Are you looking for high-quality metal parts that meet unique requirements? Standard extruded profiles might not always be suitable, and custom aluminum extrusion could be the ideal solution for you.

After reading this article, you will learn:

- What design principles should be followed for custom aluminum extrusion?

- What are the costs associated with custom aluminum extrusion?

- What are the common defects in custom aluminum extrusion? Solutions included.

Henan Chalco offers professional custom aluminum extrusion services, dedicated to creating high-precision, high-performance, and lightweight aluminum profiles. We are certified with ISO 9001:2008 and AS9100:2009, ensuring that every step of the shape development and manufacturing process meets the highest industry quality standards. Whether you require complex hollow structures, special connections, or strict dimensional tolerances, we can meet your needs.Welcome to contact

Minimum Order Quantity (MOQ): 500kg per specification.

-

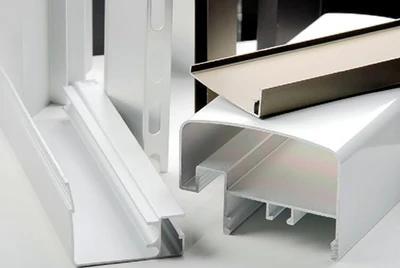

Extrusion Shapes You Can Choose From

Hollow / Semi-Hollow / Solid

Complex Cross-Sections

Large / Miniature Cross-Sections

-

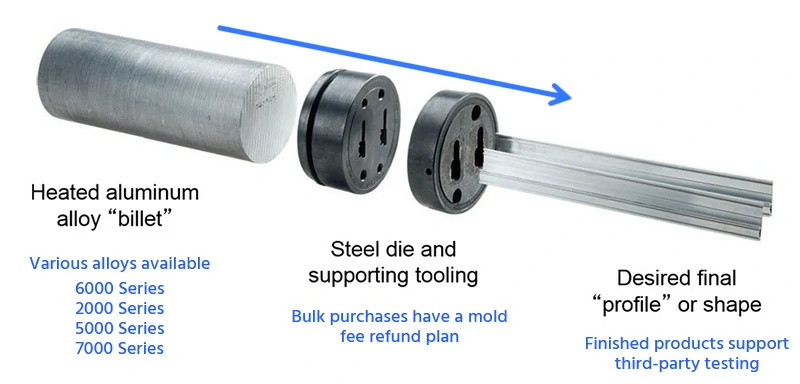

Alloys to Meet Your Requirements

Common Alloys: 6063 / 6061

Hard Alloys: 2024 / 7075 / 5083

Other Alloys: 1100 / 3003 / 5052

-

Available Secondary Processing

Anodizing / Powder Coating

Custom Length Cutting

Drilling / Tapping / Turning / Milling

What Are the Advantages of Custom Aluminum Extrusion?

- Unlimited Design Possibilities: Break free from the limitations of traditional manufacturing processes and bring your ideas to life.

- Precision Dimensional Control: Meet your strict requirements for product dimensions, ensuring a perfect fit for your parts.

- Exceptional Mechanical Properties: Achieve aluminum profiles with higher strength and durability compared to castings.

- Efficient Production Process: Quickly produce large quantities of parts, reducing lead time, while maximizing material utilization to save costs.

- One-Stop Comprehensive Service: From raw material procurement, design, and mold manufacturing to extrusion production, secondary processing, and surface treatments, we provide a full range of services to save you time and effort.

Chalco Custom Aluminum Extrusion Production Capacity

Miniature Aluminum Extrusions

Miniature aluminum extrusions are precise, small-profile aluminum parts used in fields requiring tight dimensional tolerance and surface finish. They are ideal for miniaturized designs and offer higher precision than traditional extrusions.

Contact us now

Features of Miniature Aluminum Extrusions

- High Precision Tolerances: The precision of miniature aluminum extrusions can reach ±0.001 inches, meeting strict design requirements and ensuring parts fit perfectly.

- Thin-Walled Design: Wall thickness can be as low as 0.020 inches, providing a lightweight design while maintaining strength.

- Small Pore Sizes & High Precision: Capable of processing hole diameters as small as 0.045 inches, maintaining ±0.001-inch tolerance, suitable for precision applications.

- Adaptability to Small Sizes: The production range covers circular profiles under 3 inches, with a weight of 0.008 to 0.5 lbs/ft.

- Excellent Surface Finish: Surface finish reaches 16 Ra or higher, ensuring a smooth appearance and functionality.

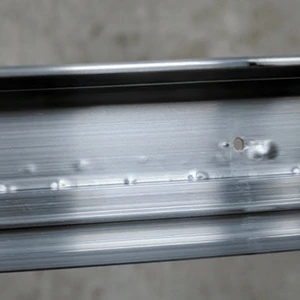

Examples of Miniature Aluminum Extrusions

Applications of Miniature Aluminum Extrusions

Miniature aluminum extrusions are widely used in industries such as electronics, precision instruments, aerospace, and medical equipment. These industries typically require aluminum profiles with very high demands for precision, surface quality, and size.

Large Aluminum Extrusions

Large aluminum extrusions are wide, high-strength profiles used in construction, transportation, and aerospace. They require specialized equipment and offer high design flexibility and production capacity.

Contact us nowFeatures of Large Aluminum Extrusions

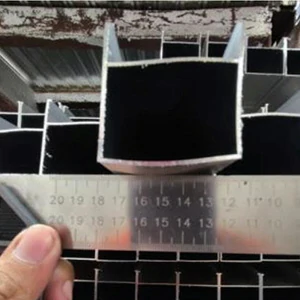

- Rectangular Container Advantage: Utilizing a unique rectangular container technology, it enables better extrusion of ultra-wide profiles, offering higher dimensional control accuracy and more stable metal flow than traditional round containers.

- Extra-Large Sizes: Large aluminum extrusions can reach widths up to 750mm, meeting the demands for various complex and large-sized products.

- Wide Weight Range: With weights ranging from 1.5kg/m to 209kg/m, these extrusions are particularly suitable for the production of heavy components and large structures.

- Porous Hollow Capability: Capable of producing porous hollow aluminum profiles with widths up to 29 inches, they meet the requirements for lightweight structures and complex designs.

- Long Production Length: The maximum production length can reach 26 meters, accommodating large-scale project demands, especially for the manufacture of large structural components.

Examples of Large Aluminum Extrusions

Applications of Large Aluminum Extrusions

Large aluminum extrusions are widely used in industries such as construction, transportation, aerospace, electronics, and energy, particularly in components that require large sizes, high strength, and structural stability. Examples include:

- Water-Cooled Motor Housings

- Truck Trailer Floors

- Container Aluminum Floors

- New Energy Battery Pallets

- Aluminum Extrusions for Large Radiators

- Large-Diameter Seamless Tubes for Hydrogen Fuel Vehicles

Thin Wall Aluminum Extrusions

Thin wall aluminum extrusions, made from 6000 series aluminum, are designed for lightweight projects. Their design reduces weight while maintaining strength, making them ideal for non-structural applications that require both lightness and precision.

Contact us now

Features of Thin Wall Aluminum Extrusions

- Ultra-Thin Wall Thickness: For 6063 aluminum, the wall thickness can be as thin as 0.3mm; for other alloys, it can reach 1mm, offering significant lightweight advantages.

- Lightweight Design: The weight per meter can be as low as 0.03 kg/m, ideal for high-efficiency, lightweight products.

- High-Precision Manufacturing: Made using 6063-T5 aluminum alloy, these extrusions offer precise dimensional control and excellent strength, ensuring perfect assembly accuracy.

- Variety of Shape Options: Supports common shapes such as circular and oval profiles, with the capability to customize special shapes as needed.

Applications of Thin Wall Aluminum Extrusions

Thin wall aluminum extrusions are widely used in areas where load-bearing requirements are low but a good appearance and ease of installation are essential. Typical applications include decorative building materials, electronic product housings, photovoltaic systems, automotive interior components, as well as display stands and exhibition structures.

In addition to custom aluminum extrusions, standard extrusions are also a common and important option. Standard extrusions generally offer versatility and high production efficiency, making them suitable for various application scenarios. In the following sections, we will cover standard extrusions to help you choose the most appropriate solution based on your needs.

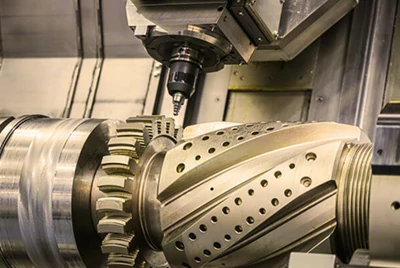

Moreover, beyond using custom molds to manufacture custom aluminum extruded profiles, we can combine extrusion with other manufacturing processes (such as CNC machining) to produce customized final parts. This approach allows us to manufacture parts faster and more economically, especially when most parts share a consistent cross-sectional profile.

Examples of Combining Custom Extrusion with CNC Machining

CNC milling

First, perform custom extrusion, then use a CNC milling machine to add details, holes, or threads.

CNC Turning

First, extrude a circular radiator, then use a CNC lathe to add tapering or other details.

Laser cutting

First, perform custom extrusion, then use laser cutting to add text or other engravings.

Standard Aluminum Extrusions

Solid Aluminum Extrusions

Aluminum Round Bar

Aluminum Rectangular Bar

Aluminum Hexagonal Bar

Aluminum Half-Round Bar

Aluminum Hollow Profiles

Aluminum Round Tube

Aluminum Oval Tube

Aluminum Flat Tube

Standard Aluminum Profiles

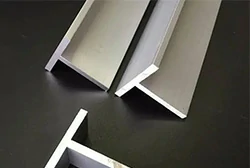

Aluminium T Section

Aluminum Beams

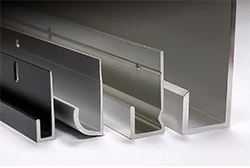

Aluminum U Channel

Aluminum Hat Channel

Aluminium Z Section

Aluminum F Channel

Aluminum J Channel

Aluminium Y Section

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Industry Customized Aluminum Extrusion Solutions

Customized aluminum extrusions play an important role in many industries. Different industries have different requirements for aluminum profiles, and customized aluminum extrusions can solve specific problems in the industry through precise design and process. The following is a combination of the needs of various industries and corresponding solutions, as well as common applications of aluminum profile parts.

Custom Aluminum Extrusion Solutions for the Aerospace Industry

Aluminum extrusions are crucial in the aerospace industry, primarily used in aircraft, spacecraft, and other high-performance aerospace structural components. The lightweight, high strength, high-temperature resistance, and excellent corrosion resistance of aluminum make it the ideal choice for aerospace applications. Custom aluminum extrusions can provide precise dimensions, shapes, and alloys to meet the specific design needs of aerospace, ensuring stability and reliability under high loads and extreme environments.

Hard Alloys: 2014, 2024, 2224, 7075, 7050, 7178, 7049, 7249

Products: Wing spars, seats, aerospace extrusions, longitudinal beams

Certifications: ISO 9001, AS9100, NADCAP HT, NADCAP NDT

Partners: Suppliers recognized by Boeing, Airbus, KLM, Safran, etc.; ultrasonic testing certification available

Shapes: Aluminum round tubes, aluminum square tubes, streamline tubes, aluminum angles, U-channels, T-beams, I-beams, frame profiles, rail profiles

Surface Treatments: Anodizing, powder coating, chemical plating, electrophoretic coating

Custom Aluminum Extrusion Examples

Specific Applications

- Aircraft Structures: Fuselage frames, wing spars, doors, support components

- Spacecraft Components: Satellite casings, structural supports, propulsion system parts, spacecraft shells

- Aviation Equipment: Engine housings, fuel system components, aircraft control systems

- Heat Exchange and Cooling Systems: Radiators, heat pipes, aluminum profiles for cooling systems

- Interior Fixtures and Equipment: Seat frames, luggage compartment dividers, cabin trim pieces

Custom Aluminum Extrusion Solutions for the Defense and Military Industry

Aluminum extrusions play a critical role in the defense and military sectors, especially in structural components that require high strength, high temperature resistance, corrosion resistance, and lightweight properties. The excellent performance of aluminum profiles makes them the ideal material for applications such as aircraft, military equipment, weapon systems, and more. Custom aluminum extrusions can provide tailored shapes, precise dimensions, and special alloys according to specific military standards, ensuring high performance and reliability under extreme conditions.

Common Alloys: 2024, 7075, 5083, 5456

Products: Missile containers, launch rails, deck panels, extruded armor, large-sized profiles

Standards: MIL-DTL-46083, ASTM B221, ASTM B241, EN 755 (ultrasonic testing certification available)

Shapes: Aluminum round tubes, aluminum square tubes, streamline aluminum tubes, rectangular aluminum tubes, I-beams, aluminum angles, T-beams, frame profiles

Surface Treatments: Anodizing, hard anodizing, powder coating, chemical plating, electrophoretic coating, high-temperature coatings

Custom Aluminum Extrusion Examples

Specific Applications

- Military Equipment: Weapon system brackets, turret support frames, military vehicle frames

- Ship and Marine Equipment: Hull frames, ship casings, offshore combat platforms

- Military Electronics: Communication device casings, power system control panels, military radar systems

- Military Transport: Military transport vehicle frames, transport equipment frames, carrier aircraft brackets

- Ammunition and Weapon Systems: Missile brackets, ammunition boxes, weapon system structures

- Protective Gear: Armor brackets, protective shields, military protective facilities

Custom Aluminum Extrusion Solutions for the Automotive Manufacturing Industry

Custom aluminum extrusions are widely used in the automotive manufacturing industry for applications such as body structures, chassis components, interior parts, and electronic device supports. The lightweight, high strength, excellent corrosion resistance, and ease of processing of aluminum alloys offer significant advantages in improving fuel efficiency, reducing emissions, enhancing safety, and extending the service life of vehicles. Through custom designs, automakers can achieve precise dimensions, complex shape designs, and the required surface treatments to meet modern automotive demands for performance, comfort, and environmental sustainability.

Common Alloys: 6061, 6060, 6082, 7075, 5052, 6005

Certification: IATF 16949

Shapes: Aluminum profile frames, round tubes, square tubes, rectangular tubes, I-beams, T-beams, U-channels, aluminum angles, radius bars

Surface Treatments: Anodizing, powder coating, electrophoretic coating, chemical plating, corrosion-resistant coatings

Custom Aluminum Extrusion Examples

Specific Applications

- Body Structures: Body frames, door frames, roof beams, front and rear bumper brackets

- Chassis and Suspension Systems: Chassis brackets, suspension system parts, axle brackets

- Interior Parts: Dashboard frames, seat brackets, door panel brackets, interior panels

- Electronics and Electrical Equipment: Battery brackets, electronic control box brackets, in-car electronic device brackets

- Heat Dissipation and Cooling Systems: Radiator frames, cooling system brackets, fan brackets

- Windows and Glass: Window frames, glass guides, sunroof brackets

- Power Systems: Engine brackets, transmission system parts, exhaust pipe brackets

Custom Aluminum Extrusion Solutions for the Marine and Shipbuilding Industry

Custom aluminum extrusions are widely used in shipbuilding for hulls, structural components, and outfitting facilities. The lightweight, strength, and corrosion resistance of aluminum profiles offer significant advantages in marine environments, especially when facing challenges such as saltwater exposure, extreme weather, and long-term use. Through custom designs, precise dimensions, complex shapes, suitable alloy choices, and high-quality surface treatments can be achieved to meet the strict requirements for ship safety, durability, energy efficiency, and performance.

Common Alloys: 5083, 5086, 5454, 5456, 6061, 6082

Certifications: BV, ABS, DNV, CSS, GL

Shapes: Aluminum round tubes, elbows, tees, aluminum square tubes, rectangular aluminum tubes, U-channels, aluminum angles, I-beams, H-beams, T-beams, frame profiles

Surface Treatments: Anodizing, powder coating, chemical plating, electrophoretic coating, seawater corrosion-resistant coatings

Custom Aluminum Extrusion Examples

Specific Applications

- Hull Structures: Hull frames, bulkhead supports, deck structures, partition walls

- Outfitting Facilities: Lifeboat brackets, hatch frames, navigation equipment supports, compartment fittings

- Exterior Covers and Decorations: Exterior railings, deck fences, cabin window frames, sunshades

- Engine Room and Power Systems: Engine brackets, propulsion system parts, internal support structures

- Interior Ship Fittings: Interior panels, seat frames, internal partitions, ventilation equipment housings

- Ship Equipment: Navigation equipment brackets, communication antenna supports, ship control panels

Customized Aluminum Extrusion Solutions for Rail Transit Industry

Customized aluminum extrusion is widely applied in the rail transit industry for vehicle structures, compartment components, bridges, and track facilities. Aluminum alloys offer advantages such as lightweight, corrosion resistance, fatigue resistance, and high strength, making them perform excellently in long-term, high-load operating environments. Through customization, rail transit equipment can achieve precise dimensions, complex shape designs, and the selection of suitable aluminum alloys and surface treatment processes to improve safety, extend service life, and reduce maintenance costs.

Common Alloys: 6061, 6082, 7075, 5083, 6005

Shapes: Aluminum profile frames, round tubes, square tubes, rectangular tubes, I-beams, T-beams, U-channels, angle bars, rounded strips

Surface Treatment: Anodizing, powder coating, chemical plating, electrophoretic coating, corrosion-resistant coating

Customized Extrusion Examples

Specific Applications

- Rail Transit Vehicles: Vehicle body frames, door frames, compartment partitions, seat brackets

- Wheels and Steering Systems: Wheel supports, axle supports, bogie structural components

- Bridges and Track Facilities: Bridge supports, track guardrails, track connectors

- Station Facilities: Escalator frames, waiting bench supports, platform railings, light poles

- Signal and Communication Equipment: Signal supports, communication antenna supports

- Interior Components: Interior panels, window frames, ventilation device housings, lighting brackets

Customized Aluminum Extrusion Solutions for the Transportation Industry

Customized aluminum extrusion is widely used in the transportation industry for commercial vehicles, transportation vehicles, and containers. Aluminum alloys, with their lightweight, high strength, corrosion resistance, and excellent machinability, have become indispensable materials in these equipment. Customized designs provide precise dimensions, complex shapes, and the right alloys and surface treatments to ensure high strength, long service life, and low energy consumption.

Common Alloys: 6061, 6082, 7075, 5052, 6005

Shapes: Aluminum profile frames, round tubes, square tubes, rectangular tubes, I-beams, T-beams, U-channels, angle bars, channel bars, rounded strips

Surface Treatment: Anodizing, powder coating, electrophoretic coating, chemical plating, corrosion-resistant coating

Customized Extrusion Examples

Specific Applications

- Commercial Vehicles: Bus frames, school bus supports, fire truck structures, refrigerated truck supports, ambulance supports

- Trucks and Transport Vehicles: Truck frames, van supports, trailer structures, freight platforms

- Containers and Transport Accessories: Container frames, container door frames, container floors, transport compartment accessories

- Transportation Facilities: Parking rack supports, cargo handling equipment supports, shelving support structures

Customized Aluminum Extrusion Solutions for the Construction Industry

Aluminum extrusions are widely used in the construction industry for structural and decorative components. Due to the lightweight, high strength, corrosion resistance, and ease of processing of aluminum, it has become an important choice of building material. Customized designs can provide different shapes, sizes, surface treatments, and alloys based on design requirements, meeting various demands for structure, appearance, and durability in construction.

Common Alloys: 6061, 6063, 6060, 5052, 3003

Shapes: Aluminum round tubes, aluminum square tubes, rectangular aluminum tubes, angle bars, U-channels, cap channels, J-channels

Surface Treatment: Anodizing, powder coating, wood grain transfer printing

Specific Applications

- Door and Window Systems: Doors, window frames, sliding tracks, thermal break frames

- Curtain Wall Systems: Curtain wall framing systems, curtain wall glass profiles, exterior facade decorations

- Conservatories and Sunshades: Conservatories, skylights, sunshades

- Partition and Railing Systems: Indoor and outdoor partition walls, handrails, railings

- Roofing and Wall Panel Systems: Ceilings, wall panels, metal roofs

Customized Aluminum Extrusion Solutions for the Machinery Equipment Industry

Customized aluminum extrusion is widely used in the machinery equipment industry for structural components, frames, brackets, transmission parts, and more. The lightweight, high strength, excellent corrosion resistance, and ease of machining of aluminum alloys make them perform excellently in high-load, complex working environments. By customizing aluminum extrusions, machinery equipment can achieve precise dimensions, complex shape designs, and high-quality surface treatments, thereby improving the equipment's stability, durability, and maintenance efficiency.

Common Alloys: 6061, 6082, 7075, 5052, 6005

Shapes: T-profiles, frame profiles, rail profiles, square tubes, rectangular tubes, I-beams, T-beams, U-channels, angle bars

Surface Treatment: Anodizing, powder coating, electrophoretic coating, chemical plating, corrosion-resistant coating

Specific Applications

- Machinery Frames: Equipment outer frames, support structures, transmission brackets

- Transmission Systems: Gearbox brackets, pulley brackets, motor supports

- Work Platforms: Operation platform frames, mobile platforms, workstation supports

- Precision Tools: Machinery tool supports, jigs and fixtures, tool racks

- Transport and Handling Equipment: Conveyor belt supports, roller supports, automated assembly line supports

- Cooling and Heat Dissipation Systems: Cooling system frames, radiator supports, fan supports

- Safety Protection Devices: Protective cover brackets, photoelectric protection device supports, emergency stop device supports

Customized Aluminum Extrusion Solutions for the Electronics and Electrical Industry

Customized aluminum extrusion is widely used in the electronics and electrical industry, especially in applications requiring heat dissipation, electromagnetic interference resistance, lightweight, and excellent mechanical properties. The high thermal conductivity, good machinability, and corrosion resistance of aluminum profiles make them ideal for electronic device enclosures, cooling systems, and support structures. Customized designs can provide different shapes, sizes, surface treatments, and alloys based on electronic product design requirements, ensuring long-term stable operation and efficient heat dissipation.

Common Alloys: 6063, 6061, 6101, 1350, 1050, 5052

Products: Conductive aluminum tubes, conductive aluminum bars, copper-clad aluminum bars, motor housings, radiators

Shapes: Aluminum round tubes, aluminum square tubes, rectangular aluminum tubes, radiator profiles, I-beams, frame profiles

Surface Treatment: Anodizing, powder coating, brushing, electroplating, chemical plating

Customized Extrusion Examples

Specific Applications

- Electronic Enclosures: Computer enclosures, electrical equipment enclosures, instrument enclosures

- Cooling Systems: LED radiators, cooling plates, heat exchangers

- Electrical Components: Motor housings, electrical control cabinets, junction boxes

- Battery and Energy Storage Devices: Power battery enclosures, energy storage device frames

- Communication Equipment: Antenna supports, communication device frames, signal reception devices

- Power Equipment: Power transformer enclosures, electrical distribution panels

Alternative Solutions for Aluminum Extrusions

Customized aluminum extrusions typically require mold development, making them more suitable for large-scale production and the manufacturing of high-volume parts. If your needs are for prototype design or small-batch production, customized aluminum extrusion may not be the best choice. Fortunately, Chalco offers the following two alternatives that are ideal for small-batch, cost-effective production:

CNC machining is a high-precision method for small-batch production, where aluminum is cut into complex shapes without the need for molds. This reduces upfront costs and allows design flexibility, making it ideal for prototypes and small-batch customizations.

Laser Cutting

Laser cutting uses high-intensity lasers to precisely cut aluminum, ideal for small-batch production. It requires no molds, allowing rapid cutting of complex shapes, reducing costs and lead times, and is perfect for intricate parts in prototypes and small-scale production.

Why Choose Henan Chalco as Your Aluminum Extrusion Partner

Selecting the right aluminum extrusion partner is crucial for the success of any project. Here’s why Henan Chalco should be your first choice:

1. Leading Equipment and Technological Strength

- Alloy Melting and Aluminum Profile Production: Chalco possesses advanced aluminum alloy tilt-casting equipment, capable of developing aluminum alloy billets with specific compositions. We cover all aluminum profile grades from 1xxx to 7xxx series.

- Ultra-Large Mold Design and Manufacturing Center: We have an ultra-large industrial aluminum extrusion mold design and manufacturing center, where all molds are self-designed and produced, enabling domestic production of difficult-to-extrude profiles.

- Powerful Extrusion Equipment: Chalco owns the largest number of large aluminum extrusion production lines globally, with over 100 production lines, including 23 lines with 75MN or higher capacity. Additionally, we have introduced 2 leading 225MN ultra-large extrusion presses, ensuring efficient and high-precision production.

2.Strict Quality Control and International Standards Certification

- Quality Control: All aluminum extrusion molds are rigorously tested before production, and the shape and size of profiles are regularly checked during production, ensuring that every product meets high-quality standards.

- International Standards: Our aluminum extrusion products comply with international extrusion standards such as EN 755, ASTM B221, ASTM B241, ensuring products meet global industry norms and customer requirements.

3.Extensive Industry Experience and Customer Trust

- Professional Technical Support: With in-depth experience in industries such as aerospace, military, automotive, shipbuilding, and construction, we offer tailored aluminum extrusion solutions to meet strict technical requirements across various sectors.

- Customer Trust: We are committed to providing high-quality service, earning the trust of numerous global clients and establishing long-term partnerships.

4.Fast Delivery and Flexible Production Capacity

- Fast Delivery: Chalco has strong production capabilities, allowing us to deliver on time, especially for urgent orders and high-volume production.

- Flexible Production: We can adjust production schedules based on customer needs, offering personalized and efficient solutions.

5.Comprehensive After-Sales Support

- Fast Response: Our professional support team ensures timely resolution of any issues encountered by customers during use.

- Long-Term Reliability: Chalco provides warranty services and after-sales support, ensuring the long-term stability and reliability of aluminum extrusions.

Available Materials for Customized Aluminum Extrusions

Common Alloys

-

6063

Known as the "architectural alloy, ” it is widely used in doors, windows, curtain walls, and furniture, offering excellent surface treatment performance.

-

6061

Highly versatile, it has greater strength than 6063 and is used in structural components such as automotive frames and aerospace parts.

-

6082

Ideal for structural components that must withstand high mechanical stresses, such as bridges, ships, and transportation vehicles.

Other Alloys

-

2024 | Aerospace-grade

Widely used in the aerospace industry, especially for high-load components like wings and fuselage structures.

-

7005

Commonly used in applications requiring high strength and weldability, such as tent poles, bicycle frames, and sports equipment.

-

7075 | Aerospace-grade

One of the strongest alloys, commonly used in aerospace, military, and other high-strength equipment parts.

-

5052

Known for its excellent corrosion resistance, it is commonly used in marine environments, chemical equipment, and industries with high corrosion demands.

-

5083 | Marine-grade

Primarily used in marine applications, tankers, chemical equipment, and refrigerated vehicles, offering excellent corrosion resistance.

-

6060

Easy to extrude and commonly used in construction, transportation, and similar fields.

-

6005

Features good extrusion properties and is commonly used in rail transportation, TV antenna brackets, and agricultural machinery components.

-

3003

Offers good corrosion resistance and formability with moderate strength. It is commonly used for heat exchanger tubes.

-

1050/1070/1100

Pure aluminum alloys with good ductility, often used in lighting fixtures, signage, and heat sinks for low-strength, complex cross-section applications.

The following detailed comparison chart of different aluminum extrusion alloys can help you choose the right alloy for your specific application. If the material you require is not listed above, please contact us, and we can offer tailored solutions based on your specific needs.Quick Quote

| Alloy | Strength | Corrosion Resistance | Weldability | Applications | Temper |

| 1xxx Series | Low to Moderate | Excellent | Excellent | Electrical conductors, heat exchangers, cookware | H12, H14, H16, H18 |

| 6063 | Moderate | Good | Good | Architectural, decorative, window frames | T5, T6, T52 |

| 6061 | High | Good | Good | Structural frames, aerospace, Marine applications | T6, T651, T4 |

| 5052 | Moderate to High | Excellent | Good | Marine, chemical tanks, fuel tanks | H32, H34, H38 |

| 7075 | Very High | Fair | Poor | Aerospace, military | T6, T651 |

| 2024 | Very High | Good | Fair | Aircraft structures, military vehicles | T3, T4, T851 |

| 3003 | Low to Moderate | Good | Good | Cooking utensils, roofing, siding | H14, H16, H18 |

| 5083 | High | Excellent | Fair | Marine structures, pressure vessels | H111, H112, H116 |

| 6082 | High | Good | Good | Structural applications, bridges, cranes | T6, T651 |

| 6005/6005A | Moderate | Good | Good | Transportation, structural components | T5, T6 |

Deep Processing Options for Customized Aluminum Extrusions by Chalco

Surface Treatment

-

Mechanical Surface Treatment

This includes polishing, sandblasting, and grinding, which are used to smooth surfaces, remove burrs, and enhance the overall texture of the material.

-

Anodizing

Anodizing is an electrolytic process that creates an oxidized layer on aluminum, enhancing corrosion and wear resistance, while allowing for color customization.

-

Brushing

Brushing uses sand belts to create a uniform texture on the surface, improving appearance, and is ideal for electronics and furniture products.

-

Spray Painting

Spray painting applies a protective coating to the surface of the profile, improving corrosion resistance and enhancing the aesthetic appearance.

-

Powder Coating

Powder coating involves spraying powder onto a surface and curing it at high temperatures, offering a wide range of colors and excellent weather resistance.

-

Wood Grain Transfer

Through transfer technology, wood grain patterns are applied to the surface of the profile, simulating the look of wood and providing a natural aesthetic.

Finishing Options

-

Precision Cutting

Precision cutting to the required size, adaptable to different shape requirements.

-

Deburring

Deburring removes sharp edges or burrs generated during the manufacturing process, improving the safety and accuracy of the product.

-

Beveling/Chamfering

Beveling or chamfering sharp edges to prevent injuries from sharp corners and improve assembly precision.

-

Bending/Rolling

Using a bending machine to adjust angles and create shapes such as U-shaped, L-shaped, and other bent configurations.

-

CNC Machining

CNC machining utilizes precision drilling, milling, and other processes to create complex structural parts.

-

Threading/Tapping

Internal threading or external thread rolling facilitates easy assembly and fastening.

-

Welding

Tungsten inert gas (TIG) welding or gas shielded arc welding is used to connect components, ensuring structural strength and durability.

-

Laser Engraving

Laser engraving provides high-precision marking, patterns, or serial numbers, adding both functionality and aesthetic value.

Principles for Designing Customized Aluminum Extrusions

In the design process of customized aluminum extrusions, a well-thought-out design not only ensures product quality and functionality but also helps reduce production costs and processing time. By following some simple yet crucial design principles, engineers can create designs that are both cost-effective and easy to process while meeting performance requirements. Here are some key points to optimize aluminum extrusion design:

- Simplify Design:Adopt symmetrical and simple profiles to reduce mold complexity and production costs. Avoid overly complex hollow structures; solid designs may be more economical.

- Wall Thickness Control:Maintain uniform wall thickness. Avoid walls that are too thin (must meet minimum thickness standards) or too thick (increases weight and cost).

- Optimize Fillets and Corners:Replace sharp corners with large-radius fillets to reduce stress concentrations and the risk of cracking. Internal right angles can be transitioned with a dogbone shape.

- Channel Proportions:Keep the width-to-height ratio of channels within ≤3:1. Higher ratios increase machining difficulty and costs.

- Standardization and Modularity:Prioritize the use of standard holes and components to minimize customization. Complex structures should be broken down into modular designs, making them easier to manufacture and assemble.

- Structural Balance:For hollow profiles, balance the web thickness to avoid making it too thin (leading to deformation) or too thick (increasing weight). The flange width should be appropriate to balance support strength and lightweight considerations.

- Appropriate Tolerances:Apply strict tolerances only to critical features. Avoid high-precision requirements for soft materials or thin-walled parts.

- Allowance for Post-Processing:Plan ahead for drilling, machining, and other post-processing steps to ensure that the extrusion's structure is adaptable for these subsequent processes.

In conclusion, for any issues, it's essential to communicate with our professional aluminum extrusion experts in advance to maximize the optimization of your design feasibility and cost.Quick Quote

Costs of Customized Aluminum Extrusions

The cost of customized aluminum extrusions mainly consists of two components: mold costs and unit costs.

- Mold Costs:Mold costs are fixed costs, typically unrelated to the number of parts produced. The mold manufacturing cost includes the design and creation process. Complex mold designs, such as external circles, cavities, and thin-wall features, may increase the cost.

- Unit Costs:Unit costs cover the raw materials, labor costs, as well as additional expenses like transportation and taxes. Unit costs vary depending on production volume and are usually determined by the size, quantity, and complexity of the parts required. Manufacturers typically provide a quotation that includes all costs, avoiding hidden fees.

Since aluminum extrusions are often relatively long, transportation costs can be higher. To reduce transportation costs, it is recommended to keep the length of aluminum extrusions under 3 meters and prioritize cost-effective transportation methods, such as sea freight.

Common Defects in Customized Aluminum Extrusions and Their Solutions

Warping

During the extrusion process, the aluminum billet experiences high forces, generating residual stresses. Uneven cooling, typically caused by inconsistent wall thickness or asymmetric design, leads to warping. Solution: Ensure uniform and symmetrical wall thickness in the design to minimize the risk of warping.

Striations

Poor mold design or variations in metal flow can lead to small marks or grooves on the surface, running parallel to the extrusion direction. Solution: Use ribbed or patterned surface designs to reduce the occurrence of striations.

Cracking/Tearing

Improper extrusion settings, excessive extrusion speed, or incorrect temperature can result in excessive friction between the metal and the tool, leading to cracks on the surface. Solution: Follow proper design guidelines to avoid concentrated stress features, such as overly thin sections or high channel ratios. Choose a reputable manufacturer to ensure correct extrusion process settings.

Blisters

Air or contaminants (e.g., lubricants) entering during the extrusion process can form bubbles. Solution: Ensure the use of high-quality materials and maintain equipment properly to avoid the formation of blisters.

FAQ

1. Can we provide finished aluminum extrusion parts?

Yes, Henan Chalco offers a full range of aluminum extrusion services, from design optimization and mold manufacturing to post-processing. With over a decade of experience, we serve industries including automotive, aerospace, electrical, and industrial processing. Our engineers work closely with our quality control team to ensure we meet your extrusion requirements.

2. How can I get technical support or design assistance?

Our engineering team provides comprehensive technical support, from design optimization to production implementation. If you have any technical questions, feel free to contact us. We will offer advice and solutions based on your needs.Quick Quote

3. How can I reduce the cost of aluminum extrusion?

Here are several ways to effectively reduce costs:

- Design: Simplify complex designs to reduce processing time.

- Material: Choose the right materials, considering bulk material options and extrusion difficulty.

- Quantity: The more units you order, the lower the unit cost.

4. Can you provide custom mold services?

Yes, we offer custom mold design and manufacturing services. Our molds are designed by an experienced team to ensure high precision and long-term durability.

5. Can you provide independent material testing?

Yes, we can send the materials to certified testing centers for calibration. Please discuss this with your sales manager at the start of your project. Typically, this may add about one week to the delivery time.

6. What is the minimum order quantity (MOQ) for aluminum extrusions?

The MOQ for our aluminum extrusion parts is 500kg. For large-volume orders, we also offer a mold cost refund plan to significantly reduce your initial investment. If you only need a single part or a prototype design, we can first offer CNC processing services for sample production. Once the samples are confirmed, we will proceed with mold manufacturing, ensuring quality while avoiding unnecessary costs.

7. How long will it take to get a quote?

Our goal is to provide a quote within 24 hours. If a request is submitted in the morning, we may sometimes provide a quote the same day.

8. What is the delivery time for aluminum extrusions?

Typically, our delivery time is 4-6 weeks, depending on the complexity and quantity of the order. For urgent orders, we can offer expedited services based on your specific needs.

9. What should I do if there are defects in the aluminum extrusions?

If any defects are found in the aluminum extrusions, we will provide return, exchange, or re-manufacturing services based on the situation to ensure customer satisfaction. We are committed to delivering high-quality products and resolving any issues that may arise.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote