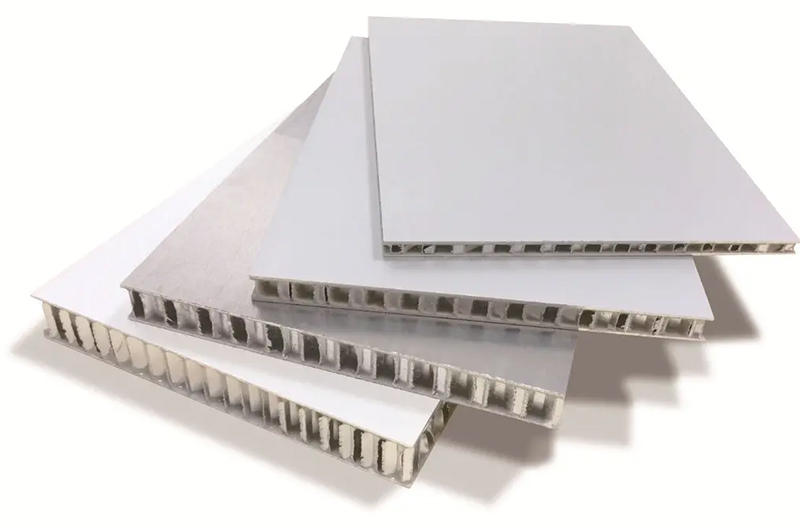

Aluminum alloy honeycomb panel is an aluminum composite panel composed of two cover plates and one aluminum honeycomb core. It is suitable for various applications in transportation, industry, or construction, demonstrating excellent product characteristics such as exceptional flatness, multiple colors, and high formability.

The decorative surface of Chalco aluminum honeycomb plate is flatness and neat, straight and neat cut edges without burrs, no exposed aluminum honeycomb cores on the front and back sides, and no obvious cracks at the folded edges; The non decorative surface has no damage that affects the use of the product, and the product has no degumming.

Detailed information of Chalco aluminum honeycomb plate

| Specification of Chalco aluminum honeycomb plate | |

| Alloy of the honeycomb core | 3003, 3005, 3103, 3104, 5052, 5056 |

| Alloy of the aluminum panel | 1100, 2024, 3003, 3014, 5005, 6063, 7075 |

| Factory Certificate | BSI ISO 9001, ISO 14001, Nadcap |

| Certification of product quality |

EN 13501-1 A2, GB8624-2006 A2-s2 d0, ASTM E84 – 10a, EN 45545 Aluminum panel: AMSQQ-A-250, GB/T 3880.2, etc. Aluminum honeycomb core: AMS-C-7438, etc. Film adhesive: AMS-A-25463 1, GB 18583, etc. |

-

Chalco aluminum honeycomb core

Main alloy grades of 3003, 3005, 3103, 3104, 5052 and 5056. Aluminum alloy core materials can be supplied separately.

-

Chalco aluminum honeycomb panel plate

Chalco aluminum alloy honeycomb plates are made of high-quality aluminum panels such as 1100, 2024, 3003, 3014, 5005, 6063, 7075, etc.

-

Honeycomb plate composite method

Double sided bonding, hot melt bonding, mechanical connection, impregnation, press bonding, chemical bonding, brazing and other composite methods.

Chalco aluminum honeycomb core material

The Chalco aluminum honeycomb core is a widely favored high-performance honeycomb material, recognized for its exceptional strength-to-weight ratio and outstanding adhesive properties.

Aluminum alloy: 3003, 3005, 3103, 3104, 5052, 5056

Thickness of the honeycomb core: 0.045", 0.17", 0.245", 0.42", 0.55" , 0.67", 0.92", etc.

Product features of Chalco aluminum honeycomb core material

- High Strength-to-Weight Ratio: The Chalco aluminum honeycomb core is distinguished by its excellent strength-to-weight ratio, allowing it to reduce structural weight while enhancing the overall strength of composite materials. It is highly suitable for applications requiring lightweight yet strong materials.

- Exceptional Bonding Performance: The aluminum honeycomb core bonds effectively with face sheet materials, ensuring the reliability and durability of composite structures.

- Easy to Transport and Process: In its unexpanded (block) form, the aluminum honeycomb core is compact and easy to transport, which reduces costs and minimizes damage risks. The block material can be easily expanded into full sheets without the need for complex equipment or processing.

Chalco aluminum hobeycomb core material product forms

- Microcellular Honeycomb Core: Features small cell sizes and high density, ideal for applications requiring soundproofing, thermal insulation, and precise airflow control.

- Corrugated Honeycomb Core: With corrugated cells, this core offers enhanced compressive strength and stability, suitable for high-strength and durable applications.

- High-Density Honeycomb Core: Smaller cell sizes and higher density provide stronger load-bearing capacity and improved thermal insulation, commonly used in aerospace and automotive industries.

- 3D Honeycomb Core: Designed with a three-dimensional structure, offering increased strength, stability, and resistance to impact and high temperatures.

Mechanical advantages of Chalco aluminum honeycomb core

Aluminum honeycomb core material is commonly utilized in sandwich panel structures, where the honeycomb core is sandwiched between two face sheets to create a strong yet lightweight panel. This structure has a unique advantage: the honeycomb core layer maintains distance between the face sheets and prevents them from moving relative to each other, significantly enhancing panel rigidity. This mechanical advantage enables the composite structure to achieve high strength with minimal weight increase.

Chalco aluminum honeycomb panel plate

Panel aluminum alloy:1100, 2024, 3003, 3014, 5005, 6063, 7075, etc.

Thickness of the aluminum panel:0.125", 0.25", 0.375", 0.5", 0.625", 0.75", 1" etc.

Size of the aluminum honeycomb plate:1200*2400, 1400*3000, 1200*240, 1400*3000, 2000*6000, 2500*1250, 3120*1500, 1500*1000, 600*600 etc.

Product features of Chalco aluminum honeycomb panel plate

- Lightweight and High Strength: The honeycomb core structure of aluminum honeycomb panels provides a high strength-to-weight ratio, making them both lightweight and rigid.

- Excellent Sound and Thermal Insulation: The air gaps within the honeycomb core deliver effective sound and thermal insulation, ideal for applications requiring these properties.

- Superior Corrosion and Impact Resistance: Aluminum honeycomb panels are corrosion-resistant and moisture-resistant, making them durable for outdoor use.

Chalco aluminum hobeycomb panel plate product forms

- Flat Aluminum Honeycomb Panel (Open Edge)

- Closed Edge Aluminum Honeycomb Panel

- Boxed Aluminum Honeycomb Panel (with Brackets)

- Aluminum Honeycomb Panel with Embedded Profiles

- Curved Aluminum Honeycomb Panel (Open Edge)

- Custom Shaped Aluminum Honeycomb Panel

Chalco aluminum honeycomb panel custom processing options

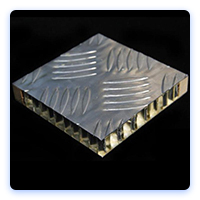

- Pattern Customization: Surface patterns like wood grain, stone texture, or custom graphics can be applied.

- Shape and Size Customization: Cutting, milling, drilling, and other processes allow for various shapes and sizes, such as flat, curved, or complex geometries.

- Edge Treatment: Options for open or closed edges, as well as folding, bending, and press molding to match different installation requirements.

- Structure and Connection Processing: Techniques like joining, fastening, and edge covering provide stability for the honeycomb structure.

- Surface Treatment: Aluminum honeycomb panels can undergo various surface treatments, including powder coating, anodizing, heat transfer printing, and additional finishes such as anti-fingerprint treatments, nano coatings, and other custom finishes to enhance both appearance and functionality.

Common sizes and thicknesses of aluminum honeycomb panel plate

Chalco aluminum honeycomb panels come in various sizes with multiple options for honeycomb core thickness, cell diameter, and panel thickness, all available in different specifications and in stock; please contact us for more information.Quick QuoteHot selling sizes: More customized sizes can click to check the [stock size table]

- 1 inch aluminum honeycomb panel large

- 1/2" aluminum honeycomb panel

- 1/2" aluminum honeycomb panel

- 1/2 aluminum honeycomb panel

- 1 4 aluminum honeycomb panel&

- 1.75" aluminum sandwich honeycomb panel

- .75 " honeycomb aluminum sign panel

- 3/8 aluminum honeycomb panel

- 3/8" aluminum honeycomb panel

- 48" × 84" honeycomb aluminum panel

- 4' x 8' honeycomb aluminum panel

- 4' × 7' 1 2 aluminum honeycomb panels

- aluminum honeycomb panels 4x8

Chalco aluminum honeycomb featured products

Aluminum honeycombe core slice-aerospace grade

Honeycomb core, composed of hexagon-shaped cells, is a lightweight, high-strength material originally developed for aircraft and now widely used in various industrial applications.Quick Quote

Brazed Honeycomb Panel

Brazed Honeycomb Panel is an aluminum honeycomb panel where the core is bonded to the face sheets through a brazing process. This creates a strong, durable bond, offering superior resistance to high temperatures and environmental conditions. Known for its lightweight, high-strength, and excellent thermal and acoustic insulation properties, it is ideal for aerospace, automotive, and architectural applications.Quick Quote

Perforated aluminum honeycomb plate or drilled aluminum honeycomb plate

The aluminum honeycomb panel can be perforated for air circulation and aesthetics, ideal for ventilation and lighting design; commonly used as a core material in vacuum workbenches and wind turbine blade mold. 6-hole perforation is the standard option, customizable.Quick Quote

Checkered surface aluminum honeycomb panels

The aluminum alloy honeycomb plate with checkered surface, combined with the anti-slip properties of patterned surfaces and the characteristics of honeycomb panels, has a wider range of applications.Quick Quote

Additional services for Chalco honeycomb aluminum plate

- Special shaped honeycomb panel: Edge honeycomb plate, curved honeycomb plate, 90 degree folding honeycomb plate, aluminum alloy honeycomb plate with V-shaped groove, 3D panel aluminum alloy honeycomb plate

- special die-cutting dimensions and tolerances product customization, CNC machining, cold and hot lamination, welding, destructive and non-destructive testing

- Precision processing: spray painting, chemical coating, powder coating, anodizing, polishing, heat transfer printing, drilling, embossing, etc.

- Surface treatment: PVDF, PE, anodizing, epoxy resin, sublimation printing, galvanized and other coatings.

Chalco not only provides aluminum honeycomb core materials and aluminum honeycomb panels but also offers various additional services for aluminum honeycomb panel products, delivering comprehensive solutions for your projects to make them more convenient and cost-effective. Contact for any issues.Quick Quote

Properties of Chalco aluminum honeycomb plate

| Property | Welding aluminum honeycomb plate | Adhesive bonded honeycomb plate | Adhesive bonded honeycomb plate with modified epoxy adhesive |

| Flatwise tensile strength | 6Mpa | 1.5Mpa | 2.0Mpa |

| Flatwise compressive strength | 5Mpa | 2Mpa | 2Mpa |

| Flatwise shear strength | 1.5Mpa | 0.5Mpa | 0.8Mpa |

| Drum peeling strength | 120N.mm/mm | 50N.mm/mm | 60N.mm/mm |

| Flexural strength | 100Mpa | 60Mpa | 60Mpa |

| Temperature resistance | Up to 600-degree Celsius | Up to 150-degree Celsius | up to 80-degree Celsius |

- Lightweight and low density

- High strength and good rigidity

- Good impact resistance and shock absorption

- Sound insulation, thermal insulation, flame retardancy, and moisture resistance

- Good formability and customizable thickness

- Pollution-free, energy-saving and environmentally friendly

- Beautiful appearance, easy to clean

9 major collaboration areas for Chalco aluminum honeycomb panel

-

Aircraft aluminum honeycomb plate

Aircraft aluminum honeycomb plateChalco aluminum honeycomb plate ensure that the internal structure of the aircraft meets strength and durability requirements.

-

Marine aluminum honeycomb plate

Marine aluminum honeycomb plateWith excellent moisture resistance, corrosion resistance, and toughness, widely used for wall and internal partitions of ships.

-

Auto aluminum honeycomb plate

Auto aluminum honeycomb plateReduce the weight and fuel consumption, create more efficient and sustainable electric vehicles.

-

Commercial vehicles and rail trains

Commercial vehicles and rail trainsVery suitable for commercial and rail vehicles. The panel can insert cables to meet specific requirements.

-

Military bulletproof honeycomb plate

Military bulletproof honeycomb plateIt is applied in the military and public sectors due to its extraordinary mechanical properties.

-

Building construction and ceiling plate

Building construction and ceiling plateLightweight, sturdy, weather resistant, insulated, soundproof, and fire-resistant, it is very suitable for exterior walls, floors etc.

-

Vacuum workbenches plate

Vacuum workbenches plateUsed for vacuum workbenches, with a reinforced structure, smooth surface, and uniform suction distribution.

-

Clean room honeycomb plate

Clean room honeycomb plateUsed by system engineers and manufacturing companies to create clean rooms or biological protection modules;

-

Signage aluminum honeycomb plate

Signage aluminum honeycomb plateA flat, weather resistant surface suitable for billboards, road signs with various surface treatments and color coatings.

Chalco other processed aluminum plate products

- Chalco porous aluminum foam sheet plate

- Chalco treat checkered aluminum plate

- Chalco stucco embossed aluminum coil

- Chalco aluminum corrugated preprinted sheets

- Chalco aluminum mirror sheet

- Chalco sublimation aluminum sheet

- Chalco deep drawing aluminum plates

- Chalco aluminum tooling & jig plate

6 FAQ for purchasing aluminum honey plate

1. How to purchase aluminum alloy honeycomb plates?

The decorative surface of aluminum alloy honeycomb plate should have a neat appearance, with straight and neat cut edges without burrs, no exposed aluminum honeycomb core on the front and back sides, and no obvious cracks at the folded edges; Non decorative surfaces are required to have no damage that affects the use of the product, and the product is not degummed.

2. How to find suppliers of aluminum alloy honeycomb plates that can be the long-term partner?

Aluminum alloy honeycomb plates have fierce competition in the aluminum product market due to their lightweight, high-strength, flexible assembly, and fire resistance, fatigue resistance, impact resistance, and other characteristics. It is a hot selling product for metal suppliers and distributors, aluminum manufacturers, e-commerce platforms, and other platforms.

However, it is not easy to choose a trustworthy long-term partner who can provide overall project solutions.

- Chalco, as a professional manufacturer and supplier of honeycomb aluminum plates, has a fully automated production line that can customize product sizes and shapes, and provide a variety of surface patterns.

- Chalco has collaborated with Mercedes Benz, Volkswagen, Ford, Lingyu Motors, Iveco, Kling Airways, Boeing, Airbus, and numerous construction companies, resulting in significant brand effects.

- Chalco can provide complete quality assurance and quality inspection certificates from production to testing, ensuring product quality;

- Chalco can provide free samples as a reference to dispel customer concerns from various aspects of production.

If you have any questions about purchasing aluminum honeycomb plates, do not hesitate to click the button and contact us. We are always welcome to your inquiry.

3. How to obtain the optimal quotation for aluminum alloy honeycomb plates?

Aluminum honeycomb plates are produced according to orders, and the price depends on various factors such as order quantity, size, configuration, processing, surface treatment, etc.

Chalco, with its own production and inventory advantages, will provide quotes based on your specifications to ensure the shortest delivery time, best quality, and most competitive prices. Please feel free to contact us for more details.

4. How to calculate the weight of aluminum honeycomb plate?

Dimensions of aluminum alloy honeycomb plates: length, width, and thickness of the plates.

Density of aluminum alloy: the density of aluminum is usually around 2.7 grams per cubic centimeter.

The type of honeycomb structure: different types of honeycomb structures have different density and strength characteristics. A honeycomb structure with lower density will result in lighter plates.

Weight calculation of aluminum alloy honeycomb panel:

Weight (kg)=Area (square meters) x Thickness (meters) x Density (kg/cubic meter)

Please note that this calculation method is an approximation as it does not take into account the effects of plate edges, borders, connections, and other complex structures. In practical applications, manufacturers usually provide detailed information about the weight of their products in order to estimate them more accurately.

5. Aluminum honeycomb plate or Aluminum-plastic composite plate, which is better?

In the construction or curtain wall industry, there are two popular types of composite panels: aluminum honeycomb plates and aluminum plastic composite panels. The two types of plates are similar on the surface, but the internal components of the two materials are different. Understanding the differences can help you make wise choices when making a purchase.

Aluminum honeycomb plate: it is a sandwich plate with a structural design where the upper and lower aluminum panels are attached to the aluminum honeycomb core. Equipped with polyester or fluorocarbon coating. The honeycomb board adopts a lighter honeycomb core layer than the plastic core, with a thickness of 12mm and 25mm. Due to its stable structure and low density, aluminum honeycomb plates are widely used in rocket fairings, automotive skins and doors, train bulkheads, building curtain walls, etc.

Aluminum plastic plate: like aluminum honeycomb plate, it is also a sandwich plate. It is formed by pressing two thin aluminum alloys and thermoplastic core materials, forming a sandwich shape. Aluminum plastic plates are made of plastic with a layer of PE or LDPE, with a thickness of 3mm to 8mm. Aluminum composite panels are commonly used for wall cladding, signage, and exterior walls. At present, the use of aluminum plastic panels has also been incorporated into the furniture industry, as they bond well with plywood or wood, giving kitchen or bathroom cabinets a gorgeous appearance.

6. Inventory dimensions and tolerance table for aluminum alloy honeycomb plates

Aluminum alloy honeycomb core is usually a hexagonal structure with a side length of 10mm or less.

Aluminum honeycomb core with a side length of less than or equal to 6mm, with an aluminum foil thickness of no less than 0.05mm;

The aluminum honeycomb core with a side length of 6 mm to 10 mm shall have an aluminum foil thickness of not less than 0.07 mm.

| Product size table for Chalco aluminum honeycomb plate | ||

| - | Thickness | Honeycomb unit size |

| 12*12 inch | 1/8" | 3/8" |

| 1/4" | 3/8" | |

| 3/8" | 1/4" | |

| 1/2" | 1/4" | |

| 3/4" | 1/4" | |

| 1" | 3/4" | |

| 24*24 inch | 1/8" | 3/8" |

| 1/4" | 3/8" | |

| 3/8" | 1/4" | |

| 1/2" | 1/4" | |

| 3/4" | 1/4" | |

| 1" | 3/4" | |

| 24*48 inch | 1/8" | 3/8" |

| 1/4" | 3/8" | |

| 3/8" | 1/4" | |

| 1/2" | 1/4" | |

| 3/4" | 1/4" | |

| 1" | 3/4" | |

| Allowable size deviation | ||

| Length L/mm | L≤2m | ±2 |

| L>2 m | ±3 | |

| Thickness/mm | ±0.25 | |

| Diagonal length difference | ≤3 | |

| Edge straightness /(mm/m) | ≤2 | |

| Evenness /(mm/m) | ≤2 | |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote