When producing aluminum alloy pressure vessels, the chosen aluminum alloy pipes must possess specific properties, including strength, processability, welding performance, heat resistance, and corrosion resistance.

Chalco's aluminum alloy pressure vessel tubes are used in boilers, pressure vessels, heat exchangers, etc., for storing energy such as crude oil, natural gas, and liquefied natural gas. They operate reliably in high-pressure, low-temperature, or high-temperature environments.

LIoyd's Register of Chalco aluminum pipe for pressure vessels

Chalco's Pressure Vessel Aluminum Pipe products have been approved by Lloyd's Register to the following standards ISO 9001:2015 GB/T 19001-2016. Approval number(s): ISO 9001 – 0067985.

For the detailed certification information, please send email to learn more. Quick Quote

| Specifications | Alloy and temper | Thickness |

| ASME SB-241/ SB-241M Aluminium alloy tubes & pipes | 5083 O; 5083 H112 | Outer diameter 20~200mm Thickness 2.0~15mm |

| 5052 O | Outer diameter 20~200mm Thickness 2.0~5mm | |

| EN 755.1-2016 Aluminium alloy tubes, pipes and rods | EN AW-5083 O; EN AW-5083 H112 tubes and pipes | Outer diameter 20~200mm Thickness 2.0~15mm |

| EN AW-5052 O tubes and pipes | Outer diameter 20~200mm Thickness 2.0~5mm |

Chalco aluminum pipe specifications for pressure vessels

Alloy: 5083 5086 6061 6063 3003 6351 1060

Temper: O H111 H112 T4 T5 T6 T4510 T4511 T51 T6510 T6511

Wall thickness: conventional 3.2-25 mm, other wall thicknesses can be customized upon consultation

Specification: ASME SB-241/ SB-241M, EN 755.1-2016, ASTM B274, ASTM B210, ASTM B241

Seamless aluminum tubes: the key to reliable pressure vessel solutions

Why do we recommend Chalco seamless aluminum tube for your pressure vessel project? It is because Chalco seamless aluminum tubes offer unmatched strength, reliability, and performance in high-pressure environments. Unlike welded tubes, seamless tubes are free from weak points, ensuring superior structural integrity. Their uniform wall thickness provides consistent strength, making them ideal for demanding applications like pressure vessels.

Additionally, Chalco seamless aluminum tubes boast excellent corrosion resistance, crucial for maintaining long-term durability in harsh conditions. With these features, Chalco seamless aluminum tubes are the optimal choice for your pressure vessel project, offering both safety and efficiency.Quick Quote

Certified alloy products: 1100, 2024, 2219, 3003, 5052, 5083, 5086, 6060, 6061, 6063, 6082, 7075

Specification: AMS QQ-A-200; ASTM B241; ASTM B345; WW-T-700; ASTM B-210; ASTM B234

Size: Standard wall thickness: SCH40/SCH80; all diameter and wall thickness can be customized according to project requirement.

Chalco featured seamless tube products

-

High-Precision Seamless Tube

Offers exceptional dimensional accuracy and surface quality, ensuring superior sealing and pressure resistance in pressure vessel applications.

-

Aluminum-Lithium Alloy Seamless Tubes

Lightweight, high-strength, and corrosion-resistant, ideal for high-performance pressure vessel requirements.

-

Thin-Walled Seamless Tubes

Available in both small and large diameters, these tubes provide excellent performance in pressure vessels with low to medium pressure applications.

-

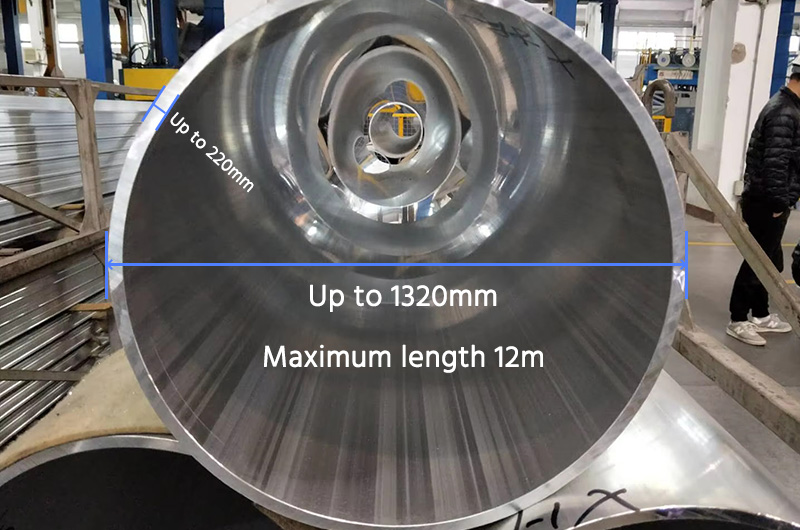

Thick-Walled Seamless Tube

Available in both small and large diameters, with a maximum diameter of 1320mm, ideal for high-pressure and heavy-duty pressure vessel applications.

Production of Chalco aluminum seamless tube

- Extrusioin: In the extrusion process, aluminum alloy material is heated and forced through a die to form a seamless tube. This method ensures uniformity and precision, suitable for various pressure vessel applications. Range diameter of Chalco extruded aluminum seamless tube: 1/2” - 18”.

- Drawing: The drawing process further shapes the extruded tube by pulling it through a die, ensuring consistent wall thickness, straightness, and surface finish. This is ideal for high-precision applications like pressure vessels. Range diameter of Chalco extruded aluminum seamless tube: 0.5” - 12” .

- Forging: Forging is used to produce high-strength seamless tubes, especially for pressure vessels. The material is heated and pressed into the desired shape, enhancing mechanical properties and resistance to high pressure.

Advantage of Chalco aluminum seamless tube in pressure vessel field

- Uniform Strength: Seamless tubes provide consistent strength throughout the entire length, ensuring the ability to withstand high internal pressure without weak points.

- No Weld Joints: The absence of welds in seamless tubes eliminates the risk of joint failures, which is critical in high-pressure environments.

- High Pressure Resistance: The continuous structure of seamless tubes offers superior resistance to pressure, making them ideal for applications where strength and safety are paramount.

- Enhanced Durability: Seamless tubes exhibit better fatigue resistance, reducing the likelihood of failure under repeated stress, which is essential for pressure vessels in dynamic conditions.

Chalco aluminum pipe solutions for pressure vessel systems

-

Aluminum pipe fittings for pressure vessels

-

Pressure pipelines for liquid transportation

-

Pressure vessel piping for gas transportation (aluminum air piping)

-

Pressure vessel pipes for food and drug processing industry

5083 aluminum tube pipe for pressure vessels

Temper: O H111 H112

5083 alloy has excellent corrosion resistance and high strength, making it suitable for marine environments. Mainly used to manufacture pressure vessels in marine engineering, such as ship fuel tanks and pipelines.

Contact us now

| Temper | Wall thickness mm | Tensile mechanical properties of 5083 aluminum tubes for pressure vessels in greenhouses | |||

| Tensile strength Rm MPa | Specified non-proportional elongation strength Rp0.2 MPa | Elongation after break % | |||

| A50mm | A | ||||

| not less than | |||||

| O | all | 270-350 | ≥110 | 14 | 12 |

| H111 | all | ≥275 | ≥165 | 12 | 10 |

| H112 | all | ≥270 | ≥110 | 12 | 10 |

6061 aluminum tube pipe for pressure vessels

Temper: T4 T6 T4510 T4511 T51 T6511

It has excellent strength and corrosion resistance and is suitable for applications with high strength requirements. Widely used in aerospace, automotive and industrial fields, such as aircraft fuel tanks and high-pressure gas cylinders.

Contact us now

| Temper | Wall thickness mm | Tensile mechanical properties of 6061 aluminum tubes for pressure vessels in greenhouses | |||

| Tensile strength Rm MPa | Specified non-proportional elongation strength Rp0.2 MPa | Elongation after break % | |||

| A50mm | A | ||||

| not less than | |||||

| T4 T4510 T4511 | all | ≥180 | ≥110 | 16 | 14 |

| T51 | ≤16 | ≥240 | ≥205 | 8 | 7 |

| T6 T6510 T6511 | ≤6.3 | ≥260 | ≥260 | 8 | - |

| >6.3 | ≥260 | ≥260 | 1 0 | 9 | |

6063 aluminum tube pipe for pressure vessels

Temper: T4 T5 T6

6063 alloy has good surface treatment properties and is suitable for applications requiring beautiful appearance. It is mainly used to manufacture pressure vessels with complex shapes, such as decorative gas bottles and special-purpose containers.

Contact us now

| Temper | Wall thickness mm | Tensile mechanical properties of 6 063 aluminum tubes for pressure vessels in greenhouses | |||

| Tensile strength Rm MPa | Specified non-proportional elongation strength Rp0.2 MPa | Elongation after break % | |||

| A50mm | A | ||||

| not less than | |||||

| T4 | ≤12.5 | ≥130 | ≥70 | 14 | 12 |

| >12.5-25.0 | ≥125 | ≥60 | - | 12 | |

| T5 | ≤12.5 | ≥150 | ≥110 | 8 | 7 |

| >12.5-25.0 | ≥145 | ≥105 | 8 | 7 | |

| T6 | ≤3.2 | ≥205 | ≥170 | 8 | - |

| 3.2-12.5 | ≥205 | ≥170 | 10 | 7 | |

5086 aluminum tube pipe for pressure vessels

Temper: O H111 H112

Alloy 5086 has properties similar to 5083, but is better in weldability. Suitable for pressure vessels in the marine and chemical fields that require welding, such as oil and gas storage tanks.

Contact us now

| Temper | Wall thickness mm | Tensile mechanical properties of 5086 aluminum tubes for pressure vessels in greenhouses | |||

| Tensile strength Rm MPa | Specified non-proportional elongation strength Rp0.2 MPa | Elongation after break % | |||

| A50mm | A | ||||

| not less than | |||||

| O | all | 240-315 | ≥95 | 14 | 12 |

| H111 | all | ≥250 | ≥145 | 12 | 10 |

| H112 | all | ≥240 | ≥95 | 12 | 10 |

3003 aluminum tube pipe for pressure vessels

Temper: O H112

It has good corrosion resistance and weldability, and is suitable for manufacturing pressure vessels with medium general requirements. Commonly used in general pressure vessels in food processing, chemical and other industries.

Contact us now

| Temper | Wall thickness mm | Tensile mechanical properties of 3003 aluminum tubes for pressure vessels in greenhouses | |||

| Tensile strength Rm MPa | Specified non-proportional elongation strength Rp0.2 MPa | Elongation after break % | |||

| A50mm | A | ||||

| not less than | |||||

| O | all | 95-130 | ≥35 | 25 | twenty two |

| H112 | all | ≥95 | ≥35 | 25 | twenty two |

1060 aluminum pipe tube for pressure vessels

Temper: O H112

1060 alloy belongs to the pure aluminum series and has good processability and thermal conductivity. Mainly used for pressure vessels with less stringent general requirements, such as household pressure cookers.

Contact us now

| Temper | Wall thickness mm | Tensile mechanical properties of 1060 aluminum tubes for pressure vessels in greenhouses | |||

| Tensile strength Rm MPa | Specified non-proportional elongation strength Rp0.2 MPa | Elongation after break % | |||

| A50mm | A | ||||

| not less than | |||||

| O | all | 60-95 | ≥15 | 25 | twenty two |

| H112 | all | ≥60 | ≥15 | 25 | twenty two |

6351 aluminum tube pipe for pressure vessels

Temper: T4 T6

It has high strength and hardness and is suitable for some applications requiring higher strength. Used in the manufacture of high-pressure gas cylinders and pressure vessels requiring high wear resistance.

Contact us now

| Temper | Wall thickness mm | mechanical properties of 6 351 aluminum tubes for pressure vessels in greenhouses | |||

| Tensile strength R m MPa | Specified non-proportional elongation strength Rp0.2 MPa | Elongation after break % | |||

| A50mm | A | ||||

| not less than | |||||

| T4 | all | ≥220 | ≥130 | 16 | 14 |

| T6 | ≤3.2 | ≥290 | ≥255 | 8 | - |

| 3.2-25.0 | ≥290 | ≥ 255 | 10 | 9 | |

Welding mechanical properties parameter table of aluminum pipes for Chalco pressure vessels

| Alloy grade and status | Tensile strength M P a | Yield strength M P a |

| 3003-H12 H14 H16 H18 | 95 | 50 |

| 5083-H111 | 270 | 145 |

| 5086-H111 | 240 | 125 |

| 5086-H112 | 240 | 95 |

| 6061-T6 T651b, c | 165 | 140 |

| 6061-T6 T651d | 165 | 105 |

| 6063-T5 T52 T6b, c | 15 | 75 |

| 6351-T6c, d | 165 | 140 |

|

a. at a gauge length of 250 mm. b. with 5183, 5356, and 5556 alloy wires, these values apply to pipes of all nominal wall thicknesses. When welding with 4043, 5154, 5254, 5554 alloy wires, these values also apply to standard pipes and tubes with a nominal wall thickness not greater than 10.00 mm. c. For pipes with a diameter less than 100 mm or a diameter-to-thickness ratio (D/t) less than 15, the actual strength value is slightly lower than the value in the table. d. When welding with 4043, 5154, 5254, and 5554 alloy wires, these values apply to pipes with a nominal wall thickness greater than 10.00mm. |

||

Chalco other aluminum products for pressure vessels

Chalco aluminum plate, aluminum rod and aluminum wire also approved by Lloyd's Register. If you have any pressure vessel projects in need of collaboration, we stand as your preferred partner. Feel free to reach out at any time for consultations; we welcome the opportunity to discuss how our expertise can contribute to the success of your endeavors.

Feel free to reach out at any time for consultations; we welcome the opportunity to discuss how our expertise can contribute to the success of your endeavors.

Aluminum plate for pressure vessels

Alloy: 1100 5083 3003 5182 5454 6061

Specification: ASME SB-209 Aluminum alloy sheets and plates; EN 485-1:2016 Aluminum alloy sheets, strips and plates; YS/T 69-2012 Clad aluminum alloy sheets & plates

Contact us now

Welding aluminum welding wire for Chalco pressure vessels

Alloy: 1100 4043 4047 5183 5356 5554 5556

Contact us nowChalco aluminum rods for pressure vessels

Alloy: 5083

Specification: EN 755.1-2016 Aluminum alloy tubes, pipes and rods

Contact us now

Advantages of Chalco aluminum products for pressure vessels

- Aluminum pipes have high strength, allowing them to maintain structural integrity when subjected to stress.

- Superior processability to ensure precision processing and assembly during container manufacturing;

- Good welding performance ensures that the welded joints of the container have excellent strength and sealing properties

- Excellent heat resistance and corrosion resistance ensure normal operation of pressure vessels in high temperature or corrosive environments.

Service industries of Chalco Aluminum Materials for Pressure Vessels

- Aluminum tubes are used to manufacture air compression cylinders, ensuring stable and safe pressure vessels.

- Aluminum tubes are widely used as gas containers in medical, industrial and scientific experiments.

- Aluminum tubes are used to manufacture various components of refrigeration equipment and withstand the pressure and temperature of the refrigerant.

- Aluminum pipes are used to manufacture gas transmission pipelines for transporting gases to various industrial sites.

- Aluminum tubes are used as fuel containers to propel rockets or missiles into flight.

- Aluminum tubes are used to make components such as air bags, braking systems and air compressors in cars, ensuring their safety and performance.

- Aluminum tubes are used as pressure vessels in the aerospace field to store gas or liquid in aircraft and spacecraft to ensure the normal operation of the aircraft.