Aluminum clad stainless steel combines the best of both worlds. Excellent thermal and electrical performance at a lower cost—far beyond what single metals can offer.

Our ASTM-certified aluminum clad stainless steel materials deliver a perfect balance of performance and value.

Specifications of aluminum clad stainless steel

Standards: MIL-J-24445A, GBT 8546-2007, ASTM A263, ASTM A264, ASTM A265, SA578-Level B, ASTM B209, ASTM A240

Certifications: FDA certification, LFGB certification, ISO 9001, CE certification, classification society certification

Popular aluminum clad stainless steel products

We offer free samples so you can test the quality before placing an order. This ensures our aluminum clad stainless steel meets your exact needs. Quick Quote

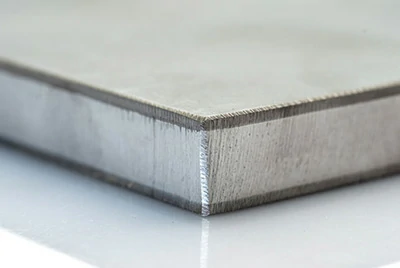

Aluminum clad stainless steel explosion bonded plate

Aluminum clad stainless steel explosion bonded plates support large-size and high-volume production with ease. They are especially ideal for composite plates with varying thickness ratios and wide surface areas.

Contact us now

Dimensions of aluminum clad stainless steel explosion bonded plates:

- Base metal (substrate): AISI types 405, 410, 410S, 429, 430, 304, 309, 316, and 321

- Cladding metal: 1050A, 1060, 1070

- Standard: MIL-J-24445A

- Cladding thickness: ≤100 mm

- Base thickness: ≤500 mm

- Length: ≤1200 mm

- Width: ≤4200 mm

Shear strength of aluminum clad stainless steel explosion bonded plates:

| Cladding plate | Aluminum | Aluminum |

| Base plate | Stainless steel | Stainless steel |

| Aluminum thickness (mm) | 3 | 12 |

| Stainless steel thickness (mm) | 18 | 18 |

| H₀ (mm) | 4 | 8.5 |

| Wg (g·cm⁻²) | 1.0 | 1.7 |

| Sample/pieces | 6 | 8 |

| σₜ (MPa) Maximum | 93.4 | 75.3 |

| σₜ (MPa) Minimum | 68.9 | 33.0 |

| σₜ (MPa) Average | 79.4 | 51.0 |

Peel strength of aluminum clad stainless steel explosion bonded plates:

| Cladding plate | Aluminum |

| Base plate | Stainless steel |

| Aluminum thickness (mm) | 12 |

| Stainless steel thickness (mm) | 18 |

| H₀ (mm) | 8.5 |

| Wg (g·cm⁻²) | 1.7 |

| Sample/pieces | 16 |

| σₜ (MPa) Maximum | 89 |

| σₜ (MPa) Minimum | 26 |

| σₜ (MPa) Average | 57 |

Advantages of aluminum clad stainless steel explosion bonded plates:

These plates combine aluminum's light weight and thermal conductivity with stainless steel's strength and corrosion resistance. They also offer excellent deep-drawing performance and cost efficiency.

Applications of aluminum clad stainless steel explosion bonded plates:

Ideal for high-end cookware, automotive components, medical devices, pressure vessels, and IC lead frames.

Notably, explosion bonding is used in low-temperature media to manufacture missile casings and aircraft auxiliary power units.

automotive component

medical device

pressure vessel

Aluminum clad stainless steel rolled plate

Our rolling composite process metallurgically bonds aluminum and stainless steel to create lightweight, high-strength, and corrosion-resistant aluminum clad stainless steel rolled plates.

Contact us now

This method uses a hot rolling mill to press stainless steel and aluminum into a layered structure, reducing thickness while achieving a strong metallurgical bond. It ensures both strength and long-term stability.

Compared to explosion bonding, roll bonding offers more consistent mechanical properties and greater precision in dimensional control.

ASTM standards:

Our composite plates meet and exceed the highest industry standards:

ASME BPVC Section II and ASTM A263, A264, and A265 for pressure vessel manufacturing.

Standard sizes of aluminum clad stainless steel rolled plates:

- Aluminum: 1050A, 1060, 1070, 1100, 3003

- Stainless steel: 304L, 316L, A-36, 301

- Width: up to 120 inches

- Length: up to 480 inches

- Thickness: from 3/16 inch to 1 inch

- Cladding ratio: 5% to 40% of total material thickness

| Thickness (in) | Width(in) | Length(in) | Sq Feet | Thickness (mm) | Width(mm) | Length(mm) | Sq Meter |

| 0.25 | 98 | 699 | 478 | 6 | 2500 | 17750 | 44 |

| 0.375 | 98 | 699 | 478 | 10 | 2500 | 17750 | 44 |

| 0.5 | 98 | 640 | 437 | 13 | 2500 | 16250 | 51 |

| 0.625 | 98 | 433 | 296 | 16 | 2500 | 11000 | 28 |

| 0.75 | 98 | 378 | 258 | 19 | 2500 | 9600 | 24 |

| 0.875 | 98 | 320 | 219 | 22 | 2500 | 8125 | 20 |

| 1 | 98 | 260 | 178 | 25 | 2500 | 6600 | 17 |

| 1.25 | 98 | 197 | 135 | 32 | 2500 | 5000 | 13 |

We also offer custom processing services, including precise control of size and flatness, cutting, bending, drilling, punching, machining, welding, and shaping into circles or custom forms to meet all your application needs. Quick Quote

Advantages of aluminum clad stainless steel rolled plates

- High mechanical strength

- Excellent corrosion resistance

- Superior heat resistance

- Outstanding thermal conductivity

- Reduced maintenance and extended service life

- Durable and cost-effective over the long term

Applications of aluminum clad stainless steel rolled plates

Aluminum clad stainless steel is widely used in chemical and petrochemical processing, defense, pulp and paper, and food processing industries.

Typical applications include pressure vessels, stock pots, boilers, griddles, steam containers, cryogenic transition plates, and specialty cutting tools.

pressure vessel

stock pot

boiler

Rigorous testing of aluminum clad stainless steel rolled plates:

All products meet SA264 shear and bend tests and SA578-Level B ultrasonic testing. HIC resistance, simulated PWHT, and Charpy impact tests are also available to meet specific project requirements.

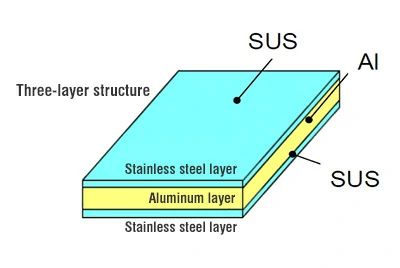

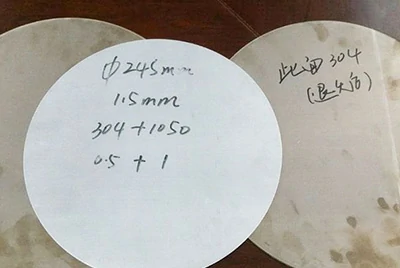

Aluminum clad stainless steel cookware

Our aluminum clad stainless steel cookware three-layer composite discs offer rapid and uniform heat conduction without any chemical reaction, ensuring even heating and improving cooking efficiency and user experience.

Aluminum clad stainless steel cookware discs are widely used across various industries due to their high strength, corrosion resistance, excellent thermal conductivity, and the fact that no additional coatings are required.

Contact us now

Custom options for aluminum clad stainless steel cookware disc:

- Material: S/S 304 + AL + S/S 430

- Stainless steel: 304, 430

- Aluminum: 1050A, 1060, 1070, 1100

- Thickness: 0.2-8.0 mm or custom

- Diameter: 200-1280 mm or custom

- Standards: FDA, LFGB, and ISO 9001

- Product form: Semi-finished discs (excluding lids and handles)

Applications of aluminum clad stainless steel cookware discs:

Vintage farberware aluminum clad stainless steel

Wear ever aluminum plus stainless inner clad

Aluminum clad stainless steel cookware

- High strength, durable, and stable

- Excellent biocompatibility, safe and non-toxic

- Outstanding thermal conductivity, even heating

- Lightweight design, easy to use

- Superior antibacterial properties for health protection

- Corrosion-resistant, acid and alkali resistant

- Suitable for gas, induction, electric stoves, and other heating methods

Deep processing of aluminum clad stainless steel cookware discs

Our aluminum clad stainless steel cookware discs can handle deep drawing, stamping, and stretching without delaminating or cracking.

We also offer specialized deep processing services, including custom stamping, precision cutting, and surface treatment to ensure the products meet your production requirements. Quick Quote

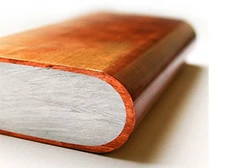

Aluminum stainless steel plate marine transition joints

Compared to traditional rivets or bolts, using aluminum steel transition joints allows direct welding of aluminum alloys to steel structures without the need for drilling or other operations.

Contact us now

Custom options for aluminum stainless steel plate marine transition joints:

- Base plate standard size: 1300 x 3800 mm, maximum size up to 4x12 meters

- Thickness: 1 mm to 100 mm

- Transition joint composition: Steel, pure aluminum, and seawater-resistant aluminum

- Stainless steel: 316L

- Aluminum: 1050, 1060, 1100

- Certifications: Lloyd's 3.2, MIL-J-24445A

- Standards: CB 1343, CB 20091, YST 850-2012

For more information on the sizes of aluminum stainless steel plate marine transition joints, please click [aluminum steel joint]to check the detailed information.

Performance of aluminum stainless steel plate marine transition joints:

- Interface bonding rate: 100%

- Tensile strength: >75 MPa

- Shear strength: >55 MPa

- Maximum operating temperature: 315°C for 30 minutes

Services for aluminum stainless steel plate marine transition joints:

- Surface cleaning and flattening

- Precise cutting of plates into discs, rectangles, rings, or custom shapes as needed

- Professional rust removal after sawing

- Deep processing services, including deep drawing, stamping, stretching, drilling, and surface sandblasting

With our advanced equipment, excellent craftsmanship, and comprehensive customer service system, we always provide high-quality and reliable aluminum steel transition joint solutions to our clients. Quick Quote

Aluminum stainless steel pipe transition joints

Our aluminum stainless steel transition joints can be customized according to customer needs, offering various shapes, sizes, and material combinations to precisely match your specific application requirements.

An aluminum stainless steel pipe transition joint is a composite material joint designed for reliably connecting dissimilar metal pipelines, such as aluminum alloys and stainless steel, using advanced explosion welding or roll bonding technology.

Contact us now

An aluminum stainless steel pipe transition joint is a composite material joint designed for reliably connecting dissimilar metal pipelines, such as aluminum alloys and stainless steel, using advanced explosion welding or roll bonding technology.

Custom options for aluminum stainless steel pipe transition joints:

- Shape specifications: Round, rectangular, ring-shaped, etc., with flexible sizing options

- Alloy selection: Aluminum alloys (e.g., 5083, 6061), stainless steel (304, 304L, 316, 316L), and other alloy combinations

- Deep processing services: Precision cutting, drilling, surface treatment, special welding, and other value-added services

Advantages of aluminum stainless steel pipe transition joints:

- High-strength connection, durable and reliable

- Lightweight design

- Excellent corrosion resistance

- Cost-saving

- Safe and leak-proof

Applications of aluminum stainless steel pipe transition joints:

Widely used in industries such as petroleum and natural gas, refrigeration, chemicals, air separation, nuclear energy, semiconductor, heat exchangers, and cryogenic engineering.

For example, they are used to connect aluminum hulls to stainless steel propeller shafts, mixing tanks, pipelines, and heat exchangers.

Natural gas

Radiator

Ship

Customer application case of aluminum stainless steel pipe transition joints:

In the aerospace industry, cryogenic containers (such as liquid hydrogen and liquid oxygen tanks) often require connections between different materials to ensure good low-temperature performance and lightweight design. However, when welding two materials is challenging and high-strength connections are necessary, special transition joints must be used.

The aluminum stainless steel pipe transition joints provided by Chalco (Henan Zhong Aluminum) have successfully achieved reliable connections between 304L stainless steel and aluminum-copper-magnesium alloys using advanced explosion welding technology. Quick Quote

Aluminum clad stainless steel strip

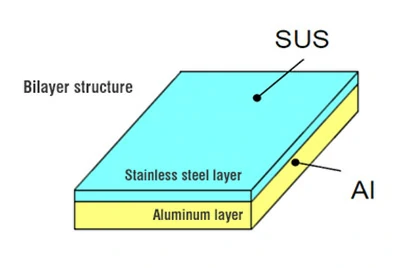

The aluminum clad stainless steel strip uses aluminum sheets as the primary material, with stainless steel coils as the secondary material.

It can be single-sided or double-sided clad based on customer requirements, and undergoes deep processing such as cold bending, stretching, and stamping.

The aluminum clad stainless steel strip is a metal composite material created through an advanced roll bonding process that firmly bonds aluminum and steel together. It combines the light weight and thermal conductivity of aluminum with the high strength and corrosion resistance of steel.

Contact us now

Custom options for aluminum clad stainless steel strip:

- Material combination: Aluminum (pure aluminum, aluminum alloys 1050, 1060, 3003, 5052) + Stainless steel 304, 316

- Thickness: 0.1 mm - 10 mm

- Width: ≤1500 mm

- Single coil weight: up to 5 tons

- Thermal industries (used for manufacturing air-cooled equipment, power generation cooling devices, automotive engines, household appliances, etc.)

- Decorative industries (e.g., escalators, elevator cabin interiors, etc.)

Machinery

Air conditioning

Automobile

Our products are strictly produced in compliance with ASTM and ISO international standards.

We also provide cutting, stretching test reports, and 100% ultrasonic flaw detection to ensure the bonding strength and product quality are stable and reliable.

Aluminum clad stainless steel foil

The aluminum clad stainless steel foil is made using advanced roll bonding technology, which firmly bonds aluminum foil with stainless steel foil.

Contact us now

The aluminum clad stainless steel foil is made using advanced roll bonding technology, which firmly bonds aluminum foil with stainless steel foil.

Custom options for aluminum clad stainless steel foil:

- Material combination: Aluminum foil (1060, 1100, 1235, etc.) + Stainless steel foil (304, 304L, 316, 430)

- Thickness range: 0.01 mm - 0.5 mm

- Width range: 10 mm - 1200 mm

- Surface treatment: Polishing, mirror finish, brushing, or special coating treatment

- Deep processing services: Slitting, precision cutting, stamping, surface coating, etc.

Friction stir welded aluminum clad stainless steel plate

The friction stir welded aluminum clad stainless steel plate uses solid-state welding technology, where high-temperature friction forms a metallurgical bond between aluminum and stainless steel without melting or welding defects.

Contact us now

Custom options for friction stir welded aluminum clad stainless steel plate:

- Aluminum alloys: 1050, 1100, 3003, 5052, 5083, 6061, 7075

- Stainless steel: 304, 304L, 316, 316L, 321, 430

- Thickness: Aluminum layer 0.5 mm - 50 mm, Stainless steel layer 0.5 mm - 50 mm

- Width: Up to 2000 mm

- Length: Up to 6000 mm

Advantages of friction stir welded aluminum clad stainless steel plate:

- No melting during welding, resulting in high bonding strength

- Strong corrosion resistance, suitable for high humidity or chemical environments

- Small heat-affected zone, stable structure

- Can be used to produce large, high-strength composite plates

Strict quality control and multidimensional testing

We place great importance on product quality assurance and strictly follow a range of professional testing methods, including:

- Mechanical performance testing: Shear, peel, tensile, tear-shear, torsion, fatigue, and impact tests to ensure material stability and reliability.

- Bonding quality testing: Separation tests and microstructural metallographic analysis to ensure a strong and defect-free interface bonding.

- Durability testing: Stress distribution tests, thermal cycling tests, and chemical corrosion tests to ensure long-term stable performance in various environments.

- Surface quality testing: Strict visual inspection to ensure no defects and compliance with customer requirements.

- Non-destructive testing (NDT): 100% ultrasonic testing (UT) to ensure flawless internal product quality.

Through a comprehensive and rigorous inspection process, we provide customers with stable, high-performance composite materials that meet your stringent usage standards. Quick Quote

Our advantages: Precise response to customer needs, ensuring flexible and reliable supply

- Regardless of order size, we respond quickly and deliver fast, reducing your procurement cycle.

- We have a selected inventory of stock plates prepared for specific needs, supporting small orders and urgent requirements, ensuring timely supply.

- We offer small batch or custom specification stock plates to meet your personalized and special demands.

- Our mature and stable processes ensure strong bonding and complete metallurgical structure, making the quality highly reliable.

- Our knowledgeable technical team provides expert material selection advice and custom solutions, helping you achieve project goals quickly.

Explosion welding process

- The surface of the cladding and base materials is finely treated to ensure a clean interface.

- Prepare explosives, charge frame, gap material, and protective layer.

- Accurately install the base plate, cladding, and explosive structure on a sand foundation.

- Select the appropriate detonation method to implement the welding process.

- Conduct visual inspection, ultrasonic non-destructive testing, and metallographic analysis after welding to ensure bonding quality.

- Perform deep processing such as cutting, turning, and heat treatment as required, completing the finished product delivery.

- The explosion welding process ensures a strong, high-strength, and corrosion-resistant aluminum-stainless steel interface, meeting customers' high-standard usage requirements.

Reasons for wave formation in the explosion welding bonding zone

The bonding zone of the explosion welding process forms a unique wavy interface due to the high-speed collision generated by the explosion. This causes the two metals to interlock in a special wavy pattern, creating surface waves, interface waves, and bottom waves.

This wave structure offers the following advantages:

- Increased bonding strength: The wavy interface increases the actual contact area between the metals, effectively improving the bonding strength and stability of the materials.

- Reduced material deformation: The presence of waves effectively absorbs the shock and thermal stress generated during welding, reducing overall material deformation and ensuring product quality.

Aluminum Clad Stainless Steel Related Products

Aluminum Clad Copper

Clad Aluminium

Titanium Aluminum Clad Material

Aluminum Clad Steel

Aluminum-Titanium-Steel Transition Joints

Titanium Clad Steel

Frequently Asked Questions about Aluminum Clad Stainless Steel

What is the bonding strength of aluminum clad stainless steel composite plates?

Our composite plates undergo rigorous testing, including shear and tensile tests, to ensure high metallurgical bonding strength and stable performance.

Can different alloy grades and specifications be customized according to requirements?

We can flexibly customize different aluminum alloys (such as 1050, 5052, 6061) and stainless steel (304, 316L) combinations and dimensions based on customer needs.

Can the composite plates meet the requirements for deep drawing, stamping, bending, and other processes?

The product has excellent processing performance, suitable for deep drawing, stamping, welding, and bending without delamination or cracking.

What is the delivery cycle and minimum order quantity for your products?

We offer flexible low minimum order quantities and fast delivery services. For special needs, we can provide stock plates to ensure flexible and reliable supply, meeting your production schedule.

Are the products internationally certified?

Our products meet ASTM and ISO standards, and we provide relevant test reports along with ISO 9001, FDA, and LFGB certifications to meet the stringent requirements of international markets.