Angle steel is often used to reinforce corners or edges or for trim in construction projects. Aluminum is a great choice for these shapes because it is lightweight, durable, and corrosion-resistant. Additionally, aluminum can be easily formed and cut into desired shapes, making it a popular choice for industrial and decorative purposes. Whether you want to reinforce a structure or add visual interest to a design, aluminum angle steel is a great choice.

Chalco aluminum angle product parameters

- Alloy: 6061, 6063, 2024, 7075, 5052, 5083, 6060

- Specification: ASTM B308; AMS-QQ-A-200/8; ASTM B221; AMS-QQ-A-200/9

- Processing services: cutting, drilling, CNC, milling, bending, rolling

- Surface treatment: anodizing, powder coating, polishing, brushing, chrome plating, grinding

- Anodizing colors: black, matt black, bronze, etc.

- Cooperation areas: construction, decoration, industrial frames, solar frames, etc.

Click to view [Selection Guide] for aluminum angle in each field

Chalco hot sale aluminum angle commonly used alloy

6061 T6 structural aluminum angle

ASTM B308; AMS-QQ-A-200/8

A high-strength extruded aluminum designed for structural applications, offering strength, corrosion resistance, and lightweight properties. Commonly used in frames, brackets, supports, trailers, and truck beds, making it ideal for industrial and engineering projects.

6063 T52 construction aluminum angle

ASTM B221; AMS-QQ-A-200/9

Famous for its excellent surface finish and corrosion resistance. Often used in lightweight applications such as building frames, decorative trims, interior and exterior decoration. Ideal architectural decorative product in the field of construction and decoration.

-

High strength 2024 aluminum angle

2024 aluminum angle has excellent strength and fatigue properties, suitable for high-load structures such as aerospace and mechanical manufacturing, but its corrosion resistance is poor and requires surface treatment.

-

Ultra-high strength 7075 aluminum angle

7075 aluminum angle is known for its ultra-high strength and hardness, and is widely used in aerospace and military fields. Its corrosion resistance is poor, but it can be improved after anodizing.

-

Corrosion resistant 5052 aluminum angle

Excellent corrosion resistance, especially suitable for marine, chemical and outdoor environments. Its good strength and weldability make it the material of choice for shipbuilding, storage tanks and decorative structures.

-

Strength & corrosion resistance 5083 aluminum angle

Excellent strength, corrosion resistance, and weldability, ideal for marine, oil & gas, and transportation applications in harsh environments.

-

Easy to process 6060 aluminum angle

Easy to process with a good surface finish, offering moderate strength and corrosion resistance. Ideal for high-precision molding, frames, and decorative applications.

Chalco basic aluminum angle products

-

Structural angle aluminum

Structural angle aluminum

"Structural" aluminum angles, typically made from 6061-T6 alloy, offer lightweight strength, good corrosion resistance, and ease of fabrication. Ideal for frames, brackets, and load-bearing structural applications.

-

Building angle aluminum

Building angle aluminum

"Architectural" aluminum angle, made from 6063 alloy, features square corners and offers good corrosion resistance and surface finish. Lighter and smaller than structural angles, it's ideal for light structural and decorative applications.

-

Aluminum equal angle

Aluminum equal angle

Equilateral angle aluminum has two sides of equal length and is suitable for applications that require symmetrical structures, such as frames, brackets and decorative structures.

-

Unequal aluminum angle

Unequal aluminum angle

Unequal angle aluminum has two sides of different lengths and is suitable for structural applications that require asymmetrical strength distribution, commonly seen in complex architectural and industrial designs.

-

Right angle aluminum sharp corner

Right Angle Aluminum has sharp inside and outside right angles and is suitable for structural applications that require precise angles, such as building supports and frames.

-

Round corner aluminum

The corners of fillet aluminum are rounded and are often used in applications that require a safer, streamlined design, such as decoration and home design.

-

Thin aluminum angle

Thin aluminum angles have thinner wall thicknesses and are suitable for lightweight applications, commonly seen in light frames and decorative structures.

-

Small aluminum angle

Small aluminum angles are suitable for small structures with limited space and are widely used in small frames, brackets and decorative strips, etc.

-

Large aluminum angle

Large aluminum angles are suitable for structural applications that carry larger loads and are often used in large frames and supporting structures.

-

Heavy duty aluminum angle

Heavy duty aluminum angles offer increased strength and are used in industrial applications that need to withstand heavy loads, such as large machinery and building support structures.

Chalco aluminum angle products - available in a variety of shapes and angles

-

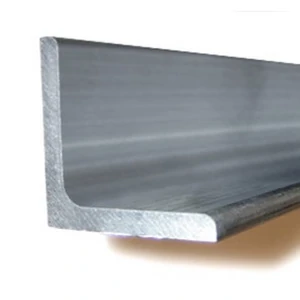

L shaped aluminum trim angle

L-shaped aluminum decorative strips have a right-angle shape and are commonly used in construction and home decoration, providing precise edge protection and decorative effects, suitable for door and window frames, wall corners, etc.

-

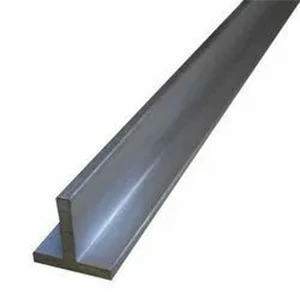

Aluminum T angle

Aluminum T Angle has a "T" shaped cross section and is commonly used in structural applications such as support and connection parts, suitable for carrying loads and providing additional stability.

-

Aluminum U angle

Aluminum U-angle has a U-shaped cross section and is widely used in frame structures, supports and connection parts, suitable for design requirements that require a U-shaped groove.

-

Z shape aluminum angle

Z-shaped aluminum angles are in the shape of a "Z" and are often used to support and connect structures. They are especially suitable for applications that require support at different angles.

-

Y aluminum angle

Y-shaped aluminum angle is suitable for special structural design. Y-shaped sections are commonly found in applications that require a combination of stability and flexibility.

-

Aluminum 90 degree angle

Aluminum 90 degree angle has a right angle shape and is widely used in frame and bracket structures, suitable for applications that require a precise 90 degree angle.

-

Aluminum 45 degree angle

Aluminum 45 degree angle is in the shape of a 45 degree angle and is often used in structural and decorative applications that require a bevel connection, such as furniture and architectural design.

-

Aluminum 120 degree angle

Aluminum 120 degree angle has a 120 degree angle and is suitable for specific structural and decorative needs, especially in applications where a larger angle is required.

-

Aluminum 135 degree angle

Aluminum 135 degree angle has a 135 degree angle and is suitable for applications that require special angle connections, such as complex frame and bracket designs.

Chalco aluminum angle processed products

-

Slotted aluminum angle

Our slotted aluminum angles can be customized according to customer needs, offering a variety of sizes and hole spacing options to suit a variety of structural support and mounting systems.

-

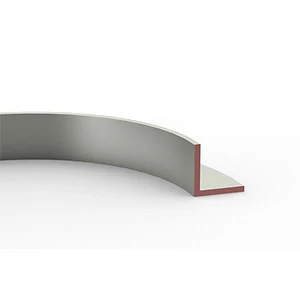

Curved aluminum angle

Customized bent aluminum angles can be processed into different curve shapes according to customer requirements, suitable for applications with special angles or curve designs, such as architectural and decorative projects.

-

Pre drilled aluminum angle

Pre-drilled aluminum angles, customizable for hole positions and diameters, enable quick assembly and are widely used in buildings, machinery, and support structures.

-

Perforated aluminum angle

With precise hole spacing and hole shape, it can be customized according to customer needs. It is suitable for ventilation, drainage and aesthetic design, and is widely used in construction, industrial equipment and other fields.

-

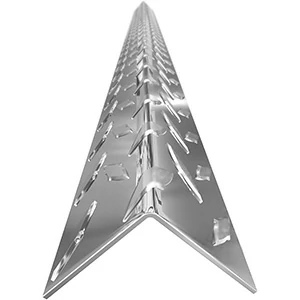

Aluminum diamond angle

The aluminum plate with diamond texture provides good anti-slip effect and unique decorative effect. We can customize the size and texture according to customer needs, suitable for stairs, platforms and other places that require anti-slip.

-

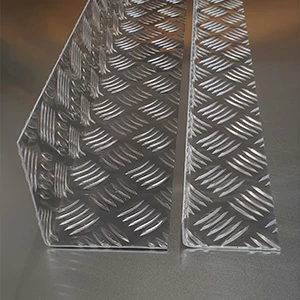

Aluminum checker plate angle

Combine the lightness and durability of aluminum, providing excellent skid resistance and decorative effects. We can customize according to customer requirements, suitable for applications that require additional wear resistance and decorative effects.

-

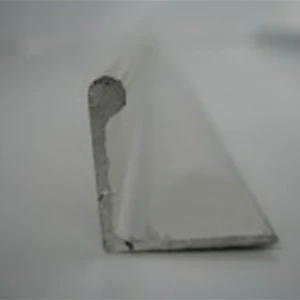

Aluminum bulb angle

Provides additional support and structural strength, especially for applications requiring greater load-bearing capacity.

-

Aluminum fluted angle

Featuring a corrugated design for added strength and aesthetic appeal, customizable for architectural and decorative applications.

-

Aluminum double angle

Double aluminum angle is a combination of two aluminum angles, suitable for structures that require additional support and stability. We provide customized services to ensure that the product meets the specific needs of the project, and is widely used in the construction and industrial fields.

Guide for aluminum angle in each field

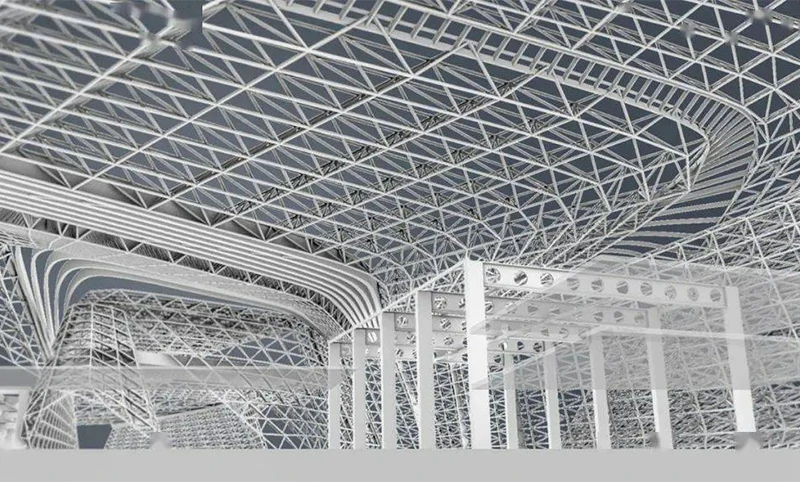

Aluminum angle for building

Aluminum angles in the construction industry are mainly used in window frames, door frames, decorative corners, etc., which can improve the structural stability and visual effect of the building.

Contact us now

Notes for purchase:

- Corrosion resistance: Choose a suitable corrosion-resistant aluminum alloy, especially in areas near the sea or with heavy humidity. Alloys such as 5052 and 6063 are recommended.

- Surface treatment: Anodizing or painting can provide better corrosion protection while improving appearance.

- Size and shape: Choose the appropriate angle, size and thickness of profile according to the architectural design requirements.

Decorative aluminum corner

Aluminum angles in the construction industry are mainly used in window frames, door frames, decorative corners, etc., which can improve the structural stability and visual effect of the building.

Contact us now

Notes for purchase:

- Appearance requirements: It is recommended to choose aluminum angles with smoother surface treatment, such as brushed and polished, to provide a high-end decorative feel.

- Dimensional accuracy: High-precision dimensional requirements to avoid asymmetry or surface defects.

- Color selection: You can choose anodized or sprayed aluminum angles, and choose different color surface treatments according to design requirements.

Aluminum angle for industrial frames

Aluminum angles in the construction industry are mainly used in window frames, door frames, decorative corners, etc., which can improve the structural stability and visual effect of the building.

Contact us now

Notes for purchase:

- Strength: Focus on selecting aluminum alloys with higher strength, such as 6061, 7075, etc., to ensure the stability and safety of the frame.

- Machinability: When the processing difficulty of aluminum angle is high, it is necessary to ensure that an aluminum alloy that is easy to process (such as 6060) is selected to reduce processing costs.

- Size selection: Choose the appropriate size and angle based on the specific frame design requirements.

Aluminum angle for solar/wind energy frame

Aluminum angles in the construction industry are mainly used in window frames, door frames, decorative corners, etc., which can improve the structural stability and visual effect of the building.

Contact us now

Notes for purchase:

- Corrosion resistance: Choose aluminum alloys with strong corrosion resistance, such as 6063 or 5052, to adapt to different climatic conditions.

- Strength and weight: Aluminum angles must have high strength and be light weight for easy installation and transportation.

- Processability: Ensure that the size and processing accuracy of the aluminum angle meet the design requirements and ensure installation accuracy.

Chalco aluminum angle production capacity - extrusion and rolling

There are two main ways to produce aluminum angles: extrusion and roll forming.

- Extrusion molding is a process of extruding heated aluminum billets through a die to form aluminum angles with specific cross-sections. It is capable of producing high-precision and complex shapes and is suitable for customized needs.

- Rolling forming uses a continuous rolling process to process aluminum plates or aluminum bars into angle shapes, which is suitable for mass production of standardized products, with high production efficiency and better surface quality. The two methods have their own characteristics, and the selection of the appropriate production process depends on the product specifications, performance requirements and production volume.

Aluminum angle extrusion equipment and production capacity

Chalco 's modern aluminum angle extrusion equipment uses high-precision technology to meet the production needs of aluminum angles of different shapes and sizes. Through precise mold design and efficient equipment operation, it ensures the high precision and high strength of each aluminum angle product, which is particularly suitable for the production of complex cross-sections and high-specification aluminum angles.

Equipment type: Pre-stretching machine; Extruder Press; Cooling system

- High-precision equipment is capable of producing aluminum angles of various specifications, including equal-leg angles, unequal-leg angles, etc.

- It can realize diversified aluminum angle production to meet the needs of multiple fields such as construction, transportation, and industry.

Aluminum angle rolling equipment and production capacity

Roll forming is another common way of aluminum angle production, mainly used for mass production of standardized aluminum angle products. Chalco's modern rolling equipment can provide high surface quality and precision while ensuring production efficiency.

Equipment type: Horizontal Rolling Mill; Cold Rolling Mill; Precision Rolling Mill

- The maximum production width can reach over 3000mm, which is suitable for use in marine engineering, transportation and other industries.

- It has high production efficiency, can respond quickly to market demand and provide a stable product supply.

Chalco aluminum angle processing capabilities——total project solution

We offer a comprehensive range of aluminium angle fabrication services to suit a wide range of industrial and commercial project needs. Whether your project requires basic cut-to-size or complex custom fabrication, we can provide a precise, efficient solution.

- Size cutting: We provide precision cutting service for aluminum angles. We can cut aluminum angles into required lengths and angles according to your needs and specified sizes to ensure your project goes smoothly.

- Different types of drilling: We can perform various types of drilling on aluminum angles according to customer needs, including small holes, large holes and custom holes. Drilling services can provide more flexibility in the assembly and installation process.

- CNC Machining: Using advanced CNC technology, we are able to perform high-precision machining, process complex aluminum angle shapes and fine details to ensure the accuracy and stability of the product.

- Milling: We can use a milling machine to mill aluminum angles to remove excess parts and achieve the required shape and size, suitable for applications that require precise processing.

- Bending and rolling: Our bending and rolling services can customize aluminum angles into various curved shapes according to project requirements. Suitable for structural and decorative applications that require a change in shape.

Chalco aluminum angle surface treatment— multiple surface options

- In addition to high-precision processing services, we also provide a variety of aluminum angle surface treatment options, which can enhance the product's aesthetics, durability and corrosion resistance. The following are the aluminum angle surface treatments we provide:

- Anodizing: Improves the corrosion resistance and wear resistance of aluminum angles, suitable for various environments.

- Spraying treatment: Enhance the corrosion resistance of aluminum angles and provide a variety of color options.

- Brushed Finish: Provides a unique texture to aluminum angles, suitable for decorative applications.

- Polishing: Gives the aluminum corners a mirror-like sheen, enhancing their appearance and making them suitable for display purposes.

- Chrome treatment: Improves the corrosion and wear resistance of aluminum angles, suitable for high-end applications.

- Tungsten ground aluminum angle: Increase the surface hardness of the aluminum angle, suitable for high wear resistance occasions.

- Grinding: Removes surface irregularities of aluminum angles and provides a smooth surface.

Frequently asked questions about Chalco aluminum angle products

1. How to calculate the weight of aluminum corner trim?

To calculate the weight of aluminum angle trim, you first need to know the type of aluminum alloy and its density. Then, use the dimensions of the aluminum angle (such as length, width, height, and thickness) to calculate its total volume, usually measured in cubic centimeters (cm³). Next, multiply the volume by the density of the aluminum (usually measured in g/cm³) to get the total weight of the aluminum angle trim.

2. How to cut aluminum angle?

The best way to cut aluminum angles is to use a miter saw with a carbon tip blade and make sure the aluminum angle molding is securely fastened to the clamp. Using handheld tools (such as a hacksaw) may cause the aluminum angle to bend and affect the cut. Using professional cutting tools will ensure a precise and clean cut.

3. How to bend aluminum angle?

Aluminum angles can be bent using a press brake, however thicker aluminum angles require greater pressure to complete the bend. It should be noted that anodized aluminum angle moldings react poorly to bending and may cause surface damage or cracks. When bending aluminum angles, it is recommended to be careful to ensure that its structure is not affected.

4. How to connect aluminum angles?

There are many ways to connect aluminum angles, and different connection methods can be selected according to different application requirements. Welding is the strongest and most durable connection method, but it may be relatively complex and costly. If welding is not required, you can consider using brazing, rivets, self-tapping screws or bolts, which can also ensure a stable connection of aluminum angles.

5. What are the common uses of aluminum angles?

Aluminum angles are widely used in construction and manufacturing projects. Common uses include:

- Window Trim : Aluminum angles provide a clean, polished finish to windows and doors and add structural support.

- Door frame reinforcement: Aluminum angles can be used to reinforce door frames to prevent sagging.

- Vehicle manufacturing: Used in trailers, truck beds, boat trailers, and car frames, it is favored for its light weight and high strength.

- Frames and brackets: Aluminum angles are widely used in the production of frames and brackets to provide stable support.

6. What size options are available for aluminum angles?

We offer aluminum angles in a variety of sizes and thicknesses, ranging from 9.5mm (3/8") to 152.4mm (6") in width and height, and from 0.9mm (0.035") to 12.7mm (1/2") in thickness. Whether it's a light-duty project or a heavy-duty application, we have the right aluminum angle size.

7. Does aluminum angle have anti-corrosion function?

Yes, aluminum is naturally resistant to corrosion and oxidation, making it ideal for both indoor and outdoor use. Aluminum angles can be painted, sprayed, or powder coated to maintain their beautiful appearance and increase durability.

8. What are the surface treatment options for aluminum angles?

We offer a variety of surface finish options, including bright polish, brushed polish, calendering, anodizing and satin anodizing, so you can choose the right finish based on your needs for beauty and durability.

9. How does the customized service of aluminum angle work?

We offer a free aluminum angle cutting service, you only need to specify the exact size you need, and we will cut the aluminum angle according to your requirements. In addition, we also provide a variety of surface treatments, hole processing, bending and other custom processing services to ensure that you can provide you with tailor-made aluminum angle products that perfectly match your project needs.

Through these frequently asked questions, you can have a clearer understanding of the use and processing of aluminum angle products, helping you make better purchasing decisions. If you have any other questions, please feel free to contact us.

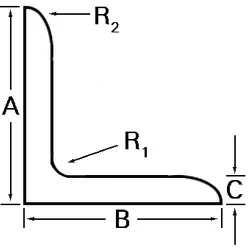

Chalco aluminum angle size reference table

| Reference size for Structural Angle |

|

|||

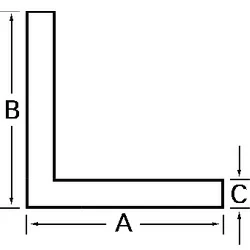

| Leg (A) | Leg (B) | Thickness (C) | Radius (R1) | Radius (R2) |

| 1 | 1 | 1/8 | .125 | .094 |

| 1 | 1 | 3/16 | .125 | .094 |

| 1 | 1 | 1/4 | .125 | .094 |

| 1 1/4 | 1 1/4 | 1/8 | .188 | .125 |

| 1 1/4 | 1 1/4 | 3/16 | .188 | .125 |

| 1 1/4 | 1 1/4 | 1/4 | .188 | .125 |

| 1 1/2 | 1 1/2 | 1/8 | .188 | .125 |

| 1 1/2 | 1 1/2 | 3/16 | .188 | .125 |

| 1 1/2 | 1 1/2 | 1/4 | .188 | .125 |

| 2 | 1 1/2 | 3/16 | .188 | .125 |

| 2 | 1 1/2 | 1/4 | .188 | .125 |

| 2 | 2 | 1/8 | .250 | .125 |

| 2 | 2 | 3/16 | .250 | .125 |

| 2 | 2 | 1/4 | .250 | .250 |

| 2 | 2 | 3/8 | .250 | .125 |

| 2 1/2 | 2 | 1/4 | .250 | .125 |

| 2 1/2 | 2 1/2 | 3/16 | .250 | .125 |

| 2 1/2 | 2 1/2 | 1/4 | .250 | .125 |

| 2 1/2 | 2 1/2 | 3/8 | .250 | .125 |

| 3 | 1 1/2 | 3/16 | .250 | .188 |

| 3 | 2 | 3/16 | .250 | .188 |

| 3 | 2 | 1/4 | .312 | .188 |

| 3 | 2 | 5/16 | .312 | .313 |

| 3 | 2 | 3/8 | .312 | .250 |

| 3 | 3 | 3/16 | .312 | .250 |

| 3 | 3 | 1/4 | .312 | .250 |

| 3 | 3 | 3/8 | .312 | .250 |

| 3 | 3 | 1/2 | .312 | .250 |

| 3 1/2 | 3 1/2 | 1/4 | .375 | .250 |

| 3 1/2 | 3 1/2 | 3/8 | .375 | .250 |

| 4 | 2 | 1/4 | .375 | .250 |

| 4 | 3 | 1/4 | .375 | .250 |

| 4 | 2 1/2 | 1/4 | .375 | .250 |

| 4 | 3 | 3/8 | .375 | .250 |

| 4 | 4 | 1/4 | .375 | .250 |

| 4 | 4 | 3/8 | .375 | .250 |

| 4 | 4 | 1/2 | .375 | .250 |

| 5 | 3 | 1/4 | .250 | .250 |

| 5 | 3 | 3/8 | .375 | .312 |

| 5 | 5 | 3/8 | .500 | .375 |

| 5 | 3 | 1/2 | .375 | .312 |

| 6 | 4 | 3/8 | .500 | .375 |

| 6 | 4 | 1/2 | .500 | .375 |

| 6 | 6 | 3/8 | .500 | .375 |

| 6 | 6 | 1/2 | .500 | .375 |

| 6 | 6 | 3/4 | .750 | .375 |

| 8 | 8 | 1/2 | .500 | .375 |

| Reference size for Sharp Corner Architectural Angle |

|

|

| Leg (A) | Leg (B) | Thickness (C) |

| 1/2 | 1/2 | 1/8 |

| 1/2 | 1/2 | 1/8 |

| 3/4 | 3/4 | 1/8 |

| 1 | 3/4 | 1/8 |

| 1 | 1 | 1/8 |

| 1 1/4 | 1 1/4 | 1/8 |

| 1 1/2 | 1 | 1/8 |

| 1 1/2 | 1 1/2 | 1/16 |

| 1 1/2 | 1 1/2 | 1/8 |

| 1 1/2 | 1 1/2 | 3/16 |

| 2 | 1 | 1/8 |

| 2 | 1 1/2 | 1/8 |

| 2 | 2 | 1/8 |

| 2 | 2 | 3/16 |

| 2 | 2 | 1/4 |

| 3 | 1 | 1/8 |

| 3 | 3 | 1/4 |