Chalco aluminum extruded tube product introduction

Alloys: 6061, 6063, 6082, 2024, 2014, 3003, 7075, 7050, 7055, 5052, 5083, 1100 [Click to view alloy details and purchase by alloy]

Patented product: large-size extruded tube, diameter up to 1320mm; length up to 13 meters [View details]

Hot-selling products: [Extruded seamless tube] [Precision extruded tube]; [Different cross-section shape tube]; [Extruded structural tube]

Specification: AMS QQ-A-200, ASTM B241, ASTM B345

Surface: mill finish; polished, painted, power coated, anodized, galvanized

Colors: black, white, satin silver, matte black powder, glossy white

Polished

Color coated

Anodized

Chalco large diameter extruded aluminum tube — patented hot-selling product

The company produces large-diameter seamless aluminum alloy square pipes using a 50, 000-ton vertical extruder, with a maximum diameter of 1, 320 mm, wall thickness up to 200 mm, and length of 12 meters—making them the largest and thickest of their kind globally.

Contact us now

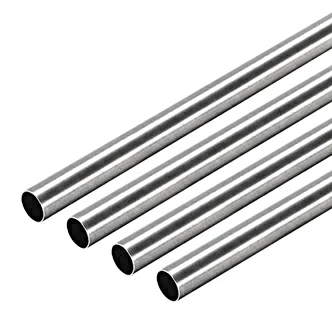

Chalco extruded seamless aluminum tube — high pressure resistance

Produced through seamless extrusion process, it ensures smooth inner and outer surfaces, with outer diameter tolerance up to ±0.1mm and wall thickness tolerance up to ±0.15mm, suitable for high pressure and high strength application.

Contact us now

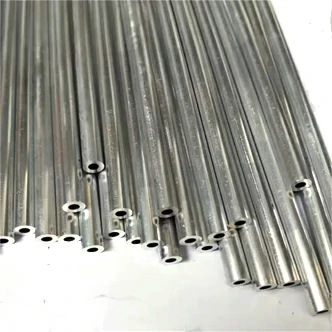

Chalco precision extruded tubes—meeting different project requirements

Chalco precision extruded tubes adopt advanced production technology to ensure the outer diameter tolerance can reach ±0.05mm and the wall thickness tolerance can reach ±0.1mm, meeting the strict design and engineering requirements and ensuring high precision and consistency.

Contact us now

-

Continuous extruded coil tube

The coils produced by the continuous extrusion process have excellent shape consistency and surface quality and are suitable for cooling and heat exchange systems.

-

Extruded thin wall tube

Thin-walled aluminum tubes provide lightweight solutions while ensuring strength. They are widely used in aerospace, automotive industry, electronic equipment housings, and structural parts that need to reduce weight.

-

Extruded capillary

Capillaries have extremely small inner diameters and are suitable for precision fluid transfer and high-precision instrumentation, providing excellent fluid control capabilities.

-

Extruded fin tube

Finned tubes are designed to improve heat exchange efficiency and are suitable for a wide range of heat exchange systems, providing excellent heat dissipation performance.

-

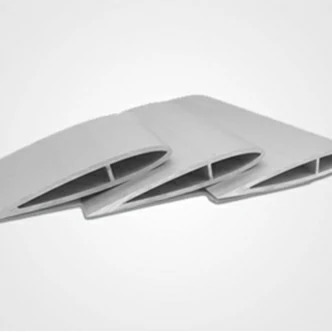

Airfoil tube

The airfoil tube design optimizes fluid dynamics for aerospace and high-efficiency fluid delivery systems.

-

Extruded microchannel tube

Microchannel tubes have extremely small channels and are suitable for precision fluid control systems. They are widely used in refrigeration and heat exchange equipment.

-

Extruded porous tube

The porous tube is manufactured using a special process and has excellent air permeability and fluid control capabilities, making it suitable for filtration and gas distribution systems.

-

Extruded telescopic tube

The telescopic tube is flexibly designed and can be extended and retracted within different length ranges, making it suitable for application scenarios where length adjustment is required.

-

Extruded reducer

The reducer adopts precision extrusion technology to ensure smooth transition between different diameters, which is suitable for fluid transportation and gas pipeline systems.

-

Pump tube

Pump tubes have high pressure resistance and corrosion resistance and are widely used in liquid transportation and pump systems.

-

Extruded composite pipe

Advanced manufacturing combines alloys on the core's surfaces, providing excellent corrosion, hydrogen embrittlement, and wear resistance for automotive heat exchanger piping.

Diversified extrusion shapes and molds—saving mold costs

Chalco provides a wide range of extruded tube shapes, including round tubes, square tubes, rectangular tubes, etc., with a full range of molds to meet the needs of different projects. Most products can be exempted from mold opening fees.

Contact us now

Extruded round tube

The most common structural design, suitable for a variety of applications.

Extruded square tube

High strength and simple appearance, suitable for construction and furniture industries.

Extruded rectangular tube

It has high space utilization and is widely used in mechanical equipment and frame structures.

Extruded oval tube

Streamlined design, both beautiful and practical.

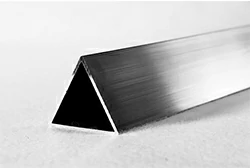

Extruded triangle tube

Unique shapes to suit specific engineering needs.

Extruded hexagonal tube

Multi-faceted design for increased stability and strength.

U-shaped tube

Meet special connection and installation requirements.

Customized/Irregular tube

Customized according to customer requirements to meet diverse design needs.

Extruded structural tube

Chalco's extruded structural tubes include grooved, cylinder, and reinforced rib tubes, offering customizable solutions with various shapes and die options. These are ideal for frames, pneumatic systems, and high-strength applications, while reducing mold opening costs.

Contact us now

-

Extruded cylinder tube

Extruded cylinder tubeSlotted aluminium tubes for frame and connection systems.

-

Slotted aluminum tube

Slotted aluminum tubeFor use in pneumatic systems, with high-precision inner diameter and smooth surface.

-

Reinforced tube

Reinforced tubeReinforced rib structure provides extra strength for applications with high load bearing and pressure requirements.

Buy Chalco extruded tube by alloy

When purchasing Chalco extruded tubes, you can choose the most suitable aluminum alloy material according to different alloy requirements. We offer a variety of aluminum alloy extruded tubes, including 6061, 6063, 5052, 3003, 7075 and other common alloy series to meet the needs of different industrial applications.

Whether it is high strength 7075 alloy for aerospace and military applications, or 5052 alloy with good corrosion resistance for marine environments or transportation vehicles, Chalco can provide you with high quality aluminum tube solutions. We provide customized services to ensure that each project can obtain the best alloy selection and tube specifications to meet your specific needs.Quick Quote

- 6061 T4 T5 T6 Aluminum Alloy

- 6063 T5 T6 Aluminum Alloy

- 6082 T6 T651 aluminum alloy

- 2024 T3 T6 T8 aluminum alloy

- 2014 T6 Aluminum Alloy

- 3003 H14 H24 Aluminum Alloy

- 7075 T6 T651 aluminum alloy

- 7050 T6 T7451 aluminum alloy

- 7055 T6 T7751

- 5052 H32 H34 H38 aluminum alloy

- 5083 H111 H112 aluminum alloy

- 1100 H14 H24 Aluminum Alloy

Why choose Chalco as your supplier for your aluminum extrusion tube project?

Chalco is your ideal partner for your aluminum alloy extruded tube project with its strong production capacity, advanced technology and strict quality control. We are committed to providing customers with high-quality aluminum tube solutions to meet the needs of various industries.Quick Quote

- Strong extrusion capabilities: Chalco has advanced aluminum alloy extrusion technology and can provide a variety of standard and customized specifications of aluminum tubes. Whether it is round tubes, square tubes, rectangular tubes, or oval tubes, triangle tubes, special-shaped tubes, etc., we can produce them accurately to ensure that each product meets high quality standards.

- Precision processing technology: Our production line is equipped with modern equipment to ensure that the dimensional accuracy and surface quality of each aluminum tube reaches the industry-leading level. Whether it is small batch customization or large-scale production, Chalco can ensure product consistency and high performance.

- Complete molds, free mold fees: Chalco has a rich mold library and can provide aluminum alloy extruded tubes in various specifications and shapes. For most extruded products, we provide free mold fee services to help customers save costs and speed up delivery time.

- Quality Assurance and Strict Testing: Chalco strictly implements quality control during the production process to ensure that each aluminum tube meets international quality standards. We have professional testing equipment and teams to conduct comprehensive product testing, including dimensional accuracy, strength, surface quality and other tests to ensure that the product is in the best condition before delivery. Our quality management system complies with ISO standards to ensure that each batch of products is stable and reliable.

One-stop shopping experience - complete range of products, sizes, moulds and additional services

At Chalco, we not only provide high-quality aluminum alloy extruded tubes, but also provide you with a one-stop shopping experience. Whether you need standard products or customized requirements, we can meet them and provide a full range of additional services to ensure that your project is completed smoothly.Quick Quote

- Comprehensive product and size selection: Chalco offers a variety of aluminum alloy extruded tube shapes and sizes, including round tubes, square tubes, rectangular tubes, oval tubes, triangular tubes, hexagonal tubes, etc. Whatever your project needs, we can provide suitable aluminum tube products to meet different industry standards.

- Wide range of service industries: Chalco's aluminum alloy extruded tubes are widely used in multiple industries, including construction, aerospace, automotive, machinery, marine, energy, etc. We are well aware of the specific needs of different fields and can provide customized aluminum tube solutions for all walks of life to ensure the smooth implementation of each project.

- Tailor-made to perfectly match your needs: Chalco provides tailor-made aluminum tube solutions for each project to ensure that your specific needs are met. From product design to processing, our professional team will work closely with you to ensure that every need is perfectly realized.

- Rich additional processing services: In order to meet the needs of different customers, we provide a variety of additional processing services.

| Additional Services | Description |

| Aluminum tube bending | Our aluminum tube bending services ensure that the product fits perfectly into your structural design without compromising strength and appearance. |

| Aluminum pipe connection | Chalco provides two methods: mechanical connection and welding to meet the needs of different projects. According to customer requirements, we can provide bolts, rivets, clamps, plugs, grooves and other connection methods to ensure that the aluminum tube connection is stable and reliable. |

| Aluminum tube welding | We provide TIG, MIG and other welding services to firmly combine the joints of aluminum tube products to ensure the strength and stability of the structure. They are widely used in construction, automobiles, machinery and other fields. |

| Surface treatment services | Chalco provides a variety of aluminum tube surface treatment services, including anodizing, electrophoretic coating, spraying, polishing, etc., and can provide different surface effects according to customer needs. These surface treatments not only improve the corrosion resistance of aluminum tubes, but also improve their appearance and ability to adapt to different environments. |

Chalco extruded aluminum tube cooperation areas

Aluminum alloy extruded tubes are widely used in many industries due to their light weight, high strength, corrosion resistance and other characteristics. Whether it is aerospace, automobile manufacturing, or construction, marine and other fields, aluminum alloy extruded tubes can provide excellent performance. With the continuous advancement of technology, our products can meet the needs of different industries and provide customers with efficient and reliable solutions.

Automotive industry

Aluminum alloy extruded tubes are widely used in the automotive industry in areas such as car bodies, engines, and cooling systems, providing lightweight and high-strength support to improve vehicle performance and fuel efficiency.

Contact us now

Common alloys: 6061, 5052, 7075

Common products: large diameter extruded tubes, extruded seamless tubes, extruded finned tubes

Application area:

- Large diameter extruded tubes: used for body frames, exhaust systems

- Extruded seamless pipe: used in hydraulic systems, fuel delivery

- Extruded fin tubes: used in heat exchange systems, radiators

Transportation industry

Aluminum alloy extruded tubes are an important choice for vehicle frames, exhaust systems and other components in the transportation industry due to their lightweight, high strength and corrosion resistance.

Contact us now

Common alloys: 6061, 5052, 7075

Common products: large diameter extruded pipes, extruded seamless pipes, extruded structural pipes

Application area:

- Large diameter extruded tubes: for vehicle frames, exhaust systems

- Extruded seamless pipe: used in fuel delivery systems, hydraulic systems

- Extruded structural tube: used for body brackets, connectors

Building and construction industry

In the building and construction industry, aluminum alloy extruded tubes are often used in frames, brackets and building facades to provide structural support and decorative effects due to their excellent corrosion resistance and aesthetics.

Contact us now

Common alloys: 6063, 6061, 5052

Common products: large diameter extruded tubes, extruded structural tubes, extruded thin-walled tubes

Application area:

- Large diameter extruded tubes: used for building frames, supporting structures

- Extruded structural tube: used for building connectors and brackets

- Extruded thin-walled tubes: used for architectural decoration and facades

Aerospace industry

Aluminum alloy extruded tubes are often used in the aerospace field for aircraft fuselages, engine components, etc. due to their light weight and high strength, ensuring structural strength while reducing weight.

Contact us now

Common alloys: 2024, 7075, 7050

Common products: large diameter extruded tubes, extruded seamless tubes, extruded microchannel tubes

Application area:

- Large diameter extruded tubes: used for aircraft fuselages, structural supports

- Extruded seamless pipe: used in fuel system, hydraulic system

- Extruded microchannel tubes: for cooling systems, heat exchangers

Marine industry

Aluminum alloy extruded tubes are widely used in ship structures, offshore platforms and other fields due to their excellent corrosion resistance and strength, ensuring long-term use in harsh marine environments.

Contact us now

Common alloys: 5083, 6061, 7075

Common products: large diameter extruded tubes, extruded seamless tubes, extruded finned tubes

Application area:

- Large diameter extruded tube: used for hull structure, offshore platform support

- Extruded seamless pipe: used for marine pipelines, hydraulic systems

- Extruded fin tubes: for marine heat exchange systems

Military and defense industry

In the military and defense industry, aluminum alloy extruded tubes are widely used in high-demand fields such as weapon systems, fighter jets, and military equipment due to their strength and corrosion resistance.

Contact us now

Common alloys: 7050, 7075, 6061

Common products: large diameter extruded pipes, extruded seamless pipes, extruded structural pipes

Application Area:

- Large diameter extruded tubes: used for military equipment, fighter aircraft structures

- Extruded seamless pipe: used in weapon systems, hydraulic systems

- Extruded structural tube: used for load-bearing components and connectors

Compressed gas storage industry

In the field of compressed gas storage, aluminum alloy extruded tubes are widely used in gas storage systems due to their high strength and corrosion resistance to ensure safe and efficient storage of gas.

Contact us now

Common alloys: 6061, 7075, 5052

Common products: extruded seamless pipes, extruded structural pipes, extruded large diameter pipes

Application area:

- Extruded seamless pipe: used for gas transportation and storage pipelines

- Extruded structural tube: Support structure for gas storage tanks

- Extruded large diameter pipe: for large gas storage systems

Energy industry

Aluminum alloy extruded tubes provide lightweight and high corrosion resistance in the energy industry, especially in oil, natural gas, heat exchange and pipeline transportation systems, ensuring the efficiency and safety of the system.

Contact us now

Common alloys: 6061, 5052, 7075

Common products: extruded seamless tubes, extruded microchannel tubes, extruded composite tubes

Application area:

- Extruded seamless pipe: used for oil and gas pipelines

- Extruded microchannel tubes: used in heat exchange systems, cooling systems

- Extruded composite pipe: Pipes for high corrosion resistance and resistance to hydrogen embrittlement

Chalco standard hollow profile extrusion die size reference

| Round shape | |||||

| OUTSIDE DIAMETER x WALL THICKNESS | OUTSIDE DIAMETER x WALL THICKNESS | OUTSIDE DIAMETER x WALL THICKNESS | OUTSIDE DIAMETER x WALL THICKNESS | OUTSIDE DIAMETER x WALL THICKNESS | OUTSIDE DIAMETER x WALL THICKNESS |

| 0.625 X 0.156 | 2.250 X 0.125 | 3.250 X 0.375 | 4.500 X 1.000 | 6 X 1.250 | 8.250 X 0.500 |

| 1 X 0.125 | 2.250 X 0.188 | 3.250 X 0.500 | 4.750 X 0.375 | 6.250 X 0.375 | 8.250 X 0.625 |

| 1 X 0.250 | 2.250 X 0.250 | 3.250 X 1.000 | 4.750 X 0.500 | 6.250 X 0.500 | 8.300 X 0.375 |

| 1.125 X 0.188 | 2.250 X 0.375 | 3.500 X 0.125 | 4.750 X 1.000 | 6.250 X 0.750 | 8.500 X 0.500 |

| 1.125 X 0.125 | 2.250 X 0.500 | 3.500 X 0.250 | 5 X 0.125 | 6.250 X 1.000 | 8.500 X 0.750 |

| 1.250 X 0.125 | 2.500 X 0.065 | 3.500 X 0.375 | 5 X 0.188 | 6.500 X 0.130 | 8.500 X 1.000 |

| 1.250 X 0.188 | 2.500 X 0.125 | 3.500 X 0.500 | 5 X 0.250 | 6.500 X 0.250 | 9 X 0.040 |

| 1.250 X 0.250 | 2.500 X 0.188 | 3.500 X 0.625 | 5 X 0.375 | 6.500 X 0.500 | 9 X 0.750 |

| 1.375 X 0.062 | 2.500 X 0.250 | 3.500 X 0.750 | 5 X 0.500 | 6.500 X 1.000 | 9 X 1.000 |

| 1.375 X 0.125 | 2.500 X 0.350 | 3.750 X 0.250 | 5 X 0.750 | 6.625 X 0.625 | 9 X 2.000 |

| 1.500 X 0.188 | 2.500 X 0.375 | 3.750 X 0.500 | 5 X 1.000 | 6.750 X 0.375 | 9.500 X 0.750 |

| 1.500 X 0.250 | 2.500 X 0.500 | 3.750 X 0.750 | 5.125 X 0.563 | 7 X 0.064 | 10 X 0.094 |

| 1.500 X 0.375 | 2.500 X 0.625 | 3.750 X 1.063 | 5.250 X 0.500 | 7 X 0.250 | 10 X 0.250 |

| 1.625 X 0.250 | 2.625 X 0.789 | 4 X 0.125 | 5.250 X 1.000 | 7 X 0.500 | 10 X 0.500 |

| 1.625 X 0.312 | 2.750 X 0.125 | 4 X 0.188 | 5.250 X 1.375 | 7 X 0.750 | 10 X 1.000 |

| 1.750 X 0.065 | 2.750 X 0.250 | 4 X 0.250 | 5.500 X 0.052 | 7 X 1.000 | 10 X 2.000 |

| 1.750 X 0.083 | 2.750 X 0.375 | 4 X 0.313 | 5.500 X 0.125 | 7 X 1.500 | 10.500 X 0.375 |

| 1.750 X 0.125 | 2.750 X 0.500 | 4 X 0.375 | 5.500 X 0.375 | 7.154 X 0.001 | 10.500 X 0.500 |

| 1.750 X 0.188 | 2.750 X 0.688 | 4 X 0.500 | 5.500 X 0.500 | 7.250 X 6.825 | 10.500 X 1.000 |

| 1.750 X 0.250 | 2.937 X 0.281 | 4 X 0.625 | 5.500 X 0.750 | 7.500 X 0.375 | 10.500 X 1.750 |

| 1.750 X 0.281 | 2.953 X 0.394 | 4 X 0.750 | 5.500 X 1.000 | 7.500 X 0.500 | 11 X 1.000 |

| 1.750 X 0.375 | 3 X 0.125 | 4 X 1.000 | 5.906 X 0.394 | 7.500 X 1.000 | 12 X 0.250 |

| 1.875 X 0.375 | 3 X 0.134 | 4.250 X 0.250 | 6 X 0.058 | 7.900 X 1.750 | 12 X 0.500 |

| 2 X 0.065 | 3 X 0.188 | 4.250 X 0.375 | 6 X 0.125 | 8 X 0.125 | 12 X 1.000 |

| 2 X 0.125 | 3 X 0.250 | 4.250 X 0.500 | 6 X 0.250 | 8 X 0.250 | 12.750 X 0.500 |

| 2 X 0.188 | 3 X 0.375 | 4.250 X 1.000 | 6 X 0.375 | 8 X 0.500 | 13.750 X 0.552 |

| 2 X 0.250 | 3 X 0.500 | 4.500 X 0.250 | 6 X 0.500 | 8 X 0.694 | 16 X 0.500 |

| 2 X 0.352 | 3 X 0.750 | 4.500 X 0.375 | 6 X 0.750 | 8 X 0.750 | |

| 2 X 0.375 | 3.250 X 0.125 | 4.500 X 0.500 | 6 X 1.000 | 8 X 1.000 | |

| 2 X 0.500 | 3.250 X 0.250 | 4.500 X 0.750 | 6 X 1.125 | 8.100 X 1.125 | |

| Square shape | |||||

| SIZE x WALL THICKNESS | SIZE x WALL THICKNESS | SIZE x WALL THICKNESS | SIZE x WALL THICKNESS | SIZE x WALL THICKNESS | SIZE x WALL THICKNESS |

| 0.750 X 0.062 | 1 X 0.125 | 1.750 X 0.125 | 2 X 0.250 | 3 X 0.250 | 6 X 0.188 |

| 0.750 X 0.125 | 1.250 X 0.065 | 2 X 0.062 | 2.500 X 0.250 | 3 X 0.375 | 6 X 0.250 |

| 0.750 X 0.750 | 1.250 X 0.125 | 2 X 0.120 | 2.500 X 2.500 | 4 X 0.125 | 6 X 0.500 |

| 1 X 0.062 | 1.250 X 1.250 | 2 X 0.125 | 3 X 0.125 | 4 X 0.250 | 8 X 0.188 |

| 1 X 0.080 | 1.500 X 0.125 | 2 X 0.188 | 3 X 0.188 | 4 X 0.500 | |

| Rectangular shape | ||||

| HEIGHT | x | WIDTH | x | WALL THICKNESS |

| 0.5 | X | 1 | X | 0.125 |

| 0.75 | X | 2 | X | 0.187 |

| 1 | X | 1.5 | X | 0.125 |

| 1 | X | 2 | X | 0.125 |

| 1 | X | 3 | X | 0.125 |

| 1.25 | X | 2.5 | X | 0.125 |

| 1.5 | X | 0.75 | X | 0.125 |

| 1.5 | X | 2 | X | 0.125 |

| 1.5 | X | 3.75 | X | 0.188 |

| 1.5 | X | 5 | X | 0.188 |

| 1.75 | X | 4 | X | 0.125 |

| 2 | X | 1 | X | 0.125 |

| 2 | X | 1.5 | X | 0.125 |

| 2 | X | 3 | X | 0.125 |

| 2 | X | 6 | X | 0.125 |

| 2.5 | X | 1.25 | X | 0.125 |

| 2.52 | X | 1.6 | X | 0.08 |

| 3 | X | 1 | X | 0.12 |

| 3 | X | 1.5 | X | 0.188 |

| 3 | X | 2 | X | 0.125 |

| 3 | X | 2 | X | 0.25 |

| 3 | X | 6 | X | 0.188 |

| 3.396 | X | 1.25 | X | 0.09 |

| 4 | X | 2 | X | 0.125 |

| 5 | X | 2 | X | 0.125 |

| 6 | X | 4 | X | 0.125 |

| 6 | X | 4 | X | 0.5 |

Extruded aluminum tube product selection guide

When choosing extruded aluminum tube products, it is important to understand the different types, processing methods, specification requirements and related services. Here are answers to some common questions to help you make an informed choice.

1. The difference between extruded tube and drawn tube

- Extruded tubes are made by heating aluminum alloy raw materials and extruding them through a die. Extruded tubes have high precision and good surface quality and are suitable for a variety of industrial applications.

- Drawn tubes are formed by stretching aluminum tubes and are usually used for more delicate tube production, suitable for applications that require higher wall thickness uniformity and precision. The production process of drawn tubes is usually slower and suitable for small batches and high precision products.

2. The difference between forward extrusion and reverse extrusion tube

- Direct extrusion refers to the extrusion of aluminum alloy raw materials from the inlet end of the die. It is suitable for conventional aluminum tube production and is usually used to produce shorter or more standard-sized aluminum tubes.

- Reverse extrusion refers to the extrusion of aluminum alloy raw materials from the outlet end of the die. It is usually used for more complex aluminum tube shapes. It can better control the wall thickness and shape of the tube and is suitable for high-demand customized products.

3. The difference between extruded seamless pipe and extruded structural pipe

- Extruded seamless pipe: produced by extrusion process, ensuring seamless pipe, smooth inner and outer surfaces, excellent pressure resistance and strength, suitable for high pressure, high strength applications, such as fuel delivery system, hydraulic system, etc. They usually have small tolerances and are suitable for occasions requiring high precision and quality.

- Extruded structural tubes: Extruded structural tubes are more commonly used in situations where structural forces need to be carried, and are usually used in frames and supporting structures. Their shapes and cross-sections can be customized according to demand, such as round, square, rectangular, etc., and are widely used in construction, automobiles, machinery and other fields. Compared with seamless tubes, structural tubes are usually lower in strength and pressure resistance, but they perform well in load bearing and structural stability.

| Characteristic | Extruded seamless pipe | Extruded structural tube |

| Advantage |

- Higher strength, stronger resistance to deformation and internal pressure - Uniform appearance after anodizing |

- Very consistent wall thickness around the cross section - Extrusion speed is faster than seamless pipe, reducing costs - Multiple openings can be installed in a single die when extruding small cross sections, increasing efficiency |

| Shortcoming |

- Extrusion process is slower and increases costs - Poor concentricity between inner and outer diameters - Seams are susceptible to corrosion (although most aluminum alloys are not susceptible to corrosion) |

- Welds can create weak areas that are susceptible to breakage - There may be visible seams on the surface, which will be highlighted after anodizing |

| Applicable scenarios |

- Applications involving large internal pressure or deformation - Occasions with high requirements on appearance |

- Cost-sensitive applications, suitable for load-bearing structures and frames - Not involving high pressure or large deformation |

| Selection suggestions |

- If the application involves internal pressure or deformation, choose seamless pipe - When the appearance requirements are very high, choose seamless pipes |

- If cost reduction is a priority, choose structural pipe - structural applications that do not involve high stresses |

4. Quote for the quantity of extruded aluminum tubes

Quotations for extruded aluminum tubes are usually determined based on factors such as order quantity, specifications, shape, alloy type, and whether custom processing is required. Generally speaking, larger orders result in lower unit prices; small orders may incur additional costs. In order to obtain an accurate quotation, it is recommended to provide detailed demand information.

5. How is the weight of extruded aluminum tube calculated?

The weight of the extruded aluminum tube can be calculated by the following formula:

Weight = pipe length × (outer diameter 2 − inner diameter 2 ) × π / 4 × density

The outer diameter and inner diameter are the dimensions of the pipe, and the density is usually the standard density of aluminum alloy (approximately 2.7 g/cm³).

6. Extruded aluminum tube packaging and transportation

Extruded aluminum tubes are usually packaged in wooden boxes, cartons or waterproof films to prevent damage during transportation. The transportation method can be selected by land, sea or air according to customer needs. For long-distance transportation, standard pallets and bundling methods are used to ensure the safety of the tubes.

7. What are the advantages of using aluminum alloy extruded tubes compared to other materials such as steel?

- Lightweight: Aluminum alloy is lighter than steel and has a lower weight, making it suitable for applications that require reducing overall weight.

- Corrosion resistance: Aluminum alloy has good corrosion resistance, especially in wet environments, and performs better than steel.

- Processability: Aluminum alloy is easy to process and shape, and can meet more complex design requirements.

- Cost-effectiveness: The production cost of aluminum alloy extruded tubes is relatively low, making them suitable for large-scale production.

8. Are there different grades of aluminum alloy used in extruded aluminum tubes? How do they affect the performance?

Yes, there are different grades of aluminum alloys used in extruded aluminum tubes; the common ones include:

- 1000 Series: Pure aluminum with excellent corrosion resistance but lower strength for light duty applications.

- 2000 series: Aluminum-copper alloy, with higher strength, commonly used in the aerospace field.

- 3000 Series: Aluminum-manganese alloy, good corrosion resistance and medium strength, suitable for construction and home appliance industries.

- 5000 series: Aluminum-magnesium alloy, with excellent corrosion resistance and good strength, widely used in shipbuilding and chemical industries.

- 6000 series: Aluminum-magnesium-silicon alloy, a common material for construction, transportation and mechanical applications, with good comprehensive properties.

- 7000 Series: Aluminum-zinc alloys with very high strength, widely used in aerospace and high-strength applications.

- Different aluminum alloy grades have an important influence on the strength, corrosion resistance, processing performance and other aspects of aluminum tubes. Choosing the right alloy can ensure the performance of the product in a specific application.

9. Do you supply black extruded aluminum tubes?

Yes, Chalco offers black extruded aluminum tubes. We can treat the aluminum tube surface to black through surface treatment processes such as anodizing, electrophoretic coating, etc. to meet specific design requirements. Black aluminum tubes not only have an aesthetic appearance, but also enhance the corrosion resistance of the aluminum tube, which is suitable for a variety of industrial applications.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote