Why custom aluminum tubing matters

- Industry Needs: Standard tubes can't meet the diverse shape, size, and strength demands across automotive, aerospace, construction, and medical industries.

- Custom Advantage: Custom aluminum tubes offer better fit, less waste, and optimized performance with tailored alloys and dimensions.

- Product Range: Chalco provides a wide range of custom aluminum tube products, all made to match your project's exact specifications.

Chalco aluminum tube custom capabilities

Full alloy range: 6061, 6063, 7075, 5083, 2024, and more

Custom sizes: OD 5–300mm or larger diameter, wall thickness 0.5–20mm

Tolerance control: ±0.05mm on diameter, ±0.02mm on wall thickness

Complex shapes: round, square, oval, tapered, multi-chamber, finned, corrugated

Processing: CNC, bending, laser cutting, TIG/MIG welding

Finishing: anodizing, powder coating, polishing, electrophoresis

Fast delivery: samples in 7 days, small batches accepted

Click to check the detailed [Custom capability ]

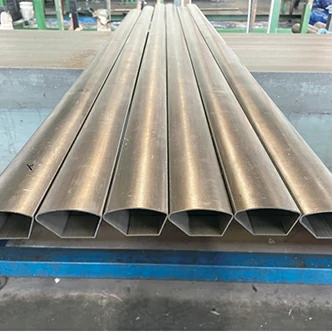

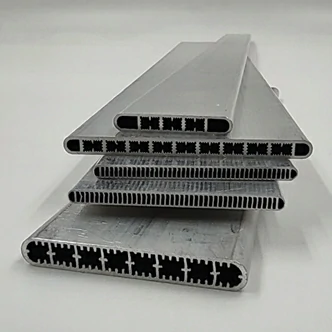

Aluminum special-shaped extruded section tube products

Our custom aluminum extrusion tubes are designed for special-shaped requirements across various industries, including automotive, aerospace, and structural engineering. We offer high-precision aluminum profiles in complex geometries, ensuring lightweight, high-strength, and corrosion-resistant solutions tailored to your specific needs.Quick Quote

Aluminum special-shaped extruded tubes feature complex cross-sections like fan, teardrop, D-shape, and trapezoid, meeting multifunctional design needs for aerospace, automotive frames, and high-end industrial equipment.

Contact us now

-

Aluminum Sector Section Tube

Alloy: 2A12/2024 T4

Size: 61.53mm*34mm*1.5mm

Straightness: whole root ≤0.15mm,

Shape tolerance: ±0.1mm

Specification: GB/T6893-2010

-

Aluminum streamlined tube

Alloy: 2024 T3

Size: long axis 196.85mm* short axis 83.56mm* thickness 3.4mm

Specification: AMS-WW-T-700-3A

Application: Seaplane Wing

-

Aluminum D-Section Tube

Alloy: 6061 T6

Size: Height 50mm Width 30mm Wall thickness 2mm

Shape tolerance: ±0.2mm

Application: Communication equipment housing

-

Oval aluminum tubing

Alloy: 6063 T5

Size: Long axis 120mm; Short axis 60mm; Wall thickness 2.5mm

Shape tolerance: ±0.15mm

Application: Medical device bracket

-

Triangular cross section tube

Alloy: 7075 T6

Size: side length 100mm*wall thickness 3mm

Shape tolerance: ±0.2mm

Specification: ASTM B221-2021

Application: Aerospace structural parts

-

Trapezoidal cross section tube

Alloy: 6063 T6

Size: Upper base 40mm; Lower base 80mm; Height 50mm

Straightness: whole root ≤0.15mm,

Application: Industrial machinery support

-

Semicircular cross section tube

Alloy: 6061 T6

Size: diameter 100mm*wall thickness 2mm

Shape tolerance:±0.15mm

Application: lamps and decorative materials

-

Special-shaped aluminum square tube

Alloy: 6082 T6

Size: Side length 50mm; Wall thickness 3mm

Specification:EN 755-9:2008

Application: Construction and industrial framing

-

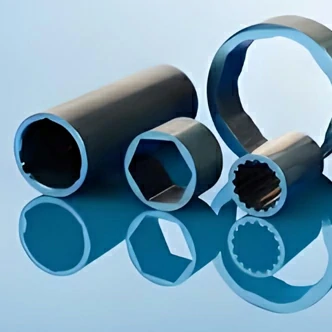

Inner shaped round tube

A tube with a circular exterior and a specific internal geometry (such as square, star, triangle, etc.). The internal structure can be customized to meet specific functional requirements.

-

Inner round outer shaped tube

While maintaining the internal circular cross-section, the external shape is designed with special shapes (such as rectangle, triangle, wave, etc.) to optimize the strength, stability and aesthetics of the pipe.

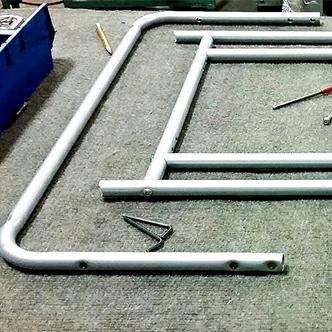

Aluminum pipe bending products

Chalco Aluminum provides custom bent aluminum tubes, meeting the needs of industries such as automotive exhaust systems, handrails, aerospace components, and industrial machinery. Our precision bending technology ensures seamless bends, minimal deformation, and excellent mechanical properties, making our products ideal for high-performance applications.Quick Quote

Aluminum alloy elbows are designed with arc or custom bending, with excellent mechanical properties and fatigue resistance. They are ideal for automotive exhaust pipes, frame systems, fluid delivery pipelines and cooling systems.

Contact us now

-

Aluminum elbows

Alloy: 2A12/2024 O

Size: ∅ 90*5mm, ∅ 50* 5mm, ∅ 34*4mm

Specification: According to customer requirements

-

Aluminum bends

Alloy: 6061 T6, 5052 H32

Bending angle: 45 degrees, 90 degrees, 180 degrees

Curvature: Usually 1.5D to 3D, the curvature is relatively gentle.

-

Al mandrel bends

Bending angle: 30°, 45°, 60°, 90°, 180°

CLR: 1D, 1.5D or larger Precision bending, smooth tube wall.

-

Large diameter bends

Pipe diameter: 4 inches or larger

Designed for large diameter aluminum pipe, it provides smooth connections and precise bends for high flow piping systems.

-

Bending tubing for propane natural gas

Alloy: 5052 H32, 6061 T6

Size: ∅15mm- ∅50mm, wall thickness 1.5mm-4mm

Bending angle: usually 90° and 45°, supporting multi-segment bending.

-

Aluminum lighting fixtures

Alloy: 6063 T5

Highly reflective, it is an excellent choice for threading wires in lamps and fixtures.

-

Aluminum equipment handle

Alloy: 6061 T6, 5052

Bending: Usually U-shaped and C -shaped, the specific angle can be customized. Rugged and durable, it is widely used in medical equipment, industrial machinery and household appliances.

-

Large aluminum cooling coil

Alloy: 6061 T6, 3003 H14

Curved: Usually spiral, can be customized in many shapes.

Excellent heat dissipation and structural strength, used in air conditioning and refrigeration equipment.

-

Aluminum bent frame tube

Alloy: 6063 T5, 6082 T6

Diameter: ∅ 50mm- ∅ 100mm

Wall thickness: 2mm-6mm

Bending: Customizable bending angles, suitable for complex frame structures.

-

Foldable and bendable bicycle rack

Alloy: 7005 T6, 6061 T6

Tube diameter: ∅25mm- ∅50mm

Wall thickness: 1.5mm-3mm

Bending: Customized according to folding design to precisely match the connecting parts.

Aluminum telescopic pipe products

We specialize in adjustable and extendable aluminum telescopic tubes, widely used in tripods, medical equipment, telescopic poles, and industrial tools. These lightweight, corrosion-resistant, and high-strength tubes offer smooth sliding adjustments, with customized diameter and thickness options available to fit your project needs.Quick Quote

The aluminum telescopic tube is based on the round tube, and also has square, rectangular, oval and other cross-sections. Through the adjustable length telescopic design, it is lightweight and easy to carry, suitable for flexible scenes such as outdoor brackets, photographic equipment and medical equipment.

Contact us now

-

Telescopic tube for radar communication

Alloy: 2A12 T451

Size: ∅30.85*1.4mm-∅26.65*1.4mm- ∅22*1.4mm-∅16*1.4mm

Application: Radar communication

-

Aluminum telescopic pole for tent

Alloy: 6061 T6

Size: Ø28-Ø24-Ø20mm (telescopic section)

The tent stand is adjustable in length and highly portable.

-

Telescopic pole for outdoor equipment

Alloy: 7075 T6

Size: Ø32-Ø25-Ø19mm

Suitable for trekking poles, camping equipment and outdoor tools, high strength.

-

Aluminum telescopic antenna pole

Alloy: 6063 T5

Size: Ø40-Ø35-Ø30mm

Used for retractable communication antenna pole.

-

Telescopic rod for communication equipment

Alloy: 6082 T6

Size: Ø50-Ø40-Ø30mm

Communication tower pole, adjustable height, stable structure.

-

Thick-walled telescopic tube

Alloy: 5052 H32

Size: Ø60-Ø55-Ø50mm

High-load applications, including industrial supports and robotic arms.

Square/rectangular aluminum telescopic tube

Round aluminum telescopic tube

Oval aluminum telescopic tube

Eccentric aluminum telescopic tube

Single groove aluminum alloy telescopic tube

Streak aluminum telescopic tube

Aluminum tapered pipe products

Our custom tapered aluminum tubes are designed for structural applications requiring strength variation along the length of the tube, such as flagpoles, lighting poles, telescopic components, and sporting equipment. These tubes are manufactured with precision forming techniques, ensuring seamless transition in diameter for optimal performance.Quick Quote

The aluminum tapered tube, with one end larger than the other, optimizes fluid dynamics and is used in hydraulic pipelines, heat pipes, energy transmission, lamp posts, and weapons.

Contact us now

-

Aluminum tapered tube for weapon parts

Alloy: 5A06 O

Size: Ø200*10mm-Ø 150*10mm

Specification: GB/T6893—2010

Application: Parts of a certain type of weapon

-

Aluminum tapered tube for equipment support

Alloy: 6061 T6

Features: moderate strength, light weight, easy to weld.

Application: Industrial equipment support rods, robotic arms, etc.

-

Aluminum tapered tube for street light pole

Alloy: 6063 T 6

Big end: 180-240mm

Small end: 140-180mm

The wind resistance is improved, but the processing is complicated.

-

Large diameter aluminum tapered tube

Alloy: :5A06 O

Size: Ø200*10mm-Ø 150*10mm

Specification: GB/T6893—2010

Application: Parts of a certain type of weapon

Aluminum shell tube

Chalco Aluminum produces protective aluminum shell tubes designed for electronic enclosures, aerospace applications, and high-end industrial equipment. Our high-strength aluminum alloy shell tubes offer lightweight, durable, and corrosion-resistant solutions, ensuring superior heat dissipation, shielding, and mechanical protection.Quick Quote

Aluminum alloy shell tubes, with circular, square, or custom cross-sections, offer lightweight strength for protection and support. Used in electronics, motors, aerospace, and medical enclosures, they ensure vibration resistance, corrosion resistance, and precision for critical components.

Contact us now

-

Aluminum integrated shell and tube

Alloy: 5A06 H14

Size: 30*30mm-27*27mm *195mm

Inner hole tolerance: +0.2mm

Specification: Both parties draft a technical agreement

-

Aluminum motor housing

Alloy: 6061 T6

High strength, vibration resistance, easy to process. Used for industrial motors and household appliances motor housings.

-

Aluminum optical brazing protection tube

Alloy: 6082 T5

Size: Ø10mm-Ø20mm, wall thickness 0.8mm-1.5mm

Moisture-proof, corrosion-resistant, and high-strength, ideal for optical fiber protection and transmission.

-

Aluminum car/motorcycle exhaust pipe

Alloy: 6063 T5

Size: elbow or straight tube design, outer diameter and curvature can be customized.

Lightweight, high temperature resistant and easy to shape.

Aluminum heat dissipation and heat exchange aluminum tube products

Our heat dissipation aluminum tubes are essential in HVAC systems, refrigeration, automotive radiators, and aerospace cooling systems. Made from high thermal conductivity aluminum alloys, these tubes enhance heat exchange efficiency while offering lightweight and corrosion-resistant properties.Quick Quote

Aluminum alloy heat sinks are represented by finned tubes or internal spiral grooved tubes. They combine excellent thermal conductivity and corrosion resistance and are core components in heat exchangers, refrigeration systems and power equipment.

Contact us now

-

Aluminum heat pipe

Alloy: 6061, 6063, 6005

Excellent thermal conductivity, suitable for efficient heat dissipation design. Used in electronic equipment radiators and power module housings.

-

Aluminum heat exchanger fin tube

Alloy: 1050, 1060, 1070, 1100, 5052, 6063

Excellent thermal conductivity and strong corrosion resistance. Used in heat exchangers such as industry and refrigeration.

-

IHX pipeline

Alloy: 1050 , 1060 , 1100 , 6061

Internal heat exchangers, coaxial exchangers: production and assembly of complete straight components.

-

Grooved pipe fittings

Alloy: 1050 , 1060 , 6063

The interior is designed with small diameter fin tubes to increase the exchange surface and internal fluid turbulence.

-

AC pipe

Alloy: 1050, 1060, 6061

Tubing designed specifically for applications requiring high heat exchange efficiency.

Aluminum tube with multi-barrel products

Chalco Aluminum manufactures multi-barrel aluminum tubing, designed for applications requiring multiple fluid or air channels, such as HVAC systems, compressed air pipelines, and fuel transport. These tubes are customized in size, shape, and internal configurations, ensuring optimal performance for complex engineering requirements.Quick Quote

Aluminum alloy multi-cavity tubes have complex internal cavity designs, including symmetrical multi-cavity and special-shaped multi-cavity structures, which provide high strength and versatility while maintaining lightweight. They are widely used in aerospace frames, automobile chassis and precision instruments.

Contact us now

-

Double-barrel shaped aluminum tube

Lightweight double-cavity design offers strength, corrosion resistance, and thermal conductivity, widely used in automotive, aerospace, and refrigeration.

-

8 shape double barrel aluminum tube

The appearance is "8" shaped, with two pipes connected, and has good strength and bending resistance. It is widely used in pipeline frames, brackets, engineering machinery, etc.

-

Aluminum waist wheel tube

Alloy: 6063 6063

Size: According to drawings

Shape tolerance: ±0.03m

Application: Instrument measuring device assembly

-

Aluminum cylinder tube

Alloy: 6063 T5 T6 T832, 6061 T6511

Full range of standard size cylinder tubes in stock, hundreds of standard molds to choose from; in accordance with ISO 6430, ISO 6431, VDMA 24562, ISO 15552 …

-

Aluminum microchannel tube

Alloy: 1050, 1100, 3003, 6063, 6061, 3102

key components such as automotive air-conditioning condensers, evaporators, and oil coolers. The design of microchannel aluminum tubes is developing towards more channels and ultra-thin walls.

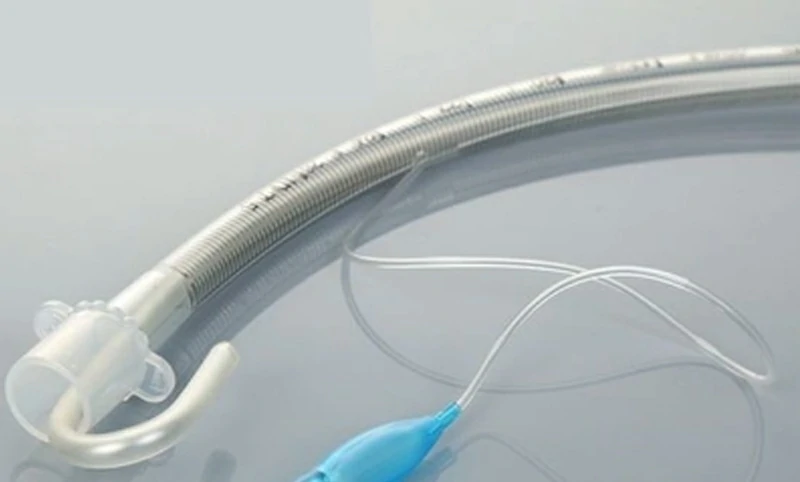

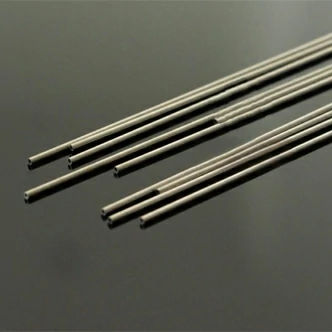

Aluminum high precision tube products

Our high-precision aluminum tubing is tailored for aerospace, medical devices, automotive fuel lines, and instrumentation applications. Using advanced CNC machining and precision extrusion, we ensure tolerance control down to microns, meeting the most stringent industry standards.Quick Quote

Specializing in high-precision aluminum tubes, we offer diameters from 0.094 inches with ±0.0005-inch tolerance, including telescopic, oval, and square shapes. Used in laparoscopic surgery, satellite cooling, and precision-demanding fields.

Contact us now

-

High precision reinforced tube

Manufactured with high-precision processes, offering excellent strength and durability, ideal for high-pressure and high-strength applications.

-

High precision capillary tube

Featuring extremely tight inner and outer diameter tolerances, widely used in precise liquid flow control and medical devices.

-

High temperature resistant precision tube

Providing exceptional high-temperature resistance, suitable for precision piping systems in high-temperature environments.

-

High precision seamless pipe

Made using seamless technology to ensure high precision and reliability, widely used in aerospace and precision industries.

-

High-precision multifunctional composite pipe

Combining multiple functional properties, ideal for complex structures and diverse industrial applications.

More custom aluminum tube solution

We also offer a series of special-shaped aluminum tubes in a wide range of alloys, including 6061, 5052, 5A02, 3003, and 7075, designed for structural, fluid, gas, and electrical applications. This includes trough structure tubes, aviation ducts, liquid and gas transport pipes, fuel lines, and high-precision electrical conduits — all fully customizable in shape, size, and performance.Quick Quote

-

Aluminum trough structure tube

Alloy: 6061 6063

Featuring a channel-shaped cross-section, they offer enhanced load capacity and bending resistance, with various sizes and wall thicknesses for diverse structural needs.

-

Aluminum aviation duct

Alloy: 5A02, 5052, 2024, 5A06, 6061, 7075

Application: Suitable for complex machining, used in aerospace applications.

-

Aluminum liquid transport pipe

Alloy: 5052 H32

Size: Customized large diameter and long tubes.

Excellent corrosion resistance, suitable for a variety of liquid media.

-

Aluminum gas transport pipe

Alloy: 6061 5083

Size: ∅25mm-∅ 100mm, wall thickness 2mm-4mm

High air tightness, high pressure resistance. Used for industrial gas and medical oxygen delivery.

-

Aluminum fuel pipe

Alloy: 3003 H14

Features: Small diameter and high precision.

Leak-proof, corrosion-resistant, suitable for long-term use. Used in aviation fuel transportation, vehicle fuel systems.

-

Aluminum electrical conduit

Alloy: 6061 T6

Feature: high precision, high temperature resistance.

Offering excellent conductivity and corrosion resistance, ideal for power transmission and electrical systems.

Need other alloy special-shaped tubes?

Although our main product of Chalco Aluminum is aluminum, the group company is also involved in other metal fields and can provide a variety of metal products. If you have needs for other metal alloy special-shaped tubes, please feel free to communicate with our sales staff. We will do our best to allocate resources and provide you with the best solution. Quick Quote

Customized Titanium Alloy Tube

Custom steel pipe

Custom stainless steel pipe

Custom copper pipe

Custom brass tube

Custom composite pipe

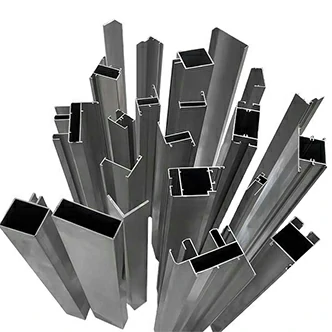

Chalco aluminum tube customization service & processing capabilities

We provide industry-leading aluminum tube customization services with advanced equipment, precise control, and deep technical know-how — from extrusion to finishing, end to end.

Extrusion Capabilities (Production Foundation)

- Specialized in complex hollow profiles and special-shaped tube extrusion

- Equipped with 600–3600 tons extrusion lines, supporting thin-wall, large-section, and multi-chamber tubes

- In-house die design and rapid tooling for custom cross-sections and faster development

- Alloy support: 1xxx to 7xxx series, including high-strength aerospace alloys

Machining & Forming (Precision Processing)

- CNC cutting & slotting: tight-tolerance trimming and connector features

- 3D CNC bending: high-accuracy bending for small to large diameters, including compound and serpentine forms

- Cold drawing: enhances tube precision, straightness, and surface finish — ideal for thin-wall applications

- Swaging & expanding: for end-shaping, connector fitment, and diameter transitions

- TIG/MIG welding: for structural joining, especially in multi-part or reinforced tube assemblies

- Laser cutting: for ports, notches, and high-speed pattern work

Surface Finishing (Performance & Aesthetics)

- Anodizing: protective and decorative, up to 25μm thickness

- Electrophoresis: smooth, durable, ideal for architectural use

- Powder coating: UV and corrosion resistant, full color options

- Mechanical finishes: polishing, brushing, sandblasting for enhanced appearance and grip

Full Customization Control (Fit Your Function)

- OD 5–300mm, wall thickness 0.5–20mm, custom lengths up to 6m+

- Tolerance control: ±0.05mm OD, ±0.02mm wall thickness

- Alloy coverage: 6061, 6063, 5052, 5083, 2024, 7075 and more

- Rapid prototyping: samples in as fast as 7 days

- Support for both low volume and mass production

Cooperative field

Our custom-shaped aluminum tubes are engineered to meet the functional and technical demands of diverse industries, offering tailored solutions for strength, precision, conductivity, and corrosion resistance.

- Aerospace: Lightweight, high-strength tubing for airframes, ducts, and structural components

- Automobile manufacturing: Custom tubes for cooling systems, drivetrains, fuel delivery, and body structures

- EConstruction & Architecture: Corrosion-resistant structural and decorative profiles with surface finishing

- Electronic appliances: Thermal and electrical conductive tubes for heat sinks, housings, and connectors

- Medical equipment: High-precision tubing for fluid delivery, equipment frames, and device integration

Ordering Guidance & Service Advantages

Chalco helps customers simplify the customization of special-shaped aluminum tubes — reducing mold costs, shortening delivery time, and ensuring quality production.Quick Quote

Why choose Chalco for custom shaped tubes?

- Ready-to-use mold inventory: Access to a large library of standard dies — no mold fee required

- Free design optimization: Custom mold design support to reduce development cost

- Mold fee discounts: Free mold policy for qualifying orders or batches

- Streamlined workflow: From requirement → solution → sample → mass production, fast and efficient

- One-stop processing: Extrusion, bending, welding, CNC, surface finishing — all in-house

High-precision manufacturing support

We operate advanced lines for extrusion, cold drawing, welding, and CNC processing, supporting:

- Seamless and welded tubes

- Heat treatment & hardness control

- Full testing coverage to meet international standards

Custom Aluminum Tube FAQ

Q1: What alloys are commonly used?

A: 6063 for complex shapes, 6061 for structural parts, 7075 for high strength.

Q2: What’s the manufacturing process?

A: Mold design → Billet prep → Extrusion → Cooling → Cutting → Heat treatment → Finishing.

Q3: Is customization more expensive?

A: Yes, due to tooling, low volume, and special specs — but our mold support policies help reduce costs.

Q4: What should I provide when ordering?

A: Alloy type, size, tolerances, surface finish, order quantity.

Q5: How to enhance tube strength?

A: Heat treatment such as aging or tempering is commonly applied.

Q6: Do you offer extra services?

A: Yes — including drilling, welding, anodizing, coating, polishing, and custom packaging.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote