The production of extra large diameter seamless aluminum tubes has long been a technical challenge in the industry. Due to the tonnage limitations of traditional extrusion equipment, as well as the limitations of welding and hot spinning processes in terms of wall thickness and performance, it has been a significant challenge to meet the growing demand for large-diameter seamless aluminum tubes in high-end industries such as aerospace, military, wind power, and oil and gas.

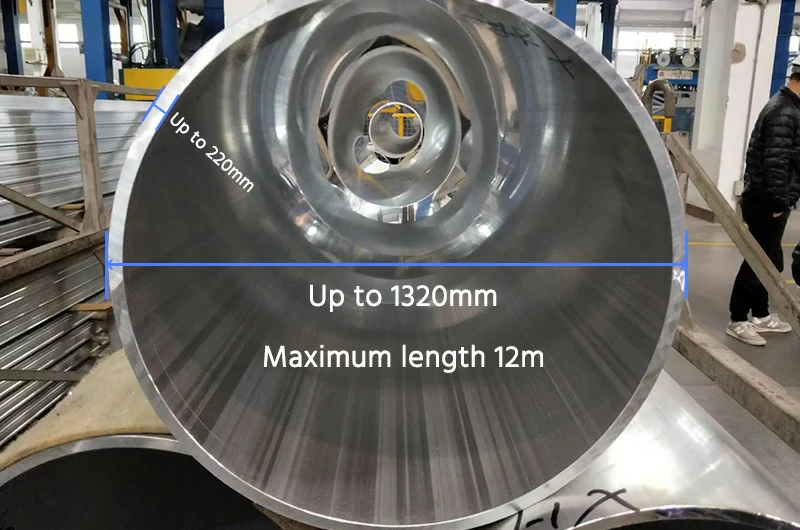

To break through this technical bottleneck, Chalco, together with its strategic partners, has successfully developed the world's first 500MN vertical extrusion press. This equipment has ultra-strong extrusion capabilities, capable of producing extra-large diameter seamless thick-walled aluminum tubes with a maximum diameter of 1320mm, a maximum wall thickness of 220mm, and a maximum length of 12 meters in a single pass, completely breaking the limitations of traditional processes.

Instant Quote

With this innovation, Chalco has successfully filled the global gap in the production of extra-large diameter seamless tubes through hot extrusion. More importantly, Chalco has passed multiple certifications, including ISO9001:2015, ISO14001, OHSAS, and Class A pressure pipelines, ensuring that product quality meets the highest international standards and can meet the stringent requirements of high-end industries such as aerospace, military, and wind power.

Introduction to extra large diameter seamless aluminum tubes pipe

| Aluminum alloy | 2000 series:2024 |

| 5000 series:5A05, 5A06, 5083 | |

| 6000 series:6061, 6063, 6082 | |

| 7000 series:7075, 7055, 7034 | |

| Aluminum-lithium alloy | 1420, 2195, 2050, 2055 |

| Outer diameter | 200-1320mm |

| Wall thickness | 18-220mm |

| Length | 4-12m |

| Heat treatment | Well-type heat treatment system |

| Fine machining | Outer bore inner turning, precision calibration |

| Inspection | Surface inspection, dimension inspection, nondestructive inspection, metallographic inspection, hardness inspection |

| Surface protection | Rust-proof treatment on the outer surface, drying treatment on the inner surface, protective cover on the port |

Chalco extra-large diameter seamless aluminum tube die dimensions

The cost of dies for large-diameter tubes has always been a major concern for end customers.

Choose Chalco, and you can easily solve this problem!

Instant Quote| OD(mm) | WA(mm) | OD(mm) | WA(mm) |

| 210 | 16,20,25 | 810 | 22,32,46,55,65,85,90,100,110 |

| 260 | 20,25,30 | 860 | 46,55,65,85,100,120,140 |

| 310 | 20,25,30,35 | 910 | 32,46,55,65,80 |

| 360 | 20,24,30 | 960 | 32,46,55,65,85,90,100,110 |

| 410 | 24,28,32 | 1010 | 55,65,85,90,100,110 |

| 460 | 27,30,35,45 | 1060 | 55,65,85,90,100,110,120,140 |

| 510 | 26,33,38,45,50 | 1110 | 55,65,85,90,100,110 |

| 560 | 16,20,25,30,35,50,60,85 | 1160 | 65,80,100,120 |

| 610 | 32,46,55,65,85,90,100,110 | 1210 | 65,80,100,120,140 |

| 660 | 38,48,65,85,90,100 | 1260 | 30,35,45,55,65,85,100,120,140 |

| 710 | 25,34,46,55,65,85,90,100,120 | 1320 | 30,35,45,55,65,85,100,120,140,160 |

| 760 | 38,44,55,65 |

Our die library is extremely rich, covering a wide range of specifications, with a basic increment of 50mm. This means you can find a die that closely matches your required size, significantly saving you the cost of custom-made dies.

Even if your size requirements are quite special, we are equipped with advanced external and internal lathe machining equipment. The machined tubes have a higher surface finish and more precise dimensions. Contact us to tailor a solution for your specific needs.

Instant QuoteMost popular extra-large diameter seamless aluminum tubes

Aluminum alloy extra-large diameter seamless tubes

2024 large diameter tube pipe

2024 aluminum is a high-strength, heat-treatable alloy with an excellent strength-to-weight ratio and fatigue resistance. In the T551 temper, it has a tensile strength of 470 MPa and is widely used in satellite structures and racing suspension systems.

Instant Quote

7075 large diameter tube pipe

7075 aluminum is a cold-worked forging alloy with high strength, far superior to mild steel. With a tensile strength of 570 MPa in the T651 temper, it is used in wind turbine hubs, aircraft landing gear, and oil drill pipes.

Instant Quote

6061 large diameter tube pipe

6061 aluminum is a medium-strength alloy with good formability, machinability, and corrosion resistance. It is one of the most widely used aluminum alloys. It is widely used in mechanical equipment structures, large pressure vessels, mold manufacturing, and industrial pipelines.

Instant Quote

5083 large diameter tube pipe

5083 aluminum is a non-heat-treatable high-magnesium alloy with moderate strength, excellent corrosion resistance, and good machinability. It is widely used in ship hull structures, offshore platform structures, submarine pipelines, and pressure vessels.

Instant QuoteSpray forming extra-large diameter seamless aluminum tubes

For high-performance alloys and aluminum-lithium alloys, we offer Spray Forming billets. Compared to traditional casting, the microstructure of spray-forming billets is finer, resulting in superior fatigue strength and crack resistance. It is the best choice for aerospace, spacecraft, aircraft structures, and military applications.

7034 large diameter tube pipe

7034 aluminum is a forging alloy, belonging to the ultra-high-strength aluminum category. With a tensile strength of up to 750 MPa in the T6 temper, it combines ductility, fatigue resistance, and corrosion resistance. It is applied in rocket engine nozzles and hydraulic cylinders.

Instant Quote

7055 large diameter tube pipe

7055 aluminum is a heat-treatable wrought aluminum alloy with an ultimate tensile strength of up to 630 MPa. It possesses high strength, high toughness, and excellent ballistic performance, making it suitable for rocket engine joints, aircraft blast-resistant barrels, and missile nozzle housings.

Instant Quote

1420 large diameter tube pipe

1420 is a new type of high-performance aluminum-lithium alloy. The addition of lithium reduces density and improves strength, modulus of elasticity, and specific stiffness. It is widely used in rocket engines, satellite structures, and high-speed rail components.

Instant Quote

2195 large diameter tube pipe

2195 is a typical representative of aluminum-lithium alloys, featuring high specific strength, good low-temperature toughness, fatigue resistance, and excellent resistance to stress corrosion cracking. It is widely used in aircraft landing gear, rocket engine components, and liquid oxygen tanks.

Instant QuoteChalco's cutting-edge technology for ultra-large diameter seamless aluminum tubes

Chalco and its strategic partners operate the world's largest 500MN vertical hot extrusion press, equipped with high-efficiency descaling machines, a proprietary lubricant spraying technology, rapid mold changeover technology, and precision straightening technology for large-diameter seamless tubes.

This press boasts exceptional pressure, a wide range of product specifications, high production efficiency, high material utilization, and superior tube quality. It is ideally suited for the extrusion of high-strength, high-grade aluminum and steel tubes. With a single extrusion, it can produce ultra-large diameter, thick-walled seamless tubes with an outer diameter of up to 1320mm, a wall thickness of 220mm, and a length of 12 meters.

Instant QuotePremium raw material selection: spray forming

Chalco offers a wide range of aluminum billets to meet your customized needs. We can produce according to international standards such as EN 573-3, and AA H35.1, and can also develop new alloys based on your specific requirements. All billets can be produced using advanced spray-forming technology.

Spray forming, also known as spray deposition or spray casting, is a rapid solidification process that produces aluminum billets with a fine, dense microstructure and excellent properties. Compared to traditional casting, spray forming is not limited by alloy composition, allowing for the production of high-performance alloys. The fine grain size significantly improves the material's fatigue strength and crack resistance.

Typical alloys include 7034, 7055, 1420, and 2195.

We can customize the production of aluminum billets with special alloys, specifications, or properties to meet small-batch, high-performance customized production needs. Currently, our largest spray-formed aluminum round billet has a diameter of 950mm, and we are actively developing a 1200mm diameter billet with a single weight of over 5 tons, which will provide high-quality raw materials for the production of ultra-large diameter seamless aluminum tubes and lead the way in aluminum alloy applications.

500MN vertical hot extrusion technology: crafting excellence

Chalco employs world-leading 500MN vertical hot extrusion technology, similar to those used by renowned international companies such as Wyman-Gordon (USA), Vallourec (Germany), and Sumitomo (Japan). Through a precise and complex process, we can produce large-diameter extruded seamless tubes with outer diameters ranging from 406 to 1320mm, wall thicknesses from 18 to 220mm, and lengths up to 12 meters.

Core Process Advantages:

Single-pass Extrusion: Using a 500MN extrusion press, the billet is first perforated and then vertically extruded from top to bottom, completing the entire process in just 10 minutes.

Heat Treatment: Heat treatment is conducted in a pit-type electric furnace with a professional temperature control system, ensuring a heating rate deviation of less than ±5℃ and a holding temperature deviation of less than ±5℃.

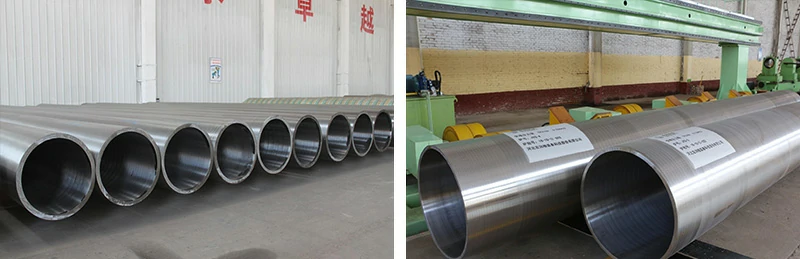

Precision Machining: External boring and internal turning are performed to ensure a concentricity deviation of less than 0.5mm, a surface roughness of less than 12.5μm, and a straightness of better than 1:1000.

With our robust production capacity and technological advantages, we provide high-quality, high-performance large-diameter seamless tubes to our customers. Our finished products feature large dimensions, a dense grain structure, superior strength and toughness, high dimensional accuracy, and excellent surface quality. Whether it's for nuclear power, wind power, thermal power, marine engineering, military, or aerospace engine components, we can provide reliable solutions.

Equipment parameters for the 500MN vertical hot extrusion press:

| Nominal pressure | 500MN |

| Main pump pressure | 31.5MPA |

| Ultra-high pressure system pressure | 100 MPA |

| Return force | 30MN |

| Maximum opening height of press | 8500 MM |

| Slider stroke | 2500 MM |

| Effective table surface | 3800 *6800 MM |

| Main power | 4500KW |

| Press dimensions | 10.1(L)*9.1(W)* 30M(H) |

| Total weight of equipment | 10,000 tons |

In addition to large-diameter seamless tubes, this equipment can produce various large-sized extruded components such as cylinders, discs, and columns, serving as alternatives to forged parts. Furthermore, straight tubes can be bent into various radii and shapes to meet the specific requirements of different engineering projects.

Instant QuoteTube bending and softening treatment

To meet the customized shape requirements of different customers, we are equipped with advanced tube bending machines. After extruding straight tubes, we can further bend the aluminum tubes according to the specific needs of engineering projects.

Under the action of the tube bending machine, tubes of up to ten meters in length can be gradually bent into shape. Notably, the diameter and wall thickness of the bent portion of the aluminum tube remain consistent with the straight section, without any thinning or deformation.

The excellent bending performance is attributed to the precise forming of the aluminum material under high temperature and high pressure by the 500MN vertical extrusion press, resulting in a denser and more uniform internal microstructure and excellent ductility.

Rigorous testing, guaranteed quality

Chalco boasts a world-class physical and chemical testing center, equipped with advanced testing equipment such as NHO gas analyzers for metal chemical analysis, Zeiss metallographic microscopes for metallographic testing, and high-temperature creep rupture testing machines for mechanical performance testing. Our testing capabilities have been certified by ISO/IEC and CNAS, ensuring the accuracy and reliability of our test results.

Every finished tube undergoes rigorous testing, including:

- Surface Inspection: Ensuring a smooth surface, free from scratches or visible defects, and no internal contaminants.

- Dimensional Inspection: Precisely controlling the inner and outer diameters, length, and other dimensions strictly according to customer tolerance requirements.

- Geometric Tolerance Inspection: Guaranteeing the roundness and straightness of the tube.

- Non-destructive Testing: Employing advanced eddy current and ultrasonic testing techniques for comprehensive inspection of the internal quality of the tube.

- Metallographic Examination: Strictly controlling grain size to ensure a uniform material structure.

- Hardness Testing: Ensuring the product hardness meets the required specifications.

Multiple protection for safe transportation

To ensure our products remain undamaged during transportation and storage, we employ multiple layers of protection:

- Rust Prevention: The outer surface of the tubes undergoes specialized rust prevention treatment to effectively prevent oxidation and corrosion.

- Wrapping Protection: Multiple layers of straw rope are used to wrap the tubes, cushioning them against vibrations during transportation and preventing scratches and bumps.

- Drying Treatment: The inner surface of the tubes is dried to prevent moisture from entering and causing rust.

- Port Protection: Protective caps are used to seal the tube ends, preventing the entry of foreign objects and protecting the ends from damage.

Chalco's complementary fittings for extra-large seamless aluminum tubes

To fulfill your demand for complete piping system solutions, Chalco not only provides high-quality extra-large seamless aluminum tubes but also offers a comprehensive range of complementary fittings. Our fittings include elbows, tees, reducers, flanges, and more, catering to the connection requirements of various piping systems.

Our fittings are manufactured using advanced production processes to ensure quality and performance. Based on different pipe diameters and pressure requirements, we employ a variety of processes such as hot pressing, cold drawing, and extrusion.

Low and Medium Pressure Fittings: Produced using seamless extrusion, hot-pressed plate welding, and cold drawing processes.

High-Pressure Fittings: Primarily manufactured using hot pressing, while large-diameter elbows can be produced through extrusion.

Bends: Bends with a nominal diameter below DN150 can be produced using cold bending or medium-frequency induction heating bending, while those above DN150 are exclusively produced using medium-frequency induction heating.

Aluminum elbow

45° Long Radius Elbow

90° Long Radius Elbow

90° Long Radius Elbow

Aluminum tee

Equal Tee

Reducing Tee

Reducing Y Tee

Other pipe fittings

Concentric reducers

Eccentric reducers

Flanges

What are the advantages of chalco's pipe fittings?

- Strong Production Capacity: Equipped with a comprehensive range of tools and molds and adhering to a wide spectrum of standards, Chalco can meet the demands of large-volume and diversified production.

- Excellent Corrosion Resistance: Through multiple anti-corrosion treatments such as pickling, passivation, and electroplating, Chalco extends the service life of its products.

- Design Services: Chalco provides technical services including pipe fitting strength and wall thickness design.

- Reliable Quality: Strict adherence to standards in material inspection and testing ensures product quality.

Why choose vertically extruded extra-large seamless aluminum tubes?

Vertical extrusion, renowned for its exceptional performance and efficient production process, has become the preferred method for producing extra-large seamless aluminum tubes.

High Material Utilization, Lower Cost: Extrusion maximizes material utilization, minimizes waste, and significantly improves material efficiency. Compared to traditional processes, more products can be produced per ton of material, resulting in substantial cost reductions.

Superior Product Quality and Performance: The extrusion process creates a denser and more uniform material structure, resulting in seamless aluminum tubes with higher strength, toughness, and corrosion resistance, meeting the stringent material performance requirements of high-end industries such as nuclear power and aerospace.

Flexible and Efficient Production, Strong Customization: We possess extrusion dies of various sizes, allowing us to quickly match the nearest size die based on customer needs. Combined with external boring and internal turning machining, we can achieve efficient and flexible customized production to meet the individualized needs of different customers.

High Dimensional Accuracy and Excellent Surface Quality: The vertical extrusion process combined with external boring and internal turning machining enables the production of products with high dimensional accuracy and excellent surface quality, ensuring that products meet stringent quality standards.

Detailed explanation of cooperation areas for ultra-large diameter seamless aluminum tubes

Aerospace applications

Common Alloys: 2024, 7075, 7055, 6061

Extra-large seamless aluminum tubes are widely used in the aerospace industry for structural components, fuel lines, and hydraulic systems in aircraft and spacecraft. Their lightweight and high-strength properties significantly enhance flight performance.

Contact us now

- Aircraft Structural Components: In aircraft fuselage structures, large-diameter seamless aluminum tubes are used for frames, support structures, and load-bearing components. They need to balance structural strength with weight reduction to improve flight performance and fuel efficiency. Common alloys include 7075-T6 and 7150.

- Aircraft Engine Components: In aircraft engines, large-diameter seamless aluminum tubes are used to manufacture exhaust pipes and intake systems. They need to maintain stability under high temperatures and pressures while providing effective weight control. Common alloys include 7055 and 7034.

- Spacecraft Structures: Large-diameter aluminum tubes are used to manufacture support frames and thruster components for rockets, satellites, and space stations. Their lightweight properties in the space environment help reduce launch weight and ensure sufficient strength and weather resistance. Common alloys include 2618, 7055, and 7150.

Shipbuilding applications

Common Alloys: 5083, 5086, 5059, 6061, 6082

Due to their lightweight, corrosion resistance, and strength, extra-large seamless aluminum tubes find extensive applications in various ship structures and components in the shipbuilding industry.

Contact us now

- Hull Structures: In high-performance vessels, patrol boats, and speedboats, extra-large seamless aluminum tubes can be used as frames, keels, and support beams. Their high strength and lightweight properties contribute to improved vessel speed and fuel efficiency. Common alloys include 5083 and 5059.

- Ship Piping Systems: In ship drainage systems, ventilation ducts, and other low-pressure piping systems, large-diameter aluminum tubes are used to transport liquids and gases. The lightweight, airtight, and corrosion-resistant properties of large-diameter aluminum tubes make them highly popular. Common alloys include 5059, 5083, and 5086.

- Ship Propulsion Systems: In ship propulsion systems, large-diameter seamless aluminum tubes can be used to manufacture thruster brackets, pipes, and other structural components. The use of aluminum alloys helps reduce system weight and improve propulsion efficiency. Common alloys include 6061-T6 and 6082-T6.

- Ship Masts and Rails: Large-diameter aluminum tubes can be used for ship deck railings, masts, and guardrails. These components require sufficient strength and weather resistance while also preventing seawater corrosion. Common alloys include 5083 and 6061.

Military manufacturing applications

Common Alloys: 5083, 6061, 2024, 7075

Thanks to their lightweight, high strength, and corrosion resistance, extra-large seamless aluminum tubes are widely used in military manufacturing. The low density reduces equipment weight, improving mobility, while corrosion resistance extends lifespan and cuts maintenance costs.

Contact us now

- Missile and Rocket Structures: Extra-large seamless aluminum tubes are used to manufacture components such as thruster casings, fuel tanks, and support structures. Aluminum's lightweight and high strength help reduce overall weight, increasing the speed and range of missiles and rockets. Common alloys include 7075-T6 and 2024-T3.

- Warship Structures: Extra-large seamless aluminum tubes are used to manufacture warship superstructures, radar towers, and shipboard equipment supports. The low density reduces ship weight, improving speed and maneuverability. Common alloys include 5083 and 6061-T6.

- Military Communication and Radar Systems: Large-diameter aluminum tubes are used in military communication towers, radar antenna supports, and other high-frequency equipment. Aluminum's electromagnetic shielding properties and corrosion resistance make it an ideal material for these applications.

- Military Vehicle Structures: Used to manufacture frames, support structures, and armored components. Aluminum's lightweight properties enhance vehicle mobility while maintaining sufficient protective capabilities. Common alloys include 6061-T6, 7075-T6, and 5083.

Marine engineering applications

Common Alloys: 5083, 5086, 6063, 7075

Compared to traditional steel pipes, extra-large seamless aluminum tubes offer significant advantages in marine engineering. Their lightweight properties reduce structural weight, enhancing equipment flexibility. Moreover, their superior corrosion resistance effectively withstands seawater erosion, extending equipment lifespan.

Contact us now

- Offshore Platform Structures: Extra-large seamless aluminum tubes can be used for non-pressure components such as support frames, railings, stairs, and walkways on platforms, helping to reduce overall structural weight and resist seawater corrosion.

- Seawater Desalination Equipment: Due to their lightweight nature, aluminum tubes can be used to transport low-pressure seawater or freshwater. 5083/6061 extra-large seamless aluminum tubes can be used in piping systems, reducing equipment weight and minimizing seawater corrosion of the pipes.

- Marine Renewable Energy: Extra-large seamless aluminum tubes can be used in the inlets, outlets, and guide tubes of wave/tidal energy generation equipment. Their seawater corrosion resistance reduces maintenance costs. Common alloys include 5083, 5086, and 6061.

- Subsea Pipelines: Extra-large seamless aluminum tubes can be used in subsea oil and gas pipelines, subsea cable protection pipes, and seawater sampling pipes. Due to the low density of aluminum, pipe weight can be reduced, lowering installation difficulty. In deep-sea environments with high water pressure, large-diameter thick-walled seamless tubes are generally required.

Wind energy applications

Common Alloys: 6061, 6082, 7075

Wind farms are often located in coastal or remote areas. The low density, corrosion resistance, and excellent machinability of aluminum alloys make them an ideal choice for wind energy equipment manufacturing.

Contact us now

- Wind Turbine Towers: Large-diameter seamless aluminum tubes can be used to manufacture the main load-bearing structure of small wind turbine towers. This reduces tower weight, lowers transportation and installation costs, and improves turbine stability.

- Blade Brackets: Aluminum's strength and lightweight properties make it an ideal material for manufacturing wind turbine blade brackets.

- Inverter Enclosures: Aluminum's thermal conductivity and electrical conductivity make it an excellent material for manufacturing inverter enclosures, aiding in heat dissipation and reducing electromagnetic interference.

Oil and gas industry applications

Common Alloys: 5052, 5083, 6061, 6063, 7075

The oil and gas industry demands materials with high strength, pressure resistance, corrosion resistance, and high-temperature performance. Aluminum alloys, being lightweight and corrosion-resistant, are suitable for non-critical components like pipe linings, non-pressure vessels, and instrument housings.

Contact us now

- Drilling and Production Equipment: The upstream oil and gas industry, involving drilling and production, often requires materials with high strength, high pressure resistance, and corrosion resistance. 7000 series alloys like 7075-T6 aluminum tubes can be used in areas like drill pipes, tubing, and casing.

- Liquefied Natural Gas (LNG) Pipelines: In the low-temperature transportation and storage of liquefied natural gas (LNG), such as low-temperature LNG piping systems, LNG tank linings, and LNG station equipment, medium-diameter 5083 and 5059 aluminum tubes are commonly used.

Pressure vessel applications

Common Alloys: 5083, 5086, 6061

Thanks to their lightweight, corrosion resistance, and thermal conductivity, large-diameter seamless aluminum tubes are widely used in low-temperature pressure vessels, especially in the food and pharmaceutical industries for storing and transporting products like liquid nitrogen and oxygen.

Contact us now

Chalco's large-diameter seamless aluminum tubes for pressure vessels have obtained certifications from ASME SB-241, ASTM B241, ISO 9001:2015, and Lloyd's Register.

- Food Storage and Transportation Containers: Widely used for storing and transporting food and beverages like milk, juice, and beer. Their lightweight and corrosion-resistant properties make them an ideal choice for the food transportation industry.

- Pharmaceutical Storage and Transportation Containers: Can be used to store and transport pharmaceuticals, vaccines, and other medical products. Their hygienic and safe properties make them a reliable choice for the pharmaceutical industry.

- Cryogenic Storage Tanks: In low-temperature environments, such as for storing liquid nitrogen, large-diameter seamless aluminum tubes also find some applications.

Chalco's large diameter aluminum tubes: beyond the ordinary

- 1200x1200mm Extra Large diameter Aluminum Square&Rectangular Tube

Chalco's 48"x 48" extra large seamless aluminum square and rectangular tubes are produced using vertical extrusion and round-to-square equipment, offering high strength and toughness. These tubes are ideal for large-scale engineering projects and mechanical manufacturing.

- Large Diameter Aluminum Pipe

Chalco possesses robust capabilities in aluminum pipe production, offering a wide range of products including large-diameter extruded aluminum pipes, forged aluminum pipes, vertically extruded aluminum pipes, and spiral welded pipes. Equipped with advanced production equipment and processes, Chalco can customize various specifications and alloys of aluminum pipe products to meet diverse customer needs.

- Φ500-1000mm Large Diameter Aluminum Forged Pipe

Chalco produces large-diameter aluminum forged pipes with diameters ranging from 500 to 1000mm, offering exceptional strength, corrosion resistance, and fatigue resistance. These pipes are suitable for demanding applications in aerospace, marine engineering, and other industries.

- Max.1580mm Ultra diameter spiral weld pipe

Chalco exclusively innovates low-temperature spiral welding technology and introduces world-leading advanced equipment to produce patented products - spiral weld pipe and its accessories. Machinable aluminum pipe diameter is Φ 219-1580mm.

Chalco can provide you the most comprehensive inventory of aluminum products and can also supply you customized products. Precise quotation will be provided within 24 hours.

Get a quote