About deep drawing aluminum

Deep drawing is a process where a metal sheet or circular blank is formed into a cylindrical or cup shape, creating objects with circular or oval borders. This technique shapes concave forms from flat metal sheets while maintaining consistent thickness, achieved by using a punch to push the sheet into a die.

Why ALUMINUM is suitable for deep drawing?

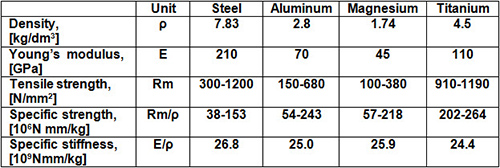

Aluminum or other metal?

Compared to metals like steel or others, aluminum's excellent ductility, lightweight, corrosion resistance, and good surface finish make it more advantageous in deep drawing processes, particularly for applications that require a balance of strength, appearance, and durability.

- Lighter weight: Aluminum offers the same strength as steel at only one-third the weight, ideal for high-strength, low-weight applications.

- Greater durability: Aluminum resists impacts without denting or deforming.

- Environmental impact: 100% recyclable, aluminum reduces overall waste.

- Corrosion resistance: Naturally resistant to corrosion, aluminum endures harsh environments without extra treatments.

- Conductivity: Aluminum's excellent thermal and electrical conductivity suits cables and wires.

- Lower cost: Aluminum is an affordable choice for both small and large-scale production.

Chalco's aluminum sheet, circle products for deep drawing

Chalco's cold-rolled aluminum plate, sheet and circle products utilize soaking technology to eliminate internal stress, reducing intragranular segregation and structural unevenness. This process enhances the tensile strength and plasticity of the product, making it ideal for deep drawing applications.

Chalco's aluminum sheets and circular products for deep-drawn offer superior deep drawing performance and low ear rate, ensuring optimal results under consistent deep drawing process parameters, sheet thickness, and mold design. The products are widely used in automotive, aerospace, digital electronics, kitchenware, and various can manufacturing sectors, and we collaborate with many well-known enterprises.Quick Quote

| Alloy | 1000 | 1070 1070A 1060 1050 1050A 1035 1100 1200 etc. |

| 2000 | 2024 2014 etc. | |

| 3000 | 3003 3004 3005 3104 3105 etc. | |

| 5000 | 5005 5A02 5A43 5052 5A66 5182 5083 5754 etc. | |

| 8000 | 8006 8A06 8011 8011A 8079 etc. | |

| Temper | O H14 H16 H18 H19 H22 H24 H26 H32 H34 H36 H38 O/F | |

| Thickness | Commonly 0.2-6mm, other thickness can contact to customize. | |

| Width | Customized according to requirements | |

| Length | Customized according to requirements | |

| Deviation | Click to specific [Deviation data table] | |

| Characteristics | The product has good flatness, uniform color, and good stretching ability | |

| Standard | ASTM B209, GB/T 3880, EN 485, JIS H 4000 etc. | |

| Application | Cannes, lamps, cookware, storage equipment, appliances, cars, ships, airplanes, etc. | |

Cooperative fields of Chalco aluminum sheet, circle for deep drawn

Chalco aluminum sheet plate for automotive deep drawn part

Alloy: 5052, 5182, 6016, 6061

Cooperative partner: Tesla, Ford, Weilai Automobile, Beiqi New Energy, Changan Automobile…

Contact us now

Driven by advancements in the automotive industry, the deep drawing process, a key method for forming metal sheets into hollow components, has demonstrated aluminum's performance advantages over steel.

- Body panels

- Doors

- Engine hoods

- Internal structural components

Aluminum discs for Can Manufacturing

Alloy: 3004, 3104, 5052

Cooperative partner: Guala Colosures, Nippon Colosures, CSI Colosures, Herti, Mala Colosures, Federfin tech…

Contact us now

Aluminum discs play a crucial role in can manufacturing, particularly for applications requiring high deep-drawing performance. The selected alloys offer exceptional deep-drawing properties, ensuring that the material does not crack during processing while maintaining structural stability and safety.

These products also provide excellent corrosion resistance and formability, allowing aluminum discs to retain their appearance and functionality even after high-strength deep drawing, meeting the stringent requirements of beverage cans, food cans, and aerosol cans.

- Beverage Cans: Ensure that the material does not crack during high-speed deep-drawing on production lines, resulting in thin, uniform can walls with a smooth surface.

- Food Cans: Provide excellent corrosion resistance, suitable for sealed containers under long-term storage and transportation conditions.

- Aerosol Cans: Maintain high strength during deep drawing and capping processes, ensuring safe use.

- Can Lids: Offer superior sealing performance during the capping process, suitable for use in high-pressure environments.

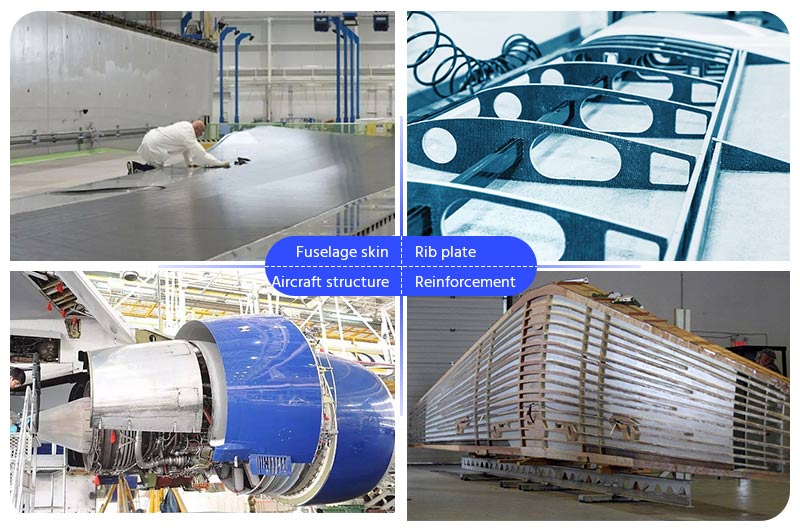

Aluminum plates for aircraft components

Alloy: 2024, 7075, 7475 etc.

Cooperative partner: Collins Aerospace, Boeing, Airbus, Air Industries Group, Airframer, The Alinabal Group of Companies…

Contact us now

These high-strength alloys have excellent deep drawing performance and fatigue resistance, making them suitable for aerospace structures subjected to high stress and harsh environments.

- Aircraft fuselage

- Wing spars

- Brackets

- Bulkheads

-

Aluminum sheet, circle for Kitchen ContainersQuick Quote

Common Alloys: 1050, 1100, 3003, 3004, 3005, 3104, 3105, 8006, 8A06, 8011, 8011A, 8079

Chalco aluminum sheet and circle products offer outstanding thermal conductivity and deep drawing performance, making them suitable for the production of various kitchen containers.

- Cookware

- Frying pans

- Pot lids

- Baking trays

-

Chalco aluminum sheet plate for Transportation-train truck or marineQuick Quote

Common Alloys: 5005 5A02 5A43 5052 5A66 5182 5083 5754, etc.

These aluminum sheet and plate products exhibit excellent deep drawing performance and fatigue resistance, making them ideal for manufacturing transportation equipment.

- Train car bodies

- Ship hulls

- Commercial vehicle structural components

- Bus and truck exteriors

-

Aluminum plate for Electronic Product EnclosuresQuick Quote

Common Alloys: 5052, 6061, 1050 etc.

These alloys are widely used in the manufacture of electronic product enclosures due to their good formability, heat dissipation, and aesthetic appeal.

- Mobile phone enclosures

- Laptop enclosures

- Tablet enclosures

- Other consumer electronic enclosures

-

Aluminum sheets and discs for Lighting FixturesQuick Quote

Common Alloys: 1050, 1060, 3003 etc.

These aluminum sheets and discs are perfect for lighting fixtures due to their excellent reflectivity, formability, and corrosion resistance. They perform well in deep drawing and spinning, allowing for smooth shaping without cracking. The alloys are ideal for creating durable and aesthetically pleasing reflectors, lamp housings, and heat sinks.

- Reflectors

- Lamp housings

- Heat sinks

- Decorative trims

Advantages of Chalco aluminum alloy deep drawing plate

Deep drawing is one of the most commonly used metal forming methods by manufacturers, which involves using metal molds to shape metal blanks into the desired shape. Specifically, if the depth of the created item is equal to or greater than its radius, the metal forming process can be referred to as deep drawing.

Due to the unique nature of deep drawing technology, strict requirements are placed on the performance of aluminum alloys. Chalco deep drawn aluminum alloy plates are renowned in the industry for their outstanding performance advantagesQuick Quote

- Good plasticity, easy to withstand various pressure processing, bending, and stretching;

- Excellent molding effect and beautiful appearance;

- Good welding performance, suitable for gas welding, hydrogen atom welding, and resistance welding;

- High thermal conductivity;

- Good corrosion resistance;

- Mature technology, good quality, and low price.

| Performance reference for some deep drawn aluminum plate products | |||||

| Alloy | Temper | tensile strength Rm/MPa | Prescribed plastic extension strength Rp0.2/MPa | Elongation after fracture A50mm% | Earing rate % |

| 1050 | O | 60-100 | 20 | 17-35 | ≤5 |

| 1060 1070 | O | 55-95 | 15 | 30-35 | ≤6 |

| H12 H22 | 70-130 | 55 | 4-12 | ≤5 | |

| H14 H24 | 85-140 | 65 | 1-5 | - | |

| H16 H26 | 95-150 | 75 | 1-4 | - | |

| 1035 | O | 60-105 | - | 25-30 | - |

| 1100 1200 | O | 75-110 | 25 | 15-35 | ≤3 |

| H12 H22 | 95-130 | 75 | 2-8 | ||

| H14 H24 | 110-150 | 95 | 1-5 | ||

| H16 H26 | 130-165 | 115 | 1-4 | ||

| 2024 | O | ≤220 | - | 14 | - |

| 3003 | O | 95-130 | 35 | 18-25 | ≤4 |

| H12 H22 | 120-160 | 90 | 2-3 | ||

| H14 H24 | 140-190 | 125 | 1-5 | ||

| 3005 | O | 115-165 | 45 | 18-22 | ≤5 |

| 5005 | O | 100-145 | 35 | 15-20 | - |

| 5052 | O | 170-215 | - | 3-6 | ≤5 |

| H12 H22 H32 | 215-265 | 130 | 4-7 | ||

| H14 H24 H34 | 235-285 | 150 | 3-4 | - | |

| H18 H19 | - | - | - | ≤4 | |

| 8011 | O | 80-110 | 30 | 15-35 | ≤3 |

| H12 H22 | 95-130 | - | 2-8 | ||

| H14 H24 | 120-160 | 100 | 1-5 | ||

| H16 H26 | 140-180 | - | 1-4 | ||

Size deviation reference table of Chalco deep drawing aluminum plate

| Allowable thickness deviation (mm) | Thickness | Width (≤1000) | Width>1000-1500 | Width>1500 |

| >0.20-0.25 | ±0.01 | ±0.02 | ±0.03 | |

| >0.25-0.50 | ±0.02 | ±0.03 | ±0.03 | |

| >0.50-0.8o | ±0.03 | ±0.04 | ±0.04 | |

| >0.80-1.30 | ±0.04 | ±0.05 | ±0.05 | |

| >1.30-1.50 | ±0.05 | ±0.06 | ±0.06 | |

| > 1.50-2.00 | ±0.06 | ±0.07 | ±0.08 | |

| >2.00-2.50 | ±0.07 | ±0.08 | ±0.09 | |

| >2.50-3.00 | ±0.08 | ±0.10 | ±0.12 | |

| >3.00-4.00 | ±0.10 | ±0.15 | ±0.17 | |

| Allowable width deviation (mm) | Width | Allowable width deviation | ||

| ≥12-100 | ±0.5 | |||

| >100-500 | ±1.0 | |||

| >500-1500 | ±2.0 | |||

| Allowable deviation in length (mm) | Length | Allowable deviation in length | ||

| ≤1000 | +8 0 | |||

| >1000-2000 | +1- 0 | |||

| >2000-3000 | +14 0 | |||

| >3000-5000 | +20 0 | |||

| >5000 | +25 0 | |||

| Flatness | Except for the O temper, the flatness error of the plate end is less than 10mm, and the flatness error of other parts is less than 7mm. The end part refers to the entire surface of the board along the length direction of the board, within a length range of 300mm at both ends. If the board is square, the end part is the board surface containing a square circle 300mm around the edge. | |||

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote