Aluminum channel is an aluminum profile with many applications, commonly used in many fields such as construction, industry, decoration, etc. It usually presents a variety of structures such as U-shape, C-shape, T-shape, etc., with good strength and corrosion resistance. Aluminum channel is widely used in supporting structures, frames, rails, decorative edges and other customized needs because of its lightness and durability.

With its excellent plasticity, Chalco can customize aluminum channels according to customers' specific needs to meet various size, shape and performance requirements. Therefore, aluminum channels are not only a functional material, but also an important element to enhance the design aesthetics.

Chalco aluminum channel product parameters

Alloy: 6061, 6063, 7075, 2024, 5083, 7050, 5086, 5456, 6082, 6060, etc.

Specification: ASTM B308; AMS-QQ-A-200/8; ASTM B221; AMS-QQ-A-200/9

Width: 12.7 mm (1/2") - 76.2 mm (3"); Click to view detailed [Size Table]

Height: 12.7 mm (1/2") - 50.8 mm (2"); Click to view detailed [Size Table]

Thickness: 1 mm (0.04") - 6.3 mm (1/4"); Click to view detailed [Size Table]

Surface treatment: mill finish, mechanical sandblasting, grinding, polishing, bright dipping, color coating, anodizing, powder coating

Collaborative Industry: structural support, guide rails, decorative edges, glass frame grooves, etc.

Click to view [Selection Guide]for aluminum channel in each field

Chalco aluminum channel basic products

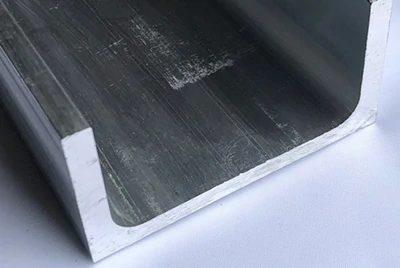

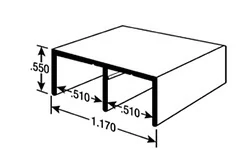

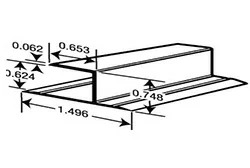

Structural aluminum channel

Structural aluminum channels are high-strength, corrosion-resistant, and stable, ideal for load-bearing structures, frames, and equipment supports in construction and manufacturing.

Contact us now

Chalco structural aluminum channel product advantages

- High strength: Structural aluminum channels have good tensile strength and are suitable for applications with heavy loads.

- Strong corrosion resistance: Made of aluminum alloy, it has excellent corrosion resistance and is particularly suitable for outdoor or harsh environments.

- Easy to process: Structural aluminum channels have good processability and are easy to cut, weld and install to meet various structural requirements.

- Lightweight: Aluminum is lightweight compared to steel, which helps reduce the overall weight of the structure and facilitates installation and maintenance.

- Durability: After surface treatment (such as anodizing), its durability can be significantly improved and its service life can be extended.

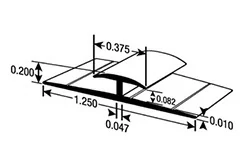

Architectural aluminum trim channel

Used indoors and outdoors, aluminum decorative grooves are durable, lightweight, and attractive. Ideal for windows, doors, ceilings, and walls, they offer weather resistance and design flexibility.

Contact us now

Chalco architectural decorative aluminum channel product advantages

- Aesthetics: It has a modern and refined appearance design, suitable for decoration and modification of building exteriors.

- Lightweight and durable: Aluminum itself is lightweight and durable, suitable for long-term use without requiring much maintenance.

- Good weather resistance: It can effectively resist climate change and ultraviolet radiation, and is suitable for various indoor and outdoor environments.

- Customizability: Size, shape and surface treatment can be customized according to different design requirements to meet unique architectural styles.

Chalco aluminum channel hot selling products

-

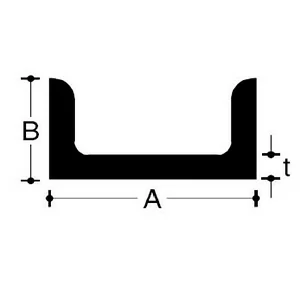

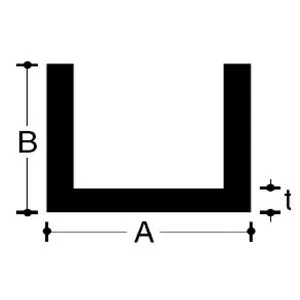

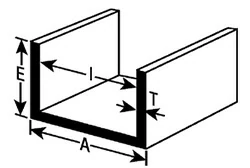

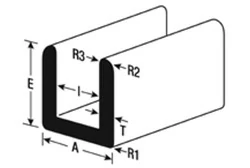

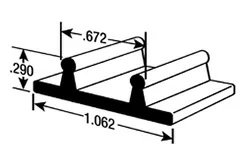

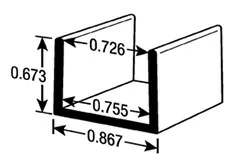

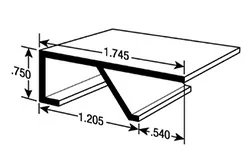

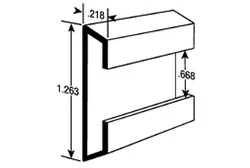

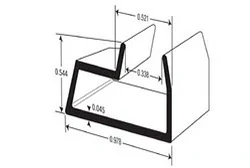

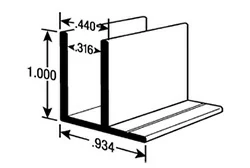

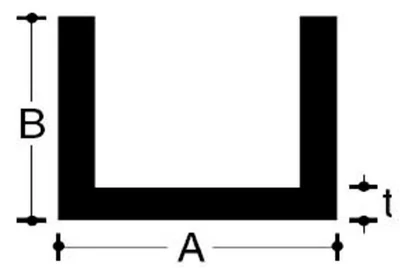

U-shaped channel

The simple design of the U-channel is commonly used in construction projects to support windows, doors and glass panels, and can also be used in manufacturing environments to support machinery and equipment.

-

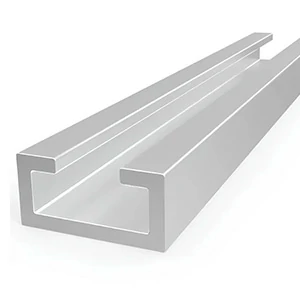

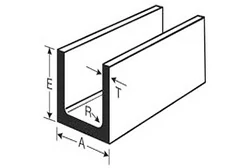

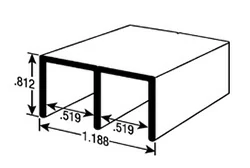

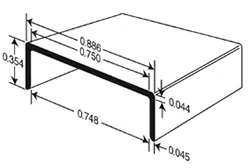

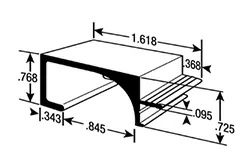

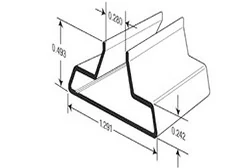

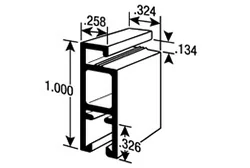

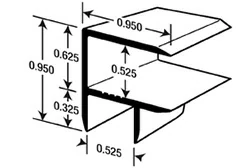

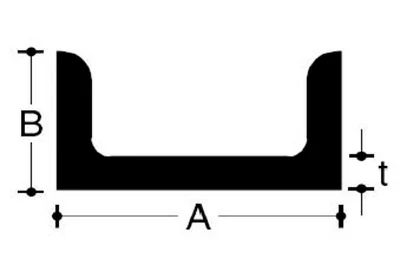

C channel

C-channels have a flatter profile and are suitable for mounting mirror frames and lighting equipment. They are widely used in industrial environments for low-profile applications.

-

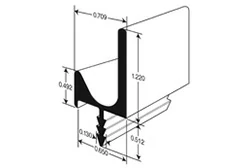

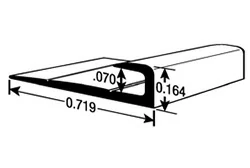

J-channel

The unique "J" shape of the J-Channel makes it ideal for secure fastening applications such as installing siding, roofing materials and supporting the edges of glass panels.

-

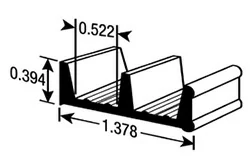

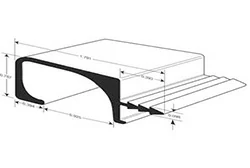

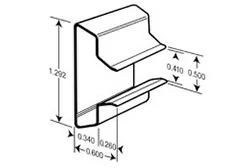

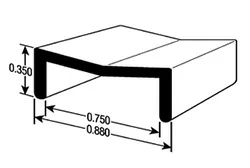

Hat channel

Hat channels have a large span support capability and are often used to support drywall, finishing materials, and pipes and wires in industrial settings.

-

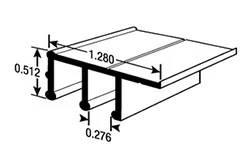

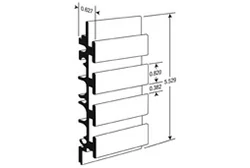

T-Slot channel

T-slot top groove design for applications such as manufacturing workstations, conveyor systems, etc. that require customization and flexibility.

-

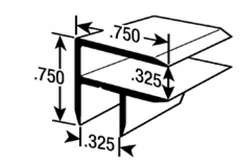

F-type aluminum channel

F-channels have an extended web and flange and are commonly used to support and secure devices in structures or mechanical equipment.

-

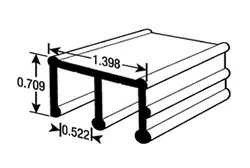

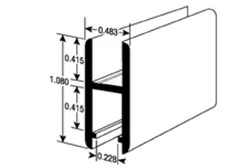

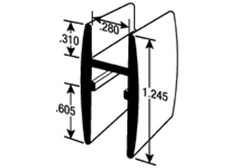

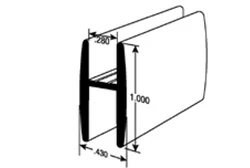

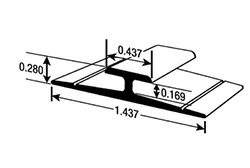

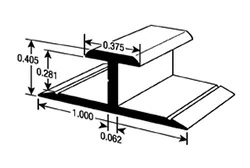

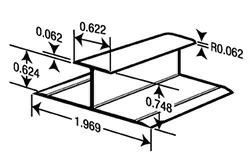

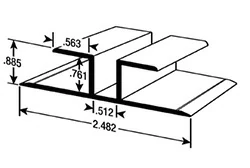

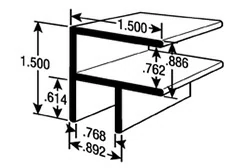

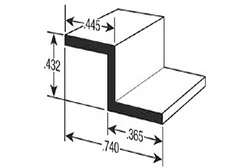

H-type aluminum channel

The stability and variety of finishes of the H-channel make it widely used in decorative and structural applications such as railings, door frames, ceiling system connections, etc.

-

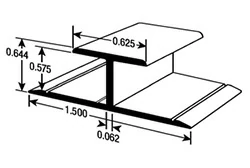

I-type aluminum

I-channel design is similar to an I-beam, designed to handle larger loads and is widely used for beam support in buildings and structures.

-

Z-shaped aluminum channel

The unique profile of the Z-channel is suitable for installation on metal roofs, wood roofs and panel receivers, preventing leaks and enhancing the seal of ridge caps and flashings.

-

Nut channel

An aluminum profile with internal grooves for receiving nuts and fasteners, widely used in frame and component assembly.

-

Door track

A door track system that guides and supports the smooth sliding movement of a door.

-

Other channel product customization

Chalco can also provide customized aluminum channel services, customized in various shapes and sizes according to drawings and requirements.

Chalco best-selling aluminum channel alloy series

Chalco provides aluminum alloy channel materials covering different grades from high strength to high corrosion resistance, suitable for different industrial and construction applications. According to your specific needs, we can recommend the most suitable aluminum alloy and tempering state to ensure the quality and performance of the product.

-

6061 structural aluminum channel

The magnesium content of 6061 alloy is about 1%, and the silicon content is about 0.6%, which enhances its corrosion resistance, stress resistance and cracking resistance. It has good formability and weldability, and is widely used in structural applications.

-

6063 architectural aluminum channel

Grade 6063 is known for its medium strength and is often used for extruded aluminum channels. It is capable of being extruded into very thin-walled, small-sized shapes. Its glossy finish makes 6063 a popular choice for architectural applications.

-

7075 aluminum channel

With extremely high strength, it is widely used in heavy-duty structural support in the aerospace and military industries.

-

2024 aluminum channel

Provides excellent fatigue resistance and is commonly used in structural aluminum channel applications in the aerospace industry.

-

5083 aluminum plate

Excellent corrosion resistance, particularly suitable for use in marine and chemical handling environments.

-

7050 aluminum channel

High strength and stress corrosion resistance, suitable for aluminum channel structures requiring high durability in the aerospace field.

-

5086 aluminum channel

With strong corrosion resistance and strength, it is suitable for aluminum channels that require load-bearing and durability in harsh environments.

-

5456 aluminum channel

5456 aluminum alloy is known for its excellent strength and corrosion resistance, and has high resistance to salt water corrosion.

-

6082 aluminum channel

High strength and good corrosion resistance, suitable for aluminum channels used in heavy industry and large equipment support.

-

6060 aluminum channel

Good processability and corrosion resistance, widely used in aluminum channels in light structure and construction fields.

-

6005 aluminum channel

Moderate strength and corrosion resistance, often used for support and framing structures in industrial applications.

Chalco aluminum channel four major application fields and selection guide

Aluminum channels for structural support

Aluminum channels provide strong, stable support for buildings, industrial equipment, and infrastructure, offering durability and corrosion resistance in harsh environments.

Contact us now

Application areas:

- Construction industry: used to support structures such as roofs, walls, floors and beams.

- Industrial equipment: Provides stable support for manufacturing equipment, heavy machinery, etc.

- Infrastructure: Used in bridges, road facilities and other places where durability and pressure resistance are required.

Buying Guide:

- Alloy selection: It is recommended to choose high-strength aluminum alloys such as 6061 and 7075. These aluminum alloys have the characteristics of high strength, corrosion resistance, and adaptability to high loads. We provide high-strength 6061 and 7075 aluminum alloy aluminum channels to ensure stability and durability under high loads, especially suitable for applications requiring high load support.

- Surface treatment: Anodizing can increase the corrosion resistance of aluminum tanks, making them suitable for outdoor or harsh environment applications. We provide anodizing surface treatment for aluminum tanks to enhance their corrosion resistance and ensure that they still perform well even when exposed to outdoor or harsh environments for a long time.

- Customized service: For load-bearing applications, it is very important to select the right size and thickness of aluminum channel. We provide customized sizes and shapes of aluminum channels to ensure a perfect match for your engineering needs and meet special load support requirements.

Aluminum channel for guide rails

Aluminum guide rail channels ensure precise, smooth operation in automation systems, offering excellent processability for accuracy and durability.

Contact us now

Application areas:

- Automated production lines: used to guide the movement of robotic arms, conveyor belts and automated equipment.

- Mechanical equipment: Used as guide rails in precision equipment to ensure equipment accuracy and stability.

- Warehousing systems: Rails are used in racking systems to help materials flow smoothly in warehouses.

Buying guide:

- Alloy selection: It is recommended to choose 6063 aluminum alloy, which has excellent processing performance and can ensure the accuracy of the guide rail. We provide 6063 aluminum alloy aluminum grooves to ensure the accuracy and stability of guide rail applications, suitable for automated production lines and precision equipment.

- Precision requirements: Choose aluminum channels with smooth surfaces and high precision to ensure smooth operation of the equipment. Our aluminum channels are precision machined to ensure smooth surfaces and high precision to meet the needs of the guide rail system.

- Surface treatment: Choose anodized aluminum troughs to increase wear resistance and be suitable for long-term use. We provide anodized surface treatment for aluminum troughs to enhance their wear resistance and corrosion resistance, ensuring the stability and durability of the guide rails in long-term use.

Aluminum channel for decorative edge strips

Decorative aluminum channels not only have beautiful appearance design, but also have good durability and practicality. They are widely used in interior decoration, building facades and display design. The bright surface and various surface treatment methods of aluminum channels can enhance the visual effect of the space.

Contact us now

Application areas:

- Interior design: used for interior decoration such as walls, ceilings, lamps, etc.

- Building facade: used for decoration and protection of the facade to enhance the appearance of the building.

- Display design: used in exhibition stands, display cabinets, display racks, etc. to enhance exhibition effects.

Buying guide:

- Alloy selection: It is recommended to choose 6063 aluminum alloy, which has good surface treatment performance and is suitable for various decorative purposes. We provide 6063 aluminum alloy aluminum channels, which can ensure decorativeness and practicality, and are suitable for various indoor and outdoor decoration applications.

- Surface treatment: Choose anodizing, painting or polishing to ensure that the aluminum trough has a beautiful and durable appearance. We provide a variety of surface treatment services, including anodizing, painting and polishing, to ensure that the aluminum trough has a bright and durable appearance and meets various decorative requirements.

- Design requirements: Choose the appropriate size and shape according to the decoration style to ensure that the aluminum channel is coordinated with the environment. We support customized size and shape of aluminum channels to meet the needs of different decoration designs and ensure that the aluminum channel is coordinated with the overall style.

Aluminum channel for glass installation

Aluminum channels for glass installation are used to fix and support glass sheets and are widely used in doors, windows, curtain walls and other glass structures. The corrosion resistance and good processability of aluminum channels make them an ideal choice for glass installation.

Contact us now

Application areas:

- Door and window installation: used to fix glass windows, glass doors, etc.

- Curtain wall system: used to support and fix glass curtain walls.

- Other glass structures: used to support glass partitions, display screens, etc.

Buying guide:

- Alloy selection: 6063 or 6061 aluminum alloy is recommended, these alloys have good corrosion resistance and weldability, suitable for glass installation applications. We provide 6063 and 6061 aluminum alloy aluminum channels to ensure the stability and durability of glass installation, suitable for various glass structures such as doors, windows, curtain walls, etc.

- Size and shape: Choose the right size of aluminum channel according to the thickness of the glass and the installation method. We provide customized size and shape of aluminum channels according to customer needs to ensure a perfect match with the glass.

- Surface treatment: Anodizing can increase the corrosion resistance of aluminum tanks, especially suitable for long-term exposure to outdoor or humid environments. We provide anodizing surface treatment for aluminum tanks to enhance their corrosion resistance and ensure stability in long-term use.

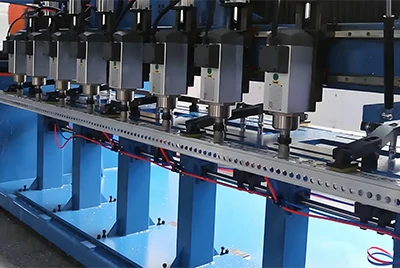

Chalco aluminum channel production capabilities - precision die extrusion

- Efficient aluminum extrusion technology: Chalco uses advanced aluminum extrusion technology to ensure that aluminum channel products achieve high precision and high quality during the production process. We are able to process a variety of aluminum alloys and meet the production needs of aluminum channels of various specifications.

- Precision aluminum extrusion equipment: We are equipped with high-precision aluminum extrusion machines that can stably produce various aluminum channel profiles under different working conditions. This equipment has high production efficiency and stability, and can ensure that the size and performance of each aluminum channel meet customer requirements.

- Precision billet heating system: Chalco uses an efficient billet heating system to precisely heat the billet before extrusion. This system ensures uniform heating of the aluminum material, improves forming quality, reduces defects, and ensures high quality and stability of aluminum channel products.

- Profile pulling and handling equipment: We use advanced profile pulling technology to ensure that the aluminum channel profile moves smoothly throughout the extrusion process, maintaining good shape and consistency. This equipment has adjustable pulling speeds to meet the production needs of different specifications of aluminum channels.

- Customized processing service: Chalco provides customized aluminum channel processing service. Customers only need to provide drawings, and we can produce special sizes, shapes and aluminum alloy materials according to their needs. By combining advanced CAD design and CNC processing technology, we ensure that each mold is accurately made, and complete customized processing quickly and efficiently to meet the requirements of different applications.

Chalco aluminum channel processing capabilities - overall project solutions

- High-precision cutting technology: Chalco is equipped with high-speed precision cutting equipment that can cut aluminum channels quickly and accurately. We use a programmable control system to adjust the cutting length and angle to ensure that the cutting accuracy of each aluminum channel meets the standard requirements.

- Reserved holes and drilling: Use automated punching equipment to accurately complete the hole processing of the aluminum slot to ensure the convenience of installation and use.

- Precision bending and forming: Using advanced CNC bending machines, Chalco is able to precisely bend and form aluminum channels according to design requirements, ensuring high consistency in structure and appearance.

- Welding and assembly services: Chalco provides welding and assembly services, which can firmly connect aluminum channels with other components to meet customers' customized assembly needs and ensure the stability and safety of the structure.

- Surface treatment: we provide surface treatment processes such as anodizing and spraying to increase the corrosion resistance and aesthetics of the aluminum tank to adapt to different environmental requirements.

FAQs on purchasing aluminum trough

What types of aluminum channels are there?

- Standard aluminum profile: suitable for industrial automation equipment and structural frames.

- T-type aluminum channel: commonly used for quick installation and disassembly.

- Aluminum alloy slot: reinforced, suitable for heavy loads.

- Slotted aluminum channel: The channel surface is slotted for easy installation of accessories.

What is the difference between U-shaped aluminum trough and C-shaped aluminum trough?

- U-shaped aluminum channel: The cross section is "U" shaped, suitable for bearing large lateral loads, and is often used in support and track systems.

- C-type aluminum channel: The cross section is "C" shaped, suitable for light loads or environments that require flexible adjustment, and is often used for wall installation, etc.

What is the difference between T-shaped aluminum channel and U-shaped aluminum channel?

- T-type aluminum channel: The cross section is "T" shaped, suitable for multi-directional connection, and is commonly used in frame structures.

- U-shaped aluminum channel: symmetrical on both sides, suitable for bearing strong lateral support, simple structure, often used in support systems.

What factors should be considered when purchasing aluminum channels?

- Specifications and Sizes: Choose the appropriate size, length and cross-sectional shape.

- Material: Commonly used aluminum alloy to ensure strength and corrosion resistance.

- Load requirements: Select the appropriate load capacity based on the usage scenario.

- Surface treatment: oxidation, spraying and other treatments improve durability and appearance.

- Connection method: bolt connection, clamping connection, etc.

How to determine the specifications of aluminum channels?

Select the aluminum channel specifications based on the use environment (temperature, humidity, etc.), load requirements, required size, and whether it is customized.

What are the price factors of aluminum trough?

- Material and craftsmanship: High-quality aluminum and complex craftsmanship will increase costs.

- Size and Length: Large sizes and special lengths of aluminum channels are more expensive.

- Brand and Supplier: Aluminum channels from well-known brands and high-quality suppliers are more expensive, but have better quality and after-sales service.

How to install aluminum channel?

- Secure with bolts and nuts.

- The connection is made using special connection accessories.

- Adjust the length and direction as needed for easy splicing.

What are the precautions for the maintenance of aluminum troughs?

- Regular inspection: Check whether the aluminum slot is deformed, loose or worn.

- Cleaning: Keep the surface of the aluminum tank clean to avoid accumulation of contaminants.

- Lubrication: Lubricate moving parts regularly to ensure smooth operation.

What is the difference between structural aluminum channels and architectural aluminum channels?

- Structural aluminum channel: suitable for machinery, automation, and industrial equipment, emphasizing strength and load-bearing capacity.

- Architectural aluminum channel: used in the construction industry, such as curtain walls, doors and windows, etc., focusing on appearance design and corrosion resistance.

What is the difference between aluminum channels and aluminum profiles?

- Aluminum Channel: A track or groove of specific shape and function, mainly used for support, fixing or as the basis of an assembly system.

- Aluminum Profiles: Aluminum profiles with fixed cross-sections and continuous lengths, widely used in customized structural frames.

What is the difference between closed aluminum trough and open aluminum trough?

- Closed aluminum trough: closed on two sides or all around, suitable for sealing or protective environments, such as wire and pipe protection.

- Open aluminum trough: no closed shell, suitable for exposed occasions, easy to dissipate heat, install components or maintain.

What is the difference between angle aluminum channel and right angle aluminum channel?

- Angle aluminum channel: It is "L" shaped and is often used for corner structure connection and is suitable for building angle frames.

- Right-angle aluminum channel: has a 90-degree right angle, suitable for right-angle connection or straight frame structure.

What is the difference between the different surface treatments of aluminum channels?

- Alumina tank: Improves corrosion resistance and wear resistance through oxidation treatment, suitable for outdoor or high humidity environment.

- Spray-coated aluminum tank: The appearance and corrosion resistance are enhanced by spraying anti-corrosion coating, which is suitable for occasions with high requirements on appearance.

- Untreated aluminum tank: without surface treatment, suitable for clean or non-corrosive environment.

Chalco standard size aluminum channel size reference table

| 6061 structural aluminum channel size and weight reference table (25 foot lengths) |

|

||||

| A (Inch) | B (Inch) | t (Inch) | Weight per foot (estimated) | Weight per piece (estimated) | |

| 3.000 | 1.410 | 0.170 | 1.434 | 35.850 | |

| 3.000 | 1.498 | 0.258 | 1.775 | 44.375 | |

| 3.000 | 1.596 | 0.356 | 2.117 | 52.925 | |

| 4.000 | 1.580 | 0.180 | 1.895 | 47.375 | |

| 4.000 | 1.647 | 0.247 | 2.218 | 55.450 | |

| 4.000 | 1.720 | 0.320 | 2.552 | 63.800 | |

| 4.000 | 2.000 | 0.250 | 2.250 | 56.250 | |

| 5.000 | 1.750 | 0.190 | 2.382 | 59.550 | |

| 5.000 | 1.885 | 0.325 | 3.172 | 79.300 | |

| 5.000 | 2.032 | 0.472 | 4.055 | 101.375 | |

| 6.000 | 1.920 | 0.200 | 2.894 | 72.350 | |

| 6.000 | 1.945 | 0.225 | 3.078 | 76.950 | |

| 6.000 | 2.034 | 0.314 | 3.622 | 90.550 | |

| 6.000 | 2.157 | 0.437 | 4.597 | 114.925 | |

| 7.000 | 2.110 | 0.230 | 3.542 | 88.250 | |

| 7.000 | 2.194 | 0.314 | 4.084 | 102.100 | |

| 7.000 | 2.299 | 0.419 | 5.100 | 127.500 | |

| 8.000 | 2.290 | 0.250 | 4.344 | 108.600 | |

| 8.000 | 2.343 | 0.303 | 4.848 | 121.200 | |

| 8.000 | 2.435 | 0.395 | 5.748 | 143.700 | |

| 8.000 | 2.527 | 0.487 | 6.628 | 165.700 | |

| 10.000 | 2.600 | 0.240 | 5.430 | 135.750 | |

| 10.000 | 2.886 | 0.526 | 8.644 | 216.100 | |

| 12.000 | 2.960 | 0.300 | 7.564 | 189.100 | |

| 12.000 | 3.047 | 0.387 | 8.640 | 216.000 | |

| 12.000 | 3.170 | 0.510 | 10.370 | 259.250 | |

| 15.000 | 3.400 | 0.400 | 11.710 | 292.750 | |

| 6063 sharp corner aluminum channel size and weight reference table (16 foot lengths) |

|

||||

| A (Inch) | B (Inch) | t (Inch) | Weight per foot (estimated) | Weight per piece (estimated) | |

| 0.375 | 0.375 | 0.109 | 0.120 | 1.920 | |

| 0.500 | 0.375 | 0.125 | 0.150 | 2.400 | |

| 0.500 | 0.500 | 0.062 | 0.103 | 1.648 | |

| 0.500 | 0.500 | 0.094 | 0.148 | 2.368 | |

| 0.500 | 0.500 | 0.125 | 0.187 | 2.992 | |

| 0.500 | 0.750 | 0.125 | 0.265 | 4.240 | |

| 0.625 | 0.625 | 0.125 | 0.243 | 3.888 | |

| 0.750 | 0.375 | 0.125 | 0.187 | 2.992 | |

| 0.750 | 0.500 | 0.125 | 0.224 | 3.584 | |

| 0.750 | 0.750 | 0.125 | 0.300 | 4.800 | |

| 0.750 | 1.500 | 0.125 | 0.527 | 8.432 | |

| 1.000 | 0.500 | 0.125 | 0.262 | 4.192 | |

| 1.000 | 0.750 | 0.125 | 0.337 | 5.392 | |

| 1.000 | 1.000 | 0.062 | 0.214 | 3.424 | |

| 1.000 | 1.000 | 0.125 | 0.413 | 6.608 | |

| 1.000 | 1.500 | 0.125 | 0.564 | 9.024 | |

| 1.250 | 0.500 | 0.125 | 0.300 | 4.800 | |

| 1.250 | 0.750 | 0.125 | 0.376 | 6.016 | |

| 1.250 | 1.250 | 0.125 | 0.526 | 8.416 | |

| 1.500 | 0.500 | 0.125 | 0.336 | 5.376 | |

| 1.500 | 0.750 | 0.125 | 0.413 | 6.608 | |

| 1.500 | 1.000 | 0.125 | 0.487 | 7.792 | |

| 1.500 | 1.500 | 0.125 | 0.637 | 10.192 | |

| 1.500 | 1.500 | 0.250 | 1.270 | 20.320 | |

| 1.750 | 0.500 | 0.125 | 0.374 | 5.984 | |

| 1.750 | 0.750 | 0.125 | 0.450 | 7.200 | |

| 1.750 | 1.000 | 0.125 | 0.526 | 8.416 | |

| 1.750 | 1.750 | 0.125 | 0.751 | 12.016 | |

| 2.000 | 0.500 | 0.125 | 0.413 | 6.608 | |

| 2.000 | 1.000 | 0.125 | 0.563 | 9.008 | |

| 2.000 | 2.000 | 0.125 | 0.863 | 13.808 | |

| 2.000 | 2.000 | 0.250 | 1.126 | 26.400 | |

| 2.250 | 0.875 | 0.125 | 0.563 | 9.008 | |

| 2.500 | 1.000 | 0.125 | 0.637 | 10.192 | |

| 2.500 | 1.500 | 0.125 | 0.787 | 12.592 | |

| 2.500 | 2.000 | 0.125 | 0.937 | 14.992 | |

| 2.500 | 2.500 | 0.125 | 1.089 | 17.424 | |

| 3.000 | 0.500 | 0.125 | 0.563 | 9.008 | |

| 3.000 | 1.000 | 0.125 | 0.713 | 11.408 | |

| 3.000 | 1.500 | 0.188 | 1.266 | 20.256 | |

| 3.000 | 2.000 | 0.125 | 1.013 | 16.208 | |

| 3.000 | 3.000 | 0.125 | 1.313 | 21.008 | |

| 4.000 | 1.000 | 0.125 | 0.863 | 13.808 | |

| 5.000 | 2.000 | 0.188 | 1.950 | 31.120 | |