed ranges from 2 to 5 m/s, and consider the effective area ratio of the vent (30% to 60%).

Verify technical performance: Check the main technical specifications of the selected vent, such as throw distance, pressure loss, noise levels, and airflow speed and temperature differences in the working area.

Layout and installation method: Determine the layout and installation method of the vent and its connection to the ductwork.

Square or rectangular diffusers: These are commonly used in air conditioning systems, offering uniform airflow distribution and a sleek appearance. They can be made square or rectangular as needed, with options for 1 to 4 directions of airflow. The core section can be removed for easy installation and cleaning, and the rear can be equipped with a damper (OBD) for airflow adjustment.

What services can Chalco provide for you?

Custom design: Provide tailored services for dimensions, shapes, and surface treatments to ensure products perfectly match project requirements.

Solution provision: Develop professional solutions customized to meet specific client needs.

Quality control: Implement strict quality management from raw materials to production processes to ensure products meet high standards.

Technical support: Offer selection, design optimization, and installation guidance to assist clients in using products correctly.

Free samples: Quickly provide free samples for performance testing.