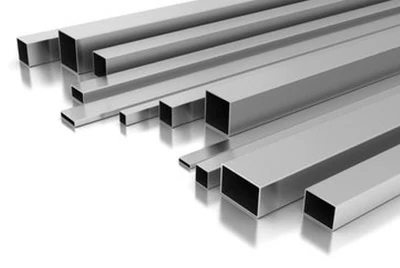

Chalco aluminum square tube product introduction

Alloy: 6061 (T4, T6, T651, T6511), 6063 (T5, T52), 6060, 6082, 5052, 7075, 2024

[Click to view alloy details and purchase by alloy]

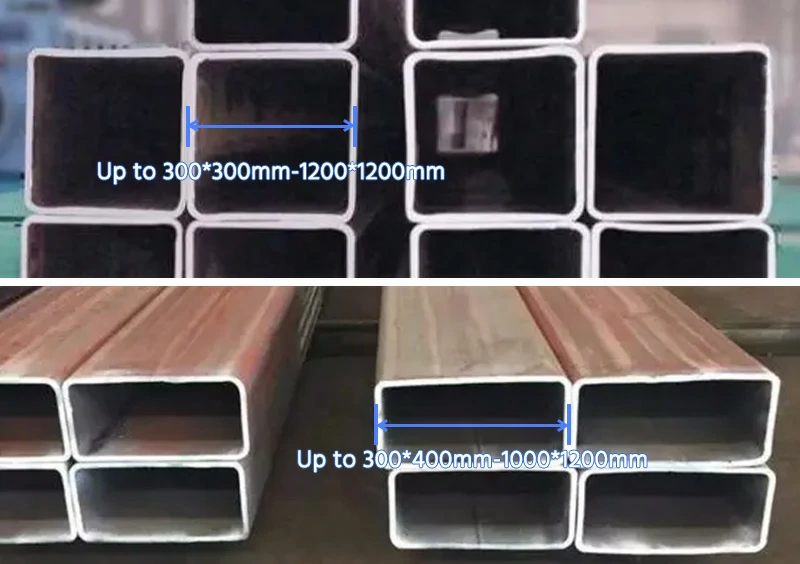

Patented product: large diameter square tube up to 1200*1200mm (48*48''); length up to 13 meters [View details]

Hot-selling products: telescopic; perforated; square tube channel; slotted square tube; pre-bent square tubing; square tube with flange; thick wall/thin wall square tubing … [View details]

Specification: AMS-QQ-A-200/9; BSEN755; ASTM B241; ASTM B429; ASTM B483; ASTM B221-08

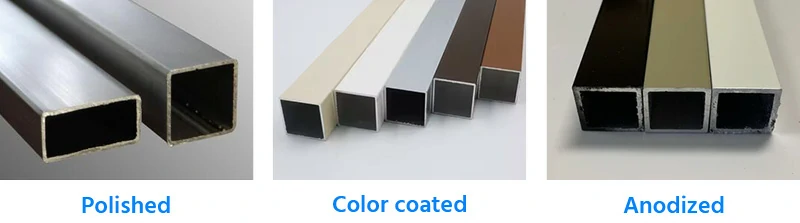

Surface: mill finish; Polished, painted, power coated, anodized, galvanized

Colors: black, white, satin silver, matte black powder, glossy white

Chalco aluminum square tube stock dimensions

To find the right aluminum square box profile for your next project, we offer a wide range of sizes, wall thicknesses, and lengths. Each aluminum profile has custom cutting options.

| Metric | Inch | Purchase |

| 12.7x12.7x1.6mm | 1/2"x1/2"x16swg | Quick Quote |

| 15x15x2mm | - | Quick Quote |

| 15.8x5.8x1.6mm | 5/8"x5/8"x16swg | Quick Quote |

| 19x19x1.6mm | 3/4"x3/4"x16swg | Quick Quote |

| 19x19x3.2mm | 3/4"x3/4"x10swg | Quick Quote |

| 20x20x2mm | - | Quick Quote |

| 25x25x2mm | - | Quick Quote |

| 25.4x25.4x1.6mm | 1"x1"x16swg | Quick Quote |

| 25.4x25.4x 3.2mm | 1"x1"x10swg | Quick Quote |

| 30x30x1.5mm | - | Quick Quote |

| 31.7x31.7x1.6mm | 1 1/4"x 1 1/4"x10swg | Quick Quote |

| 31.7x31.7x3.2mm | 1 1/4"x1 1/4"x16swg | Quick Quote |

| 38.1x38.1x1.6mm | 1 1/2"x1 1/2"x16swg | Quick Quote |

| 38.1x38.1x3.2mm | 1 1/2"x1 1/2"x10swg | Quick Quote |

| 40x40x2.5mm | - | Quick Quote |

| 40x40x3mm | - | Quick Quote |

| 44.5x44.5x3.2mm | 1 3/4"x1 3/4"x10swg | Quick Quote |

| 50x50x2mm | - | Quick Quote |

| 50x50x3mm | - | Quick Quote |

| 50.8x50.8x1.6mm | 2"x2"x16swg | Quick Quote |

| 50.8x50.8x 3.2mm | 2"x2"x10swg | Quick Quote |

| 50.8x50.8x4.8mm | 2"x2"x3/16" | Quick Quote |

| 50.8x50.8x6.3mm | 2"x2"x1/4" | Quick Quote |

| 60x60x3mm | - | Quick Quote |

| 60x60x4mm | - | Quick Quote |

| 63.5x63.5x3.2mm | 2 1/2"x2 1/2"x10swg | Quick Quote |

| 76.2x76.2x3.2mm | 3"x3"x10swg | Quick Quote |

| 76.2x76.2x 4.8mm | 3"x3"x3/16" | Quick Quote |

| 76.2x 76.2x 6.3mm | 3"x3"x1/4" | Quick Quote |

| 100x100x2mm | - | Quick Quote |

| 101.6x101.6x3.2mm | 4"x4"x10swg | Quick Quote |

| 101.6x101.6x6.3mm | 4"x4"x1/4" | Quick Quote |

| 152.4x152.4x 3.175mm | 6"x 6"x 1/8" | Quick Quote |

| 152.4x 152.4x6.35mm | 6" x 6" x 1/4" | Quick Quote |

| 152.4x152.4x12.7mm | 6"x 6"x 1/2" | Quick Quote |

| 203.2x203.2x12.7mm | 8"x 8"x 1/2" | Quick Quote |

Chalco large diameter aluminum square tube—patented hot-selling product

The seamless pipes produced by the company adopt a 50, 000-ton vertical extruder to produce large-diameter seamless aluminum alloy square pipes with a maximum diameter of 1200mm*1200mm, a wall thickness of up to 200mm, and a length of 12 meters. These are the largest and thickest seamless aluminum square pipes of their kind in the world, filling an international gap.

Chalco's technological innovation in large diameter aluminum square tubes

- Equipment Advantages: Utilization of the world's largest 500MN vertical extrusion press, combined with efficient scalping machines and proprietary lubricant spraying technology to ensure high production efficiency and material utilization.

- Extrusion Process: Single-pass extrusion technology allows for the production of ultra-large aluminum square tubes with maximum dimensions of 1200x1200mm within 10 minutes.

- Round to Square Forming: Rolling forming machines convert round tubes into square tubes, ensuring dimensional accuracy and uniform wall thickness.

- Heat Treatment: Heat treatment is conducted in a pit furnace with a precise temperature control system, ensuring temperature deviations within ±5°C during heating and holding.

- Precision Machining: External boring and internal turning processes guarantee a concentricity deviation of less than 0.5mm, surface roughness of less than 12.5μm, and straightness better than 1:1000.

Collaboration areas for Chalco large diameter aluminum square tubes

- Military: Used for structural components in military equipment and vehicles, enhancing mobility and durability due to its lightweight and strength.

- Nuclear Energy: Serves as structural support and cooling system components in nuclear facilities, ensuring safe operation with high-temperature and corrosion resistance.

- Construction and Structural Engineering: Used in frameworks and facades for modern buildings and bridges, offering high strength and corrosion resistance.

- Transportation: Serves as structural components and accessories in automotive, maritime, and aerospace industries, reducing weight while maintaining strength and safety.

- Mechanical Manufacturing: Used in industrial equipment and mechanical components, providing excellent load-bearing capacity and rigidity.

- Energy and Environment: Commonly used in solar panel supports and wind energy systems for its lightweight and weather resistance.

- Transport Containers: Used for manufacturing containers and storage racks, ensuring good sealing and durability.

Chalco deep processing aluminum square tube—meet the needs of different projects

Square telescopic tubes

Adjustable length, lightweight and durable. Used in retractable structures, furniture and sports equipment.

Contact us now

Perforated aluminum square tubing

With hole design, it reduces weight and has good ventilation. It is widely used in architectural decoration and breathable structures.

Contact us nowAluminum punched square tube

Stamped to increase beauty and functionality. Used for framing, supporting structures and decorative purposes.

Contact us now

Rectangular aluminum box section

Strong and durable, providing extra load-bearing capacity. Commonly used in mechanical parts and frame structures.

Contact us nowAluminum square tubing channel

Opening design for easy connection and installation. Used for cable management, architecture and support systems.

Contact us now

Slotted aluminum square tubing

Slotted design allows for flexible connection and adjustment. Suitable for assembling adjustable structures and mechanical devices.

Contact us nowPre bent aluminum square tubing

Pre-bent for quick installation. For use on frames and brackets where a specific angle is required.

Contact us now

Aluminum square tube with flange

Flange design enhances connection stability. Used for fixing structures and supporting devices.

Contact us nowThick wall aluminum square tubing

Thick wall increases strength and high load-bearing capacity. Suitable for heavy load support and industrial applications.

Contact us now

Thin wall aluminum square tubing

Lightweight design, easy to process and transport. Used for light frames and building decoration.

Contact us nowLightweight aluminum square tubing

Extremely light and corrosion resistant for easy handling. Commonly used in aviation, automotive and mobile equipment.

Contact us now

Square nut channel

Designed for bolting and provides stability. Suitable for fastening and structural connections.

Contact us nowChalco aluminum square tube fittings—one-stop shopping experience

Aluminum square tube end cap

Aluminum square tube connection

Aluminum square tube support feet

Aluminum square tube corner bracket

Aluminum square tube slide rail accessories

Aluminum square tube sealing strip

90° square aluminum tube connector (elbow, tee)

Bolts, Nuts

Aluminum square tube mounting clamp

Purchase aluminum square by alloy grade

Aluminum is often the metal of choice for fabrications that require strength and durability, as well as an excellent strength-to-weight ratio. Similar to our square and rectangular tubing.

The aluminum square tube alloy grades we stock are 6000 series, the more corrosion resistant 5000 series, and the high strength 2000 series and 7000 series alloys.

-

6061 T6 T651 aluminum square tube

Good formability, weldability and corrosion resistance. Used in engineering and structural applications.

-

6063 T5 T52 aluminum square tube

High tensile properties and finishing properties, widely used in indoor and outdoor buildings, such as windows, doors, etc. Ideal choice for anodizing applications.

-

2024 aluminum square tube

2024 Aluminum Square Tube has high strength and good fatigue properties and is mainly used in aviation and military applications.

-

6060 aluminum square tube

Good formability and weldability, suitable for architectural and structural purposes.

-

5052 aluminum square tube

Good corrosion resistance and formability and is often used in automotive and marine applications.

-

7075 aluminum square tube

7075 Aluminum Square Tube is a high strength alloy mainly used in aerospace and high load structures.

| Chalco aluminum square tube alloy performance reference table | |||||||

| Alloy | 6061 | 6063 | 6082 | 6060 | 5052 | 7075 | 2024 |

| Elastic Modulus (GPa) | 69 | 68 | 70 | 68 | 70 | 71 | 72 |

| Elongation at Break (%) | 3.4-20 | 7.3-21 | 6-18 | 6-20 | 8-22 | 5-11 | 4-16 |

| Shear Strength (MPa) | 84-210 | 70-190 | 100-260 | 80-190 | 120-180 | 150-340 | 130-320 |

| Ultimate Tensile Strength (MPa) | 130-410 | 110-300 | 240-360 | 150-260 | 170-215 | 240-590 | 200-540 |

| Yield Tensile Strength (MPa) | 76-370 | 49-270 | 200-310 | 100-200 | 65-175 | 120-510 | 100-490 |

| Thermal Conductivity (W/m·K) | 170 | 190-220 | 170-190 | 180 | 140 | 130 | 120 |

| Electrical Conductivity Equal Volume (% IACS) | 43% | 49-58% | 48-52% | 50-55% | 35% | 33% | 30% |

| Electrical Conductivity Equal Weight (% IACS) | 140% | 160-190% | 150-180% | 155% | 120% | 98% | 92% |

Why choose Chalco as your supplier for your aluminum alloy square tube project?

- Aluminum Square Tube Production: A fundamental advantage of all our tube and box profiles is the way they are manufactured. Aluminum extrusion is the process of converting aluminum alloy from aluminum rod or billet into a hollow square tube. Once it is pushed through a die in a hot furnace under extreme pressure, the new aluminum profile is extracted and then cooled to solidify its newly formed shape. The entire process is controlled with the utmost precision. This method ensures that the final product you receive has a good surface finish and beautiful square edges.

- Large diameter aluminum square tube processing capability: Aluminum Corporation of China uses a 500MN extruder to pierce the billet once and then extrude it vertically into a round tube, and then use a roll forming machine to roll it into an aluminum square tube. Our advanced technology not only makes breakthroughs in product production, but also reflects strong production strength and innovation capabilities. We are committed to becoming your long-term partner for aluminum alloy square tubes to meet the needs of different projects.

- Aluminum tube testing: After the product is produced, we will conduct a series of rigorous tests to ensure product quality. This includes surface inspection, dimensional inspection, geometric tolerance inspection, non-destructive testing, metallographic inspection and hardness testing. Through these testing processes, we ensure that each aluminum alloy square tube meets the highest standards and provides customers with reliable products.

- Packaging and transportation: In order to ensure that our products arrive at the destination intact, we implement multiple layers of protection during transportation and storage, covering rust prevention, winding protection, drying treatment, end cap protection, etc. Escort your product safe transportation.

Additional processing services for aluminum square tubes that Chalco can provide

Square tube bending

Chalco can provide square tube bending services. Through professional equipment, aluminum square tubes are bent at specific angles and radii, which are suitable for structural designs that require changes in direction, such as brackets and frames.

Square tube connection

Chalco can provide two ways of connecting aluminum tubes: mechanical connection and welding to meet the needs of different projects. Bolts, rivets, clamps, plug-ins, grooves, etc. can be provided according to customer requirements.

Square tube welding

Chalco can provide welding services to firmly combine the joints of aluminum square tubes to ensure the strength and stability of the structure. Welding connections for aluminum tube products can be provided according to customer requirements, including TIG and MIG welding.

Aluminum square tube product selection guide

Aluminum square tube vs rounded corner aluminum square tube

Aluminum square tube: suitable for structures that require right-angle connections, providing higher strength and rigidity.

Rounded aluminum square tube: The edges and corners are smooth and the appearance is beautiful. It is suitable for projects with higher design requirements, but it is slightly inferior in strength.

6061 aluminum square tube and 6063 aluminum square tube

6061 Aluminum Square Tube: Higher strength, suitable for load-bearing applications, but slightly less workability. 6061 Square Tube is precipitation hardened and can be used to increase the yield strength of forgeable materials.

6063 Aluminum Square Tube: With better formability and surface treatment performance, suitable for complex shapes and architectural applications.

Seamless aluminum square tube vs structural aluminum square tube

Seamless aluminum square tube: no welding seams, uniform strength, suitable for applications with high pressure and high strength requirements.

Structural aluminum square tube: usually a welded structure, suitable for general load-bearing requirements and low cost.

Thin wall aluminum square tube vs Thick wall aluminum square tube

Thin Wall Aluminum Square Tube: Lightweight and suitable for weight-sensitive applications, but with lower load-bearing capacity.

Thick Wall Aluminum Square Tube: Provides increased strength and rigidity, suitable for structures requiring high load-bearing capacity.

Perforated aluminum tube vs punching aluminum tube

Perforated aluminum tube: with specific hole position and hole diameter, suitable for air permeability and lightweight requirements.

Punching aluminum tube: Holes are produced by stamping process, usually used for decorative and functional needs, and the shapes and sizes of holes are more diverse.

More information about aluminum box profiles

Can I get a quote for specific sizes and quantities of aluminum box profiles?

Yes. We are happy to discuss your specific Aluminum Square Tube size and quantity requirements to help you get the product you need.

How is the weight of aluminum box profiles calculated?

The weight of the aluminum box profile is calculated in kg/ m and then multiplied by the length of the final product.

What are the common applications of aluminum square tubes?

aluminum hollow profiles include the construction industry, as well as the manufacturing of different products such as doors and windows, furniture, medical equipment and shelving.

What is the corrosion resistance of aluminum box profiles?

Aluminum box profiles are highly resistant to corrosion. A thin oxide layer naturally and quickly forms on the surface of aluminum, protecting the rest of the material from further corrosion.

What are the advantages of using aluminum square tubes compared to other materials such as steel?

Aluminum tubes have several advantages over other materials, primarily due to their high strength-to-weight ratio compared to other metals, as well as corrosion resistance and nearly unlimited recyclability.

Are there different grades of aluminium alloy used in box profiles? How do they affect the properties?

Aluminum box profiles come in several different grades, depending on the materials used in the alloy. The most common is the 6000 grade alloy, which is also the main material we stock at Chalco. These alloys mainly use magnesium and silicates as alloying materials. We also stock some 5000 series, 2000 series, 7000 series, and 1000 series aluminum square tube products. Products that are not in stock can be produced online.

Do you supply black aluminum box profiles?

Yes. We offer black aluminum enclosure profiles, as well as a range of other powder coated aluminum enclosure profiles, all cut to size. Chalco also offers anodized and coated aluminum tubes in other colors to suit different customer project requirements.