An anodized aluminum tube is an aluminum alloy tube that has undergone anodizing treatment, forming a dense layer of aluminum oxide on its surface through an electrochemical reaction.

This process enhances its corrosion resistance, wear resistance, and hardness. Additionally, it improves the appearance of the aluminum tube, offering a variety of colors and finishes. It is widely used in industries such as construction, automotive, electronics, and aerospace.

Common alloys of Chalco anodized aluminum tubes

6061 anodized aluminum tube

6061 aluminum alloy is a high-strength, corrosion-resistant heat-treatable alloy. After anodizing, its surface hardness and corrosion resistance can be further enhanced.

Contact us now

Condition: T6 (solution heat-treated + artificial aging)

Colors: Silver, black, gold, bronze

Shapes: Round tube, square tube, rectangular tube

Applications: Aerospace structural components, bicycle frames, mechanical parts, automotive parts, etc.

| Products | OD (in) | Wall (in) | Length (in) |

| 6061 anodized aluminum tube | 0.5" | 0.035" | 240" |

| 6061 anodized aluminum tube | 0.75" | 0.049" | 240" |

| 6061 anodized aluminum tube | 1" | 0.065" | 240" |

| 6061 anodized aluminum tube | 1.25" | 0.083" | 240" |

| 6061 anodized aluminum tube | 1.5" | 0.095" | 240" |

| 6061 anodized aluminum tube | 2" | 0.12" | 240" |

| 6061 anodized aluminum tube | 2.5" | 0.125" | 240" |

| 6061 anodized aluminum tube | 3" | 0.125" | 240" |

| 6061 anodized aluminum tube | 3.5" | 0.188" | 240" |

| 6061 anodized aluminum tube | 4" | 0.25" | 240" |

| 6061 anodized aluminum tube | 4.5" | 0.25" | 240" |

| 6061 anodized aluminum tube | 5" | 0.25" | 240" |

| 6061 anodized aluminum tube | 5.5" | 0.25" | 240" |

| 6061 anodized aluminum tube | 6" | 0.25" | 240" |

| 6061 anodized aluminum tube | 6.5" | 0.375" | 240" |

| 6061 anodized aluminum tube | 7" | 0.375" | 240" |

| 6061 anodized aluminum tube | 8" | 0.5" | 240" |

| 6061 anodized aluminum tube | 9" | 0.5" | 240" |

| 6061 anodized aluminum tube | 10" | 0.5" | 240" |

| 6061 anodized aluminum tube | 12" | 0.5" | 240" |

6063 anodized aluminum tube

6063 aluminum alloy has excellent extrudability, and after anodizing, it provides a smooth surface with strong decorative appeal. It is commonly used in the construction and decoration industries.

Contact us now

Condition: T5, T6

Colors: Silver, black, gold, champagne, bronze

Shapes: Round tube, square tube, oval tube, custom-shaped tube

Applications: Building windows and doors, railings, radiators, furniture frames, electronic device enclosures, etc.

| Products | OD (in) | Wall (in) | Length (in) |

| 6063 anodized aluminum tube | 0.25" | 0.035" | 240" |

| 6063 anodized aluminum tube | 0.5" | 0.035" | 240" |

| 6063 anodized aluminum tube | 0.75" | 0.049" | 240" |

| 6063 anodized aluminum tube | 1" | 0.065" | 240" |

| 6063 anodized aluminum tube | 1.25" | 0.083" | 240" |

| 6063 anodized aluminum tube | 1.5" | 0.095" | 240" |

| 6063 anodized aluminum tube | 2" | 0.12" | 240" |

| 6063 anodized aluminum tube | 2.5" | 0.125" | 240" |

| 6063 anodized aluminum tube | 3" | 0.125" | 240" |

| 6063 anodized aluminum tube | 3.5" | 0.188" | 240" |

| 6063 anodized aluminum tube | 4" | 0.25" | 240" |

| 6063 anodized aluminum tube | 4.5" | 0.25" | 240" |

| 6063 anodized aluminum tube | 5" | 0.25" | 240" |

| 6063 anodized aluminum tube | 5.5" | 0.25" | 240" |

| 6063 anodized aluminum tube | 6" | 0.25" | 240" |

| 6063 anodized aluminum tube | 6.5" | 0.375" | 240" |

| 6063 anodized aluminum tube | 7" | 0.375" | 240" |

| 6063 anodized aluminum tube | 8" | 0.5" | 240" |

5052 anodized aluminum tube

5052 aluminum alloy is a high corrosion-resistant aluminum-magnesium alloy. After anodizing, its weather resistance is further enhanced, making it suitable for marine and chemical environments.

Contact us now

Condition: H32, H34

Colors: Silver, gray, black

Shapes: Round tube, rectangular tube

Applications: Marine equipment, chemical pipelines, ship structures, storage tanks, etc.

| Products | OD (in) | Wall (in) | Length (in) |

| 5052 anodized aluminum tube | 0.25" | 0.035" | 240" |

| 5052 anodized aluminum tube | 0.5" | 0.035" | 240" |

| 5052 anodized aluminum tube | 0.75" | 0.049" | 240" |

| 5052 anodized aluminum tube | 1" | 0.065" | 240" |

| 5052 anodized aluminum tube | 1.25" | 0.083" | 240" |

| 5052 anodized aluminum tube | 1.5" | 0.095" | 240" |

| 5052 anodized aluminum tube | 2" | 0.12" | 240" |

| 5052 anodized aluminum tube | 2.5" | 0.125" | 240" |

| 5052 anodized aluminum tube | 3" | 0.125" | 240" |

| 5052 anodized aluminum tube | 3.5" | 0.188" | 240" |

| 5052 anodized aluminum tube | 4" | 0.25" | 240" |

| 5052 anodized aluminum tube | 4.5" | 0.25" | 240" |

| 5052 anodized aluminum tube | 5" | 0.25" | 240" |

| 5052 anodized aluminum tube | 5.5" | 0.25" | 240" |

| 5052 anodized aluminum tube | 6" | 0.25" | 240" |

| 5052 anodized aluminum tube | 6.5" | 0.375" | 240" |

| 5052 anodized aluminum tube | 7" | 0.375" | 240" |

| 5052 anodized aluminum tube | 8" | 0.5" | 240" |

7075 anodized aluminum tube

7075 aluminum alloy is a high-strength aerospace-grade alloy. After anodizing, its wear resistance is improved, making it suitable for high-load structures.

Contact us now

Condition: T6, T73

Colors: Silver, black, dark gray

Shapes: Round tube, square tube

Applications: Aerospace, racing car frames, military equipment, sports equipment, etc.

3003 anodized aluminum tube

3003 aluminum alloy is a highly corrosion-resistant, easily formable aluminum-manganese alloy. After anodizing, its weather resistance is further enhanced.

Contact us now

Condition: H14, H24

Colors: Silver, light gray

Shapes: Round tube, rectangular tube

Applications: Air conditioning pipes, chemical equipment, food industry equipment, etc.

Chalco's specialized anodized aluminum tubes

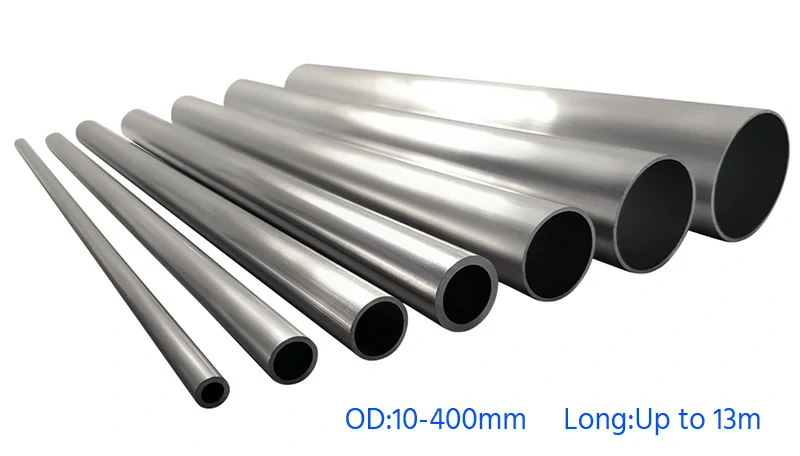

An anodized aluminum round tube is a lightweight and corrosion-resistant tube, with its surface treated through anodizing, commonly used in structural, construction, and decorative applications.

An anodized aluminum square tube is a durable aluminum profile with a square cross-section, treated through anodizing, making it suitable for frames, enclosures, and industrial structures.

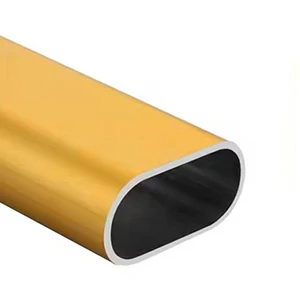

An anodized aluminum oval tube is a corrosion-resistant tube with a smooth appearance and an oval cross-section, commonly used in applications where aesthetics and aerodynamics are important, such as in automotive, furniture, and handrails.

What colors are available for Chalco anodized aluminum tubes?

Black anodized aluminum tube

An aluminum tube that has been anodized and dyed black, offering excellent corrosion resistance, wear resistance, and decorative appeal. It is widely used in fields such as construction, electronic devices, automotive parts, and high-end furniture.

Silver anodized aluminum tube

An aluminum tube with a natural silver oxide film formed through anodizing, offering excellent corrosion resistance, wear resistance, and a metallic finish. It is widely used in construction decoration, industrial equipment, vehicles, and household items.

Gold anodized aluminum tube

With its bright gold surface, the gold anodized aluminum tube adds a touch of luxury to any project, making it suitable for various size requirements and offering a unique style. This material combines durability and elegance, making it the perfect choice for high-end design solutions.

Chalco's anodized aluminum tubes offer a variety of color options, as follows:

Red anodized aluminum tube

Blue anodized aluminum tube

Bronze anodized aluminum tube

White anodized aluminum tube

Champagne anodized aluminum tube

Purple anodized aluminum tube

Typical applications of anodized aluminum tubes

Building decoration: Used for curtain walls, window and door frames, railings, handrails, etc., providing aesthetically pleasing and corrosion-resistant structural support.

Aerospace: Applied in lightweight structural components, such as brackets and piping systems, to increase strength while reducing weight.

Automotive manufacturing: Used for exhaust pipes, roof racks, bicycle frames, etc., enhancing durability and oxidation resistance.

Electronic devices: Used for heat sinks, enclosures, and connecting pipes to ensure thermal conductivity and interference resistance.

Medical instruments: Used for surgical instruments and rehabilitation equipment supports, offering corrosion-resistant and easy-to-clean surface treatments.

Furniture manufacturing: Used for tables, chairs, brackets, and decorative frames, enhancing modernity and wear resistance.

Sports equipment: Used for tent poles, trekking poles, golf clubs, etc., ensuring lightweight and high strength.

Shipbuilding industry: Used for deck railings, drainage pipes, etc., resistant to seawater corrosion, extending service life.

Types of anodizing

Ordinary Anodizing (Type I, Chromic Acid Anodizing)

Uses chromic acid for oxidation treatment, resulting in a thinner oxide layer (approximately 0.5-2μm). It is mainly used in fields requiring high dimensional precision, such as aerospace, offering some corrosion resistance but lower wear resistance.

Hard Anodizing (Type III, Hard Anodizing)

Uses higher voltage and low-temperature conditions to form a thicker oxide layer (up to 25-150μm), significantly enhancing wear resistance and hardness. It is suitable for high-strength applications such as mechanical parts, military equipment, and automotive components.

Thick Film Anodizing

Falls between ordinary and hard anodizing, with an oxide layer thickness generally ranging from 10-25μm. It offers good corrosion resistance and moderate wear resistance, widely used in industrial, construction, and electronic products.

Colored Anodizing

Involves dyeing after ordinary or thick film anodizing, offering a variety of colors such as black, gold, red, and blue. It is mainly used for decorative applications such as in construction, home furnishings, and electronic device enclosures.

What are the notable advantages of anodized aluminum tubes?

Corrosion resistance: The anodizing process forms a durable oxide layer on the surface of the aluminum tube, significantly enhancing its corrosion resistance. The oxide layer effectively resists environmental factors and chemicals, extending the tube's lifespan, especially in harsh conditions.

Increased surface hardness: The oxide layer formed during anodizing greatly increases the surface hardness of the aluminum tube, making it more wear-resistant than untreated aluminum. This increased hardness allows anodized aluminum tubes to perform excellently under mechanical friction and impact.

Scratch resistance: The surface of anodized aluminum tubes is smooth and hard, making it less prone to scratches. This scratch resistance ensures that the tube maintains its appearance and performance during transportation and use.

Colorability: After anodizing, the surface of the aluminum tube can easily be dyed to meet aesthetic and customization needs. This coloring not only enhances the appearance but also further improves the material's corrosion resistance.

Extended lifespan: Due to its excellent wear resistance, anodized aluminum tubes have a significantly extended service life, reducing the need for frequent replacements or maintenance, thus lowering overall operating costs.

Why choose Chalco's anodized aluminum tubes?

Extra-long products: We offer anodized aluminum tubes up to 13 meters in length to meet the demands of various complex applications.

Outstanding quality control: Chalco uses advanced production processes and a strict quality management system to ensure that every aluminum tube meets international standards, providing excellent corrosion resistance, wear resistance, and aesthetic appeal.

Diverse product options: Chalco provides a variety of sizes, colors, and surface treatment options to meet the needs of different industries and customers, from construction to aerospace.

Customization services: Chalco offers personalized customization based on specific customer requirements, including size, color, surface treatment, etc., ensuring the product meets the exact application needs.

Environmentally friendly and sustainable: Chalco values environmental protection, with the anodizing process being eco-friendly and aluminum itself being recyclable, in line with sustainable development goals.

High-quality customer service: Chalco provides professional technical support and customer service to help clients with product selection, applications, and after-sales issues.