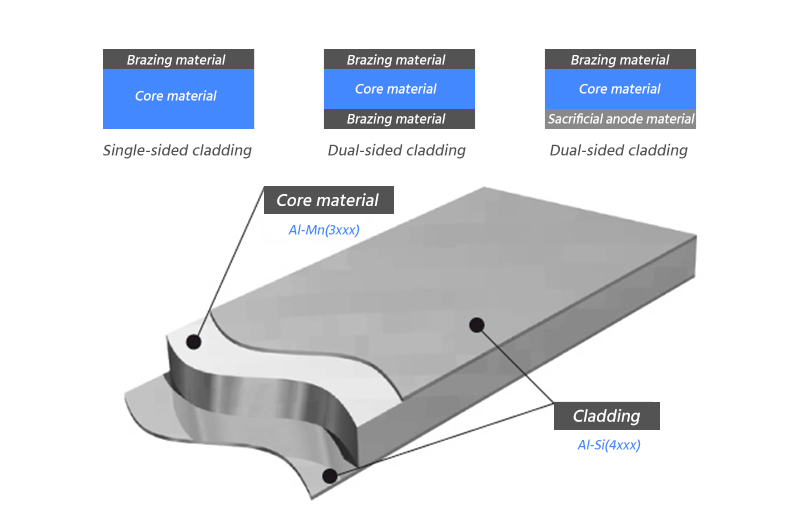

Brazing sheet is a layered aluminum alloy with a lower melting temperature than the core material, clad on one or both sides. Primarily employed in crafting heat exchange system components for motor vehicles.

Different proportion of aluminum materials in the automobile heat exchange system: brazed sheet metal 29%, aluminum die-casting 23%, aluminum extruded tube 23%, aluminum heat dissipation fin foil 21%, and other aluminum products 4%.Welcome contact

Chalco brazing aluminum products alloy series

Brazing aluminum products alloy series

Brazing layer materials: Al-Si(4000 series aluminum alloy)

Sacrificial anode material(Anticorrosive coating): AL-Zn-Cr(7072, etc.

Brazing core material: Al-Mn(3000 series aluminum alloy), Al-Si-Mg(6000 series alumuinum alloy)

Chalco brazed aluminum plate hot selling product

Under the background of lightweight and electrification, Aluminum has the outstanding cost performance as the automobile heat transfer materials. The density of aluminum is 2.7g/cm3, which is only 34% of that of steel and 30% of that of copper.

Brazing aluminum sheet for engine radiator

Hot selling products

4343/3003,4343/3003/7072

The radiator consists of a water inlet chamber, water outlet chamber, radiator core, and fan. It employs a combination of water and air cooling for heat dissipation.

Contact us now

| Product parameters | ||

| Alloy | 4343/3003 | 4343/3003/7072 |

| Temper | O | O |

| Thickness(mm) | 1.2~3.0 | 1.2~3.0 |

| Tolerance(mm) | ±0.03 | ±0.03 |

| Clad Ratio(%) | 5~10 | 5~10 |

| Tensile Strength (MPa) | 100~150 | 100~150 |

| Yield Strength (MPa) | ≥45 | ≥45 |

| Elongation (%) Min | 25 | 25 |

Brazing aluminum sheet for Oil cooler

Hot selling products

3003,6951

The oil cooler, essential for high-performance engines, accelerates lubricating oil heat dissipation to maintain lower temperatures due to increased heat loads.

Contact us now

| Product parameters | |||

| Alloy | 3003 (inner fin) | 6951(inner fin) | 3003(external fin) |

| Temper | O | O | H14 |

| Thickness (mm) | 0.2~0.3 | 0.2~0.3 | 0.1~0.15 |

| Tolerance (mm) | ±0.007 | ±0.007 | ±0.005 |

| Clad Ratio (%) | None | None | None |

| Tensile Strength (MPa) | 100~150 | 115~165 | 150~200 |

| Yield Strength (MPa) | ≥45 | ≥50 | ≥120 |

| Elongation (%) Min | 15 | 15 | 1 |

Brazing aluminum sheet for air conditioning condenser

Hot selling products

3003

The condenser transforms gas or steam into liquid, releasing heat to the surrounding air. As an exothermic process, the condenser operates at high temperatures.

Contact us now

| Product parameters | |

| Alloy | 3003 |

| Temper | H14 |

| Thickness (mm) | 0.08~0.12 |

| Tolerance (mm) | ±0.005 |

| Clad Ratio (%) | None |

| Tensile Strength (MPa) | 150~200 |

| Yield Strength (MPa) | ≥120 |

| Elongation (%) Min | 1 |

Brazing aluminum sheet for air conditioner evaporator

Hot selling products

3003

The air conditioning evaporator uses low pressure to evaporate cryogenic refrigerant, turning it into steam and absorbing heat from the cooled medium for refrigeration.

Contact us now

| Product parameters | |

| Alloy | 3003 |

| Temper | H14 |

| Thickness (mm) | 0.08~0.12 |

| Tolerance (mm) | ±0.005 |

| Clad Ratio (%) | None |

| Tensile Strength (MPa) | 150~200 |

| Yield Strength (MPa) | ≥120 |

| Elongation (%) Min | 1 |

Brazing aluminum sheet for heater

Hot selling products

3003 4047

Primarily used for winter engine preheating and heating truck drivers' cabs or coach passenger cabins, it harnesses the engine's generated heat.

Contact us now

| Product parameters | |||

| Alloy | 3003 | 3003 | 4047 |

| Temper | O | H16 | H18 |

| Thickness (mm) | 0.2~0.3 | 0.5~0.7 | 0.05~0.1 |

| Tolerance (mm) | ±0.01 | ±0.02 | ±0.005 |

| Clad Ratio (%) | None | None | None |

| Tensile Strength (MPa) | 100~150 | 150~210 | ≥200 |

| Yield Strength (MPa) | ≥45 | ≥120 | ≥170 |

| Elongation (%) Min | 15 | 1 | 0.5 |

Brazing aluminum sheet for intercooler

Hot selling products

4343/3003/4343 4045/3003/4045

The intercooler, integral to turbocharging, lowers post-turbo air temperature, decreasing engine heat load and increasing air intake volume to enhance engine power.

Contact us now

| Product parameters | ||

| Alloy | 4343/3003/4343 | 4045/3003/4045 |

| Temper | H14 | H14 |

| Thickness (mm) | 0.1~0.12 | 0.1~0.12 |

| Tolerance (mm) | ±0.005 | ±0.005 |

| Clad Ratio (%) | 8~12 | 8~12 |

| Tensile Strength (MPa) | 150~120 | 150~200 |

| Yield Strength (MPa) | ≥120 | ≥120 |

| Elongation (%) Min | 1 | 1 |

Brazing aluminum sheet for battery material and battery cooler

Hot selling products

4104/3003/4104 4104/6063/4104 3003

New energy vehicle power batteries heat up during operation, risking thermal runaway at high temperatures. Hence, ensuring effective battery pack cooling is crucial.

Contact us now

| Product parameters | ||

| Parts | Material | Cladding rate of composite layer |

| Mainboard | 4104/3003/4104 | 10% |

| Side plate | 4104/6063/4104 | 10% |

| Pressing plate | 3003 | 0 |

Performance advantages of aluminum brazing plate in heat exchanger

- Heat transfer rate: good thermal conductivity to dissipate heat

- Corrosion resistance performance: cannot be corroded by refrigerant or coolant

- Strength: high strength,

- Weight: as light as possible,

- Anti-sag performance: no high-temperature buckling during brazing

Supplier of brazing aluminum plate: Chalco Aluminum

We manufacture the core material and brazing metal combination products from numerous available alloys. The products are the most suitable for the using environment and customer requirement.

We are developing the aluminum material to form the welding joints with high reliability by adjusting the alloy setting of blazing filler metal, the cladding rate, the interface diffusion and flow control caused by the metal composition of core material.

In order to provide heat exchanger with high corrosion resistance, the compatibility with brazing counterpart (fin material or tube) shall also be considered, and the alloy design, metal composition and optimum tempering of core material shall be processed.

We are able to provide full range of aluminum brazing sheet for heat exchangers, composite fins, composite plates, composite strips, tube blanks and various weld tubes.

Chalco automotive brazing sheet related products

Common function of brazing aluminum sheet alloy elements

The function of Mn Aluminum alloy with Mn as the main alloy element cannot be strengthened by heating, and it has good corrosion resistance. It can also be called antirust aluminum. It has good welding performance and good plasticity.

The function of Zn The corrosion potential of this kind of alloy is reduced. The more Zn is added, the more potential is reduced. The heatsink after punching is first corroded as an anode to protect the media channel. Reduce the strength of the oxide film on the alloy surface, the surface will be easy to peel off and completely corroded, so as to inhibit corrosive pitting. However, if the content of Zn is too high, it may accelerate the corrosion of the heatsink, which will cause the heatsink to lose its cooling effect and reduce its service life.

The function of Si The lowest melting point of Al-Si alloy can be 577 ℃ near eutectic point, which is its advantage as brazing material.

After recombination, the Si element will diffuse to the matrix alloy due to the gradient of concentration, forming [Al (MnFe) Si] anode strip, which makes the corrosion preferentially occur on the sub surface layer of the matrix.

Si can change the fluidity of solder, make the material uniform and fine, and improve the brazing quality.

The function of Mg Mg in the cladding layer is an activator and getter to ensure the quality of vacuum brazing, but it has a certain impact on the corrosion resistance of composite plates.