Aluminum foam is a high-performance, lightweight metal material that combines excellent energy absorption, sound insulation, and high-temperature resistance properties. It is widely used in aerospace, construction, automotive, and other industries.

Its unique structure allows for reduced weight while still providing exceptional strength and vibration damping, offering industries improved cost-efficiency and performance advantages. By adjusting the density and pore structure, aluminum foam meets the needs for safety, durability, and energy savings in various sectors.

Next, we will explore product types, pore size, surface finishes, colors, and other specifications. If you're interested in its specific applications in any industry, you can also check out the industry solutions for aluminum foam.

Types of Aluminum Foam

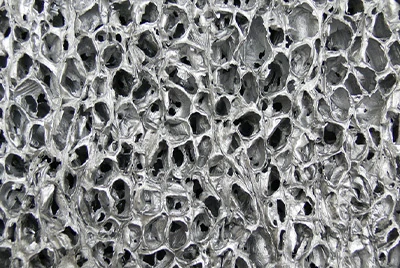

Open Cell Aluminum Foam

Open-cell aluminum foam has interconnected pores, ideal for high permeability and sound absorption applications. Its high porosity excels in soundproofing, noise reduction, and heat exchange.

Contact us now

Specifications

- Pore size: 0.5-1.0mm

- Porosity: 70-90%

- Open cell rate: 55%-65%

- Thickness: 3/8" (9.5mm), 1/2" (12.7mm), 1" (25.4mm), 1.7" (43.2mm), custom sizes available

- Standard sizes: 4ft x 8ft (1220x2440mm), 4ft x 12ft (1220x3658mm)

- Common sizes: 500x500mm, 500x1000mm, 600x1200mm

- Density: 0.2-0.5g/cm³

- Compressive strength: 3MPa-17MPa

- Bending strength: 3MPa-15MPa

- Energy absorption: 8J/m³-30J/m³

- Noise reduction coefficient (NRC): >0.75

- Fire rating: A1

Features

- High permeability: Interconnected pores offer strong sound absorption, fire resistance, and dust protection.

- High porosity: 70-90% porosity makes it ideal for noise reduction and sound isolation.

- Corrosion resistance: Suitable for complex environments and will not corrode over long-term use.

Applications

Open cell aluminum foam is widely used in urban rail transit, elevated roads, railways, cooling towers, and other noise-sensitive environments. It effectively reduces noise, protects equipment from vibration, and is also used in soundproofing and noise isolation for equipment such as HVDC converter stations and concrete mixing plants.

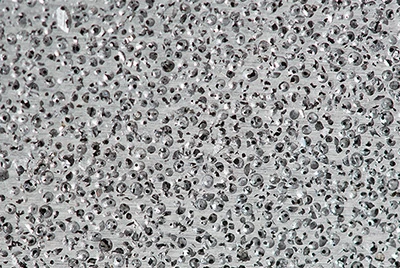

Closed Cell Aluminum Foam

Closed-cell aluminum foam has sealed pores, offering excellent load-bearing and impact absorption. Its low thermal conductivity and electromagnetic shielding make it ideal for thermal insulation, structural reinforcement, and electronic device protection.

Contact us now

Specifications

- Pore size: 3-10mm

- Density: 0.3-0.75g/cm³

- Porosity: 68%-91%

- Thickness: 6-300mm

- Standard sizes: 4ft x 8ft (1220x2440mm), 4ft x 12ft (1220x3658mm)

- Common sizes: 500x500mm, 500x1000mm, 600x1200mm

- Tensile strength: 2-7MPa

- Compressive strength: 3-17MPa

- Melting point: Approximately 780℃

- Thermal conductivity: 0.25-0.62 W/m²

- Soundproofing (20mm): 20-40 dB

- Sound absorption (1000Hz-2000Hz): 40%-80%

- Electromagnetic wave shielding: >90dB

- Salt spray test: No corrosion

Features

- Strong structure: The closed-cell structure gives it strong load-bearing and impact absorption capabilities.

- Thermal insulation: Its low thermal conductivity provides excellent thermal insulation.

- Electromagnetic shielding: Effectively shields high-frequency electromagnetic waves, suitable for protecting electronic devices.

Applications

Closed cell aluminum foam is widely used in load-bearing and energy-absorbing structural materials. It is commonly applied in industries such as automotive, aerospace, and construction to enhance structural strength, absorb impact, and provide thermal insulation. Its electromagnetic wave shielding properties also make it an important material in the electronics industry.

