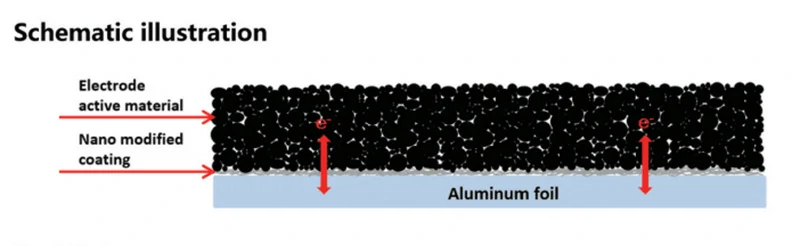

Modified aluminum foil is created by coating the aluminum foil surface with one or more conductive materials, forming an excellent two-dimensional or multi-dimensional conductive network structure.

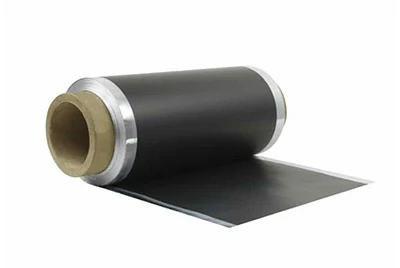

Chalco's modified aluminum foil for battery features a thinner coating, lower resistance, and stronger adhesion. It significantly enhances the electrochemical performance and stability of lithium batteries while greatly reducing production and usage costs.

Chalco's featured modified aluminum foil for battery: diversified options, precise customization

- Alloys: 1235, 1145, 1060, 1070, 1100, 1085, 1A99, 8011

- Colors: Black, gray, silver

- Substrate: Aluminum foil, copper foil

- Substrate thickness: 10-20μm

- Coating type: Single coating, double coating

- Effective coating width: Customizable

- Material width: Customizable

- Core inner diameter: 76mm

We have ample stock to meet your purchasing needs and can also provide customized solutions based on your requirements. Quick Quote

Specifications of modified aluminum foil for battery

We actively participate in the formulation of battery industry standards and technological innovations. Partnering with NAATBatt and the Electrochemical Society, we drive advancements in energy storage technology.

Standards

GB/T 36187-2018, GB/T 3198-2010, IEC 62660-1/2/3, YS/T 854-2013, ASTM B209

Certifications

ISO 9001, IATF 16949, UL 94, UL 1973, UL 2580, IEC 62619, IEC 61960, RoHS (2011/65/EU)

Chalco's invention patents

Through multiple proprietary patents, we have achieved high conductivity, strong adhesion, and superior corrosion resistance in modified aluminum foil for battery.

- Patent for graphene-coated aluminum foil device – N201610537599.1

- Graphene-coated aluminum foil coating machine – N201610537016.1

- Stroboscopic detection device for aluminum foil surface quality – N201610534336.5

- Energy-saving and eco-friendly aluminum foil coating drying device – N201710537753.5

Chalco's featured modified aluminum foil for battery – CAW series

Evaluated by the Expert Committee of the Guangdong Battery Industry Association, Chalco's CAW series modified aluminum foil for battery won the Gold Award at the 2020 World Battery Industry Expo.

Carbon-coated aluminum foil for lithium-ion battery cathode – CAW2

The CAW2 series graphene carbon-coated aluminum foil, a modified current collector with proprietary core patent technology, offers outstanding performance and guaranteed quality. It has gained high recognition from customers worldwide. Quick Quote

Carbon-coated aluminum foil has excellent conductivity, low internal resistance, strong mechanical properties, and good toughness. It enhances the adhesion of electrode materials, increases the discharge capacity of the battery.

Contact us now

Performance of graphene carbon-coated aluminum foil

| Surface density (double-sided) | 1.0 g/m² 1.0±0.2mg/cm² | 1.5g/m² 1.5±0.3g/m² | 2.0g/m² 2.0±0.3g/m² | 2.5g/m² 2.5±0.3g/m² |

| Coverage rate | ≥80% | ≥90% | 100% | 100% |

| Coating conductivity | 2S/cm | 3S/cm | 5S/cm | 5S/cm |

| Peel strength | 2.0N | 2.0N | 2.5N | 2.5N |

| Electrolyte immersion resistance | No shedding | No shedding | No shedding | No shedding |

Advantages of graphene carbon-coated aluminum foil

- Improves surface tension, enhancing adhesion between aluminum foil and active materials.

- Reduces the use of electrode binders, increasing battery energy density and lowering electrode production costs.

- Protects the aluminum current collector from surface corrosion and oxidation.

- Lowers battery interface resistance and internal resistance.

- Reduces polarization, enhancing electrode material rate performance and specific capacity.

- Mitigates exothermic reactions, improving battery safety.

- Enhances production stability and reproducibility, increasing battery yield.

- Improves cell consistency and cycle life, reducing production costs.

Applications of graphene carbon-coated aluminum foil

- Lithium-ion batteries for electric vehicles and energy storage (LFP, LMFP, LMO, NCM, NCA, LNM, LTO)

- Lithium-ion batteries for 3C products (LCO, LMO)

- Supercapacitors

- Lithium-ion capacitors

- Lithium-ion batteries for aqueous systems

- Alkaline batteries

Lithium-ion batteries for electric vehicle

Lithium-ion batteries for 3C product

Supercapacitors

Nano-graphite coated aluminum foil for lithium-ion battery cathode – CAW1

CAW1 is one of the highest-quality current collector products available. Developed over five years, it utilizes high-performance nano-graphite as the functional coating material.

Thanks to its high conductivity and small particle size, nano-graphite forms an ultra-thin 400nm coating, boosting both energy and power density.

Contact us now

| Surface density (double-sided) | 0.5g/m² 0.5±0.2mg/cm² | 1.0g/m² 1.0±0.2g/m² | 1.5g/m² 1.5±0.3g/m² | 2.0g/m² 2.0±0.3g/m² |

| Coverage rate | ≥80% | ≥90% | 95% | 100% |

| Coating conductivity | 30S/cm | 30S/cm | 30S/cm | 30S/cm |

| Peel strength | 2.0N | 2.5N | 2.8N | 2.8N |

| Electrolyte immersion resistance | No shedding | No shedding | No shedding | No shedding |

Applications of nano-graphite coated aluminum foil:

- Lithium-ion batteries for electric vehicles and energy storage (LFP, LMFP, LMO, NCM, NCA, LNM, LTO)

- Lithium-ion batteries for 3C products (LCO, LMO)

- Supercapacitors

- Lithium-ion capacitors

- Lithium-ion batteries for aqueous systems

- Alkaline batteries

Lithium-ion batteries for electric vehicle

Lithium-ion capacitor

Lithium-ion batteries

Usage precautions:

- The product should be used in an environment with a temperature of 20-25°C and humidity ≤20% RH.

- The coating is highly hydrophilic; appropriate personal protective equipment should be worn during handling.

- Avoid using this product in dusty environments; the dust purification rate should be above 0.1M.

- Prevent contact with hard materials and handle the product gently.

This product is specifically developed for battery applications. For other applications, please contact us! Quick Quote

Carbon-coated aluminum foil for battery cathode – CAW3

CAW3 carbon-coated aluminum foil features high conductivity, ultra-thin thickness, and weldability, significantly reducing internal resistance, optimizing electron transfer, and enhancing battery power density.

Contact us now

- Appearance: Dark gray coating

- Coating thickness (double-sided) μm: 0.5

- Surface density (double-sided) mg/cm²: 0.04-0.1

- Applications: Lithium-ion batteries, supercapacitors

Carbon-coated copper foil for lithium-ion battery anode substrate – CCW2

Carbon-coated copper foil is a new anode substrate with high conductivity, low resistance, strong mechanical properties, and excellent flexibility.

Contact us now

Si/C anode testing:

Advantages of carbon-coated copper foil:

- Increases surface tension, enhancing adhesion between copper foil and active materials.

- Reduces the amount of binder in the electrode, improving energy density and cycle life of the battery.

- Protects the copper current collector from surface corrosion and oxidation.

- Lowers interface resistance and internal resistance of the battery.

- Reduces polarization, enhancing the rate performance and specific capacity of electrode materials.

- Mitigates exothermic reactions, improving battery safety.

- Enhances production stability and repeatability, increasing the cell yield rate.

- Improves cell consistency and cycle life, reducing production costs.

High specific surface area modified aluminum foil

Through mechanical rolling and chemical etching, the aluminum foil's surface area is increased, enhancing active material loading, energy density, and rate performance.

Contact us now

- Cleanliness: 50 mN/m

- Specific capacitance: 12 µF

- Specific surface area: Increased by 15%

Dry-coated electrode – EDLC electrode tape

Our continuous dry-roll pressing process forms a high-density, uniform dry electrode film by simply rolling the evenly mixed electrode materials through multiple stages. The electrode sheet is then created by thermally pressing it with the current collector, ensuring a compact structure and uniform thickness.

Compared to the wet process, dry electrode manufacturing eliminates the need for large factory space for solvent drying, significantly reducing capital and labor costs while being more environmentally friendly.

Contact us now

Features of EDLC electrode tape

- Thicker electrodes, solvent-free.

- High electrode density, excellent conductivity, high capacity, low internal resistance, minimal carbon powder shedding, and long cycle life.

- High purity, free of impurities, clean, and environmentally friendly.

- Outstanding vibration resistance, customizable specifications.

Applications of EDLC electrode tape

- Semi-solid-state and solid-state lithium-ion batteries

- EDLC supercapacitors (double-layer capacitors)

Porous current collector aluminum foil for batteries

Porous current collectors effectively address lithium-ion migration issues, significantly improving first charge-discharge efficiency, high-rate charge-discharge capacity, and cycle life.

Contact us now

Advantages of porous current collector aluminum foil for batteries

- Reduces the weight of the current collector.

- Enhances adhesion between active materials and the current collector.

- Lowers interface resistance and reduces battery internal resistance.

- Decreases polarization, improving high-rate charge-discharge performance and maximizing the specific capacity of active materials.

- Reduces battery heat generation, enhancing battery safety.

- Increases lithium-ion migration speed.

- Boosts battery energy density.

Ceramic-coated modified aluminum foil

Coating the aluminum foil with nano-ceramic materials enhances corrosion resistance, prevents oxidation at high voltage, and reduces interface side reactions, improving overall battery stability.

Contact us now

Phosphate-modified aluminum foil

Phosphate chemical treatment forms a protective phosphate layer, enhancing corrosion resistance and optimizing electrode interface stability for LFP and sodium-ion batteries.

Contact us now

How to choose the substrate alloy for modified aluminum foil for battery?

| Alloy model | Purity (%) | Features | Suitable battery types |

| 1235 | ≥99.35 | Low cost, high conductivity, good ductility | Consumer electronics, low-power batteries |

| 1145 | ≥99.45 | Higher purity, excellent corrosion resistance | Standard lithium batteries, energy storage batteries |

| 1060 | ≥99.6 | High conductivity, good processability | Power batteries, energy storage batteries |

| 1070 | ≥99.7 | Superior conductivity | High-rate fast-charging batteries, power batteries |

| 1100 | ≥99.0 | Slightly higher strength than 1060, slightly lower conductivity | General lithium batteries, energy storage systems |

| 1085 | ≥99.85 | Ultra-high conductivity | High-end power batteries, aerospace batteries |

| 1A99 | ≥99.99 | Highest purity, extremely low resistance, optimal performance | High-end energy storage, specialty batteries |

| 8011 | - | Higher mechanical strength, excellent corrosion resistance | Special energy storage applications, pouch battery packaging |

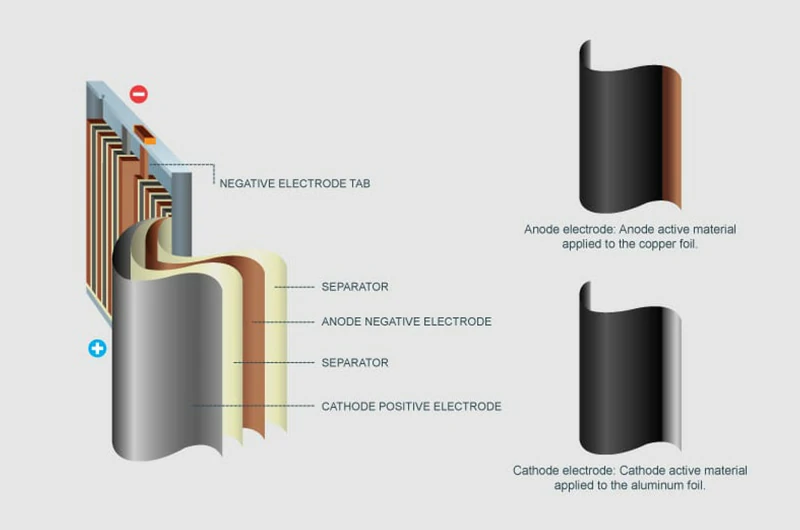

Lithium-ion battery structure: cathode aluminum foil & anode copper foil

A lithium-ion battery consists of a cathode (negative electrode), anode (positive electrode), electrolyte, and separator. Among them, the current collector (conductive carrier on the electrode) is a key component.

Cathode (aluminum foil)

Aluminum foil is the only suitable material for lithium-ion battery cathode current collectors, with no substitutes. UACJ

The foil is made from carefully selected aluminum alloys specifically designed for automotive applications. The thickness precision is within ±0.5μm.

Anode (copper foil)

Copper foil is used as the anode current collector due to its ease of processing and high conductivity. UACJ

Manufactured using advanced rolling technology, it provides ultra-thin, high-strength copper foil, enhancing battery performance.

What can we offer our customers?

Customized current collectors to meet personalized needs

Founded in 2013, our research center is dedicated to the in-depth development of modified aluminum and copper foils, from raw material preparation to coating and adhesive application.

We tailor our materials, processes, and formulations to produce customized products that meet specific customer requirements.

Wholesale current collectors

Equipped with large-scale high-speed PCB lubricated aluminum foil coating lines, modified current collector production lines, and high-speed slitting machines, we ensure high production efficiency.

Our ISO 9001 and IATF 16949-certified quality management system guarantees reliability. With a well-stocked warehouse, we can meet the supply demands of various customers.

Technical support

We are more than just a materials supplier—we are your trusted technical partner. Through comprehensive technical support, we help enhance your battery products' performance and market competitiveness.

After-sales service

If you have any issues with our products, please contact our after-sales team immediately. We will resolve your concerns as soon as possible. "Customer first" is our core principle.

Related products of modified battery aluminum foil

Beyond providing modified current collector aluminum foil, we offer a comprehensive battery material solution, ensuring product consistency and a stable supply chain for your production needs. Quick Quote

Graphene conductive paste

Aluminum-plastic film for pouch batteries

Aluminum strip for battery tabs

Aluminum battery casing

Aluminum alloy heat sink

Aluminum PCB

Packaging and transportation assurance – ensuring safe delivery

Inner packaging

- Sealed plastic bottles (for small rolls), effectively preventing moisture and contamination.

- Anti-static film wrapping, reducing electrostatic impact during transportation.

Outer packaging

- Aluminum-plastic composite film sealing, providing additional moisture-proof, anti-static, and anti-oxidation protection.

- Reinforced carton/wooden box packaging, preventing damage from compression or vibration during transport.

Custom packaging options

- Custom sizes and roll widths available to meet automated production line requirements.

- Vacuum packaging option, ideal for products with high anti-oxidation requirements.

We recommend the most suitable shipping method—courier, air freight, or sea freight—based on customer requirements.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quoteFAQ – Common questions about modified aluminum foil for battery

Can you provide a free sample for testing?

Yes, we can send you an A4-sized sample for free, but the shipping cost needs to be negotiated.

Can you send me a product catalog?

We can send you a Word or PDF product catalog via email as an attachment.

What is your minimum order quantity (MOQ)?

The standard weight is 50 kg, depending on the size.

What is the main function of modified aluminum foil? Why is coating necessary?

Modified aluminum foil reduces interface resistance, enhances adhesion, improves conductivity and corrosion resistance, and extends battery lifespan. The coating optimizes electrode performance and enhances stability.

What types of batteries are suitable for modified aluminum foil?

It is suitable for power batteries (EVs), energy storage batteries (ESS), and consumer electronics batteries (phones/laptops). Different coatings are designed for specific applications.

How to choose the right modified aluminum foil? What are the differences between battery systems?

- Power batteries: Ceramic-coated or high-conductivity carbon-coated foil is recommended.

- Energy storage batteries: Phosphate-modified aluminum foil is suitable.

- High-rate fast-charging batteries: High specific surface area carbon-coated aluminum foil is required.

How strong is the coating adhesion? How do you ensure active materials won't fall off?

We use a high-adhesion nano-coating with adhesion strength of ≥0.6N/cm. Stability is ensured through peeling tests and cycle life testing.

How stable is modified aluminum foil under high temperature/high pressure? Is it suitable for NCM811/NCA high-voltage systems?

Coated aluminum foil is compatible with NCM811/NCA high-voltage systems (4.4V+), preventing aluminum foil oxidation and improving interface stability.

Which type of modified aluminum foil is suitable for LFP and NCM/NCA batteries?

LFP: Phosphate-modified aluminum foil is recommended.

NCM/NCA: Ceramic-coated or high-conductivity carbon-coated aluminum foil is preferred to enhance interface stability and conductivity.