Aluminum sheets are extensively used across various automotive applications due to their excellent properties, including lightweight and high strength. This versatility makes them ideal for components ranging from body panels to structural parts.

At Chalco, we not only offer a diverse range of aluminum sheet products but also provide comprehensive services including deep drawing, bending, cutting, brazing, surface processing (MF, EDT, NP, P, DO, EO), and technical support. Our commitment to delivering both high-quality products and specialized services makes us the optimal partner for all your automotive aluminum sheet needs.

- Chalco automotive body panel product specifications

- Overview of Chalco aluminum sheet product applications in automotive components

- Aluminum brazed clad sheet and strip for automotive heat exchange systems

- Advanced aluminum panels: key components in New Energy Cars

- Choose Chalco, choose a one-stop experience for automotive aluminum sheets

- Chalco – a leading enterprise of automotive market

- Performance parameter table of Chalco auto body panel hot selling product

Chalco automotive body panel product specifications

| Alloy | 5000 series 6000 series |

| Temper | O T4 T6 T4P T6B H32 H111 |

| Width | Hot selling width 200-2000mm, the max. width can reach 2650mm |

| Thickness | Hot selling aluminum sheet thickness 0.2-8mm Hot selling aluminum plate 4.5-100mm |

| Length | 1000-16500 or coil |

| Additional service | Surface treatment, stamping, bending, stretching, welding, heat treatment, custom cutting and sizing, quality inspection and certification... |

| Surface finishing | MF, EDT, Ti/zr; Click to check to [Surface finishing information] |

| Surface treatment | NP, P, DO, EO Click to check to [Surface treatment information] |

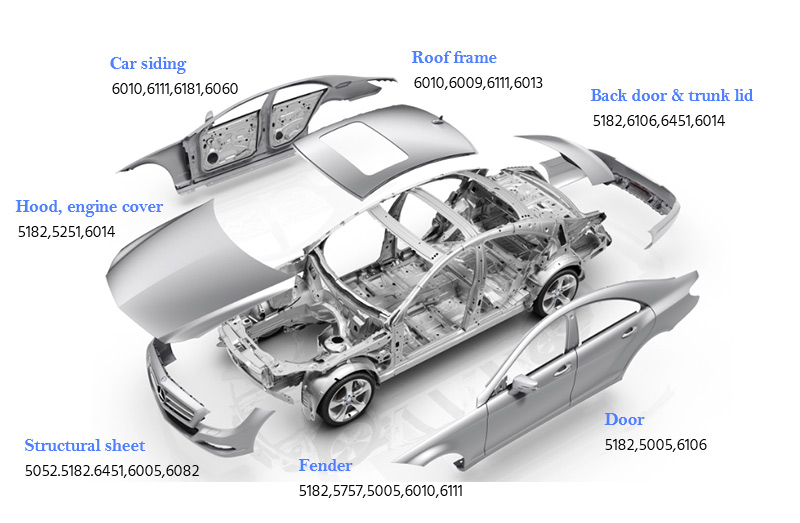

Overview of Chalco aluminum sheet product applications in automotive components

| Component | Alloy and Product | Material Characteristics |

| Inner and outer panels (shell plate) | 2008, 2010, 2036 3004 (outer panel) 5052, 5182 (inner shell plate), 5754 (inner shell plate) 6022 (inner and outer shell plate), 6016, 6A16, 6014 | These alloys combine excellent formability, strength, and corrosion resistance, making them suitable for automotive inner and outer panels. They ensure durability and good appearance while maintaining structural strength, fitting complex shapes and environmental conditions. |

| Inner door panels, sunroof panels, grille panels | 6010, 6009, 6016 Aluminum honeycomb panels | Good stamping and formability, suitable for complex-shaped components. |

| Front fender | 6010 Aluminum honeycomb panels | Good strength and flatness, suitable for critical parts like the front fender. |

| Side panels | 6010, 6111 | High strength, good formability, excellent corrosion resistance, and weldability, suitable for side panels under high stress. |

| Wings (front wing, sliding wing, outer wing) | 6010, 6016 | Suitable for complex-shaped wings, with good formability and strength. |

| Mudguards | 5182, 5754 | Excellent corrosion resistance and formability, suitable for mudguards exposed to external environments. |

| Chassis frames and power trays | 6009, 6061, 7021 | Durable and strong, balancing strength and lightweight properties, suitable for supporting vehicle weight and power systems. |

| Engine hood inner and outer panels | 6010, 6016, 6111 | Good formability and corrosion resistance, lightweight yet providing adequate strength. |

| Generator casing | 6061 | Good corrosion resistance and strength, suitable for generator protection casings, ensuring stability during prolonged use. |

| Load-bearing floor | 2036, 5182, 5754, 6009 | These materials for automotive load-bearing floors combine high strength, impact resistance, corrosion resistance, and good formability, meeting various load requirements. |

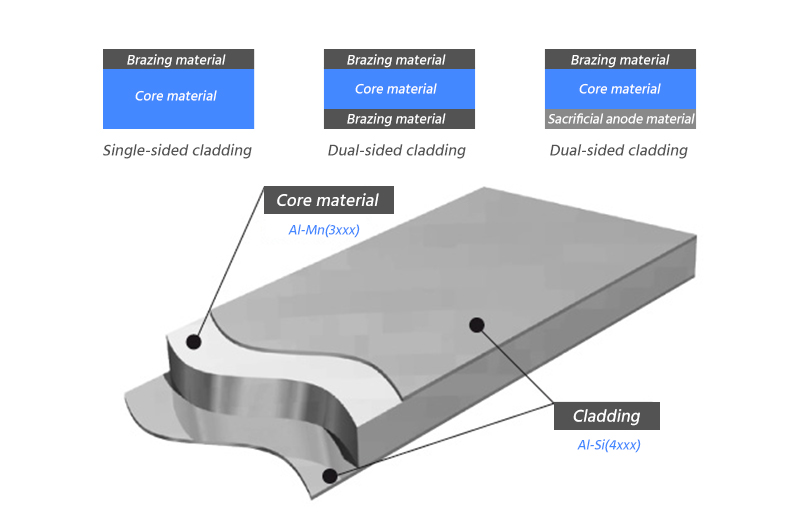

Aluminum brazed clad sheet and strip for automotive heat exchange systems

Brazing sheet is a layered aluminum alloy with a lower melting temperature than the core material, clad on one or both sides. Primarily employed in crafting heat exchange system components for motor vehicles.

Different proportion of aluminum materials in the automobile heat exchange system: brazed sheet metal 29%, aluminum die-casting 23%, aluminum extruded tube 23%, aluminum heat dissipation fin foil 21%, and other aluminum products 4%. The following are the main automotive components where Chalco brazed aluminum sheets are applied, along with examples of alloys used.

- Brazing aluminum sheet for engine radiator: 3003, 4045/3003/7072

- Brazing aluminum sheet for Oil cooler: 6951, 4A17/3003/7A01

- Brazing aluminum sheet for air conditioning condenser

- Brazing aluminum sheet for air conditioner evaporator

- Brazing aluminum sheet for heater: 3203+Zn, 4043+Zn/3003/7072

- Brazing aluminum sheet for intercooler: 1100, 3005, 6063

- Brazing aluminum sheet for battery material and battery cooler

| Structural Forms of Various Aluminum Heat Exchangers and Intercoolers and Their Main Reference Materials | ||

| Structural Form | Fins | Cooling Water Pipe |

| Tube-and-Strip Vacuum Brazing | 1100, 3003, 3005, 6063, 5005, 6951 | Double-sided clad strip made into flat tubes by high-frequency seam welding: 4045/3003/7072/4045/3005/7072, 4A17/3003/7A01, 4A17/3005/7A01 |

| Tube-and-Strip Gas Shielded Brazing | 3003, 3003+Zn, 3203+Zn, 7072 | Double-sided clad strip made into flat tubes by high-frequency seam welding: 4043+Zn/3003/7072, 4045+Zn/3003/7072, 4043+Zn/3003/7A01, 4045+Zn/3003/7A01 |

| Plate-Fin Welding | 1100, 3003 | Stamped plate fins: 3003, 3A21 |

The above is just a partial display of product applications and alloys. For more details, please click Application of Brazing Sheet in Automobile to view, or contact our sales representatives for inquiries. Quick Quote

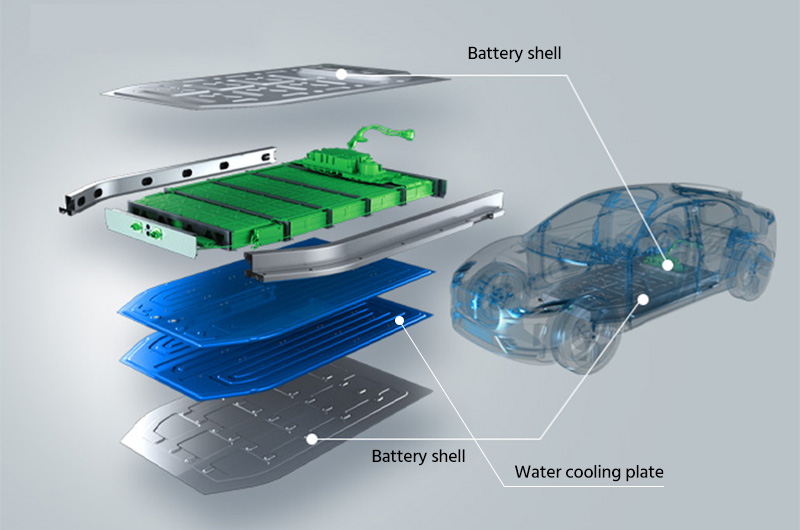

Advanced aluminum panels: key components in New Energy Cars

Aluminum plays a crucial role in lightweighting electric and hybrid vehicles. Chalco's aluminum components for electric vehicles include battery packs and all-electric vehicle enclosure frame solutions. Other products include aluminum battery cables, radiator systems, motor housings, cabin heaters, and structural body components.

| Aluminum Alloy for Electric Vehicle Applications and Corresponding Parts | ||

| Application Part | Alloys Used | Product Form |

| Power Battery Casing | 1050, 3003, 3005 | Aluminum coil |

| Power Battery Cover Plate | 3003, 5182 | Aluminum sheet |

| Power Battery Side Plate | 5083 | Aluminum sheet |

| Battery Tray | 6063, 6016, 6061, 6082, 5083 | Aluminum sheet, Aluminum alloy extrusions |

| Power Battery Water Cooling Plate | 3003, 3003/43443 | Brazed composite sheet |

Choose Chalco, choose a one-stop experience for automotive aluminum sheets

Specialized Aluminum Sheets

1100, 3003, 1050 Embossed Aluminum Sheet: Used for engine hoods and underbody shields, offering insulation and anti-slip properties.

5052, 3003 Aluminum Honeycomb Panel: Applied in car partitions and roofs, known for being lightweight and strong.

Deep Drawing, Cutting, and Other Additional Services

We provide deep drawing, cutting, and forming services to ensure aluminum sheet products meet the stringent requirements of automotive components during manufacturing.

Surface Processing: Enhancing Performance and Appearance

FM: provides a smooth base for treatments

EDT: Improves paint adhesion with fine texture

Ti/Zr:Boosts corrosion resistance and bonding for automotive parts

Surface Treatment: Adapting to Harsh Environments

NP(No Protection): leaves the surface untreated

P(Protection): adds a temporary protective layer

DO(Dry Oil): offers better corrosion resistance and uniform oil coverage for automotive applications

EO(Electrostatic Oil): high strength, corrosion resistance

One-stop recommendation for related products

Choose Chalco auto body panel by aluminum alloy grade

The 5000 series aluminum ABS plate has the same high strength as cold rolled steel, excellent formability, corrosion resistance, high surface treatment, and good welding performance. Mostly used for car interior panels.

The 6000 series aluminum ABS board has excellent formability and exhibits high strength after coating baking, improving dent resistance. After baking hardening, it is often used for car exterior panels.

-

1050 auto panel aluminum sheet

Battery trays

Interior panels

Heat exchangers

-

1100 auto panel aluminum sheet

Engine covers

Radiator components

Air conditioning housings

-

1070 auto panel aluminum sheet

Fuel tanks

Heat shields

Electrical enclosures

-

5182 auto panel aluminum sheet

Auto door inner panel

Front brake plate inner

Structural and reinforcing components

Temper: RSS

-

5754 auto panel aluminum sheet

Tailgate inner panel

Autor fender

Auto wall panel

Temper: O REC

-

5052 auto panel aluminum sheet

Body structural components

Body reinforcement

Temper: O H32 H26 H34

-

5083 auto panel aluminum sheet

Car door panels

Car body shell

Engine hood

Temper: O H111 H32

-

6061 auto panel aluminum sheet

Car bracket inner plate

Temper: T4Pa T6Bb

-

6082 auto panel aluminum sheet

Auto body structural components

Auto body reinforcement

Temper: O T4

-

6063 auto panel aluminum sheet

Auto body structural components

Auto body reinforcement

Temper: O T4

-

6111 auto panel aluminum sheet

Door outer panel

Fender and car wall panel

Body structural components and reinforcements

Temper: T4 T6

-

6181 auto panel aluminum sheet

Door and car wall panel

Auto roof panel

Body structural components

Temper: T4Pa T6Bb

-

6013 auto panel aluminum sheet

Auto door outer panel

Fender panel

Auto roof panel

Temper: T4Pa T6Bb

-

6A16 auto panel aluminum sheet

Auto trunk inner panel

Auto roof panel

Auto skylight plate

Temper: T4Pa T6Bb

-

6022 auto panel aluminum sheet

Auto body covering panel

Carriage side panel

Auto roof panel

Temper: T4Pa T6Bb

-

6016 auto panel aluminum sheet

Engine hood inner panel

Auto door panel

Inner and outer trunk panels Car bracket plate

-

6014 auto panel aluminum sheet

Engine hood inner and outer panels

Door outer panel

Trunk outer panel

-

6060 auto panel aluminum sheet

Auto fender sheet

Auto body structural components and reinforcement

-

7075 auto panel aluminum sheet

Auto body structural components

Auto body reinforcement

-

2024 auto panel aluminum sheet

Auto body structural components

-

3A21 auto panel aluminum sheet

Auto door panel sheet

Auto roof panel plate

Chalco – a leading enterprise of automotive market

The development process of the automotive industry can almost be seen as a microcosm of the evolution of the global aluminum alloy market.

The rise of lightweight vehicles and new energy vehicles has put forward urgent requirements for the production and manufacturing of aluminum, and has also injected new vitality into the aluminum product market.

Chalco, relying on the strong market of Chinese automobile manufacturing, continuously improves its production and innovation capabilities to meet the new requirements of new energy vehicles for product width, length, quality, and performance.

Chalco has achieved remarkable results in the international trade market alongside new energy vehicle pioneers such as BYD, NIO, Xiaopeng, Ideal, and Great Wall Motors.

- IATF16949 standard audited by BSI, multi enterprise automotive panel material supply certification;

- The research and development of new alloys for automotive panels such as 6451-T4P 6460-T4P 5182-RSS 5754-REC;

- Best delivery time and price for and large batches single specification products; Complete inventory for small batches multi specification products;

- 100mm to 2650mm ultra wide body aluminum sheet; High strength hot formability, dent resistance, high bake hardening, high gloss hardening;

- Provide extended processing such as stamping, surface coating, and cutting of irregular automotive panels;

- Closed loop recycling has been put on the agenda to support green development.

Performance parameter table of Chalco auto body panel hot selling product

| Typical value diq | Rp0.2/MPa | Rm/MPa | Ag/% | A50/% | Rp0.2/MPa (2%+BH) | A50/% (BH) |

| 5754 | 94 | 215 | 21 | 24 | - | - |

| 5754-REC | 108 | 226 | 20.1 | 24 | - | - |

| 5182 | 121 | 278 | 22 | 25 | 147 | 23 |

| 5182-RSS | 115.3-121.7 | 255-278 | 20-22.9 | - | - | - |

| 5083-H32 | 246 | 309 | 8.7 | 10.5 | ||

| 5083-O | 125-145 | 275-350 | - | - | - | 13-24.5 |

| 6460 | 75 | 130 | 20 | 27 | 110 | 22 |

| 6460-T4P | 75-90 | 120-130 | - | - | - | 23-27 |

| 6460-T8x | 85-130 | 140-166 | - | - | - | 15-22 |

| 6014 T4P | 100-109 | 200-232 | 21.3-23.5 | - | - | - |

| 6016 | 101 | 204 | 23 | 26 | 200 | 17 |

| 6016-T4P | 105-129 | 204-234 | 26.0-26.4 | 26 | 200 | 17 |

| 6451 | 116 | 227 | 21 | 25 | 205 | 21 |

| 6005A-T6 | 279 | 314 | 10.0 | 15.7 | ||

| 6061-T6 | 273 | 313 | 9.8 | 14.1 | ||

| 6063-T6 | 215 | 245 | 7.7 | 12.5 | ||

| 6111-T4P | 128.6 | 254.2 | 19.4 | 29.0 | 265 | 20 |

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote