Looking for Fasteners That Are Both Lightweight and High Load-Bearing?

Chalco's aluminum threaded rods are precision-machined from high-quality aluminum billets through CNC turning or thread rolling processes. They offer a unique combination of lightweight, corrosion resistance, and excellent machinability, making them ideal for use in aerospace, automotive manufacturing, construction decoration, and industrial automation.

Compared to steel threaded rods, Chalco's aluminum rods provide the same strength while significantly reducing weight. They also deliver outstanding corrosion resistance in marine and chemical environments.

As a primary aluminum manufacturer, Chalco offers integrated extrusion and threading capabilities, providing metric/imperial, multi-alloy, and customized solutions.

Learn why you should choose Chalco's aluminum threaded rods.Quick Quote

Quick Navigation Anchors

Specifications of Aluminum Threaded Rods

Chalco operates both metric and imperial threaded rod production lines, capable of precision machining metric threads ranging from M6 to M24, and imperial threads ranging from #4-40 to ¾″-10, fully meeting the global market's needs.

Metric Threaded Rods

-

Measured in millimeters, more aligned with international standards.

Common Sizes: M3, M4, M5, M6, M8, M10, M12, M16, M20, M24, etc.

Typical Threads: 0.5mm, 1.0mm, 1.25mm, 1.75mm, 2.0mm, 2.5mm, 3.0mm, etc.

Standard Systems: DIN 975, ISO 68-1, ISO 261, ISO 965.

Metric Threaded Rods Size Chart

| Specification | Pitch (mm) | Nominal Diameter (mm) | Thread Angle (°) | Typical Applications |

| M3 | 0.5 | 3 | 60 | Small electronic & electrical screws |

| M4 | 0.7 | 4 | 60 | Household appliances, light mechanical assembly |

| M5 | 0.8 | 5 | 60 | Common small mechanical fasteners |

| M6 | 1 | 6 | 60 | General mechanical and furniture fasteners |

| M8 | 1.25 | 8 | 60 | Common in construction and mechanical structures |

| M10 | 1.5 | 10 | 60 | Most widely used medium thread |

| M12 | 1.75 | 12 | 60 | Automotive and equipment accessories |

| M14 | 2 | 14 | 60 | Wheel hub bolts, structural components |

| M16 | 2 | 16 | 60 | Higher load-bearing capacity, industrial equipment |

| M20 | 2.5 | 20 | 60 | Construction beams, heavy-duty connections |

| M24 | 3 | 24 | 60 | Large machinery, high-strength bolts |

| M30 | 3.5 | 30 | 60 | Heavy machinery and engineering equipment |

Imperial Threaded Rods

-

Measured in inches and "threads per inch (TPI)", ranging from small sizes (#0-80) to large sizes (1½″-6UN), corresponding to different thread profiles and TPI.

Common Sizes: #4 - 40, #6 - 32, #8 - 32, #10 - 24, #10 - 32

Thread Types: UNC (coarse threads), UNF (fine threads), UNEF (extra-fine threads)

Standard Systems: ASME B1.1, ANSI/ASME B18

Imperial Threaded Rod Size Chart

| Specification | Nominal Diameter (inch) | UNC (Coarse) TPI | UNF (Fine) TPI | Thread Angle (°) |

| #0 | 0.06 | 80 | - | 60 |

| #1 | 0.073 | 64 | - | 60 |

| #2 | 0.086 | 56 | - | 60 |

| #3 | 0.099 | 48 | - | 60 |

| #4 | 0.112 | 40 | 48 | 60 |

| #5 | 0.125 | 40 | - | 60 |

| #6 | 0.138 | 32 | 40 | 60 |

| #8 | 0.164 | 32 | 36 | 60 |

| #10 | 0.19 | 24 | 32 | 60 |

| 1/4″ | 0.25 | 20 | 28 | 60 |

| 5/16″ | 0.313 | 18 | 24 | 60 |

| 3/8″ | 0.375 | 16 | 24 | 60 |

| 7/16″ | 0.438 | 14 | 20 | 60 |

| 1/2″ | 0.5 | 13 | 20 | 60 |

| 9/16″ | 0.563 | 12 | 18 | 60 |

| 5/8″ | 0.625 | 11 | 18 | 60 |

| 3/4″ | 0.75 | 10 | 16 | 60 |

| 7/8″ | 0.875 | 9 | 14 | 60 |

| 1″ | 1 | 8 | 12 | 60 |

| 1‑1/8″ | 1.125 | 7 | 9 | 60 |

| 1‑1/4″ | 1.25 | 7 | 12 | 60 |

| 1‑3/8″ | 1.375 | 6 | 12 | 60 |

| 1‑1/2″ | 1.5 | 6 | 12 | 60 |

Aluminum Threaded Rod Standards and Certifications

- Aluminum Material Standards: ASTM B211, B221, EN 755/754, AA standards

- Thread Standards: ASME B1.1, ANSI/ASME B18, DIN 975, ISO 68-1, ISO 261, ISO 965

- Quality Systems: ISO 9001, AS9100, NADCAP (Heat Treatment, Non-destructive Testing)

Chalco offers high-precision, customized aluminum threaded rods across all the specifications mentioned above, leveraging our advanced metric and imperial threading capabilities to meet the diverse fastening needs of global customers. Quick Quote

Chalco Aluminum Threaded Rods Product Categories

Aluminum Threaded Rod

A long rod with full-length threads and no screw heads, typically over 12 inches (1 ft) in length, which can be cut to sizes ranging from 12" to 6 ft (about 1.5m–1.8m).

Applications: Structural support, embedded components, tensioning systems, and large equipment connections.

Aluminum Stud

A short rod with full or partial threading, no screw head, and a length of ≤12 inches. Thread length can be customized for full thread, partial thread, or depth-based installation.

Applications: Enclosure fastening, flange connections, quick equipment assembly/disassembly, and precision component positioning.

Common Thread Types

Aluminum All Thread Rod

Fully threaded rods that allow for flexible installation and the ability to secure nuts at any point, ideal for continuous adjustments and multi-point fastening.

Double-Ended Thread Rod

Threads on both ends, with a smooth center. Commonly used in machine tools, pumps, and motor installations for easy disassembly and positioning.

Single-Ended Thread Rod

Threads only on one end, with the other end left smooth or with a special head, ideal for hooks, hanging rods, and insert-type fastening.

Coarse Threaded Rod

Larger pitch (e.g., UNC/UNC series), providing quick installation and high vibration resistance, commonly used in construction, furniture, and heavy-duty connections.

Fine Threaded Rod

Smaller pitch (e.g., UNF/UNEF or metric fine threads), offering high adjustment precision and strong anti-vibration properties, suitable for precision instruments and high-accuracy assemblies.

Internally Threaded Rod

Rods with internal threads at one or both ends, compatible with external threaded rods for extensions or quick connections.

Chalco also offers customized shaped threaded rods, supporting knurling, slotting, tapering, flange heads, irregular cross-sections, and various non-standard thread processing to meet special conditions and personalized needs.

By choosing Chalco's threaded rods, you benefit from direct supply from the source manufacturer, comprehensive quality assurance, and flexible customization services. Contact us for exclusive solutions and competitive pricing.Quick Quote

Alloy Selection: In-Depth Guide to Aluminum Threaded Rods

The alloy composition of an aluminum threaded rod directly influences its tensile strength, corrosion resistance, machinability, and cost. Chalco offers a range of core alloys tailored for different application scenarios. Below, we analyze these alloys across three key aspects: mechanical properties, machinability, and typical applications, to help you make the right choice.

-

6061 Aluminum Threaded Rod

6061 Aluminum Threaded Rod6061 aluminum threaded rod features excellent cutting and welding performance. CNC turning and thread rolling are stable and burr-free, delivering a smooth thread surface. It is commonly used in building fasteners, appliance brackets, and general mechanical assemblies, balancing strength and cost-effectiveness.

Tensile Strength: 310 MPa Yield Strength: 275 MPa Elongation: 12% -

6063 Aluminum Threaded Rod

6063 Aluminum Threaded RodKnown for superior formability and surface quality, the 6063 aluminum threaded rod achieves a smooth appearance after threading, making it suitable for fine rolling and decorative applications. It is widely used in curtain wall profiles, decorative brackets, and fastening applications requiring high surface finish.

Tensile Strength: 210 MPa Yield Strength: 180 MPa Elongation: 12% -

7075 Aluminum Threaded Rod

7075 Aluminum Threaded RodWith extremely high strength, the 7075 aluminum threaded rod is ideal for thread rolling or precision turning but requires high-performance tooling. It is typically used in aerospace fasteners, high-end automotive parts, and military equipment where extreme load and fatigue resistance are required.

Tensile Strength: 560 MPa Yield Strength: 515 MPa Elongation: 11% -

5052 Aluminum Threaded Rod

5052 Aluminum Threaded RodOutstanding in corrosion resistance and easy to machine, 5052 aluminum threaded rod is widely used in marine equipment, chemical pipeline supports, and outdoor structural fastening, offering a balance of durability and workability.

Tensile Strength: 200 MPa Yield Strength: 150 MPa Elongation: 12%

Choose Chalco aluminum threaded rods for direct-from-source alloys, flexible customization, and complete quality assurance—helping your project find the best balance between performance and cost.Quick Quote

Industry Applications of Aluminum Threaded Rods

Aerospace

Chalco's aerospace-grade 7075 aluminum threaded rods feature 560 MPa tensile strength and outstanding fatigue resistance. They are ideal for critical fastening in aircraft fuselage structures, wing beams, and landing gear, ensuring stability and reliability under extreme loads and vibrations.

Automotive Manufacturing

Our automotive-grade 6061 aluminum threaded rods balance lightweight properties with strength, offering 310 MPa tensile strength and 275 MPa yield strength. They are commonly used in engine block brackets, vehicle frames, and wheel hub fastening, supporting overall vehicle weight reduction and improved fuel efficiency.

Marine Engineering

Chalco’s marine-grade 5052 aluminum threaded rods excel in corrosion resistance, with 200 MPa tensile strength and 150 MPa yield strength. They are widely applied in ship decks, offshore platforms, and dock supports, delivering long-term durability in salt spray environments.

Construction & Infrastructure

Construction-grade 6063 aluminum threaded rods are known for their 210 MPa tensile strength and excellent surface finish. They are used in curtain wall anchors, window and door frames, and decorative brackets, combining structural safety with aesthetic appeal.

Industrial Automation

Our industrial-grade aluminum threaded rods (available in 6061 or 7075) perform exceptionally well in robotic arms, transmission systems, and machine tool components. High-precision thread rolling ensures accurate fits and enhances equipment operational stability.

Are You Looking for an Aluminum Supplier?

If you need a professional aluminum supplier to provide you with high-quality, cost-effective aluminum, we will be your best choice.

Manufacturing Process of Threaded Rods

Aluminum Rod Extrusion

1. Extrusion Forming: Homogenized aluminum billets are preheated and extruded through dies in an extrusion press to produce plain rod blanks.

2. Dimensional and Structural Optimization: The extrusion process allows precise control of diameter tolerance (±0.1 mm), while plastic deformation refines the grain structure, laying a stable foundation for subsequent thread processing.

3. Common Alloys: 6061, 6063, 7075, etc., can be selected according to the required thread strength or machinability.

Thread Processing

-

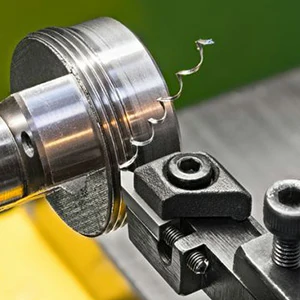

CNC Thread Cutting

CNC Thread CuttingSuitable for non-standard, custom, or small-batch production. Cutting tools follow the rotation of the workpiece to remove material and form threads. Advantages include high flexibility and precision up to ±0.05 mm.

-

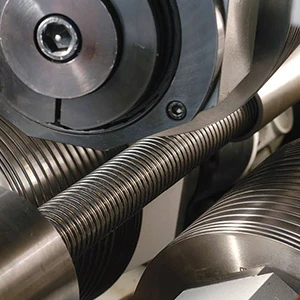

Thread Rolling

Thread RollingUses two pre-formed thread dies to cold-roll the workpiece surface at room temperature, forming rounded root threads (UNRF/UNRC) without material removal. This improves root strength and is ideal for mass production of standard coarse or fine threads (UNC/UNF).

Coarse vs. Fine Threads

- Coarse Threads (UNC/DIN 975): Larger pitch, quicker assembly, better vibration resistance.

- Fine Threads (UNF/DIN 976 or metric fine threads): Smaller pitch, higher adjustment precision, suitable for high-accuracy or anti-loosening applications.

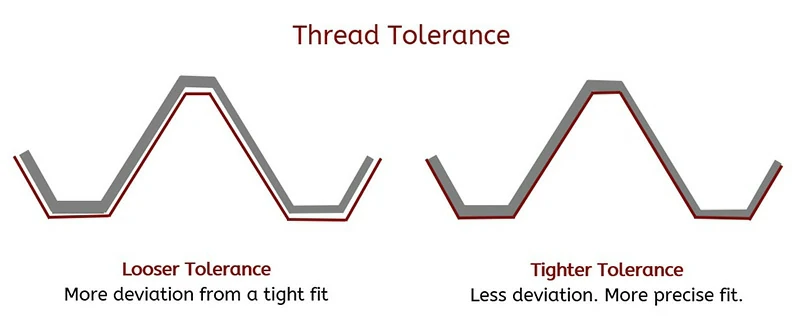

Thread Tolerance and Classes

- External Threads: Commonly class 2A

- Internal Threads: Commonly class 2B

- High-precision applications: Class 3A/3B

- Loose fit or quick assembly: Class 1A/1B

Special Threads

- UNRF/UNRC: Rounded root to enhance fatigue strength

- UNJ: Larger root radius, commonly used in aerospace

- Metric special pitch: e.g., M10×1.25, M12×1.0, etc.

Quality Inspection

- Dimensional Inspection: Thread gauges (plug/ring) verify outer diameter, pitch, and profile

- Ultrasonic Testing (UT): Ensures absence of internal cracks, pores, or casting defects

- Metallographic Analysis: Observes grain uniformity and segregation

- Mechanical Testing: Includes tensile, hardness, and torque tests to verify thread strength and durability

- Chemical Composition: Spectral analysis ensures alloy formulation accuracy

With Chalco's integrated extrusion and threading capabilities, along with a rigorous full-process inspection system, we provide high-precision, high-reliability aluminum threaded rod solutions.

Contact us now to customize your specifications and processing support!Quick Quote

Why Choose Chalco's Aluminum Threaded Rods?

Direct Supply from Manufacturer: Chalco owns its aluminum smelting and extrusion lines, eliminating middlemen and ensuring integrated delivery of raw materials and threaded rods. This guarantees stable supply and more competitive bulk pricing to help you significantly reduce fastener costs.

Guaranteed Aluminum Quality: Using advanced continuous casting and homogenization processes, along with online temperature monitoring and scalping treatment, Chalco ensures consistent and reliable quality of billets and plates.

Full Alloy Range Available: Supports multiple aluminum alloys such as 6061, 6063, 7075, and special custom alloys, meeting diverse needs from lightweight designs to high-strength requirements.

One-Stop Customization: Metric/Imperial threads, diameter, length, heat treatment status, and surface finish (anodizing, coating) can all be tailored — truly delivering what you see is what you get.

Strict Testing and International Certifications: Includes full ultrasonic testing, metallographic analysis, hardness and chemical composition checks. Products are certified under ISO 9001, AS9100, NADCAP, and other international standards.

Expert Technical Support and After-Sales Service: Our experienced engineering team provides guidance on material selection, thread tolerance fit, and fast after-sales response, ensuring your project runs smoothly.

FAQ

What is the minimum order quantity (MOQ) and delivery time?

- Standard specifications: MOQ starts at 200 kg. Common sizes are in stock and can ship within 1–2 weeks.

- Custom alloys/sizes: MOQ is negotiable. Lead time is usually 4–6 weeks depending on alloy composition and production schedule.

Can you provide custom lengths, diameters, and special thread types?

Absolutely! Chalco supports diameters from 6–30 mm (M6–M24 or ¼″–1″), lengths from 0.5–6 m, and various thread types such as coarse, fine, UNJ, and ACME. Whether you need fully threaded, partially threaded, or special head designs, we offer a one-stop solution.

Should I choose metric or imperial threads?

If your equipment or parts follow ISO standards and use millimeter-based measurements (e.g., M6, M8), choose metric threads. For U.S. equipment or inch-based parts (e.g., ¼″‑20, ½″‑13), choose imperial threads.

Chalco supports both standards with dual production lines, ensuring global compatibility and avoiding rework or delays due to mismatched threads.

Can aluminum threaded rods handle high-load applications?

Chalco's 7075-T6 aluminum threaded rods offer tensile strength up to 560 MPa and yield strength of 515 MPa, suitable for aerospace and high-end mechanical applications.

6061-T6 aluminum threaded rods offer 310 MPa tensile and 275 MPa yield strength, suitable for general industrial and automotive structural use.

How can corrosion be prevented in marine or chemical environments?

For marine-grade applications, we recommend 5052 or 5083 alloy threaded rods, with optional anodizing, hard anodizing, or polymer coatings. Chalco’s surface treatments can significantly improve corrosion resistance, effectively preventing salt spray and chemical erosion, and extending service life.

How is thread precision and assembly compatibility ensured?

All Chalco threaded rods are manufactured to 2A/2B or 6g/6H tolerance classes, with 100% inspection using thread plug and ring gauges.

Thread angle and depth are tightly controlled within ±0.05 mm through CNC cutting or thread rolling, ensuring perfect fit with standard nuts, nut seats, and accessories.

Can aluminum threaded rods be welded or heat treated?

- Welding: 6061 aluminum threaded rods are TIG/MIG weldable; pre- and post-heating is recommended for the weld zone. 7075 alloy is prone to cracking and not recommended for welding—mechanical fastening is preferred.

- Heat Treatment: Some alloys can undergo T651 stress-relief treatment after threading to improve dimensional stability and reduce assembly deformation.

Do you offer third-party inspection and quality reports?

Yes, Chalco provides third-party reports including ultrasonic testing (UT), metallographic analysis, hardness, tensile test reports, and chemical composition analysis. These meet the strict audit and certification requirements of aerospace, defense, and automotive industries.

For further technical or purchasing inquiries, contact us today. Chalco's expert team is ready to offer tailored recommendations and customized solutions to ensure your aluminum threaded rods perform exceptionally in every project!