Chalco aluminum extruded rod product introduction

Alloys: 6061, 6063, 6082, 2024, 2014, 3003, 7075, 7050, 7055, 5052, 5083, 1100[Purchase by alloy]

Patented product: large-size extruded rods, with a diameter of more than 500mm [View details]

Hot-selling products: [Standard shape extruded bar] [Complex cross-section extruded bar] [Customized aluminum bar]

Size range: from 6mm to more than 500mm; length can be customized according to requirements [Size reference table]

Specification: ISO 6361, ASTM B221, EN 755, GB/T 5237, JIS H 4000, GB/T 3190, DIN 1725

Surface: mill finish; Polished, painted, power coated, anodized, galvanized

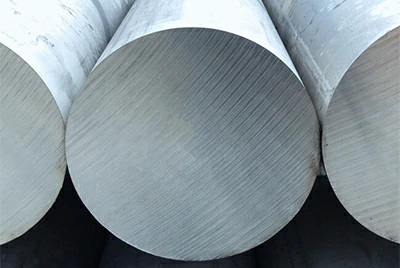

Chalco large diameter extruded aluminum bars —patented hot- selling products

Large diameter extruded aluminum bars, with diameters over 500mm, are designed for high strength and load requirements, widely used in aerospace, marine, transportation, and machinery industries, offering excellent mechanical properties and stability.

Contact us now

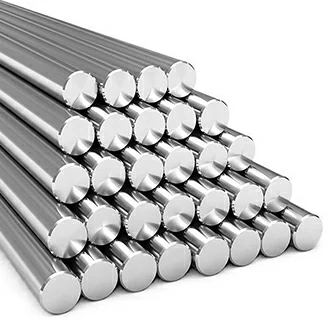

Chalco standard extruded aluminum bars/solid extruded aluminum profiles—abundant stock

-

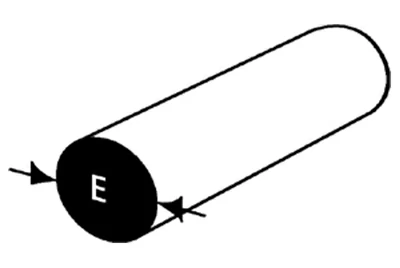

Round extruded bar

The maximum extruded round bar diameter is 500mm; the round extruded section is used for shafts and mechanical parts.

-

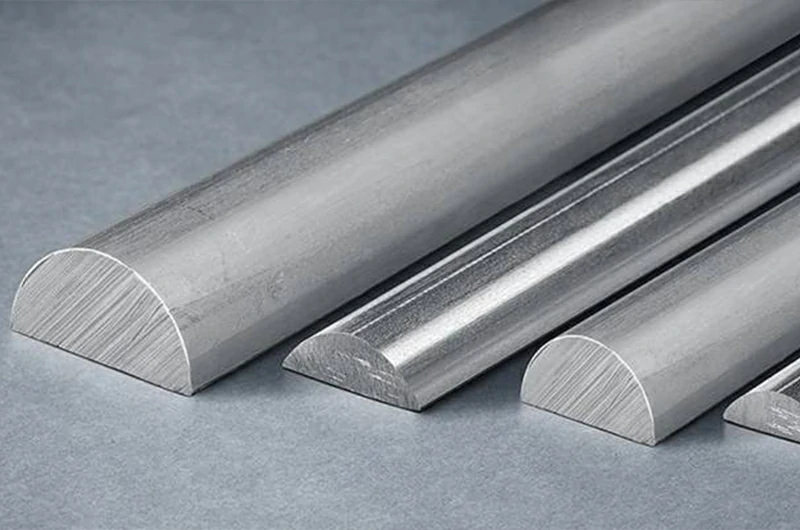

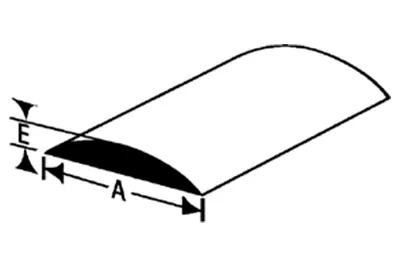

Extruded half round bar

Semi-circular cross section, suitable for decorative and edging applications.

-

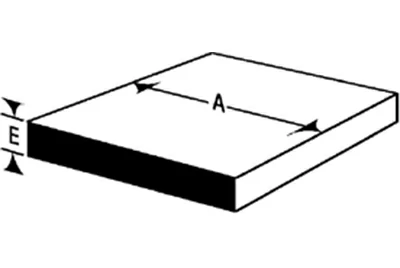

Extruded flat bars/rectangular bars

Manufacturing width from 5 mm to 120 mm; oval, rectangular or rounded rectangular cross-section.

-

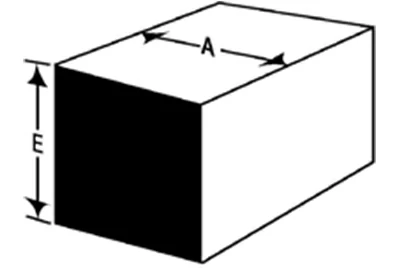

Square extruded bar

Sizes are typically 4 to 50 mm, with custom tolerances available in small and micro sizes; for framing and structure.

-

Extruded triangle bar

Triangular extruded cross-section, used for scenarios with specific support structures or mechanical requirements.

-

Extruded hexagonal bar

Hexagonal cross-section, commonly used in fastener manufacturing and high-precision mechanical parts.

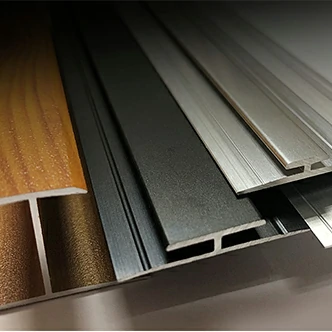

Complex cross-section extruded aluminum bars—saving mold costs

Chalco offers a wide range of complex cross-section extruded bar shapes, including T Bar, L Bar, Z Bar, U Bar, etc. We have a full range of molds to meet the needs of different projects, and most products are exempt from mold opening fees.

Contact us now

-

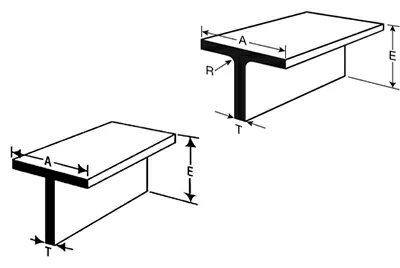

Extruded T bar

T-shaped extruded aluminum bars suitable for frames and supporting structures.

-

Extruded H bar

H-shaped extruded aluminum bars are widely used in construction and mechanical equipment.

-

Extruded L bar

L-shaped extruded aluminum rods for corner support and connection.

-

Extruded Z bar

Z-shaped extruded aluminum rods are suitable for special connection and decorative purposes.

-

Extruded U bar

U-shaped extruded aluminum bars for pipe supports and frames.

-

Extruded J bar

J-shaped extruded aluminum rod, suitable for edge protection and decoration.

-

Extruded F bar

F-type extruded aluminum rods for versatile connection and support.

-

Extruded Y bar

Y-shaped extruded aluminum rods are used for special support and frame structures.

Explore more extruded aluminum bars —meet all customization needs

T-slotted extrusion aluminum bar

T-slot extruded aluminum bars are used in industrial frames, equipment brackets, and assembly lines for their flexible installation and high precision, enabling modular assembly and various connections.

Features: Modular design, easy to assemble, suitable for a variety of applications.

Extruded conductive aluminum rod

Conductive aluminum bars offer excellent conductivity and strength, used in power transmission, busbars, electrical equipment, and energy engineering. High purity ensures efficient current transmission and light weight.

Features: High conductivity, lightweight, suitable for efficient power transmission.

High strength extruded aluminum rod

High-strength extruded aluminum bars, made from aviation or military-grade alloys like 7075 and 7050, are ideal for aerospace, automotive chassis, and mechanical parts.

Features: high strength, good fatigue resistance, suitable for high load scenarios.

High precision extruded aluminum bars

High-precision extruded aluminum bars, made with strict dimensional control, are ideal for mechanical equipment, instruments, and mold manufacturing.

Features: precise size, smooth surface, suitable for precision machining.

Grinding extruded rods

Ground extruded aluminum bars are surface-ground to create a smooth, flawless surface, and are widely used in decorative parts, sliding guides, and high-precision equipment.

Features: smooth surface, wear-resistant, suitable for decoration and high-precision requirements.

Anodized extruded rods

Anodized extruded aluminum rods have a corrosion-resistant oxide coating, making them ideal for construction, home, and industrial equipment.

Features: strong corrosion resistance, beautiful surface, suitable for a variety of environments.

High gloss extruded aluminum rod

High-brightness extruded aluminum rods are mirror-polished, offering high gloss and decorative appeal, ideal for home decoration, electronics, and premium displays.

Features: high gloss, strong decorative effect, suitable for high-end applications.

More custom aluminum bars in different shapes or surfaces

We offer custom-shaped aluminum bars and various surface treatments, including coating, sandblasting, brushing, and coloring, to meet design and functional needs.

Features: diversified shapes, flexible surface treatment, meeting personalized needs.

Chalco extrusion rod hot selling alloys and properties

When purchasing Chalco extruded tubes, you can choose the most suitable aluminum alloy material according to different alloy requirements. We offer a variety of aluminum alloy extruded tubes, including 6061, 6063, 5052, 3003, 7075 and other common alloy series to meet the needs of different industrial applications.

Whether it is high strength 7075 alloy for aerospace and military applications, or 5052 alloy with good corrosion resistance for marine environments or transportation vehicles, Chalco can provide you with high quality aluminum tube solutions. We provide customized services to ensure that each project can obtain the best alloy selection and tube specifications to meet your specific needs.Quick Quote

Chalco extrusion products basic alloy

Typical alloys: 6063, 6061, 3003.

Features: Low price, suitable for general industrial use and construction fields.

Advantages: good processing performance, high cost performance, suitable for large-volume demand.

Application scenarios: building profiles, decorative materials, and general mechanical parts.

- 6063 T5 T6 Extruded Aluminum Rod

- 6061 T6 T651 T6511 extruded aluminum rod

- 3003 H14 H18 Extruded Aluminum Bar

Chalco extruded aluminum bar medium performance alloy

Features: moderate price, taking into account both performance and cost, suitable for fields with certain requirements on mechanical properties.

Typical alloys: 5083, 6082, 5052 , 5754, 6060

Advantages: high strength, good corrosion resistance, and can meet a variety of processing needs.

Application scenarios: automotive parts, transportation equipment, and mechanical structural parts.

- 5083 H111 H116 Extruded Aluminum Bar

- 5052 H32 H34 Extruded Aluminum Bar

- 5754 H22 H24 Extruded Aluminum Bar

- 6060 T5 T56 Extruded Aluminum Bar

- 6082 T6 T651 Extruded Aluminum Bar

Chalco extruded aluminum bar rod high performance alloy

Features: The price is relatively high, mainly used in high-end manufacturing fields to meet strict performance requirements.

Typical alloys: 7075, 7050, 2024, 2014, 2219

Advantages: high strength, excellent fatigue performance and corrosion resistance, suitable for applications with high precision and high reliability requirements

Application scenarios: aerospace, national defense and military industry, sports equipment.

- 7075 T6 T73 T651 T7351 Extruded Aluminum Bar

- 7050 T6 T7451 Extruded Aluminum Bar

- 7475 T6 T7 T73 Extruded Aluminum Rod

- 2024 T3 T4 T6 Extruded Aluminum Rod

- 2014 T6 T651 Extruded Aluminum Bar

- 2219 T6 T73 Extruded Aluminum Bar

Chalco extruded aluminum bar special alloy research and development capabilities

We have a professional R&D team that can provide alloy customization services according to the specific needs of customers. Whether it is alloy composition, extrusion state or other special performance requirements, we can adjust and optimize to ensure that aluminum bar products perfectly meet the needs of customers' projects. By working closely with customers, we can provide tailor-made solutions to improve product performance and meet the stringent requirements of various high-end applications.Quick Quote

Features: customized according to customer needs, prices fluctuate due to different processing technology and specifications.

Typical alloys: any alloy is acceptable, depending on customer specific requirements.

Advantages: high flexibility to meet the needs of specific scenarios or innovative applications.

Application scenarios: special equipment components, scientific research experimental materials, and high-precision instruments.

Chalco extrusion capabilities

Chalco has advanced extrusion technology and equipment, with strong mold design and production capabilities, which can meet the extrusion needs of various aluminum profiles. Our equipment covers the production of aluminum profiles from standard to complex shapes, supporting a variety of extrusion processes, including forward extrusion, reverse extrusion, high-speed extrusion, hot extrusion, cold extrusion and segmented extrusion.

Through precise mold design and efficient production processes, we are able to provide customers with high-quality, customized aluminum profiles, ensuring that each batch of products meets strict quality standards.Quick Quote

Direct extrusion

- Introduction: Commonly used to produce simple to medium-complexity aluminum profiles, the aluminum ingot is heated and extruded through a die under pressure.

- Capacity: Our company has multiple extrusion presses such as 2200 tons, 1800 tons, 1350 tons, 1100 tons, etc., which are suitable for mass production of various standard and customized profiles.

Reverse extrusion

- Introduction: Suitable for complex shapes and high-precision profiles. The mold and pusher are in opposite directions to reduce mold wear.

- Capacity: Our company is equipped with 1800-ton and 1350-ton extruders, which can accurately control the fluidity of materials and are suitable for the production of precision profiles.

Hot extrusion

- Introduction: Suitable for large-size and complex-shaped aluminum profiles, aluminum ingots have better fluidity at high temperatures.

- Capabilities: We have 2200 ton and 1800 ton extrusion presses capable of producing high-strength aluminum alloy profiles to meet special requirements.

Cold extrusion

- Introduction: It is carried out at room temperature and is suitable for precision and small-size aluminum profiles with smooth surface and high precision.

- Capacity: Our company is equipped with 1350-ton and 1100-ton equipment, capable of producing high-precision aluminum profiles to ensure high-quality surfaces.

High-Speed extrusion

- Introduction: It is used for the production of small-size and high-yield aluminum profiles, suitable for fast and large-scale production.

- Capacity: Our company has 900-ton and 600-ton equipment, which can achieve efficient production and meet the needs of fast delivery.

Multi-Stage extrusion

- Introduction: Suitable for aluminum profiles with complex cross-sections and high-quality surfaces, gradually formed through multiple extrusions.

- Capacity: Our company has 2200 ton and 1800 ton equipment, which can accurately control each stage to ensure product quality.

Why choose Chalco as your supplier for your Aluminum Extrusion project?

ideal partner for your aluminum alloy extrusion bar project with its strong production capacity, advanced technology and strict quality control . We are committed to providing customers with high-quality aluminum bar solutions to meet the needs of various industries.Quick Quote

- Powerful extrusion capability: We have multiple high-tonnage extruders that can produce round bars, square bars, rectangular bars and other specifications to meet mass production needs.

- Precision processing technology: Modern equipment ensures the dimensional accuracy and surface quality of the aluminum bars.

- Complete molds, free mold fees: rich mold library, providing molds of various specifications, saving costs and speeding up delivery.

- Quality Assurance: Strict quality control and comprehensive testing ensure that the aluminum bars meet production standards and ISO quality management system.

- Diverse product selection: Provide a variety of aluminum rod shapes and sizes to meet different project needs.

- Widely used: widely used in construction, aerospace, automobile, machinery, marine, energy and other industries, providing tailor-made solutions.

- Additional processing services: Provide cutting, drilling, anodizing and other additional processing services to improve the application performance of aluminum bars.

| Additional Services | Description |

| Aluminum rod cutting | Provide precise aluminum bar cutting services to ensure that the aluminum bar size meets customer requirements and adapts to different processing needs. |

| Aluminum rod precision machining | We provide milling, turning and other processing services, and can perform precision processing according to customers' specific requirements to meet high-precision needs. |

| Aluminum rod welding | We provide TIG, MIG and other welding services to ensure that the joints of aluminum bars are firm and reliable, which are widely used in construction, machinery, automobile and other industries. |

| Aluminum Rod Bending | We provide aluminum bar bending services to ensure that the aluminum bars can perfectly adapt to various structural designs without compromising strength and appearance. |

| Aluminum rod connection | Provide mechanical connection and welding to ensure that the aluminum rod connection is stable and reliable. Bolt, riveting, plug-in and other methods can be provided according to needs. |

| Aluminum rod cleaning | Provide aluminum rod cleaning services to remove surface oil, oxides, etc. to ensure the best performance of the aluminum rod in subsequent processing and use. |

| Surface treatment services | We provide various surface treatments such as anodizing, electrophoretic coating, spraying, polishing, etc. to improve the corrosion resistance and appearance of aluminum rods. |

| Customization | We provide customized aluminum bar solutions according to customer needs, including special shapes, sizes and processing technology to ensure a perfect fit for project needs. |

Chalco extruded aluminum bar cooperation areas

Aluminum alloy extruded tubes are widely used in many industries due to their light weight, high strength, corrosion resistance and other characteristics. Whether it is aerospace, automobile manufacturing, or construction, marine and other fields, aluminum alloy extruded tubes can provide excellent performance. With the continuous advancement of technology, our products can meet the needs of different industries and provide customers with efficient and reliable solutions.

Aluminum extrution bar rod for Aerospace

Aluminum bars are used in the aerospace industry to manufacture aircraft structures, aircraft parts and high-strength aluminum alloy parts. Alloys such as 2024, 7075, and 7050 are widely used in the aerospace field due to their excellent strength and corrosion resistance. Alloy 6061 is used for some parts with lower strength requirements.Quick Quote

Common alloys: 2024, 7075, 7050, 6061

Common shapes: round rod, square rod, hexagonal rod

Additional Services:

- Provide mechanical property test reports for high-strength alloys to ensure compliance with aerospace standards.

- Provides heat treatment and hardening services for materials to enhance strength and fatigue resistance.

- Provide precision machining services to ensure components meet aerospace design requirements.

Aluminum extruded rods for marine vessels

Aluminum bars are widely used in the marine industry for hull structures, fittings, piping systems, and cabins. 5000 series aluminum alloys, especially 5052 and 5083 alloys, are widely used in the exterior and interior structures of ships due to their excellent seawater corrosion resistance and high strength. 6061 and 6082 alloys are used for ship frames, fittings, and interior parts.Quick Quote

Common alloys: 5000 series (5052, 5083), 6000 series (6061, 6082)

Shape: round rod, square rod, rectangular rod, T-shaped rod, L-shaped rod

Additional Services :

- Provide anti-corrosion performance test report to ensure that the material is suitable for marine environment.

- Anodizing and special coating treatments are available to enhance corrosion resistance and resistance to seawater erosion.

- We provide customized services for extra-long and large-size aluminum bars to meet the special design needs of marine engineering.

Aluminum extrusion for Military and defense industry

Aluminum bars are widely used in the military and defense industries for military equipment, weapons, aircraft and other parts. Alloys such as 7075, 7039, 2024, 7050 have extremely high strength and corrosion resistance, and are suitable for a variety of high-demand defense applications.Quick Quote

Common alloys: 7075, 2024, 7050 , 7039, 2219

Common shapes: round rod, square rod, hexagonal rod

Additional Services:

- Provide certification and material test reports that meet military standards.

- Provide high-precision cutting and processing services to meet complex military design requirements.

- Special surface treatment services are available, such as hard anodizing, to enhance wear and corrosion resistance.

Aluminum extruded products for Automotive Industry

In the automotive industry, aluminum alloys are used for body structures, chassis parts and other accessories. The industry requires aluminum alloys to have good strength, corrosion resistance and processing properties. Alloys such as 6061, 6082 and 7075 are widely used in parts such as body frames and chassis.Quick Quote

Common alloys: 6061, 6082, 5754, 7075

Common shapes: round rod, flat rod, T-shaped rod, U-shaped rod, Z-shaped rod

Additional Services:

- Provide precision cutting, welding and machining services to meet the high-precision requirements of automotive parts.

- Custom shaped rods are available to meet the specific design needs of the automotive industry.

- Available with corrosion resistance enhancing surface treatments such as anodizing or coating services.

Aluminum extruded bar rode for construction and decoration industry

Aluminum alloys are widely used in window frames, door frames, curtain wall structures, decorative strips and other parts in the construction and decoration industries. The industry has high requirements for the processability, corrosion resistance and aesthetics of aluminum alloys. Alloys such as 6063, 6061, and 6082 are widely used in the construction field due to their good surface treatment effects and processing performance.Quick Quote

Common alloys: 6063, 6061, 6082

Common shapes: round rods, square rods, rectangular rods, custom-made special-shaped rods

Additional Services:

- Aluminum rods are available in custom shapes and sizes to meet architectural design requirements.

- We offer surface treatment services such as anodizing, spraying and powder coating to enhance aesthetics and corrosion resistance.

- Provide precision machining services to ensure that products meet building standards.

Aluminum extrusion for power and energy industry

The power and energy industries have strict requirements on the electrical conductivity and corrosion resistance of aluminum alloys. Alloys such as 1350, 6063 and 6101 are widely used in components such as power transmission lines, energy equipment and conductive materials. The electrical conductivity and durability of aluminum alloys make them an ideal choice for the power industry.Quick Quote

Common alloys: 1350, 6063, 6101

Common shapes: round rods, flat rods, rectangular rods, busbars, conductive rods

Additional Services:

- Provide conductivity test reports to ensure that materials meet power industry standards.

- Provide precision cutting and machining services to ensure the size and shape meet power transmission needs.

- Surface treatment services such as anodizing are available to enhance corrosion resistance.

Machinery manufacturing industry

The machinery manufacturing industry requires aluminum alloys to have good strength, corrosion resistance and processability. Alloys such as 6061, 6082, and 7075 are widely used in mechanical structures, equipment frames, tools, and parts due to their excellent mechanical properties.Quick Quote

Common alloys: 6061, 6082, 7075

Common shapes: round rod, square rod, hexagonal rod, T-shaped rod

Additional services:

- Provide precision machining services to ensure high precision requirements of mechanical parts.

- Provide surface treatment services such as anodizing and coating to enhance corrosion resistance.

- Aluminum bars are available in custom sizes and shapes to accommodate complex mechanical design needs.

Transportation industry

The transportation industry includes railways, ships, automobiles, rail transit and other fields. Aluminum alloys are widely used in the components of various transportation vehicles. Alloys such as 6082, 6061 and 7075 are widely used in the manufacture of transportation vehicles due to their good strength, corrosion resistance and processing performance.Quick Quote

Common alloys: 6082, 6061, 7075

Common shapes: round rod, square rod, rectangular rod, T-shaped rod

Additional services:

- Aluminum bars are available in custom sizes and shapes to meet vehicle design requirements.

- Surface treatment services are available, such as anodizing, to enhance corrosion resistance.

- Provide precision cutting, machining and welding services to ensure accuracy and strength requirements.

Medical industry

Aluminum alloys are widely used in the medical industry for components such as medical equipment, instrument frames, and surgical tools. 6061 and 5052 alloys are widely used in the medical industry due to their good processability and biocompatibility.Quick Quote

Common alloys: 6061, 5052

Common shapes: round rod, square rod, rectangular rod

Additional services:

- Provide biocompatibility test reports to ensure that the materials meet the safety standards of the medical industry.

- Provide precision machining services to meet the accuracy requirements of medical equipment.

- Surface treatment services such as anodizing are available to enhance corrosion resistance and aesthetics.

Chalco standard extruded aluminum bar part size reference

We offer the widest range of Extruded Aluminum Bars. Therefore, you can choose the right product that meets your challenging project requirements . Also, this will allow you to create a custom designed product that meets your exact specifications. The Extruded Aluminum Bar products we offer are backed by our state-of-the-art equipment and extensive industry experience.Quick Quote

| SOLID BAR - Round |

|

||

| E | LENGTH | E | LENGTH |

| 15/64" | 12' | 7/8" | 12' |

| 1/4" | 4' 6' 12' | 1" | 12' |

| 3/8" | 4', 12' 24' | 1 1/2" | 12' |

| 1/2" | 4', 6' 12' | 2" | 12' |

| 5/8" | 12' | 2 1/2" | 12' |

| 3/4" | 12' | 3" | 12' |

| SOLID BAR - Half Oval |

|

||||

| E | A | LENGTH | E | A | LENGTH |

| 9/64" | 3/8" | 4', 6' 12' | 3/16" | 3/4" | 4', 6', 12' |

| 9/64" | 1/2" | 12' | 3/16" | 1" | 4', 6' 12' |

| 9/64" | 11/16" | 12' | |||

| SOLID BAR - Square |

|

||||

| E | A | LENGTH | E | A | LENGTH |

| 1/4" | 1/4" | 4', 6' 12' | 1" | 1" | 12' |

| 1/2" | 1/2" | 4', 6' 12' | 1 1/2" | 1 1/2" | 12' |

| 3/4" | 3/4" | 12' | |||

| SOLID BAR - Rectangular |

|

||||

| E | A | LENGTH | E | A | LENGTH |

| 1/16" | 1/2" | 6' 12' | 1/4" | 4" | 12', 20' |

| 1/16" | 3/4" | 4', 6' 12' | 1/4" | 5" | 12', 20' |

| 1/16" | 1" | 4', 6', 12' | 3/4" | 1" | 10', 12', 20' |

| 1/16" | 1 1/2" | 4', 6', 12' | 1/2" | 3/4" | 12', 20', 24' |

| 1/8" | 3/8" | 4', 6' 12' | 1/4" | 6" | 12', 20' |

| 1/8" | 1/2" | 4', 6', 8', 12' | 1/2" | 1" | 12', 20' |

| 1/8" | 5/8" | 4', 6', 12' | 3/8" | 2 1/2" | 20' |

| 1/8" | 3/4" | 4', 6' 8' 12' 20' | 3/16" | 2 1/2" | 20' |

| 1/8" | 1" | 4', 6' 8' 12' 20', 24' | 1/2" | 1 1/2" | 12', 20' |

| 1/8" | 1 1/2" | 4', 6' 12' 20', 24' | 1/4" | 3 1/2" | 12', 20' |

| 1/8" | 2" | 4', 6' 12' 20', 24' | 1/2" | 2" | 12', 20' |

| 1/4" | 1/2" | 20' | 3/8" | 1 1/2" | 12', 20' |

| 1/8" | 3" | 4', 6', 12' 20' | 1/2" | 3" | 12', 20' |

| 1/8" | 4" | 4', 6', 12' 20' | 3/4" | 3" | 12', 20' |

| 1/4" | 3/4" | 12' 20' | 1/2" | 4" | 12', 20' |

| 1/4" | 1" | 4', 6' 12' 20' | 1/2" | 5" | 12' |

| 1/4" | 1 3/4" | 12', 20' | 1/4" | 1 1/2" | 12', 20' |

| 1/4" | 1 1/2" | 4', 6' 12' 20' | 1/4" | 8" | 12', 20' |

| 1/4" | 2" | 4', 6', 12' 20' | 1" | 1 1/2" | 12', 20' |

| 3/8" | 3/4" | 12', 20' | 3/8" | 3" | 12' |

| 1/4" | 3" | 12', 20' | 1" | 2" | 12', 20' |

| 3/8" | 1" | 12', 20' | 1" | 3" | 12', 20' |

| T BAR |

|

||||

| E | A | T | I/R | LENGTH | |

| 3/4" | 3/4" | 1/8" | 4', 6', 12' | ||

| 1" | 2" | 1/8" | 4', 6', 12' | ||

| 1" | 1" | 1/8" | 4', 6', 12' | ||

| 2" | 2" | 1/8" | 4', 6', 12' | ||

| 2" | 1" | 0.118" | 4', 6', 12' | ||

| 1 1/2" | 1 1/2 | 3/16" | 0.188" | 12', twenty four' | |

| 2" | 2" | 1/4" | 0.250" | 20', twenty four' | |

Extruded aluminum bar product selection guide

When choosing extruded aluminum tube products, it is important to understand the different types, processing methods, specification requirements and related services. Here are answers to some common questions to help you make an informed choice.

1. What is the difference between extruded rod and drawn rod?

Extruded rods are produced by heating aluminum ingots and then applying pressure to extrude them, which is suitable for producing larger aluminum rods; while drawn rods are produced by drawing aluminum into rods through a stretching process, which is suitable for producing small-diameter, long-sized aluminum rods. The different production methods of the two affect the performance and application range of aluminum rods.

2. How is the price quote for aluminum bars determined?

The quotation of aluminum bars is usually based on factors such as order quantity, specifications, shape, alloy type, and whether custom processing is required. Large-volume orders usually enjoy lower unit prices, while small-volume customization may incur additional costs. It is recommended to provide detailed demand information to obtain an accurate quotation.

3. How is the weight of an aluminum bar calculated?

The weight of the aluminum bar can be calculated by the following formula:

Weight = length × cross-sectional area × density

Where, cross-sectional area = π × (diameter/2)² and density is usually 2.7g/cm³.

4. How is aluminum bar packaged and transported?

Aluminum bars are usually packaged in wooden boxes, cartons or waterproof films to prevent damage during transportation. The transportation method can be land, sea or air. Pallets and bundling are used to ensure the safety of aluminum bars during long-distance transportation.

5. What are the advantages of using aluminum alloy rods compared to other materials such as steel?

- Lightweight: Aluminum alloy is lighter than steel and is suitable for applications where overall weight reduction is required.

- Corrosion resistance: Aluminum alloy has excellent corrosion resistance and is particularly suitable for wet environments.

- Processability: Aluminum alloy is easy to process and shape, and can meet complex design requirements.

- Cost-effectiveness: Aluminum alloy aluminum rods have low production costs and are suitable for large-scale production.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote