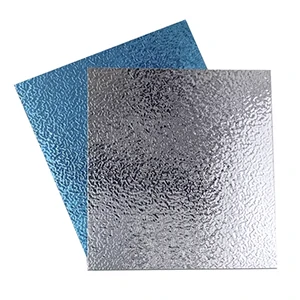

Embossed Aluminum Foil is a product that forms a variety of patterns through embossing equipment applied to standard aluminum foil. This product is lightweight and strong, with its embossed surface not only enhancing its decorative appeal but also improving its compressive strength and slip resistance.

The thinnest embossed aluminum foil offered by Chalco is 0.040 mm (40 microns), while thinner foils may experience tearing or holes during the embossing process due to insufficient thickness. The maximum thickness of embossed aluminum foil can reach 0.300 mm (300 microns).

Chalco's hot-selling stock sizes of embossed aluminum foil

| Thickness (mm) | Width (mm) | Product Name |

| 0.04 | 200 | Orange Peel Embossed Aluminum Foil |

| 0.04 | 500 | Orange Peel Embossed Aluminum Foil |

| 0.05 | 1000 | Orange Peel Embossed Aluminum Foil |

| 0.05 | 435 | Orange Peel Embossed Aluminum Foil |

| 0.055 | 250 | Orange Peel Embossed Aluminum Foil |

| 0.065 | 1000 | Orange Peel Embossed Aluminum Foil |

| 0.07 | 1500 | Orange Peel Embossed Aluminum Foil |

| 0.08 | 800 | Orange Peel Embossed Aluminum Foil |

| 0.1 | 1200 | Orange Peel Embossed Aluminum Foil |

| 0.15 | 1000 | Orange Peel Embossed Aluminum Foil |

| 0.2 | 1500 | Orange Peel Embossed Aluminum Foil |

| 0.25 | 1200 | Orange Peel Embossed Aluminum Foil |

| 0.3 | 800 | Orange Peel Embossed Aluminum Foil |

| 0.3 | 148.5 | Orange Peel Embossed Aluminum Foil |

| 0.025 | 450 | Orange Peel Embossed Aluminum Foil |

| 0.03 | 260 | Orange Peel Embossed Aluminum Foil |

| 0.1 | 201 | Orange Peel Embossed Aluminum Foil |

| 0.2 | 190 | Orange Peel Embossed Aluminum Foil |

| 0.3 | 300 | Orange Peel Embossed Aluminum Foil |

The above are the hot-selling sizes of Chalco's orange peel embossed aluminum foil. If you don't find the suitable size, please feel free to contact us.Quick Quote

Product introduction of Chalco embossed aluminum foil

Thickness range: 0.040 mm (40 microns) to 0.300 mm (300 microns)

Width range: 200 mm to 1500 mm (customizable)

Alloy series: 1050, 1060, 1100, 3003, 8011

Alloy tempers: H14, H18, H22, H24

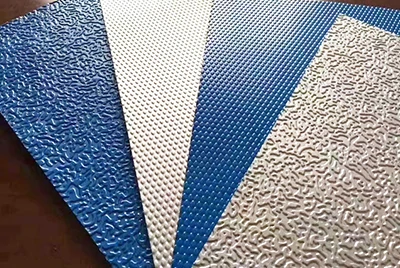

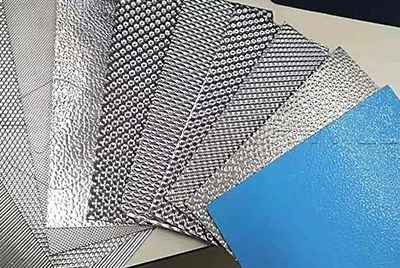

Embossed patterns: Orange peel, diamond, parallel lines, ripple, hemispherical

Surface coating: No coating, colored coating, oil protection

Coil length: Customizable based on thickness and customer requirements

Individual coil weight: 100 kg to 500 kg

Applications: Insulation materials, packaging materials, decorative materials

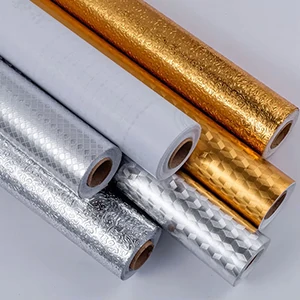

Popular embossed aluminum foil types from Chalco

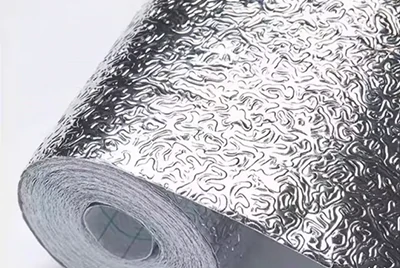

Orange peel embossed aluminum foil

The surface features an orange peel texture, enhancing both decorative and anti-slip properties. It offers good corrosion resistance and oxidation resistance.

Recommended alloys: 1060, 8011

Applications: Exterior walls of buildings, pipe coverings, and refrigeration equipment.

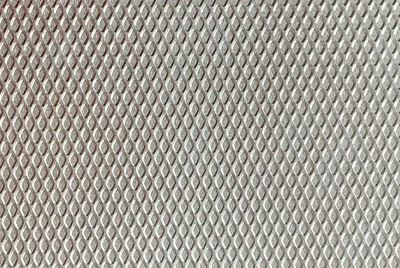

Diamond pattern embossed al foil

The surface features a regular diamond pattern, increasing the 3D effect and surface strength. It offers high wear resistance and corrosion resistance.

Recommended alloys: 1050, 1060, 8011

Applications: Interior and exterior wall decoration, high-end gift box packaging.

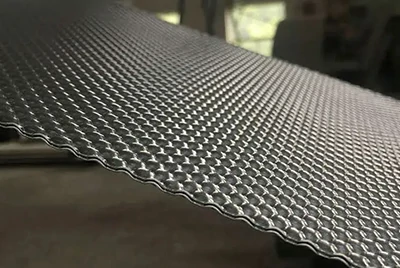

Hemispherical pattern embossed aluminum foil

The surface features evenly distributed small hemispherical textures, increasing contact area and improving heat dissipation.

Applications: Ideal for automotive heat shields, engine, and exhaust pipe heat-insulating aluminum foil.

Chalco's featured embossed aluminum foil

Anodized embossed aluminum foil

Anodized embossed aluminum foil forms a dense oxide film on the surface, significantly enhancing corrosion resistance and hardness, while offering a variety of color options and an elegant metallic finish. This type of aluminum foil combines durability and decoration, making it widely used in architectural decoration, high-end electronic product housings, and home décor.

Pre-painted embossed aluminum foil

Pre-painted embossed aluminum foil is coated with a weather-resistant colored layer on the surface, offering a wide range of colors and excellent UV resistance, while retaining the embossed texture. It combines aesthetic appeal and functionality, making it ideal for building facades, billboards, and the exterior decoration of home appliances.

Polished embossed aluminum foil

Polished embossed aluminum foil undergoes a fine polishing process, presenting a high-gloss mirror finish while retaining the unique 3D texture of the embossed pattern. Its premium metallic feel and decorative appeal make it an ideal choice for high-end packaging, light reflector sheets, and luxury product decorations.

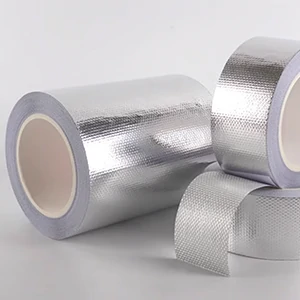

Self-adhesive embossed aluminum foil

Chalco's self-adhesive embossed aluminum foil combines B1 fire-resistance certification with a unique 5×5 or 3×3 raised grid structure, enhancing heat exchange area and condensation resistance. The product supports a variety of color customizations and is widely used in construction, air conditioning, and industrial equipment.

Hot-melt embossed aluminum foil

Hot-melt embossed aluminum foil has B1 fire-resistance certification and supports various color customizations. Its high strength, flexibility, and wrinkle resistance ensure excellent insulation performance and a longer service life. The surface anti-corrosion coating enhances UV resistance, oxidation resistance, and corrosion resistance. It uses hot-melt technology, eliminating the need for adhesives.

Chalco embossed aluminum foil solutions for different applications

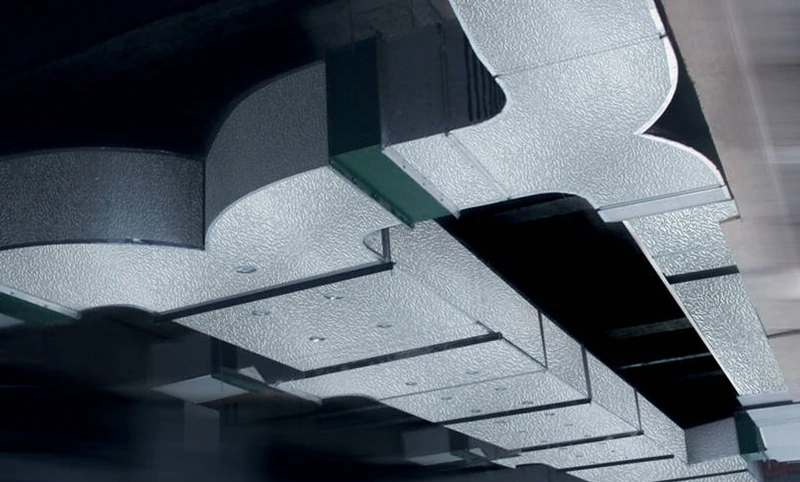

Air conditioning ducts

The air conditioning ventilation ducts made from embossed aluminum foil and phenolic boards combine the corrosion resistance and abrasion resistance of aluminum foil with the excellent thermal insulation properties of phenolic boards. This effectively reduces heat loss and improves energy efficiency. At the same time, it offers good fireproofing, soundproofing, and aging resistance, making it widely used in commercial buildings, industrial facilities, and residential air conditioning systems, ensuring efficient and stable operation of the systems.

Building and cold storage

Embossed aluminum foil combined with non-woven fabric and rock wool composite materials provides excellent thermal insulation, fireproofing, soundproofing, and corrosion resistance. It is widely used in building insulation, air conditioning ventilation, refrigeration, and industrial equipment. By combining the thermal insulation of rock wool with the fireproofing and corrosion resistance of aluminum foil, it offers efficient insulation solutions that are lightweight, durable, and adaptable to various environmental needs.

Automotive

Embossed aluminum foil is used in automobiles for engine hoods, roofs, doors, and chassis as a thermal insulation, soundproofing, and fireproofing layer. It effectively blocks high temperatures, reflects heat, maintains comfortable interior temperatures, and reduces external noise. Its high-temperature resistance, corrosion resistance, and abrasion resistance characteristics ensure long-term stable protection and extended service life.

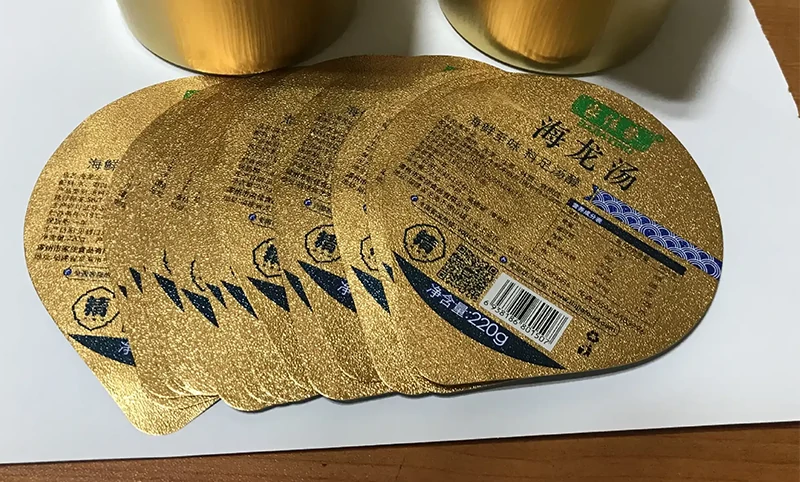

Food packaging

Embossed aluminum foil is used in food packaging to improve moisture protection, light shielding, and freshness preservation. Its unique texture design enhances the strength of the material, preventing breakage or penetration. The barrier properties of the aluminum foil effectively extend the shelf life of food, ensuring its freshness and safety.

Features of embossed aluminum foil

Unique texture design: embossed aluminum foil features distinctive patterns like orange peel and diamond textures, which enhance surface roughness, improving slip resistance and friction.

Increased heat exchange area: the embossed surface design increases the heat exchange area, enhancing thermal insulation and heat reflection.

High wear resistance: the embossed structure strengthens the aluminum foil, effectively resisting scratches and damage, thus extending its service life.

Anti-condensation performance: the unique surface structure improves anti-condensation properties, making it suitable for insulation applications in humid environments.

Efficient heat reflection: embossed aluminum foil has excellent heat reflection properties, effectively reducing heat conduction and improving insulation performance..

What services can Chalco provide?

- Customized design: offers a variety of embossing textures and size customization to meet different application needs.

- Color customization: supports multiple color options, and custom colors according to PANTONE/RAL color charts.

- Material R&D support: provides R&D services for embossed aluminum foil with specific properties according to customer requirements.

- Surface treatment and functional customization: offers anodizing, color coating, and other surface treatments to enhance material performance.

- Sample provision: provides free samples to help customers verify product suitability.

- Logistics and packaging services: provides professional packaging and logistics services to ensure safe and timely delivery.

- After-sales technical support: offers comprehensive after-sales support, including technical consulting and problem-solving.