In the design of modern homes and commercial spaces, aluminum cabinets have gradually become a popular choice in the market due to their lightweight, strong durability, good corrosion resistance and other characteristics. Whether it is kitchen cabinets, bathroom cabinets or office storage cabinets, aluminum cabinets can meet the needs of beauty, durability and personalization in different environments with their unique advantages. As an industry-leading aluminum product supplier, we are committed to providing customers with comprehensive customized aluminum cabinet overall solutions.

Customized aluminum cabinet overall solution - your one-stop partner

Alloy customization: 6061, 6063, 7075 and other aluminum alloy materials to choose from.

Cross-section customization: T-shaped, U-shaped, L-shaped and complex profiles, supporting precision extrusion.

Size customization: The length, width and thickness of profiles and plates can be fully customized.

Surface treatment: anodizing, powder coating, wood grain transfer, brushed or mirror polished.

Reserved processing: reserved slots, holes and smart component installation areas for accessories.

Modular design: splicing groove, connector interface profile design.

Brand customization: laser engraving, embossing or spraying brand logo and number.

More customization: For more customization, click [Customize] to jump to view details, check [Mold sample display] or click Quick Quote to communicate directly with business personnel.

Chalco aluminum sheet for cabinets

As an important component of cabinets, aluminum alloy panels have the advantages of being light, durable, moisture-proof and mildew-proof, and are especially suitable for use in humid kitchen and bathroom environments.

-

Aluminum panel

Aluminum panel

Aluminum panels play a vital role in the cabinet body and cabinet doors. Their moisture-proof and anti-corrosion properties make them excellent in high-humidity environments such as kitchens and bathrooms, which can effectively extend the service life of the cabinets.

-

ACP panel

ACP panel

ACP board is a composite material consisting of two layers of aluminum plates and a middle plastic layer. It has excellent corrosion resistance and durability and is often used for the exterior panels of cabinets, especially for home environments that require higher decorative and environmental performance.

-

Honeycomb aluminum panel

Honeycomb aluminum panel

Honeycomb panels are often used for cabinet door panels and cabinet bodies due to their light weight and high strength. This material can significantly reduce the weight of the cabinet while providing structural strength, and is particularly suitable for large-area panels and designs that require high durability.

Chalco aluminum profiles for cabinets

Aluminum profiles serve as the framework and support system of cabinets, covering multiple key components such as cabinet frames, door frames, rails, etc. Chalco provides a wide variety of aluminum profiles to meet the needs of different cabinet designs and ensure the stability and aesthetics of the structure.

Standard profiles for aluminum cabinet

-

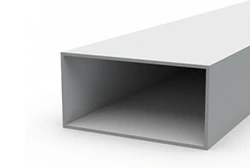

Chalco provides high-quality aluminum rods, tubes, bars and other standard profiles to provide basic materials for cabinet manufacturers. The materials are suitable for the frame structure of the cabinet, and can be further processed or extruded to meet different design requirements. We provide customers with a variety of specifications to ensure that each component can be precisely adapted to create a high-strength, durable and beautiful aluminum alloy cabinet.

Aluminum round bar

Aluminum square bar

Aluminum flat bar

Aluminum hexagonal rod

Aluminum round tube

Aluminum square tube

Aluminum rectangular tube

Aluminum oval tube

Aluminum hexagonal tube

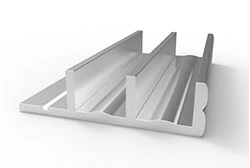

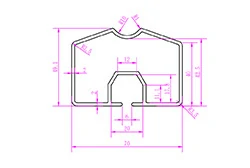

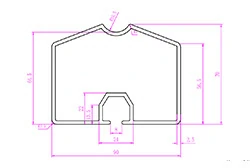

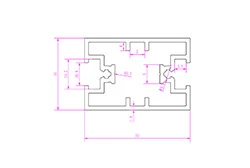

T-slot frame profile for aluminum cabinet

-

T-slot frame profiles are widely used in the frame structure of aluminum cabinets due to their unique T-slot design, which is convenient and quick to assemble. Chalco provides a variety of specifications of T-slot profiles to ensure the stability and durability of the cabinets, meet customization needs, and are suitable for various sizes and design requirements.

10 series (based on 1*1 '' profile)

15 series (based on 1.5*1.5 '' profile)

20 series (based on 20*20mm)

25 Series (Based on 25*25mm profile)

30 Series (Based on 30*30mm profile)

40 Series (Based on 40*40m profile)

50 Series (Based on 50*50m profile)

60 Series (Based on 60*60m profile)

80 Series (Based on 80*80m profile)

Aluminum channel for aluminum cabinet

-

Alloy: 6061, 6063, 7075, 2024, 5083 7050, 5086, 5456, 6082, 6060 etc.

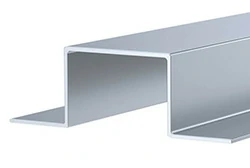

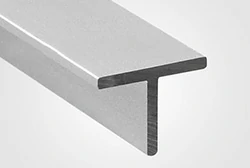

Aluminum Channel is widely used in the frame and support structure of aluminum alloy cabinets to provide stable support. It is lightweight, corrosion-resistant and anti-oxidation, suitable for humid environments such as kitchens and bathrooms. Chalco provides Aluminum Channel in various sizes and shapes to meet the customization needs of different cabinets.

U-shaped channel

C channel

J-channel

Hat channel

T channel

F-type aluminum channel

H-type aluminum channel

Nut channel

Door track

Aluminum angle for aluminum cabinet

-

Alloy: 6061, 6063, 2024, 7075, 5052, 5083, 6060

The application feature of Aluminum Angle in aluminum alloy cabinets is that it provides strong support and connection. It is widely used in cabinet frames, door frames, corners and other parts. We provide Aluminum Angle in various angles and shapes, including rounded corners and right angles, to meet different design requirements and ensure the stability and beauty of the cabinet structure.

Structural aluminum angle

Building aluminum corner

Equal/unequal aluminum angle

Y aluminum angle

Z aluminum angle

L aluminum angle

Thin aluminum angle

Large aluminum angle

Heavy duty angle

Chalco aluminum alloy accessories for cabinets

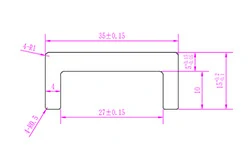

Handle

Installed on cabinet doors or drawers for opening or closing.

Hinges

Connect the cabinet door and frame to support the opening and closing of the cabinet door.

Slide rails

Used for drawer slids, providing smooth operation.

Cabinet feet/base

Support the weight of the cabinet and adjust the height to maintain balance.

Widgets

Used for fixing and bearing the load of suspended cabinets.

Angle code

Application: Used for cabinet structure reinforcement and frame connection.

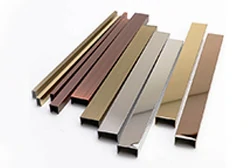

Decorative strips

Cover or protect the edge of the cabinet to beautify the appearance.

Edge strips

Wraps around the edges of glass or panels to provide protection.

Sliding door track

Provides sliding support for sliding doors.

Pulley system

Assist sliding doors or partitions to slide smoothly.

Locks

Used for locking cabinet doors or drawers.

Gas struts/hydraulic struts

Support flip doors or buffer opening and closing actions.

Tie rod

Used to strengthen the support of the internal structure of the cabinet.

Door stopper

Limit the opening and closing angles of cabinet doors to protect the door body and frame.

Drawer dividers

Divide the internal space of the drawer for easy classification and storage.

Sealing strip

Used to seal the gap between cabinet doors or drawers to prevent dust and moisture from entering.

Cabinet connector

Connect the cabinet sections and make sure the frame is secure.

Adjustable casters

Used for cabinet movement and positioning, some casters are height-adjustable.

Aluminum panel fasteners

Application: Used to fix panels and frames.

Glass fixing clamp

Application: Used to fix glass panels or glass cabinet doors.

Production and customization capabilities of Chalco cabinet aluminum product

Alloy composition customization: According to customer requirements for strength, corrosion resistance, lightweight and other properties, we provide customized aluminum alloy composition options (such as 6061, 6063, 7075, etc.).

Customized profile sections: We can produce profiles with special sections according to customer design requirements, such as T-shaped, U-shaped, L-shaped or complex profiles. Supports precision extrusion to ensure accurate dimensions and meet complex structural requirements.

Size customization: Provide full customization of the length, width, thickness, etc. of profiles and plates. Support the production of large-size integrated profiles to reduce the post-processing and splicing procedures.

Reserved processing customization: According to customer needs, reserved installation slots or holes for accessories such as slide rails, hinges, handles, locks, etc., to reduce subsequent processing costs. Provide reserved interfaces or installation areas for smart components (such as electronic locks, lighting systems) to facilitate subsequent integration.

Modular design support: Provide profile design and processing services suitable for modular cabinets, such as splicing grooves, connector interfaces, etc. Ensure seamless connection between profiles and improve installation efficiency.

Customized surface treatment: support anodizing, electrophoretic painting, powder coating, wood grain transfer, brushed or mirror polishing. Meet the appearance requirements of different styles, such as high-end home furnishings, industrial tool cabinets or retail display cabinets.

Logo and brand customization: Supports marking the customer's brand logo, product number or decorative pattern on aluminum profiles or surfaces. Provides laser engraving, embossing or spraying logo services.

Application scenarios of aluminum alloy cabinets and partner case studies

Aluminum alloy cabinets have been widely used in kitchens, bathrooms and other home spaces due to their lightness, durability, moisture resistance and corrosion resistance. With their unique advantages, aluminum alloy cabinets not only enhance the aesthetics of the home environment, but also provide a longer service life and better durability. We cooperate with many well-known cabinet manufacturers, furniture brands and home design companies to provide high-quality aluminum alloy product support to help them create high-quality custom cabinets.

Kitchen cabinets

The moisture resistance and corrosion resistance of aluminum alloy cabinets ensure that they can maintain excellent performance for a long time even in high humidity environments, and are widely used in home kitchens, commercial kitchens, etc.

Bathroom cabinets

The bathroom environment is humid, and the water resistance of aluminum alloy makes it an ideal material for bathroom cabinets. It effectively resists water vapor corrosion and maintains the long-term beauty and durability of the cabinet.

Custom furniture

Aluminum alloy cabinets are also widely used in wardrobes, wine cabinets, storage cabinets and other home customization needs, providing personalized solutions to meet the needs of different home spaces.

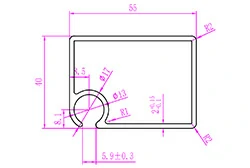

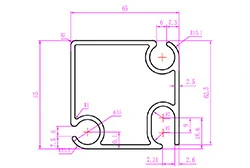

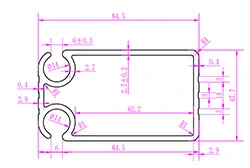

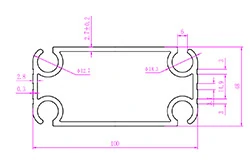

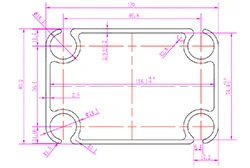

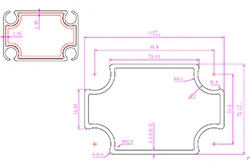

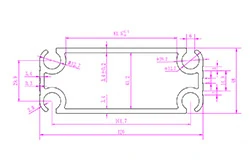

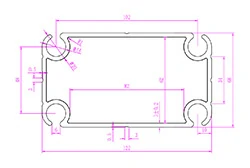

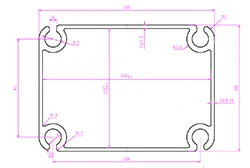

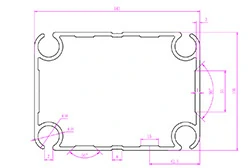

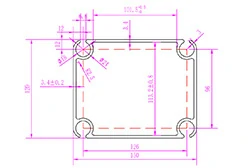

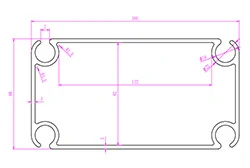

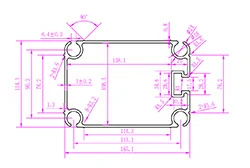

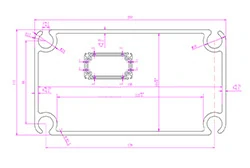

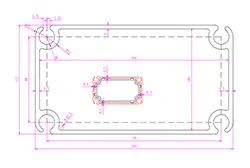

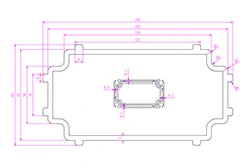

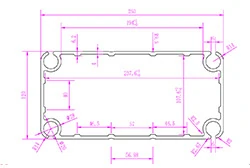

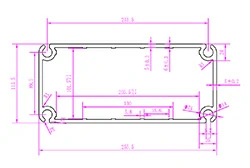

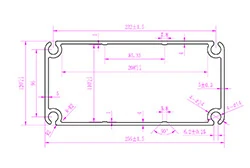

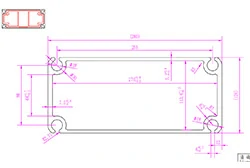

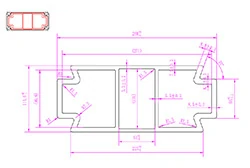

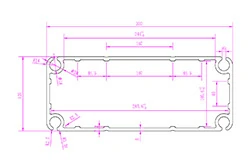

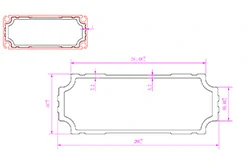

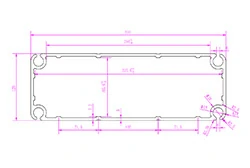

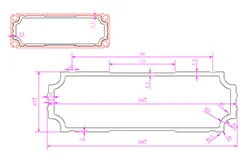

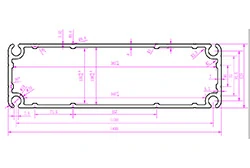

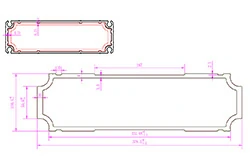

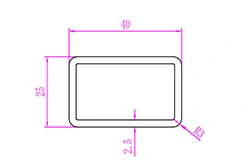

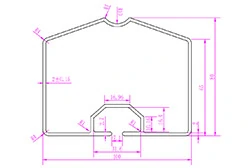

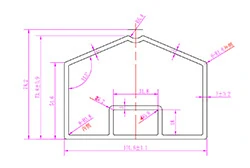

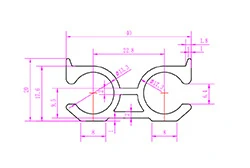

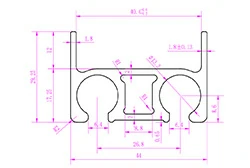

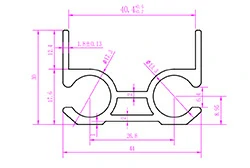

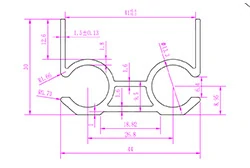

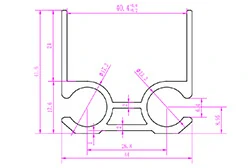

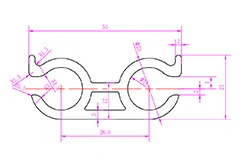

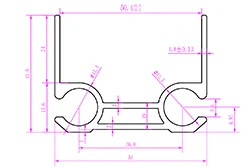

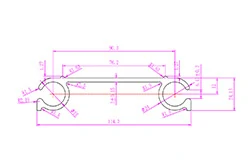

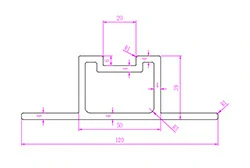

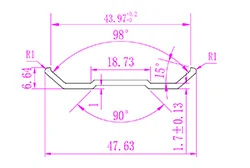

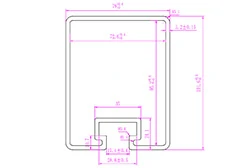

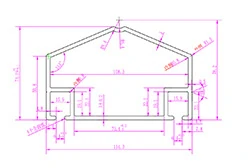

Chalco partial cabinet mold display

Alloy: 6061, 6063 and other extruded alloys

Implementation standards: GBT5237.1, GB/T14846

Product level: high precision

Curvature: ≤0.8mm per meter

Twist degree: ≤0.8m per meter

FAQs on purchasing aluminum for cabinets

What are the advantages of aluminum cabinets?

The main advantages of aluminum cabinets include corrosion resistance, moisture resistance, mildew resistance, and waterproofness. They are lighter and more durable than traditional wood or steel. They can effectively extend the life of the cabinets while maintaining their beauty. They are especially suitable for environments with heavy humidity such as kitchens and bathrooms.

How to choose suitable aluminum alloy material?

When choosing aluminum alloy materials, the first thing to consider is the use environment of the cabinet. For example, kitchen cabinets should choose aluminum alloys that are waterproof, moisture-proof and corrosion-resistant; bathroom cabinets need to pay more attention to moisture and water resistance. Secondly, according to the design requirements, choose the appropriate aluminum profile, aluminum plate or aluminum tube to ensure that the material can withstand the load of daily use.

What types of aluminum alloy products can I choose for cabinet making?

Common cabinet aluminum alloy products include aluminum plates, aluminum profiles, aluminum tubes and aluminum bars, etc. According to different cabinet designs, you can choose standard profiles, frame profiles, T-slot profiles, etc. to support the frame, make door panels and sliding door tracks, etc.

What are the processing methods of aluminum alloy cabinets?

We provide a variety of aluminum alloy materials, which customers can process according to their needs. The aluminum alloy products we provide can be further processed by extrusion, cutting, welding, etc., and can even be customized into specific profiles and sizes to meet different design requirements.

Are aluminum alloy cabinets suitable for customization?

Yes, aluminum alloy is very suitable for customization. You can customize the style and size of the cabinet according to the size of the space and personal needs. The aluminum alloy materials we provide can be combined with other materials to meet personalized design needs and create unique cabinets and home spaces.

Is it difficult to clean and maintain aluminum cabinets?

Aluminum cabinets are very easy to clean and maintain. Simply wipe with a damp cloth regularly to remove stains and oil stains. Since aluminum alloy is highly corrosion-resistant, there is no need to worry about fading or corrosion after long-term use.

How do aluminum cabinet prices compare to other cabinet materials? The initial investment for aluminum cabinets may be slightly higher than traditional wood or steel cabinets, but considering the durability, corrosion resistance and low maintenance cost of aluminum, aluminum cabinets are usually more cost-effective in the long run.

What style of home design is suitable for aluminum cabinets?

Aluminum alloy cabinets have a modern appearance and are suitable for a variety of home styles such as simple, modern, industrial, etc. At the same time, due to its flexible processing, it can also be combined with other materials such as wood and glass to meet diverse design needs.

How much weight can aluminum cabinets bear?

Aluminum alloy has high strength and hardness, and can withstand the load of daily kitchen and bathroom use. The specific load-bearing capacity will vary depending on the thickness and strength of the aluminum profile. It is recommended to choose the appropriate material for production according to actual needs.

What are the color and style options for aluminum cabinets?

The surface of the aluminum alloy cabinet can be treated by spraying, anodizing and other processes to provide a rich variety of colors and surface effects. You can choose the appropriate color and style according to the home design style to ensure that the cabinet is coordinated with the overall home atmosphere.