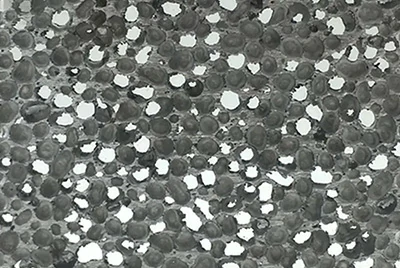

Spherical Porous Aluminum

Spherical porous aluminum combines open-cell and closed-cell foam benefits, offering high permeability and energy absorption. Its spherical pore structure enhances filtration, sound absorption, and impact resistance by repeatedly attenuating air and liquid flow.

Contact us now

Specifications

- Pore size: 3-13mm

- Spherical diameter: 3-13mm

- Wall pore size: 0.5-4mm

- Thickness: 5-150mm

- Maximum size: 1200x400mm, 1000x500mm

- Density: 0.5-1.1g/cm³

- Heat resistance: 300℃

- Sound wave frequency: 125-4000Hz

- Sound absorption coefficient: ≥0.95

- Noise reduction coefficient: ≥0.48

- Electromagnetic wave frequency: 2.6-18GHz

- Electromagnetic shielding: 60-90dB

Features

- Unique pore structure: The spherical pore structure offers exceptional permeability and energy absorption.

- Good impact resistance: Capable of absorbing multi-directional impact energy, making it highly durable.

- Excellent thermal and acoustic insulation: Provides outstanding thermal insulation and sound absorption, suitable for high-performance applications.

Applications

Spherical porous aluminum is widely used in high-precision fields such as aerospace, automotive, and environmental filtration. It is ideal for efficient energy absorption, filtration, thermal insulation, and electromagnetic shielding. Additionally, due to its excellent impact resistance, it is also used in safety protection for buildings and transportation vehicles.

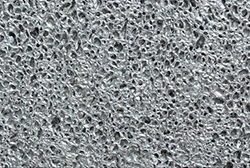

Semi-Transparent Aluminum Foam

Semi-transparent aluminum foam combines aluminum strength with foam translucency, allowing light transmission while maintaining metal strength. Widely used in architectural decoration and design, it offers a lightweight, durable, and modern appearance.

Contact us now

Specifications

- Density: 0.25-0.35g/cm³

- Thickness: 3-10mm

- Dimensions: 12400x800mm, 2000x1000mm

- Tensile strength: 2-7MPa

- Compressive strength: 3-17MPa

- Melting point: Approximately 780℃

- Thermal conductivity: 0.268 W/m²

- Electromagnetic shielding: Over 90dB

- Sound absorption coefficient: 0.70-0.75

- Salt spray test: No corrosion

Features

- Translucency: Allows natural light to pass through, creating a soft diffused light effect.

- Aesthetic appeal: The combination of metal luster and modern design offers strong decorative value.

- Fire resistance: Excellent fire-resistant properties ensure safe usage.

Applications

Semi-transparent aluminum foam is widely used in architectural decoration, wall cladding, ceiling tiles, and creative furniture design. It provides an aesthetically pleasing visual effect while also offering thermal insulation and fire resistance, making it suitable for both interior and exterior modern building designs. Additionally, its lightweight nature makes it easy to install and customize.

Aluminum Foam Pore Size Classification, Surface, and Specifications

Pore Size of Aluminum Foam

Small Pore Foam Aluminum

Pore sizes range from 0.5-3mm, offering high porosity and excellent absorption and noise reduction.

Medium Pore Foam Aluminum

Pore sizes range from 3-8mm, balancing mechanical strength, thermal insulation, and energy absorption.

Large Pore Foam Aluminum

Pore sizes range from 8-12mm, ideal for applications requiring low density and high permeability, such as filtration and shock absorption.

Surface Forms of Aluminum Foam

Single-Sided Open

Double-Sided Open(Semi-Transparent)

Natural Casting Form(Closed)

Size of Aluminum Foam

-

Thickness

5-100mm

-

5083 aluminum plate

500mmx500 mm

500mmx1000mm

1000mmx1000mm

1000mmx2000mm

1220mmx2440mm

-

Standard thickness

3/8"(9.5mm)

0.5”(12.7mm)

1”(25.4mm)

1.7”(43.2mm)

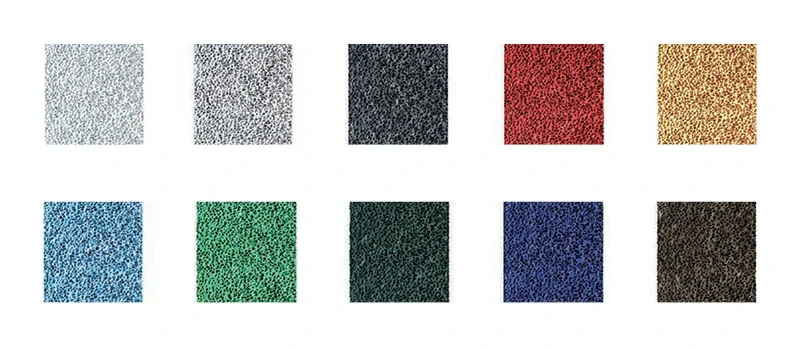

Colors of Aluminum Foam

Product Types of Aluminum Foam

Aluminum Foam Block

Aluminum Foam Block, up to 2500x900x350mm, offers excellent strength and energy absorption. Its high density makes it ideal for impact resistance, sound insulation, and structural reinforcement in large industrial and construction projects.

Aluminum Foam Sheet

Aluminum Foam Sheet comes in standard thicknesses and sizes, with customization options. It offers excellent mechanical performance and lightweight properties, ideal for thermal insulation, soundproofing, and structural enhancement.

Standard Thickness:3/8", 1/2", 1", 1.7"

Common Sizes:4x8 feet, 4x12 feet

Aluminum Foam Sandwich Panel

The Aluminum Foam Sandwich Panel, with aluminum alloy plates and a foam core, offers great strength and lightweight design. It’s ideal for bulletproof, fireproof, and soundproof applications, excelling in high-strength, low-weight construction and mobile structures.

Aluminum Foam Composite Panel

Aluminum Foam Composite Panel combines foam with materials like marble, PVC, and wood, offering fireproof, waterproof, and high-strength properties. Its lightweight, multifunctional design is ideal for furniture, construction, and vehicle interiors.

Thickness:10-100mm

Sizes:500x500mm, 500x1000mm, 1000x1000mm

Aluminum Foam Panel with Punched Holes

Aluminum Foam Panel with Punched Holes enhances sound absorption and insulation, ideal for noise control and acoustic treatment. It’s widely used in railway, elevated roads, and mechanical equipment for its excellent soundproofing performance.

Aluminum Foam Panel With Painting

The Aluminum Foam Panel with Painting features a weather-resistant coating, offering moisture, corrosion, and mildew resistance, along with high-temperature and high-strength decorative effects. It’s ideal for commercial spaces and interior design, blending aesthetics with functionality.

Custom-Shaped Aluminum Foam

The excellent processing characteristics of Aluminum Foam allow it to be customized into various shapes and sizes according to customer needs. Whether in rod, disc, or irregular parts form, aluminum foam offers great design flexibility, meeting the specific requirements of various applications.

Aluminum Foam Rod

Aluminum Foam Disc

Aluminum Foam Tube

Aluminum Foam Flange

Aluminum Foam Threaded Part

Custom-Shaped Aluminum Foam

Properties of Aluminum Foam

-

Lightweight

Lightweight

Aluminum foam has a density of 0.2–0.4 g/cm³, which is only 1/10th of aluminum, 1/20th of titanium, and even lower than that of wood. Its ultra-lightweight nature makes it highly advantageous in applications where weight reduction is essential. The composite structure design can further reduce the overall weight by up to 50%, making it ideal for use in aerospace and automotive industries.

-

High Strength and Stiffness

High Strength and Stiffness

Despite its low density, aluminum foam has a bending strength approximately 1.5 times that of metal aluminum and can even reach 1.5 times the strength of steel. Its high specific stiffness makes it widely used in structural components, offering a lightweight yet sturdy material support.

-

Excellent Acoustic Performance

Excellent Acoustic Performance

The porous structure of aluminum foam gives it outstanding sound absorption properties. In its closed-cell form, aluminum foam has an acoustic insulation coefficient of up to 0.9, making it suitable for noise isolation walls, audio equipment, and other acoustic treatment applications. It is also fire-resistant and does not absorb moisture, maintaining stable acoustic performance even in harsh environments.

-

Superior Thermal Performance

Superior Thermal Performance

Aluminum foam has a low thermal conductivity (0.3–1 W/(m·K)) and excellent thermal insulation properties. It is widely used in heat exchangers and insulation materials. Additionally, its high-temperature resistance is exceptional, as it does not melt even when heated to 1400°C and does not release toxic gases, making it ideal for high-temperature fireproof and explosion-proof applications.

-

Sound Absorption and Vibration Damping

Sound Absorption and Vibration Damping

The damping performance of aluminum foam is 5–10 times higher than that of metal aluminum. With a porosity of 84%, it can absorb 2.5 MJ/m³ of energy, far surpassing other vibration-damping materials, especially in collision protection and impact energy absorption. It effectively absorbs shock energy and maintains its damping effect even under extreme conditions.

-

Electromagnetic Shielding

Electromagnetic Shielding

Aluminum foam offers excellent electromagnetic shielding properties, effectively reducing interference from high-frequency electromagnetic waves. It can reduce over 80% of electromagnetic interference, making it widely used in electromagnetic shielding for electronic devices and communication facilities. Its performance can be enhanced up to 1000 times, making it suitable for shielding high-frequency electromagnetic environments.

-

Easy to Process and Install

Easy to Process and Install

Aluminum foam has excellent processability, allowing it to be cut, drilled, CNC machined, bonded, and brazed. This makes it easy to customize and install on-site. Due to its lightweight nature, the installation process does not require heavy equipment, reducing construction difficulty and cost.

Aluminum Foam Industry Solutions

Traffic Noise Barriers

Aluminum foam is widely used in traffic noise barrier applications, focusing primarily on soundproofing and vibration reduction. Whether for high-speed railways, subways, or roads, aluminum foam effectively reduces noise, minimizes vibrations, and enhances comfort and safety for surrounding areas.

Contact us now

Product Categories

- Closed-cell aluminum foam

- Small-pore aluminum foam

- Aluminum foam blocks

- Aluminum foam sandwich panels

- Aluminum foam protective components

Specifications & Dimensions

Thickness: 5-30mm

Standard sizes: 1000mm x 500mm, 1000mm x 1000mm, 2000mm x 1000mm

Customization: For demands exceeding 3000㎡, custom sizes and thicknesses are available.

Specific Applications

- Sound Barriers & Noise Reduction: Aluminum foam is used in sound barriers for highways, railways, and other transportation facilities. It effectively reduces low-frequency noise, improving the comfort and safety of the surrounding environment.

- Tunnel Noise Barriers: Aluminum foam sound-absorbing panels can be used for noise reduction barriers in highway and underwater tunnels. The unique structure effectively absorbs low-frequency noise generated by vehicles while protecting tunnel walls from impact damage. Additionally, aluminum foam is moisture-resistant, ensuring excellent soundproofing performance even in humid environments.

The design of sound barriers varies according to different road types and environments. Below are some examples of noise barriers that Chalco has worked on in the past. These are categorized based on the type of sound barrier, which you can refer to and see if they are suitable for your current project.

Aluminum Foam Noise Barrier Types

Fully enclosed sound barrier

Semi-enclosed sound barrier

Fully metal sound barrier

Semi-transparent sound barrier

Upright sound barrier

Arc-shaped sound barrier

Landscape sound barrier

Subway sound barrier

High-speed rail sound barrier

Aluminum Foam Noise Barriers vs. Traditional Noise Barriers

| Noise Barrier Type | Noise Reduction Range | Average Noise Reduction | Conclusion |

| Aluminum Foam Noise Barrier | 10.03dB~20.13dB | 14.96dB | The foam aluminum sound barrier reduces noise by an average of 14.96dB, which is about three times that of the traditional louver-type sound-absorbing board sound barrier. |

| Traditional Louvered Noise Barrier (Layered Materials) | 0.81dB~8.22dB | 4.84dB |

Building Decoration

In construction, aluminum foam is used in walls, roofs, floors, and more, providing structural support and excellent insulation, soundproofing, and fireproofing. Its performance makes it essential for energy-efficient, eco-friendly buildings.

Contact us now

Product Categories

- Open Cell Aluminum Foam

- Semi-Transparent Aluminum Foam

- Closed Cell Aluminum Foam

- Large Pore Aluminum Foam

- Aluminum Foam Sheet

- Aluminum Foam Composite Panel

Specifications & Dimensions

Thickness: 5-30mm

Standard sizes: 1000mm x 500mm, 1000mm x 1000mm, 2000mm x 1000mm

Customization: For demands exceeding 3000㎡, custom sizes and thicknesses are available.

Specific Applications

- Building Curtain Walls: Aluminum foam sheets are used in curtain wall systems of high-rise buildings, providing excellent energy absorption, soundproofing, and insulation functions. Their superior thermal expansion properties and fire resistance ensure the stability and safety of the curtain wall.

- Ceiling Suspension Systems: Aluminum foam sound-absorbing panels can be used in ceilings of recording studios, conference halls, and other places, offering exceptional noise control and soundproofing effects. In humid environments, aluminum foam sound-absorbing panels remain unaffected by water absorption, ensuring long-term stable noise reduction performance.

- Interior Wall Decoration: Aluminum foam sound-absorbing panels are used for interior wall decoration in entertainment venues such as karaoke lounges and nightclubs, providing excellent sound absorption and noise reduction while also featuring fire resistance.

- Curtain Walls and Composite Materials: Aluminum foam combined with materials like marble and wood reduces the weight of traditional marble by 2/3, and its impact resistance is increased by 2 times. Composite wood and aluminum foam flooring can lighten the weight of the building structure while enhancing impact resistance and durability, commonly used for soundproofing between floors.

Application Cases

Beijing Winter Olympics Ice Hockey Arena

Beijing Da Yue Cheng

Hao Li Lai

China Shougang Museum

PRADA Foundation

Earthcam Headquarters

HeyTea Brand Space

Keda Silicon Valley

Office Spaces

Aerospace

Aluminum foam is widely used in aerospace for its lightweight, energy absorption, and high-temperature resistance. Its shock absorption, soundproofing, corrosion resistance, and strength are crucial in components like aircraft carrier catapults, lander cushioning devices, and spacecraft re-entry capsules.

Contact us now

Product Categories

- Open Cell Aluminum Foam

- Closed Cell Aluminum Foam

- Spherical Aluminum Foam

- Small Pore Aluminum Foam

- Aluminum Foam Sandwich Panel

- Aluminum Foam Sheet

- Aluminum Foam Block

Specific Applications

- Aircraft Carrier Electromagnetic Catapult: Aluminum foam is used as a shock absorption and energy-absorbing material in electromagnetic catapults, helping reduce vibration and impact during the launch process. Its high energy absorption properties protect equipment and carrier-based aircraft from damage.

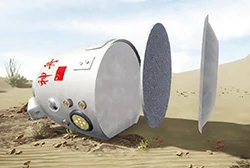

- Lander Cushioning Device: Aluminum foam effectively absorbs landing impact forces, reducing the vibration and pressure during landing. Its lightweight structure ensures the safety and stability of equipment during the landing process.

- Spacecraft Re-entry Capsule: Aluminum foam is used in the thermal protection and structural reinforcement layers of spacecraft re-entry capsules, helping to withstand high temperatures and aerodynamic loads. Its lightweight nature reduces the overall weight of the spacecraft while enhancing the safety of the vehicle.

- Ship Decks: Aluminum foam is used in the sandwich structure of ship decks, improving their corrosion resistance and impact resistance. Its lightweight properties reduce the deck weight and enhance the ship's combat capability.

- Military Heavy Weapon Airdrop: Aluminum foam is used in the cushioning devices of military heavy weapons during airdrops, effectively absorbing vibration and shock. It ensures that equipment remains undamaged during the airdrop process, guaranteeing the success of the mission.

Application Cases

Lander Cushioning Devices

Shenzhou Spacecraft Re-entry Capsule

Ship Decks

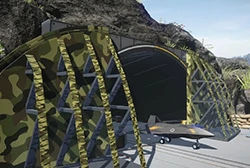

Military

Aluminum foam, known for its lightness, energy absorption, high-temperature, and impact resistance, is widely used in military protection. It reduces equipment weight, strengthens structures, and maintains performance in extreme environments. It's applied in camouflage shelters, missile launch vehicles, and composite armor panels.

Contact us now

Product Categories

- Closed Cell Aluminum Foam

- Small Pore Aluminum Foam

- Aluminum Foam Block

- Aluminum Foam Sandwich Panel

- Aluminum Foam Protective Components

Specific Applications

- Camouflage Shelter Protection Doors: Aluminum foam is used as the core material in camouflage shelter protection doors, significantly improving their blast resistance and high-temperature performance. Its lightweight structure ensures that the doors maintain strength while reducing overall weight.

- Ballistic Missile Launch Vehicles: Aluminum foam is used in the structure of ballistic missile launch vehicles, effectively absorbing vibration and shock, enhancing the stability of the vehicle. It also helps reduce damage to the vehicle body from external attacks, providing essential protection.

- Composite Armor Blast-Resistant Panels: Composite armor blast-resistant panels utilize aluminum foam's high strength and lightweight properties to enhance blast resistance. Aluminum foam not only disperses explosive energy but also strengthens the armor's penetration resistance.

- Cannon-Launched Missile Cushioning Components: Aluminum foam is used in the cushioning components of cannon-launched missiles, effectively absorbing shock and vibration during launch. It protects the internal components of the missile system, ensuring stability and accuracy during missile launches.

Application Cases

Armored Vehicle Bulletproof Structures

Combat Aircraft Camouflage Shelter Doors

Bulletproof and Blast-Resistant Field Camps

Nuclear Power

Aluminum foam has unique potential in the nuclear power industry, with its porous structure benefiting reactor cooling, radiation shielding, structural components, hydrogen storage, and composite reinforcement. As technology advances, it is expected to become a key material in nuclear energy.

Contact us now

Product Categories

- Closed Cell Aluminum Foam

- Small Pore Aluminum Foam

- Aluminum Foam Discs

- Aluminum Foam Flanges

- Aluminum Foam Protective Components

Specific Applications

- Radioactive Material Containers: Aluminum foam is used as the structural material for radioactive material containers, providing excellent shock resistance and protective performance. Its unique structure effectively prevents radioactive material leakage, ensuring safety during transportation and storage.

- Controlled Nuclear Fusion Test Devices: Aluminum foam is applied in controlled nuclear fusion test devices, primarily as thermal protection and shock absorption material. Its high-temperature resistance and structural stability help the equipment maintain normal operation in extreme environments, enhancing the safety and efficiency of the test device.

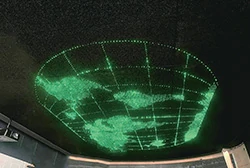

- Radiation Shielding: Due to its radiation absorption capability, aluminum foam is used for radiation shielding in nuclear power plants. It effectively reduces radiation from nuclear reactors, protecting workers and equipment from harmful radiation.

Application Cases

Fuel protection equipment

Artificial Sun Core Power System

Radar Signal Receivers

Automotive Industry

Aluminum foam is a key material in the automotive industry, enhancing safety, comfort, and energy efficiency. Its lightweight, energy absorption, sound insulation, and vibration-damping properties make it ideal for crash structures and internal components, excelling in lightweighting and energy absorption.

Contact us now

Product Categories

- Open Cell Aluminum Foam

- Small Pore Aluminum Foam

- Aluminum Foam Blocks

- Aluminum Foam Sheets

Specific Applications

- Bumpers, Crash Boxes, and Energy Absorption Structures: Aluminum foam is widely used in automotive bumpers and crash boxes, effectively absorbing collision energy and reducing body damage. Its lightweight and excellent energy absorption properties enhance the safety of the vehicle during collisions, meeting the automotive industry's requirements for lightweighting and safety enhancement.

- Car Floor and Door Core: Aluminum foam is used in the manufacture of car door cores and floor components, offering outstanding sound insulation and vibration-damping effects. It is lightweight, fire-resistant, corrosion-resistant, and extends the lifespan of these parts.

- Reinforced Pillars (A, B, C Pillars, Front Longitudinal Beams, etc.): Aluminum foam fills the reinforced pillar structures, helping to increase pillar strength, enhance energy absorption, and improve vehicle body protection during collisions.

- Mufflers: Aluminum foam sound-absorbing panels are used in automotive mufflers, capable of withstanding exhaust temperatures of 500-600°C. They offer better noise reduction performance than traditional mufflers and reduce the weight by approximately one-third.

Rail Transit

Aluminum foam plays a crucial role in rail transit, offering lightweight, sound insulation, noise reduction, and fire safety. It provides ideal solutions for subways, high-speed rail, and urban trains, reducing noise and vibration while enhancing energy efficiency and passenger comfort.

Contact us now

Product Categories

- Open Cell Aluminum Foam

- Closed Cell Aluminum Foam

- Spherical Aluminum Foam

- Punched Aluminum Foam

- Aluminum Foam Sandwich Panels

Specific Applications

- Subway Station Acoustic Linings: Punched aluminum foam sound-absorbing panels are installed on the sidewalls and ceilings of subway stations, significantly improving noise reduction performance in humid environments. This can more than double the noise reduction efficiency compared to other materials.

- High-Speed Rail Sound Barriers: Punched aluminum foam sound barriers are water-resistant and corrosion-resistant, maintaining excellent sound insulation and vibration damping even when exposed to rain, ensuring long-term structural safety.

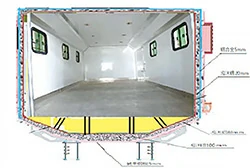

- Conventional Train Floors: A sandwich panel structure of "1mm aluminum plate + 15-20mm aluminum foam + 1mm aluminum plate” is used for conventional train floors, providing excellent sound insulation, vibration damping, and flame-retardant properties. The flexural strength is about 20 MPa, with a service life of over 30 years, and the weight is only half that of wooden floors.

- High-Speed Train Floors: The "1mm aluminum plate + 25-30mm aluminum foam + 1mm aluminum plate” sandwich panel structure is used for high-speed train floors, achieving noise reduction of over 20 dB. It also offers outstanding fire resistance, corrosion resistance, and bending strength, ensuring the safety and comfort of high-speed train operations.

- Train Door Cores: Aluminum foam is used as the core material for train doors, providing balanced stress resistance and excellent sound insulation, vibration damping, and thermal insulation.

All-Aluminum Furniture

Aluminum foam is widely used in all-aluminum furniture for its lightweight, strength, sound insulation, and fire resistance. It’s applied in cabinets, furniture, and decorative panels, enhancing functionality and modern aesthetics, making it ideal for minimalist and industrial home designs.

Contact us now

Aluminum Foam Purchasing Guide

Specifications and Dimensions

When choosing aluminum foam, the first step is to determine the appropriate size and shape based on the specific application scenario. Common thickness ranges for aluminum foam are from 5mm to 50mm, with porosity typically ranging from 70% to 90%. Selecting the right dimensions and porosity not only helps enhance the material’s performance but also optimizes processing efficiency, reduces waste, and lowers subsequent processing costs.

Aluminum Foam Pricing

Due to the complex foam molding technology involved in aluminum foam production, pricing can be influenced by factors such as pore size, density, production process, and purchase volume. Generally, aluminum foam is priced per sheet or per square meter, with additional charges for packaging, shipping, and other services. It is recommended to communicate with the supplier before purchasing to clearly understand the breakdown of the price, ensuring transparency in the final cost.

Contact us for more details on pricing and customized solutions: Contact Us. Quick Quote

Quality Standards and Documentation Support

Ensure the aluminum foam you purchase complies with relevant quality standards, such as ISO 9001. Before delivery, we will provide a detailed quality inspection report, including raw material certificates, production process control reports, and final product inspection reports. These documents guarantee the stability and traceability of each batch of aluminum foam.

Stock and Delivery Time

Our stock of aluminum foam is available in standard thicknesses of 3/8" (9.5mm), 1/2" (12.7mm), 1" (25.4mm), and 1.7" (43.2mm), with standard sizes of 1000mmx2000mm and 1220mmx2440mm (4ft x 8ft). If the required pore size and porosity meet your project needs, shipping can be arranged within a week.

For custom products, production time is based on your specific manufacturing process and order quantity. It is recommended to contact us in advance to clarify your requirements, and we will arrange the fastest production cycle to ensure timely delivery.

Export Packaging

High-quality packaging is critical for protecting aluminum foam during transportation. Proper packaging prevents deformation, corrosion, or other damage caused by impact or moisture during transit. We recommend using moisture-proof and corrosion-resistant packaging, such as fumigated wooden boxes and wooden pallets, to ensure aluminum foam remains in excellent condition throughout transportation.

Loading Solutions

Customized loading solutions can optimize space usage and improve transportation efficiency. Experienced suppliers can offer flexible loading solutions based on the aluminum foam specifications and quantity, thereby reducing logistics costs and ensuring the goods arrive at their destination safely and intact.