Aluminum alloy roofing materials are lightweight, high-performance, and eco-friendly, used in residential, commercial, and industrial buildings. They include aluminum foil, insulation, panels, honeycomb, composite materials, and wide coils, catering to various needs.

These materials offer excellent corrosion and weather resistance, with surface treatments like varnish, color coating, anodizing, and polishing for enhanced aesthetics. They also provide recyclability, thermal insulation, and waterproofing, making them ideal for modern roofs.

Chalco aluminum roofing material product introduction

Product types:

- Bare aluminum foil for roofing

- Lacquered or color coated aluminum foil for roofing

- Thermal insulation materials

- Aluminum roofing panel

- Honeycomb and composite roofing materials

- Ultra-wide aluminum sheet coil

Alloy types: 1000 series (such as 1050, 1100, 1200) and 8000 series (such as 8011, 8079).

Width: Usually 600mm-2700mm, extra-wide specifications can be customized to meet the needs of large buildings.

Thickness: Common range 0.2mm-3.0mm.

- Lightweight roofing materials: 0.3mm-0.8mm (such as color-coated and embossed materials).

- High strength requirements: 1.5mm-3.0mm (such as aluminum coils for honeycomb composite panels).

Surface treatment: anodizing, color coating, embossing, mirror [Click to check the detailed information for surface treatment]

Roof panel material specification: AS 4200.1; NCC 2019, etc.

Chalco aluminum roofing material product type

Bare aluminum foil for roofing system

Aluminum foil is a flexible, lightweight material with good reflective properties. Due to these properties, it is an excellent choice for roofing as it acts as a radiant barrier, preventing heat transfer and increasing the energy efficiency of a building.

Contact us now

Chalco roofing aluminum foil stock alloys

- 1000 Series: Excellent corrosion resistance and thermal conductivity, ideal for mild climates, roofing, and decorative panels. Lightweight but low strength.

- 3000 Series: Good corrosion resistance and moderate strength, commonly used in roofing materials and wall panels, particularly in urban environments.

- 5000 Series: High strength and excellent corrosion resistance, especially in marine and coastal areas, ideal for roofing in harsh environments.

- 8000 Series: High strength, good formability, and wear resistance, perfect for roof insulation and honeycomb composites, suitable for environments requiring durability.

-

1050 aluminum foil

Known for its excellent corrosion resistance and high formability, it is ideal for general roofing applications.

-

1060 aluminum foil

Offers high purity and good electrical conductivity, making it suitable for reflective and insulation purposes in roofing.

-

1100 aluminum foil

Lightweight and highly resistant to corrosion, it is often used in roofing applications requiring malleability and durability.

-

1200 aluminum foil

Offers excellent resistance to oxidation and corrosion, commonly used in roofing systems where high durability is needed.

-

8011 Aluminum Foil

Known for its strength and resistance to moisture, it is often used in roofing systems with insulation and vapor barriers.

-

8079 aluminum foil

Offers high strength and excellent flexibility, making it ideal for use in roofing materials that require high performance under extreme conditions.

-

5052 aluminum foil

Highly resistant to corrosion and stress cracking, it is often used in roofing systems exposed to harsh environmental conditions.

-

3003 aluminum foil

Known for its excellent strength and corrosion resistance, it is commonly used in roofing materials for both residential and commercial buildings.

-

3105 aluminum foil

Offers excellent durability and corrosion resistance, often used in residential roofing applications requiring long-lasting performance.

Advantages of aluminum foil in roofing applications

- Insulation: Reflects 97% of radiant heat, maintaining indoor temperature.

- Cost Savings: Enhances thermal efficiency, reducing energy bills.

- Moisture Barrier: Blocks moisture, protecting roof structures.

- Condensation Control: Prevents mold and structural damage in cold climates.

- Corrosion Resistance: Ensures durability and longevity.

- Lightweight: Easy to handle and install, saving time and labor.

Lacquered or color coated aluminum foil for roofing

Lacquered or color-coated aluminum foil with coatings like PE, PVDF, and Fluorocarbon offers excellent durability, thermal insulation, and weather resistance, making it ideal for modern roofing systems.

Contact us now

Introduction of Chalco color coated aluminum foil

-

PE Coating

Bright colors, cost-effective, suitable for medium to short-term use in buildings and decorations.

-

PVDF Coating

Strong weather resistance, suitable for long-term outdoor use, widely used in high-end buildings and industrial facilities.

-

Nano PVDF

Enhanced pollution resistance, easy to clean, suitable for high-end building facades and solar roofs.

-

PVC Coating

Strong flexibility, good wear resistance, commonly used in waterproofing and industrial anti-corrosion materials.

-

Polyimide Coating

High temperature resistance, excellent chemical stability, suitable for extreme environments in aerospace and electronics industries.

-

Fluorocarbon Coating

Anti-aging, corrosion-resistant, color-stable, suitable for high-end buildings and coastal environments.

Roofing coating selection guide

- Cold Regions: Choose PVDF, Nano PVDF; excellent low-temperature resistance, condensation control, mold prevention, and structural protection.

- Hot Regions: Choose PE, PVDF, Fluorocarbon; high thermal insulation, heat reflection, energy-saving cooling.

- Moist or Rainy Areas: Choose PE, Fluorocarbon, PVDF; moisture and water resistance, corrosion resistance.

- Coastal Areas: Choose Fluorocarbon, PVDF; salt spray resistance, UV protection, corrosion resistance.

- Roof Drainage Areas: Choose PE, PVDF, Fluorocarbon; waterproof, corrosion-resistant, durable.

- Residential Roofs: Choose PE, PVDF; aesthetically pleasing, insulation, suitable for various design styles.

- Commercial Building Roofs: Choose PVDF, Fluorocarbon; strong weather resistance, UV protection, long lifespan.

- Industrial Building Roofs: Choose Fluorocarbon, PVDF; high-temperature resistance, corrosion resistance, suitable for harsh environments.

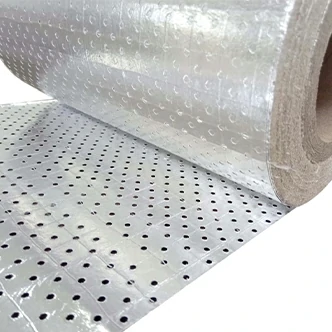

Thermal insulation material

Roof insulation materials are generally made of aluminum foil as a base and other materials, with excellent durability and adaptability. Aluminum foil is a thin and highly reflective material widely used in building insulation and heat preservation. It can reflect up to 96% of radiant heat.

Contact us now

Chalco roof insulation hot products

-

Standard/premium aluminum foil

Reflects up to 96% of radiant heat, while being lightweight, durable, corrosion-resistant, and moisture-resistant, with enhanced insulation when combined with other materials.

-

Perforated aluminum foil

Tiny holes allow air circulation to reduce condensation and mold growth, while offering enhanced durability, tear, corrosion, moisture, and mildew resistance in humid environments.

-

Roof bubble insulation

A heavy-duty, 6-layer FR-compliant composite structure with double-sided reflective aluminum, metal foil, bubble bags, and fiberglass mesh, offering 97% radiant heat reflectivity.

-

Woven foil

A 5-layer laminate with double-sided metallized material, 3-layer laminate with single-sided reflective foil, and adhesive-reinforced high-density polyethylene fabric, offering 50% reflectivity.

-

Leno foil

A 5-layer laminate with double-sided reflective material and flame-retardant polyethylene fabric, reflecting 97% of radiant heat and offering moisture-proof, tear-resistant, and mildew-resistant performance.

-

Avantgarde foil

An all-in-one system with 8mm PE foam and aluminum bubble foil, offering 97% reflectivity, excellent thermal insulation, reduced conduction heat, and noise.

-

Aluminum polyester Foil

Aluminum foil is laminated with polyester film for added strength and durability.Good tear resistance, suitable for long-term use. Suitable for roof, wall insulation and packaging.

-

Polymer foil

Aluminum foil compounded with polymer film (e.g., PET, PP) for improved tensile strength, corrosion and chemical resistance, and high flexibility for various applications.

-

Roof moisture-proof and heat-insulating film

Operating from -40°C to +80°C, this material offers excellent tear, corrosion, and moisture resistance, with longitudinal tear strength of ≥ 210 kN/m and ≥ 300 N/mm.

-

Fireproof insulation aluminum foil

Flame retardant woven, leno and bubble series foil that meets global standards. Effective protection from the elements. SIRIM approved and BOMBA certified

Features of Chalco roof insulation

- Highly reflective, effective heat insulation: Aluminum foil can reflect up to 96% of radiant heat, blocking heat radiation from entering in summer and reducing heat loss in winter.

- Lightweight and easy to handle: Aluminum foil is thin and light, easy to handle, quick and efficient to install, and suitable for thermal insulation of large-area buildings.

- Durability: Aluminum foil offers exceptional durability, extending the life of the insulation and resisting moisture and harsh environments.

- Moisture and mildew resistance: Aluminum foil acts as a moisture barrier, effectively preventing moisture infiltration and mildew growth. Perforated aluminum foil is particularly suitable for environments with large temperature differences.

- Use with other insulators: Aluminum foil can be compounded with PUR/PIR foam, plastic film, etc. to enhance tensile strength and adhesion.

Chalco aluminum foil insulation material other applications

- Buildings: Used for wall and roof insulation to improve building energy efficiency and reduce air conditioning and heating costs.

- Aerospace: Thermal management systems used in spacecraft, satellites, etc. to ensure stable temperature control.

- Cold chain transportation: As an insulating material for refrigeration and transportation, it maintains low temperatures and prevents heat loss.

- Power electronics: used for thermal insulation of cables and electrical equipment to increase stability and durability.

- Pipeline: Used for thermal insulation of industrial pipelines to reduce heat loss and prevent corrosion.

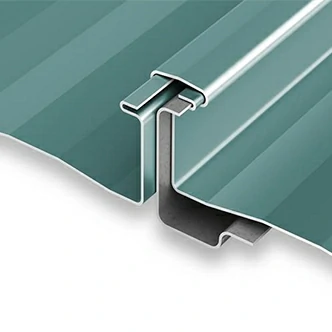

Aluminum roofing panel

Coil products used to make panels are sold by thickness in inches (usually as decimals), so the higher the number/decimal, the thicker the aluminum material.

For residential roof projects: .032 ” or .030”

For commercial roof projects: .040”

Copings or caps : .050 ” or .063 ”

Contact us now

-

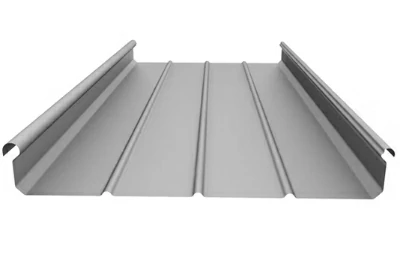

Standing seam roof panels

Unique "standing seam" design, excellent waterproof performance. High durability, adaptable to various climate environments. Simple and modern appearance, suitable for commercial and industrial buildings

-

Corrugated roof panels

Wave-shaped design provides excellent structural strength. Economical and efficient, high material utilization. Simple installation and quick construction

-

Box profile roof panels

Box-shaped profile design provides high compressive strength. Excellent wind resistance, suitable for harsh environments. Clean lines and a modern industrial look

-

Tile roof panels

Simulates traditional tile design for a classic and beautiful look. Lightweight and easy to install. Highly corrosion-resistant, suitable for long-term use

-

Sandwich roof panels

Sandwich design, excellent thermal insulation performance. Powerful sound insulation to reduce noise pollution. Energy-saving and environmentally friendly, suitable for green building needs

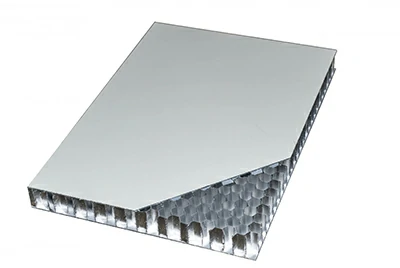

Honeycomb and composite aluminum roofing materials

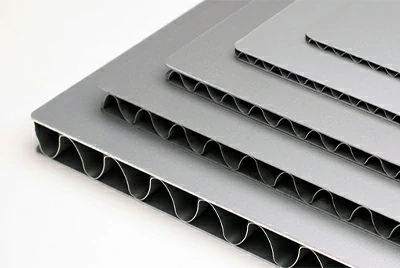

Honeycomb roof panels

The aluminum material with honeycomb structure has excellent strength and lightweight characteristics, suitable for roof projects requiring high performance.

Lightweight and strong

Excellent thermal insulation

High durability

Composite roofing materials

It is a composite of aluminum and plastic core material, combining decoration and practicality, and is often used in roof systems of high-end buildings.

Excellent decorative properties

Good rigidity

Easy installation

Sandwich composite aluminum plate

Made of aluminum panels and insulation materials like polyurethane or rock wool, ideal for energy-efficient and eco-friendly roofs.

Excellent thermal insulation

Good sound insulation

High strength and light weight

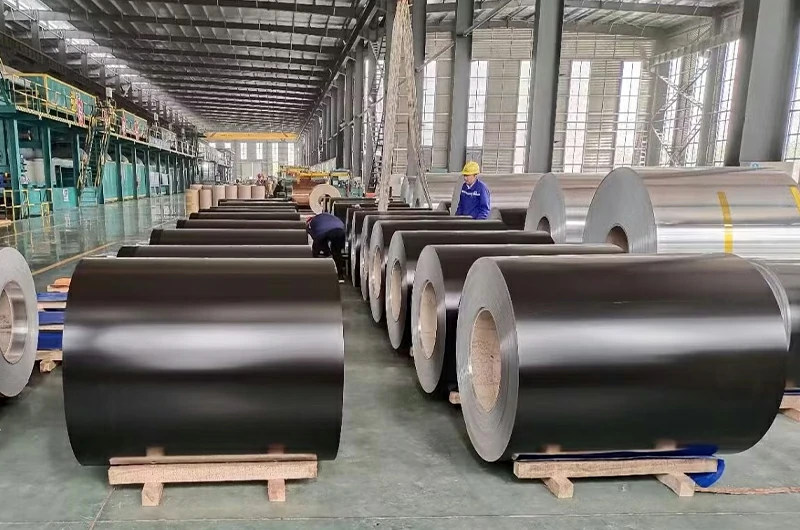

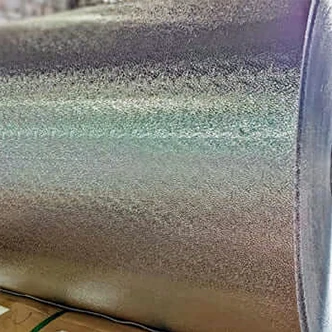

Aluminum wide sheet coil for aluminum roofing

Alloy:1050, 1060, 1200, 1100, 8111, 8011, 8079, 3003

Width:800-2000mm Max. width 2700mm

Thickness:sheet: 4.5-100mm; coil: 0.2-8mm

Contact us now

-

Chalco's ultra-wide aluminum coils can reach a width of 2700mm, which is suitable for large-span roofs, reducing the number of joints and improving the integrity and waterproofness of the roof.

-

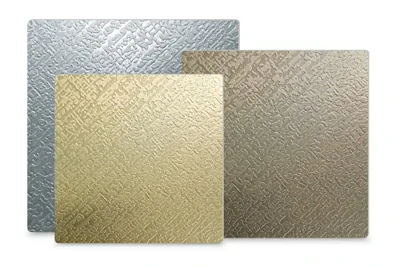

Embossed wide sheet coil

Patterns such as orange peel and diamond patterns are pressed on the surface to enhance the visual effect and improve the wear resistance of the material. The material's compressive and bending resistance is enhanced.

-

Color coated wide sheet coil

The surface features high-performance coatings with a wide color selection, offering excellent weather, corrosion, and UV resistance for long-lasting color.

-

Ultra wide aluminum mirror sheet coil

The polished surface creates a high-reflectivity mirror effect, enhancing the roof's modern look and energy efficiency by reducing heat absorption.

Need other metal roofing materials?

Although we primarily offer aluminum products, thanks to our strong partnerships with group companies and other collaborators, we are also able to provide roofing materials made from other materials. If you require roofing solutions beyond aluminum, please feel free to contact our sales manager, and we will do our utmost to meet your needs.

Chalco aluminum roofing material project overall solution

Design support and technical consulting

Our team provides comprehensive design support to help customers choose the most suitable aluminum alloy roofing materials and solutions. Whether it is a new project or a renovation project, our professionals will provide technical consultation based on specific needs to ensure that the performance and design effects of the roofing materials are optimized.

Size customization

We offer a variety of size options to ensure that aluminum roofing materials perfectly fit the customer's roof structure needs. Whether it is standard size or special customization, we can provide precise material cutting to minimize waste and maximize installation efficiency.

Surface treatment customization

We offer customers a variety of surface treatment options, including different coatings, to ensure that the roofing materials are not only highly durable, but also meet aesthetic and functional requirements. Customers can choose different surface effects according to the architectural style or specific application to enhance the visual effect and performance of the roof.

Lacquered

A clear lacquer layer enhances durability and protects against oxidation and corrosion, making it ideal for residential and commercial roofs without special color or gloss requirements.

Protection function

Improved durability

Color coating

Common types like PE, PVDF, Nano PVDF, PVC, Polyimide, and Fluorocarbon offer color variety, weather, UV, and corrosion resistance, ideal for various roofs.

Color Variety

Weather and UV resistant

Corrosion resistance

Reflective

With a smooth mirror effect and high reflectivity, this surface treatment enhances aesthetics, making it ideal for energy-saving and decorative roofs.

High reflectivity

Aesthetics

Anodizing

The aluminum oxide film enhances corrosion resistance, strength, and wear resistance, making it ideal for durable roofing in harsh environments.

Corrosion resistance

High strength and wear resistance

Aesthetics

Embossing

This process adds patterns for enhanced aesthetics, slip resistance, and durability, ideal for commercial, decorative roofs, and systems requiring friction.

Aesthetic appeal

Increased slip resistance

Enhanced durability

Chalco aluminum roof material application scenarios

- Commercial buildings: It is durable and can withstand severe weather, suitable for roofs of large and medium-sized commercial buildings.

- Residential buildings: modern and beautiful, suitable for all types of housing, especially in areas with fire protection requirements.

- Industrial plants: High-strength aluminum alloys adapt to high temperatures and corrosive climates in industrial environments.

- Green building: Excellent thermal insulation helps save energy and reduce emissions, suitable for green building projects.

- Coastal buildings: hotels, apartments, houses, houseboats, etc.

- Structural or industrial: warehouse, factory, etc.

Chalco roofing material purchasing FAQs

Aluminum roofing installation and maintenance

Aluminum roofing materials are light and easy to install, with a long maintenance cycle and low cost. After installation, regular inspection and cleaning of the drainage system can extend the service life.

Are aluminum roofs more durable than other materials?

Aluminum roofing materials are light and easy to install, with a long maintenance cycle and low cost. After installation, regular inspection and cleaning of the drainage system can extend the service life.

Are aluminum roofs suitable for all climate conditions?

Aluminum roofs are suitable for all climates, especially extreme weather and humid environments. Its corrosion resistance and weather resistance make it excellent in marine climates, tropical climates and other regions.

Will the aluminum roof generate heat?

Aluminum roofs have good heat reflection ability and can effectively prevent the conduction of solar heat. Modern aluminum roofs usually have insulation layers to reduce heat accumulation.

How much does an aluminum roof cost to maintain?

Aluminum roofs are low maintenance. Due to their durability and lack of susceptibility to corrosion, maintenance only requires regular cleaning and inspection of the drainage system, reducing the need for frequent repairs.

How long is the warranty period after aluminum roof installation?

Chalco aluminum roofing materials typically come with a longer warranty, which varies depending on the project requirements and is usually 20 years or longer.

Are aluminum roofs noisy?

Modern aluminum roofs are not much noisier than traditional tile roofs. Today, aluminum roofs are installed on a solid roof deck and are often equipped with insulation, which means that noise levels are reduced.

Chalco construction project related products

Building exterior

Aluminum curtain wall

Aluminum ceiling

Aluminum gusset plate

Aluminum ceiling panels

Aluminum railing