Aluminum billets are semi-finished aluminum products produced through advanced continuous casting or direct chill casting processes. Typically, they have a circular cross-section and elongated shape. These billets serve as essential raw materials for subsequent processes like extrusion, forging, and machining, and can be further processed into aluminum profiles, pipes, rods, and other products.

With their uniform metallographic structure, high density, and stable chemical composition, aluminum billets find wide applications across various industries, including aerospace, automotive manufacturing, construction engineering, electronic consumer products, and industrial equipment.

Chalco's aluminum billets are manufactured in strict compliance with ASTM/EN standards, ensuring uniform metallographic structure and superior mechanical properties. Additionally, we offer multiple alloy options and customization for diameter and length to meet your high-end manufacturing needs.

Quick Navigation

Specifications & Sizes of Aluminum Billets

Chalco offers high-quality, customized aluminum billets produced using advanced continuous casting technology and full-process quality control, ensuring stable and reliable performance in size, composition, and mechanical properties. Our products strictly adhere to AA, ASTM, and AMS standards, making them an ideal material choice for high-end industries such as aerospace, automotive, and construction.

Size Range

- Standard Diameters: 7 inches, 8 inches, 9 inches, 11 inches, 16 inches, and 20 inches

- Standard Lengths: 191 inches to 228 inches (approximately 4800–5800 mm)

- Custom Cutting and Processing: Available to meet special process and equipment requirements

Standard Specifications

- Products strictly follow AA, ASTM, and AMS standards

- Custom alloy chemical composition available per customer requirements, ensuring consistent and reliable performance

Quality Inspection & Process

- Produced using ISO 9001:2008 certified advanced casting equipment

- Full homogenization and peeling to the final diameter treatment, ensuring uniform internal structure

- Equipped with ultrasonic testing, metallographic analysis, and mechanical property testing to ensure no internal defects and stable mechanical performance

Choose Chalco's round aluminum billets for high performance, customization, and stringent quality control, providing full product support. Contact us now for a custom quote and professional selection advice to ensure solid material support for your high-end manufacturing needs.

Features of Aluminum Billets

Homogenization Treatment & Optimized Plastic Deformation

Through homogenization treatment, the alloy elements inside the aluminum billets are evenly distributed, significantly reducing micro-segregation during the casting process. This advantage optimizes the plastic deformation performance for subsequent processes like extrusion, forging, and machining, further enhancing the product's mechanical properties.

Strict Inspection Guarantee

Each round aluminum billet undergoes ultrasonic testing, hardness testing, metallographic analysis, and chemical composition inspection to ensure that there are no cracks or defects inside the material, meeting the precision machining and high strength standards required for high-end manufacturing.

High Consistency & Stability

Using advanced continuous casting technology and full-process quality control, every aluminum billet meets strict dimensional tolerances and stable internal structures, providing a reliable foundation for high-precision forming.

Flexible Customization & Optimized Cost

Custom diameters, lengths, conditions, and special requirements are available based on customer needs. This not only optimizes raw material utilization but also effectively reduces subsequent processing costs, meeting the personalized application needs of various industries.

Aluminum Billet Alloy Options

Choosing the right alloy is crucial when purchasing aluminum billets, as it directly affects the product's mechanical properties, corrosion resistance, and adaptability to subsequent processing. Chalco offers a variety of alloys including 2000, 4000, and 7000 series, catering to a wide range of applications from aerospace high-strength to corrosion-resistant construction needs.

-

2000 Series Aluminum Billets

2000 Series Aluminum BilletsThe 2000 series aluminum is significantly strengthened by adding copper, improving tensile strength and rigidity. This series is widely used in aerospace and high-performance structural components. Although it has high strength, its corrosion resistance is relatively low and often requires additional surface treatment for enhanced durability.

2014 Aluminum Billets 2024 Aluminum Billets 2219 Aluminum Billets 2618 Aluminum Billets -

4000 Series Aluminum Billets

4000 Series Aluminum BilletsThe 4000 series aluminum is alloyed with silicon to enhance wear resistance and high-temperature performance. It is commonly used in applications that require high-temperature stability, such as automotive engine parts and other industrial components.

4032 Aluminum Billets -

7000 Series Aluminum Billets

7000 Series Aluminum BilletsThe 7000 series aluminum alloys are strengthened by adding zinc, providing extremely high strength and fatigue resistance, making them ideal for aerospace and military applications. Although they are slightly more difficult to process, they offer unmatched advantages in applications requiring extreme strength.

7005 Aluminum Billets 7050 Aluminum Billets 7075 Aluminum Billets

Choose Chalco's aluminum extrusion billets for not only high-quality products but also professional technical support and flexible customization services. Contact us now for a tailored alloy solution and competitive pricing.

Applications of Aluminum Billets

As high-quality semi-finished raw materials, aluminum billets, after advanced casting and homogenization treatment, offer excellent mechanical properties and processing stability. They are not only ideal feedstock for processes such as extrusion, forging, and turning, but also provide reliable performance guarantees for various finished products.

Subsequent Processing Technologies

-

Aluminum Profile Extrusion

Aluminum Profile Extrusion

Aluminum billets can be processed through extrusion to create products like building doors and windows, industrial profiles, radiators, and solar mounts. The continuous casting and homogenization treatments ensure consistent profile dimensions and smooth surfaces.

-

Forging Processing

Forging Processing

Through forging, aluminum billets can be used to produce critical components like aerospace parts, automobile wheels, structural brackets, and drive shafts. Their high strength and fatigue resistance ensure the parts remain stable under heavy loads.

-

CNC Turning

CNC Turning

Aluminum billets are suitable for high-precision turning and are commonly used to produce grooved, knurled, threaded, tapered components, and various shaft parts. Homogenized aluminum billets ensure high machining accuracy and stable component dimensions, meeting the strict requirements of complex parts.

Industry-Specific Applications

Aerospace

Aircraft-grade billets are used for manufacturing aircraft structures, wing beams, landing gears, and interior components. 7075 billets offer high strength and fatigue resistance, meeting extreme load and safety standards. Their stable, homogenized nature ensures consistent dimensions, making them ideal for aerospace applications.

Automotive Manufacturing

Aluminum billets, through forging and turning, are used to produce engine parts, vehicle frames, wheels, manifolds, and drivetrains. This reduces weight, boosts fuel efficiency, and enhances safety. Their excellent machinability ensures high precision and durability during turning, grooving, knurling, and threading processes.

Construction & Industrial Equipment

In construction, 6061 billets for extrusion are used to create doors, windows, curtain walls, beams, columns, and decorative elements, ensuring structural stability and aesthetic appeal. Their corrosion resistance and strength make them the ideal choice for modern construction and infrastructure projects.

Electronics & Appliances

Homogenized aluminum billets, after precision machining, are used for electronic device housings, radiators, and key components, offering excellent thermal conductivity and durability. Their stable properties and high surface quality make them ideal for appliances and consumer electronics.

Industrial Manufacturing

Aluminum billets are essential for producing molds, tools, machinery, and automated components. Their homogeneity and machinability ensure high precision and stability. Custom aluminum billets for CNC machining create precise components like shafts, tapered parts, and threads.

Consumer Goods & Other Sectors

Besides high-end applications, aluminum billets are widely used in furniture, cookware, sports equipment, and packaging. Their strength, lightweight properties, and machining flexibility make these products practical and aesthetically appealing, meeting diverse market needs.

Chalco's aluminum extrusion billets, with advanced processes, strict quality inspections, and customized services, provide high-performance, stable, and reliable raw materials for various industries. Contact us now for professional material selection advice and customized quotations!

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Manufacturing Process Selection for Aluminum Billets

At Chalco, we utilize a variety of advanced manufacturing processes to ensure that our aluminum billet products meet the highest standards in quality, dimensions, and internal structure. Below are the key processes we use:

-

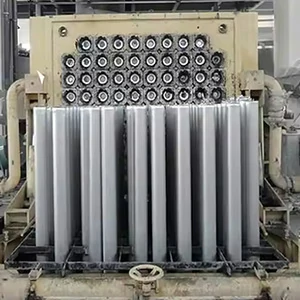

Continuous Casting

Continuous Casting

Chalco's continuous casting process involves continuously injecting molten aluminum into a water-cooled mold, achieving rapid and uniform solidification. The billets produced through this method have fine grains and consistent dimensions, making it ideal for high-volume production. It is especially suitable for industries like aerospace and automotive, where material uniformity and high precision are crucial.

-

Direct Chill Casting

Direct Chill Casting

In the direct chill casting process, molten aluminum is poured into preheated molds and rapidly cooled through water quenching or natural cooling. This process is simple and cost-effective, making it ideal for applications requiring high-quality microstructures with faster production speeds. It is widely used in industries like construction and consumer electronics, ensuring material purity while accommodating customization needs.

-

Semi-Continuous Casting

Semi-Continuous Casting

Chalco's semi-continuous casting process combines the benefits of both continuous casting and batch casting. By producing in segments, it offers enhanced dimensional control and uniformity in the internal structure. This method is particularly suited for producing large-diameter billets or billets made from special alloys, providing reliable quality for diverse industrial applications such as heavy-duty equipment and high-load structural parts.

Why Choose Chalco Aluminum Billets?

Comprehensive Alloy Series

Chalco offers a wide range of aluminum alloys, including 2000, 4000, 5000, 6000, and 7000 series, catering to diverse needs—from high-strength aerospace materials to corrosion-resistant marine-grade alloys. Choose the most suitable alloy for your specific application to ensure the optimal balance of performance and cost.

Diverse Manufacturing Processes

We operate advanced continuous casting, direct chill casting, and semi-continuous casting production lines, providing flexibility to switch between process modes to meet both small-batch prototyping and large-scale stable production needs. Our versatile processes guarantee excellent metallurgical performance in aluminum billets across different diameters and alloys.

Homogenization Treatment for Superior Material Properties

Each aluminum billet undergoes high-temperature homogenization annealing, significantly reducing alloy segregation and optimizing grain structure. This treatment enhances plasticity and uniformity in the billets, making them ideal for subsequent extrusion, forging, and machining.

Strict Process Control and Comprehensive Testing

Chalco implements online temperature monitoring, automated skinning, ultrasonic flaw detection, metallographic analysis, and hardness testing throughout production, ensuring that each billet is free from cracks, inclusions, and meets stable mechanical properties. Our ISO 9001, AS9100, and NADCAP certifications ensure quality assurance across all products.

Direct Manufacturer with Flexible Customization Services

As the source manufacturer of aluminum billets, Chalco offers customization of diameter, length, alloy composition, and heat treatment state according to customer requirements, maximizing material utilization and reducing processing costs. Whether for standard specifications or special needs, we can respond quickly and provide one-stop solutions.

Contact us today for exclusive round aluminum billet customization plans and competitive quotes, and let Chalco’s high-performance billets safeguard your project’s success!

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quoteFAQ

How to Choose the Right Alloy Series Based on Final Product Requirements?

When selecting an alloy, it's essential to define the product's mechanical properties, corrosion resistance, and processing requirements:

- High Strength, Fatigue Resistance: Recommended alloys are 2000 series (e.g., 2024, 2219) or 7000 series (e.g., 7075, 7050), often used in aerospace structures and high-load components.

- Corrosion Resistance, Good Weldability: 5000 series (e.g., 5083, 5052) performs excellently in marine environments and chemical equipment.

- General-purpose, Easy Machining: 6000 series (e.g., 6061, 6063) balances strength and formability, making it suitable for construction, automotive, and industrial profiles.

Chalco’s technical team can provide optimal alloy recommendations based on your specific operating conditions (temperature, load, surface treatment).

How is the Internal Quality of Aluminum Billets Ensured?

Chalco implements strict homogenization heat treatment for each batch of billets, eliminating casting segregation and optimizing grain structure.

- Ultrasonic Testing (UT): 100% inspection for internal cracks and pores.

- Metallographic Analysis: Verifying grain uniformity and phase distribution.

- Chemical Composition and Hardness Testing: Ensuring the alloy composition and mechanical properties meet standards.

Multiple testing methods work together to ensure that aluminum billets remain stable and reliable during subsequent processing.

What is the Minimum Order Quantity (MOQ) and Delivery Lead Time?

MOQ: For standard alloys and common sizes, the minimum order is generally 1 ton. For special alloys or small batch requirements, negotiations are possible.

Delivery Lead Time: For standard stock products, 1–2 weeks delivery is typical. For customized alloys or special specifications, 4–6 weeks is required (including alloying, casting, homogenization, and testing).

Chalco has a flexible production schedule and can adjust priorities based on your project’s urgency.

How to Customize the Size and Alloy of Aluminum Billets?

You can provide your required diameter range (3"–24") and length (2–6 meters or longer), along with the alloy composition or performance specifications. Chalco will:

Precisely control the alloy composition during the alloying stage.

Perform homogenization and skin removal after casting.

Provide a traceable process, including composition reports and mechanical test data to ensure each billet meets the customer’s standards.

How Do Aluminum Billets Match with Subsequent Extrusion, Forging, and Machining Processes?

- Extrusion: Homogenized billets ensure flowability and crack resistance, producing extrusions with consistent dimensions and smooth surfaces.

- Forging: Refined grains enhance plasticity, making forged parts both strong and tough.

- CNC Machining: The excellent internal structure and uniform hardness of the billets ensure stable machining, with high precision for threading, grooving, and taper machining.

Chalco can provide process parameter recommendations to help you optimize production efficiency and product quality.

What are the Key Storage and Handling Considerations for Aluminum Billets?

- Dry Environment: To avoid surface corrosion from moisture and salt spray.

- Stable Stacking: Prevent deformation and scratching of billets.

- Regular Inspections: Conduct visual and ultrasonic checks on stored billets to detect any potential defects early.

How is the Safety of Aluminum Billets Ensured During Transportation and Packaging?

Chalco uses moisture-proof films, wooden pallets, or steel frames to secure aluminum billets, along with shock-absorbing cushioning materials to prevent damage during long-distance sea or land transport. All packaging meets international logistics standards and can be customized for enhanced protection based on destination requirements.