- Specifications of the cooking bag foil

- Chemical composition of cooking bag foil

- Effect of chemical composition on the performance of cooking bag foil

- Cooking bag foil mechanical properties

- Cooking bag foil quality requirements

- Cooking bag foil size deviation

- Why choose Chalco Aluminum cooking bag foil?

- Frequently asked questions for buying cooking bag foil from Chalco aluminum

- Application of cooking bag foil

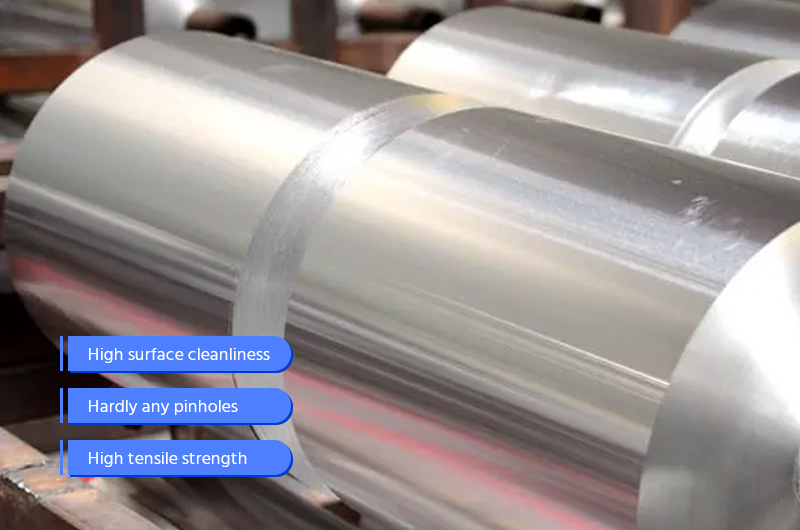

Chalco's cooking bag foil has minimal pinholes, is easily processed, and has obtained BSCI, PDA, and KOF-K certifications.

Specifications of the cooking bag foil

| Alloy | 1235 | 8011 | 8079 |

| Temper | O | O | O |

| Width | 300-1790 mm (11.81-70.47 in) | 300-1600 mm (11.81-62.99 in) | 700-980 mm (27.56-38.58 in) |

| Thickness | 0.0065-0.007 mm | 0.006-0.015 mm | 0.007mm-0.009mm |

| Pinhole | 0.0065mm: <=150/mm² | 0.007mm: <=100/mm² | 0.007mm: <=100/mm² |

| 0.007mm: <=100/mm² | 0.009mm: <=20/mm² | 0.009mm: <=20/mm² | |

| Brush water test | Spray Class A | ||

| Price | (LME ingot price + processing fee) × weight + packaging fee + transportation fee | ||

| Sample | Send samples for free, if you need samples, please clickInstant Quote | ||

| stock | In stock | ||

| Custom Made | The above specifications and packaging spraying can be customized according to customer needs | ||

| For other questions, such as minimum order quantity, payment method, delivery date, packaging and transportation, etc., please click to view | |||

Chemical composition of cooking bag foil

| Element | Composition (%) | ||

| 1235 | 8011 | 8079 | |

| Al | 99.3 | Remainder | Remainder |

| Si | - | 0.50-0.90 | 0.05-0.30 |

| Fe | - | 0.6-1.0 | 0.7-1.3 |

| Cu | 0.05 | 0.10 | 0.05 |

| Mn | 0.05 | 0.20 | - |

| Mg | 0.05 | 0.05 | - |

| Cr | - | 0.05 | - |

| Zn | 0.10 | 0.10 | 0.10 |

| Ti | 0.06 | 0.08 | - |

| Ga | - | - | - |

| V | 0.05 | - | - |

| Si + Fe | 0.70 | - | - |

| Other(each) | 0.03 | 0.05 | 0.05 |

| Other(total) | - | 0.15 | 0.15 |

| The chemical composition will affect the performance and can be produced according to the standard required by the customer. | |||

Effect of chemical composition on the performance of cooking bag foil

Effect of chemical composition on 1235 cooking bag foil

- The solid solution of Fe and Si in Al will increase the material's work hardening rate, leading to a relatively higher rolling difficulty for Cooking Bag Foil.

- The mechanical properties of 1235 aluminum foil for Cooking Bag Foil are not only affected by purity and Fe/Si content but also by the Fe/Si ratio.

Effect of chemical composition on 8011 8079 cooking bag foil

- Adding an appropriate amount of Cu to the alloy can enhance its strengthening ability during annealing.

- The alloy with a higher manganese content has a higher yield strength compared to an alloy with a lower manganese content under the same conditions.

- Chromium (Cr) can also impede the nucleation and growth processes of recrystallization, impart a certain degree of strengthening to the alloy, and improve its toughness.

Cooking bag foil mechanical properties

| Alloy | Temper | Tensile Strength Rm/(N/mm²) | Elongation After Break % |

| 1235 | H18 | ≥140 | ≥1 |

| H16 | 120-160 | ≥1 | |

| H14 | 105-145 | ≥2 | |

| 8011 8079 | H18 | ≥160 | ≥1 |

| H16 | 145-185 | ≥1 | |

| H14 | 125-165 | ≥2 | |

| If you have special requirements for performance, please contact us in advance and indicate it in the contract. | |||

Cooking bag foil quality requirements

Hydrogen content

The hydrogen content in the cold-rolled strip of Cooking Bag Foil does not exceed 0.14 mL/100 g of molten aluminum.

Appearance quality

The cold-rolled strip of Cooking Bag Foil should have no defects that would hinder further processing, such as corrosion, oil stains, peeling, impressions from metal or non-metal objects, or severe scratches on the surface.

The ends of the cold-rolled strip of Cooking Bag Foil should be free from cracks, burrs, impacts, or scratches.

The cold-rolled strip of Cooking Bag Foil should be free from bird nests, collapsing rolls, and joints.

Grain size

The as-cast (casting) grain size should not be lower than grade two.

The annealed grain size should not be lower than grade one.

Other requirements

If customers have other special requirements, please contact us in advance and indicate them in the contract.

Cooking bag foil size deviation

| Thickness mm | Width mm | Convexity | Flatness | Coil end dimension deviation |

| ±4% of nominal thickness | ±1.5 | 0-1% | 95% of the flatness on the strip is less than 201 | The layering should be no more than 3mm; the telescoping should be no more than 10mm (excluding the first and last 5 coils, but not exceeding 20mm). The width of the paper core sleeve is 0-10mm less than the width of the strip on each side. |

Why choose Chalco aluminum cooking bag foil?

Company strength

Currently, China holds the position of being the world's leading producer and exporter of aluminum foil. Chalco Aluminum, in particular, stands as the largest aluminum manufacturer in China.

Our production of ultra-thin aluminum foil ranging from 0.0045 to 0.005mm has been recognized as a key new product by the Chinese government.

For several consecutive years, we have been honored by ABB as an outstanding supplier of the year, and we have also received the Annual Excellence Award from the American company GE.

Production equipment

Chalco Aluminum boasts impressive production equipment.

We possess a 2000mm Achenbach and Davy aluminum foil rolling mill, alongside the incorporation of the German Herkules roll grinder, with a maximum roll diameter of 650mm and a grinding precision that reaches a remarkable 0.0001mm.

Furthermore, we have the Kampf aluminum foil slitter, which enhances the diversification of our production line, catering to the needs of various customers.

To ensure product quality, we have invested in high-precision annealing furnaces that utilize negative pressure vacuum annealing technology.

The furnace gas temperature differential is controlled within a range of ±3℃, ensuring a steadfast enhancement of product quality for every batch.

Quality assurance

The Cooking Bag Foil produced by Chalco Aluminum exhibits toughness, strong puncture resistance, high temperature resistance, clean and burr-free surface, and ease of processing.

We commit to maintaining a 34-35 Dyne value for the Cooking Bag Foil product within two weeks of usage. All water brush tests meet the highest A-level spray standard, and all pressure resistance tests pass with approval.

Furthermore, we provide online surface defect and pinhole inspection reports for the entire length of the Cooking Bag Foil product.

We consistently adhere to a zero-defect principle, ensuring that every piece of product leaves the factory without defects, and offering you high-quality Cooking Bag Foil products.

Management system and certification

ISO 14001 Environmental Management System

ISO9001 quality management system

ISO45001 occupational health and safety management system

FSSC22000 food safety management system certification

BSCI Business Social Standard Certification

PDA US Food and Drug Administration Food Grade Certification

KOF-K Kosher Certification

Frequently asked questions for buying cooking bag foil

Payment method

Contact us to get quotation information.

Instant QuoteDelivery time

We have enough stock for common models and colors. That's why our MOQ is so low, please confirm with sales before placing an order.

Cooking bag foil packaging

The packaging methods of Cooking Bag Foil can be divided into two types according to the thickness and status: box packaging and tic-tac-toe packaging.

Box packaging is divided into stacking type, suspension type and bottom bracket type.

The stacking type is mainly used for products with small specifications and light weight.

the bottom bracket type is mainly used for products with large specifications and heavy weight; the suspension type is mainly used for products with general specifications and weight.

To learn more about packing methods, please click How to Pack Aluminum Products (to Avoid Shipping Damage).

Is Chalco Aluminum a trading company or a manufacturer?

We are manufacture of aluminum foil for the cooking bag foil.

Does Chalco Aluminum offer other aluminum foil products?

We offer the following hot selling aluminum foils:

Vial sealed with 1060 aluminum foil

Aluminum foil for 3105 screw cap

5052 Aluminum foil for EOE and tabs

0.006-0.05mm household aluminum foil roll

8011 8011A Aluminum foil for bottle caps

Aluminum foil for candy packaging

1145 1235 8011 Aluminum foil for cigarette packing

Application of cooking bag foil

- Grill Bags.

- Foil oven bags.

- Foil BBQ.

- Aluminum foil bag.

- High temperature aluminum foil cooking bag.

- Standing pouch aluminium foil.

- Used in cosmetics packaging.

- Face bag.

- Etc.